End Grain Cutting Board Bowing . Making a cutting board that won't warp: I purchased an end grain cutting board from a woodworker at an art fair. For an end grain board (example: Most cutting boards are made so that the end grain is facing up. This is because the end grain is a lot harder than the side grain and it holds up a lot. Learn how to get started. I used mineral oil to season the board on both sides and the edges. I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. The best fix is always prevention The board is roughly 30″ x 17″, and just over an inch thick. If you have a cupped cutting board, skip the iron, skip the steam, skip the grass, skip the trip to the wood shop (although that would. John boos end grain chopping block), your best bet is a wide belt sander that would essentially sand the board down so that it is even. It was custom made for me out of cherry with size and a built in tray to catch gravy. Attempting to use a planer on end grain board would likely be too tough on the saw blade and result in damage. When i cut the face grain pieces perpendicularly to make the.

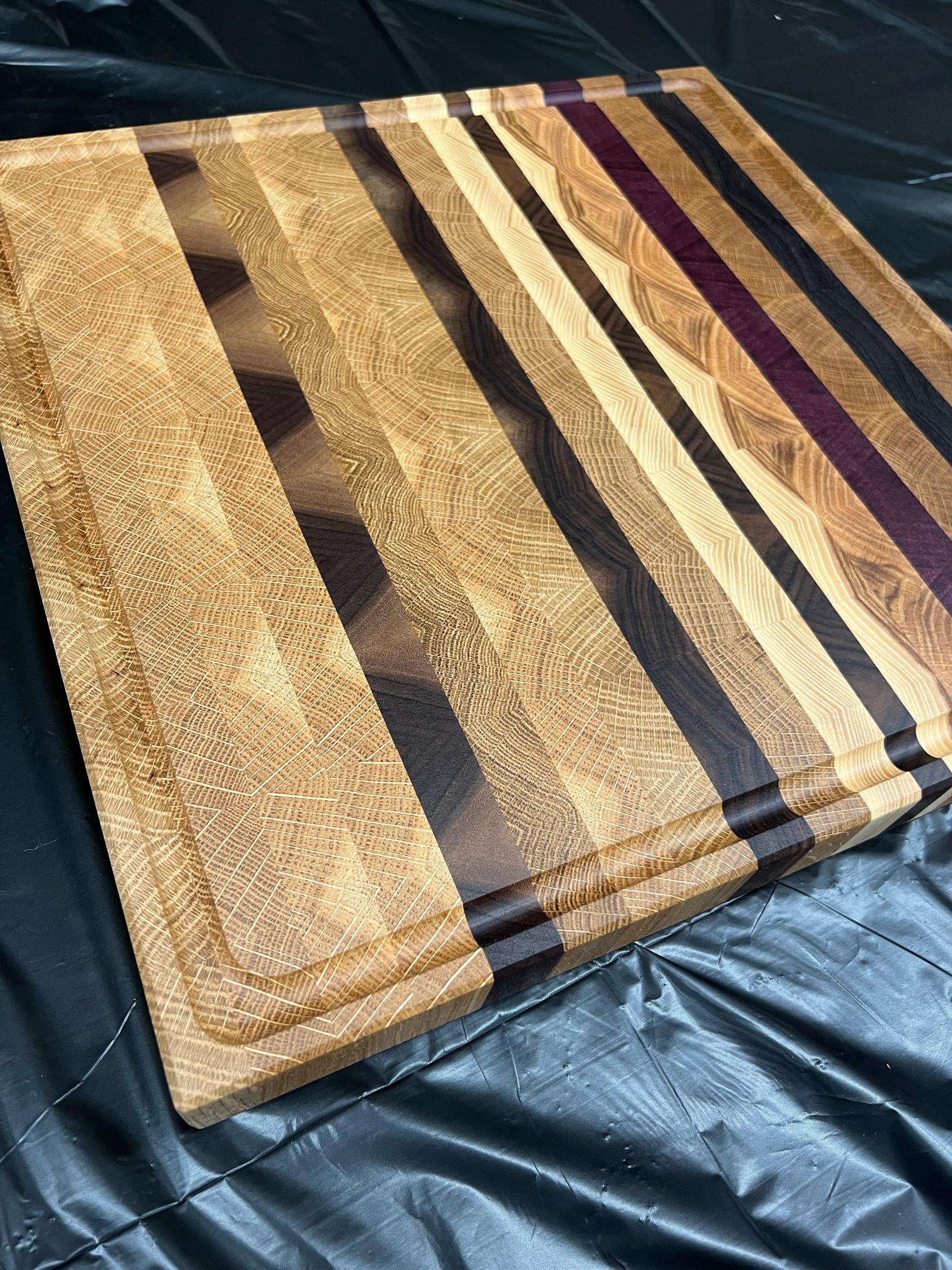

from highpointcustoms.ca

For an end grain board (example: Making a cutting board that won't warp: I purchased an end grain cutting board from a woodworker at an art fair. It was custom made for me out of cherry with size and a built in tray to catch gravy. The board is roughly 30″ x 17″, and just over an inch thick. John boos end grain chopping block), your best bet is a wide belt sander that would essentially sand the board down so that it is even. This is because the end grain is a lot harder than the side grain and it holds up a lot. Most cutting boards are made so that the end grain is facing up. When i cut the face grain pieces perpendicularly to make the. Attempting to use a planer on end grain board would likely be too tough on the saw blade and result in damage.

End Grain Cutting Board Highpoint Customs

End Grain Cutting Board Bowing Learn how to get started. This is because the end grain is a lot harder than the side grain and it holds up a lot. Learn how to get started. John boos end grain chopping block), your best bet is a wide belt sander that would essentially sand the board down so that it is even. The best fix is always prevention I purchased an end grain cutting board from a woodworker at an art fair. It was custom made