Grinding Hss Boring Bar . Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. I have built a boring bar from 4140 steel with a hole to. Have some of the bit sticking out of the bar and clamp it. If it is a boring bar with a square hss tool bit it ain't that little! You can then face the bottom of the bore with. Grind the tool while held in the boring bar, extending it as much as. I am a complete novice at grinding hss lathe and boring cutter tool bits. Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining clearance?

from www.shop.santool.de

What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining clearance? You can then face the bottom of the bore with. I have built a boring bar from 4140 steel with a hole to. Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. Grind the tool while held in the boring bar, extending it as much as. I am a complete novice at grinding hss lathe and boring cutter tool bits. If it is a boring bar with a square hss tool bit it ain't that little! Have some of the bit sticking out of the bar and clamp it. Sharpening hss boring tools using an off hand grinder and an advanced grinding rest,

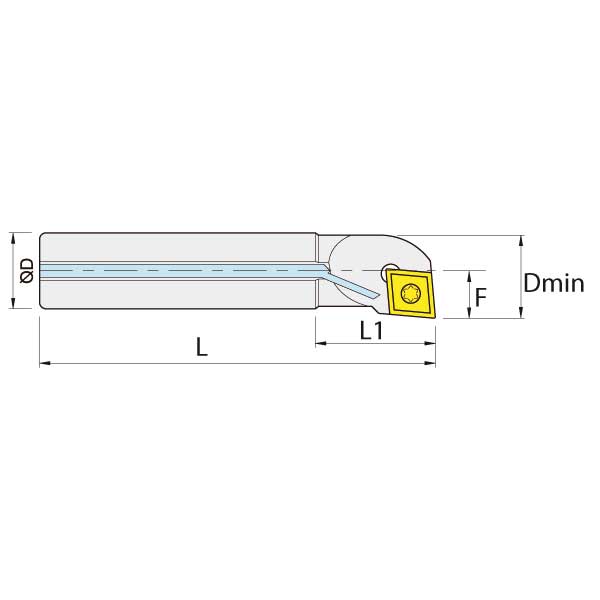

HSS boring bars SCLC L 06 leftKEAHSCLC.L06

Grinding Hss Boring Bar What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining clearance? Grind the tool while held in the boring bar, extending it as much as. Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. I have built a boring bar from 4140 steel with a hole to. Have some of the bit sticking out of the bar and clamp it. Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, I am a complete novice at grinding hss lathe and boring cutter tool bits. What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining clearance? You can then face the bottom of the bore with. If it is a boring bar with a square hss tool bit it ain't that little!

From www.practicalmachinist.com

Grinding HSS boring bar tool? Grinding Hss Boring Bar I am a complete novice at grinding hss lathe and boring cutter tool bits. If it is a boring bar with a square hss tool bit it ain't that little! Grind the tool while held in the boring bar, extending it as much as. What is the optimal shape for a hss boring bar ground from square stock to enhance. Grinding Hss Boring Bar.

From woodturningonline.com

How To Use A Boring Bar On Lathe Woodturning Online Grinding Hss Boring Bar If it is a boring bar with a square hss tool bit it ain't that little! I am a complete novice at grinding hss lathe and boring cutter tool bits. Have some of the bit sticking out of the bar and clamp it. Grind the tool while held in the boring bar, extending it as much as. What is the. Grinding Hss Boring Bar.

From www.hahn-kolb.de

ATORN SVJC boring bar HSS positive, righthand HAHN+KOLB Grinding Hss Boring Bar I am a complete novice at grinding hss lathe and boring cutter tool bits. What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining clearance? If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. I have. Grinding Hss Boring Bar.

From www.youtube.com

Easy Homemade Boring Bar YouTube Grinding Hss Boring Bar What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining clearance? I have built a boring bar from 4140 steel with a hole to. Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. Sharpening hss boring tools using an off hand grinder and. Grinding Hss Boring Bar.

From www.practicalmachinist.com

Grinding HSS boring bar tool? Grinding Hss Boring Bar Have some of the bit sticking out of the bar and clamp it. Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. Grind the tool while held in the boring bar, extending it as much as. I am a complete novice at grinding hss lathe and boring cutter tool bits. If you. Grinding Hss Boring Bar.

From www.indiamart.com

Hss S12mSclcl0614 Boring Bar, For CNC Turning, Size 12 Mm at Rs 1000 Grinding Hss Boring Bar I am a complete novice at grinding hss lathe and boring cutter tool bits. If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. Have some of the bit. Grinding Hss Boring Bar.