for me out of cherry with size and a built in tray to catch gravy. For an end grain board (example: I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. Attempting to use a planer on end grain board would likely be too tough on the saw blade and result in damage. The board is roughly 30″ x 17″, and just over an inch thick. Most cutting boards are made so that the end grain is facing up. I used mineral oil to season the board on both sides and the edges. When i cut the face grain pieces perpendicularly to make the. Making a cutting board that won't warp: If you have a cupped cutting board, skip the iron, skip the steam, skip the grass, skip the trip to the wood shop (although that would.

From craftedathome.com

End Grain Cutting Boards Archives Crafted At Home End Grain Cutting Board Bowing I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. For an end grain board (example: I used mineral oil to season the board on both sides and the edges. This is because the end grain is a lot harder than the side grain and. End Grain Cutting Board Bowing.

From highpointcustoms.ca

End Grain Cutting Board Highpoint Customs End Grain Cutting Board Bowing I used mineral oil to season the board on both sides and the edges. The board is roughly 30″ x 17″, and just over an inch thick. For an end grain board (example: Learn how to get started. I purchased an end grain cutting board from a woodworker at an art fair. When i cut the face grain pieces perpendicularly. End Grain Cutting Board Bowing.

From www.becknerwoodproducts.com

End Grain Cutting Board Mixed Domestics Beckner Wood Products End Grain Cutting Board Bowing For an end grain board (example: This is because the end grain is a lot harder than the side grain and it holds up a lot. Making a cutting board that won't warp: I purchased an end grain cutting board from a woodworker at an art fair. I've made a few end grain cutting boards, and i'm quite satisfied with. End Grain Cutting Board Bowing.

From www.etsy.com

Custom Cutting Board End Grain Chopping Block Butcher Etsy End Grain Cutting Board Bowing For an end grain board (example: The board is roughly 30″ x 17″, and just over an inch thick. It was custom made for me out of cherry with size and a built in tray to catch gravy. Learn how to get started. Most cutting boards are made so that the end grain is facing up. This is because the. End Grain Cutting Board Bowing.

From www.youtube.com

How to make a cutting board End grain vs face grain YouTube End Grain Cutting Board Bowing When i cut the face grain pieces perpendicularly to make the. Attempting to use a planer on end grain board would likely be too tough on the saw blade and result in damage. Learn how to get started. The board is roughly 30″ x 17″, and just over an inch thick. If you have a cupped cutting board, skip the. End Grain Cutting Board Bowing.

From craftedworkshop.com

How To Make End Grain Cutting Boards from Scrap Wood — Crafted End Grain Cutting Board Bowing If you have a cupped cutting board, skip the iron, skip the steam, skip the grass, skip the trip to the wood shop (although that would. When i cut the face grain pieces perpendicularly to make the. I used mineral oil to season the board on both sides and the edges. This is because the end grain is a lot. End Grain Cutting Board Bowing.

From highpointcustoms.ca

End Grain Cutting Board Highpoint Customs End Grain Cutting Board Bowing John boos end grain chopping block), your best bet is a wide belt sander that would essentially sand the board down so that it is even. I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. This is because the end grain is a lot. End Grain Cutting Board Bowing.

From www.becknerwoodproducts.com

Edge grain cutting board Beckner Wood Products End Grain Cutting Board Bowing I used mineral oil to season the board on both sides and the edges. Most cutting boards are made so that the end grain is facing up. For an end grain board (example: The best fix is always prevention John boos end grain chopping block), your best bet is a wide belt sander that would essentially sand the board down. End Grain Cutting Board Bowing.

From www.archerwoodworking.com

ENDGRAIN CUTTING BOARD (EG004) Archer Woodworking End Grain Cutting Board Bowing The best fix is always prevention I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. For an end grain board (example: I purchased an end grain cutting board from a woodworker at an art fair. I used mineral oil to season the board on. End Grain Cutting Board Bowing.

From www.stskraftworks.com

Black Walnut End Grain Hybrid Cutting Board — STS Kraftworks Cutting Boards End Grain Cutting Board Bowing It was custom made for me out of cherry with size and a built in tray to catch gravy. John boos end grain chopping block), your best bet is a wide belt sander that would essentially sand the board down so that it is even. Making a cutting board that won't warp: I used mineral oil to season the board. End Grain Cutting Board Bowing.

From craftedathome.com

Chaotic End Grain Cutting Board Crafted At Home End Grain Cutting Board Bowing I purchased an end grain cutting board from a woodworker at an art fair. The best fix is always prevention Learn how to get started. When i cut the face grain pieces perpendicularly to make the. Most cutting boards are made so that the end grain is facing up. It was custom made for me out of cherry with size. End Grain Cutting Board Bowing.

From craftedworkshop.com

How To Make End Grain Cutting Boards from Scrap Wood — Crafted End Grain Cutting Board Bowing For an end grain board (example: This is because the end grain is a lot harder than the side grain and it holds up a lot. I purchased an end grain cutting board from a woodworker at an art fair. The best fix is always prevention I've made a few end grain cutting boards, and i'm quite satisfied with the. End Grain Cutting Board Bowing.

From www.etsy.com

Edge Grain Cutting Board Etsy End Grain Cutting Board Bowing Attempting to use a planer on end grain board would likely be too tough on the saw blade and result in damage. The best fix is always prevention Making a cutting board that won't warp: If you have a cupped cutting board, skip the iron, skip the steam, skip the grass, skip the trip to the wood shop (although that. End Grain Cutting Board Bowing.

From www.royalzig.com

End grain cutting board End Grain Cutting Board Bowing I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. When i cut the face grain pieces perpendicularly to make the. The board is roughly 30″ x 17″, and just over an inch thick. John boos end grain chopping block), your best bet is a. End Grain Cutting Board Bowing.