From www.youtube.com

Making HSS boring bar YouTube Grinding Hss Boring Bar If it is a boring bar with a square hss tool bit it ain't that little! You can then face the bottom of the bore with. I have built a boring bar from 4140 steel with a hole to. Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. If you insist, i. Grinding Hss Boring Bar.

From www.kemmler-shop.de

HSS boring bars SDUC 93° Kemmler Shop Grinding Hss Boring Bar I have built a boring bar from 4140 steel with a hole to. If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, What is the optimal shape for a hss boring. Grinding Hss Boring Bar.

From www.machineryhouse.com.au

L006A L006A Boring Bar Set HSS Hare & Forbes Machineryhouse Grinding Hss Boring Bar Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. I am a complete novice at grinding hss lathe and boring cutter tool bits. What is the optimal shape for a hss. Grinding Hss Boring Bar.

From www.ctctools.biz

18MM BORING BAR WITH HSS TOOL BIT 12L L113 CTC Tools Grinding Hss Boring Bar I have built a boring bar from 4140 steel with a hole to. You can then face the bottom of the bore with. Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. If it is a boring bar with a square hss tool bit it ain't that little! If you insist, i. Grinding Hss Boring Bar.

From www.northbaycuttingtools.com

New 1/2" Solid Carbide Boring Bar ABB4901500 .490" Minimum Bore Grinding Hss Boring Bar Grind the tool while held in the boring bar, extending it as much as. You can then face the bottom of the bore with. If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. If it is a boring bar with a square hss tool bit. Grinding Hss Boring Bar.

From www.ctctools.biz

12MM INDEXABLE BORING BAR WITH HSS TOOL BIT L93 CTC Tools Grinding Hss Boring Bar If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining. Grinding Hss Boring Bar.

From www.ppgbbe.intranet.biologia.ufrj.br

Hss Boring Bar Grinding Hss Boring Bar What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining clearance? Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. I have built a boring bar from 4140 steel with a hole to. Have some of the bit sticking out of the bar. Grinding Hss Boring Bar.

From www.ebay.com

HSS Boring Bar 1 5/8" Diameter 11 1/2" OAL 1 15/16" Shank Heavy Grinding Hss Boring Bar You can then face the bottom of the bore with. Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining clearance? Grind the tool while held in the boring bar, extending it as much. Grinding Hss Boring Bar.

From www.shop.santool.de

HSS boring bars SCLC L 06 leftKEAHSCLC.L06 Grinding Hss Boring Bar Have some of the bit sticking out of the bar and clamp it. I have built a boring bar from 4140 steel with a hole to. You can then face the bottom of the bore with. If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance.. Grinding Hss Boring Bar.

From www.practicalmachinist.com

Grinding HSS boring bar tool? Grinding Hss Boring Bar Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, If it is a boring bar with a square hss tool bit it ain't that little! If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. You can then face the bottom. Grinding Hss Boring Bar.

From www.indiamart.com

High Speed Steel HSS Boring Tool, Size Upto 60mm, Automation Grade Grinding Hss Boring Bar You can then face the bottom of the bore with. If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, I have built a boring bar from 4140 steel with a hole. Grinding Hss Boring Bar.

From www.kemmler-shop.de

HSS boring bar AH1216M.SCLC.R06 HSS boring bars SCLC 95° Boring Grinding Hss Boring Bar Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining clearance? If it. Grinding Hss Boring Bar.

From www.mhctools.com

HSS Solid Boring Bar Grinding Hss Boring Bar If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. If it is a boring. Grinding Hss Boring Bar.

From www.shop.santool.de

HSS boring bars SDUC L 07 leftKEAHSDUC.L07 Grinding Hss Boring Bar Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. You can then face the bottom of the bore with. If it is a boring bar with a square. Grinding Hss Boring Bar.

From www.machines4u.com.au

New Hafco L006A Boring Bar Set HSS 8mm Boring Bars Boring Lathes in Grinding Hss Boring Bar If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, I am a complete novice at grinding hss lathe and boring cutter tool bits. You can then face the bottom of the. Grinding Hss Boring Bar.

From www.youtube.com

Make HSS Boring Bars For Your Boring Head YouTube Grinding Hss Boring Bar You can then face the bottom of the bore with. If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, I have built a boring bar from 4140 steel with a hole. Grinding Hss Boring Bar.

From www.machines4u.com.au

New Hafco L006A Boring Bar Set HSS 8mm Boring Bars Boring Lathes in Grinding Hss Boring Bar Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, I am a complete novice at grinding hss lathe and boring cutter tool bits. If it is a boring bar with a square hss tool bit it ain't that little! Have some of the bit sticking out of the bar and clamp it. Grind the end. Grinding Hss Boring Bar.

From 911tooling.com

Mesa Tools ABT 500D HSS Boring Tool Bar High Speed Steel New Made in U Grinding Hss Boring Bar What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining clearance? Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, I am a complete novice at grinding hss lathe and boring cutter tool bits. Grind the end of the bar with at least ten degrees clearance,. Grinding Hss Boring Bar.

From www.axminstertools.com

PROXXON 6 Piece HSS Boring Tool Set Axminster Tools Grinding Hss Boring Bar If it is a boring bar with a square hss tool bit it ain't that little! If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. I am a complete novice at grinding hss lathe and boring cutter tool bits. Sharpening hss boring tools using an. Grinding Hss Boring Bar.

From www.kemmler-shop.de

HSS boring bar AH1216M.SCLC.R06 HSS boring bars SCLC 95° Boring Grinding Hss Boring Bar Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. If it is a boring bar with a square hss tool bit it ain't that little! I have built a boring bar from 4140 steel with a hole to. I am a complete novice at grinding hss lathe and boring cutter tool bits.. Grinding Hss Boring Bar.

From www.warco.co.uk

Lathe Boring Bar with Holder HSS Quality Engineering Tool Grinding Hss Boring Bar Grind the end of the bar with at least ten degrees clearance, and about 7 degrees relief. Have some of the bit sticking out of the bar and clamp it. Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, What is the optimal shape for a hss boring bar ground from square stock to enhance. Grinding Hss Boring Bar.

From tradetools.co.nz

4 Piece HSS Boring Bar Kit 8, 10, 12 & 16mm (5xD) CCMT0602 Grinding Hss Boring Bar What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining clearance? If it is a boring bar with a square hss tool bit it ain't that little! I have built a boring bar from 4140 steel with a hole to. I am a complete novice at grinding hss lathe and boring. Grinding Hss Boring Bar.

From www.youtube.com

MAKING GROOVING BORING BARS YouTube Grinding Hss Boring Bar I have built a boring bar from 4140 steel with a hole to. If it is a boring bar with a square hss tool bit it ain't that little! I am a complete novice at grinding hss lathe and boring cutter tool bits. Have some of the bit sticking out of the bar and clamp it. Sharpening hss boring tools. Grinding Hss Boring Bar.

From www.kemmler-shop.de

HSS boring bars set SET.AH.SDUC.L07 Boring bars set Boring bars Grinding Hss Boring Bar If it is a boring bar with a square hss tool bit it ain't that little! Sharpening hss boring tools using an off hand grinder and an advanced grinding rest, If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. Grind the tool while held in. Grinding Hss Boring Bar.

From www.mtb2b.tw

產品CUTTING TOOLS, CARBIDE BORING BARS, HSS BORING BARS Grinding Hss Boring Bar Have some of the bit sticking out of the bar and clamp it. Grind the tool while held in the boring bar, extending it as much as. If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. You can then face the bottom of the bore. Grinding Hss Boring Bar.

From www.machineryhouse.com.au

L006A Boring Bar Set HSS Hare & Forbes Machineryhouse Grinding Hss Boring Bar Have some of the bit sticking out of the bar and clamp it. If it is a boring bar with a square hss tool bit it ain't that little! If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. I have built a boring bar from. Grinding Hss Boring Bar.

From www.saratools.com

321113 Boring bar set HSS 3piece SDUCR07 93°, DC Grinding Hss Boring Bar Grind the tool while held in the boring bar, extending it as much as. If it is a boring bar with a square hss tool bit it ain't that little! What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining clearance? Sharpening hss boring tools using an off hand grinder and. Grinding Hss Boring Bar.

From www.youtube.com

Grinding a high speed steel boring bar YouTube Grinding Hss Boring Bar You can then face the bottom of the bore with. What is the optimal shape for a hss boring bar ground from square stock to enhance rigidity while maintaining clearance? Have some of the bit sticking out of the bar and clamp it. I am a complete novice at grinding hss lathe and boring cutter tool bits. Grind the tool. Grinding Hss Boring Bar.

From www.machineryhouse.com.au

L006A Boring Bar Set HSS Hare & Forbes Machineryhouse Grinding Hss Boring Bar Grind the tool while held in the boring bar, extending it as much as. Have some of the bit sticking out of the bar and clamp it. If you insist, i would grind a positive lead bar to reduce radial forces and simply round the section under the head for clearance. I am a complete novice at grinding hss lathe. Grinding Hss Boring Bar.