From www.etsy.com

End Grain Mixed Wood Handcrafted Cutting Board Etsy End Grain Cutting Board Bowing I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. I used mineral oil to season the board on both sides and the edges. I purchased an end grain cutting board from a woodworker at an art fair. The board is roughly 30″ x 17″,. End Grain Cutting Board Bowing.

From www.lakelandwoodcrafting.com

End Grain Cutting Board Cherry, Maple, Walnut Lakeland End Grain Cutting Board Bowing If you have a cupped cutting board, skip the iron, skip the steam, skip the grass, skip the trip to the wood shop (although that would. For an end grain board (example: Learn how to get started. The board is roughly 30″ x 17″, and just over an inch thick. When i cut the face grain pieces perpendicularly to make. End Grain Cutting Board Bowing.

From shwalaska.com

EndGrain Walnut Cutting Board Superior Hardwoods End Grain Cutting Board Bowing I used mineral oil to season the board on both sides and the edges. When i cut the face grain pieces perpendicularly to make the. I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. Making a cutting board that won't warp: Attempting to use. End Grain Cutting Board Bowing.

From info.lagunatools.com

Tips On How To Make An End Grain Cutting Board End Grain Cutting Board Bowing I used mineral oil to season the board on both sides and the edges. The board is roughly 30″ x 17″, and just over an inch thick. If you have a cupped cutting board, skip the iron, skip the steam, skip the grass, skip the trip to the wood shop (although that would. This is because the end grain is. End Grain Cutting Board Bowing.

From www.reddit.com

End grain board with black walnut, canarywood, purpleheart and cherry End Grain Cutting Board Bowing If you have a cupped cutting board, skip the iron, skip the steam, skip the grass, skip the trip to the wood shop (although that would. It was custom made for me out of cherry with size and a built in tray to catch gravy. John boos end grain chopping block), your best bet is a wide belt sander that. End Grain Cutting Board Bowing.

From www.etsy.com

End Grain Cutting Board Cherry and Maple Etsy End Grain Cutting Board Bowing I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. Learn how to get started. If you have a cupped cutting board, skip the iron, skip the steam, skip the grass, skip the trip to the wood shop (although that would. I used mineral oil. End Grain Cutting Board Bowing.

From butcherwood.com

OAK and BIRCH end grain cutting board Butcher Wood End Grain Cutting Board Bowing If you have a cupped cutting board, skip the iron, skip the steam, skip the grass, skip the trip to the wood shop (although that would. When i cut the face grain pieces perpendicularly to make the. I used mineral oil to season the board on both sides and the edges. The board is roughly 30″ x 17″, and just. End Grain Cutting Board Bowing.

From cellcare1.com

Edge Grain Cutting Board End Grain Cutting Board Bowing It was custom made for me out of cherry with size and a built in tray to catch gravy. Most cutting boards are made so that the end grain is facing up. Attempting to use a planer on end grain board would likely be too tough on the saw blade and result in damage. I used mineral oil to season. End Grain Cutting Board Bowing.

From matagrande.al.gov.br

End grain cutting charcuterie board matagrande.al.gov.br End Grain Cutting Board Bowing I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. Most cutting boards are made so that the end grain is facing up. John boos end grain chopping block), your best bet is a wide belt sander that would essentially sand the board down so. End Grain Cutting Board Bowing.

From www.youtube.com

End Grain Cutting Board through Planer? Best woodworking method to End Grain Cutting Board Bowing For an end grain board (example: John boos end grain chopping block), your best bet is a wide belt sander that would essentially sand the board down so that it is even. I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. I purchased an. End Grain Cutting Board Bowing.

From www.itsoverflowing.com

15 Free DIY End Grain Cutting Board Plans and Designs End Grain Cutting Board Bowing Making a cutting board that won't warp: For an end grain board (example: I used mineral oil to season the board on both sides and the edges. If you have a cupped cutting board, skip the iron, skip the steam, skip the grass, skip the trip to the wood shop (although that would. Most cutting boards are made so that. End Grain Cutting Board Bowing.

From www.etsy.com

End Grain Cutting Board Etsy End Grain Cutting Board Bowing Attempting to use a planer on end grain board would likely be too tough on the saw blade and result in damage. The board is roughly 30″ x 17″, and just over an inch thick. I purchased an end grain cutting board from a woodworker at an art fair. I used mineral oil to season the board on both sides. End Grain Cutting Board Bowing.

From blosstory.net

Cutting Boards Maple with Black Walnut Border End Grain Cutting Board End Grain Cutting Board Bowing The best fix is always prevention If you have a cupped cutting board, skip the iron, skip the steam, skip the grass, skip the trip to the wood shop (although that would. Attempting to use a planer on end grain board would likely be too tough on the saw blade and result in damage. This is because the end grain. End Grain Cutting Board Bowing.

From highpointcustoms.ca

End Grain Cutting Board Highpoint Customs End Grain Cutting Board Bowing When i cut the face grain pieces perpendicularly to make the. I purchased an end grain cutting board from a woodworker at an art fair. For an end grain board (example: Making a cutting board that won't warp: I used mineral oil to season the board on both sides and the edges. The board is roughly 30″ x 17″, and. End Grain Cutting Board Bowing.

From www.instructables.com

Edge Grain Butcher Block a DIY Tutorial 5 Steps (with Pictures End Grain Cutting Board Bowing Most cutting boards are made so that the end grain is facing up. I used mineral oil to season the board on both sides and the edges. I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. Attempting to use a planer on end grain. End Grain Cutting Board Bowing.

From www.reddit.com

End grain cutting board bowing, why? r/woodworking End Grain Cutting Board Bowing John boos end grain chopping block), your best bet is a wide belt sander that would essentially sand the board down so that it is even. I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. I purchased an end grain cutting board from a. End Grain Cutting Board Bowing.

From www.custommade.com

Buy Handmade Signature Black Walnut End Grain Cutting Board, made to End Grain Cutting Board Bowing I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. The board is roughly 30″ x 17″, and just over an inch thick. The best fix is always prevention Learn how to get started. Attempting to use a planer on end grain board would likely. End Grain Cutting Board Bowing.

From highpointcustoms.ca

End Grain Cutting Board Highpoint Customs End Grain Cutting Board Bowing I've made a few end grain cutting boards, and i'm quite satisfied with the result, but i've noticed that they are bowing a few days. The best fix is always prevention It was custom made for me out of cherry with size and a built in tray to catch gravy. For an end grain board (example: John boos end grain. End Grain Cutting Board Bowing.

From www.chiangraitimes.com

The Art Of End Grain Cutting Board Beauty And Functionality Combined End Grain Cutting Board Bowing Attempting to use a planer on end grain board would likely be too tough on the saw blade and result in damage. For an end grain board (example: It was custom made for me out of cherry with size and a built in tray to catch gravy. When i cut the face grain pieces perpendicularly to make the. John boos. End Grain Cutting Board Bowing.

From www.pinterest.com

Pin on End Grain Cutting Boards End Grain Cutting Board Bowing It was custom made for me out of cherry with size and a built in tray to catch gravy. Most cutting boards are made so that the end grain is facing up. Attempting to use a planer on end grain board would likely be too tough on the saw blade and result in damage. When i cut the face grain. End Grain Cutting Board Bowing.

From walnuthillwoodworks.com

Large End Grain Cutting Boards Walnut Hill Woodworks End Grain Cutting Board Bowing The best fix is always prevention For an end grain board (example: The board is roughly 30″ x 17″, and just over an inch thick. It was custom made for me out of cherry with size and a built in tray to catch gravy. I've made a few end grain cutting boards, and i'm quite satisfied with the result, but. End Grain Cutting Board Bowing.