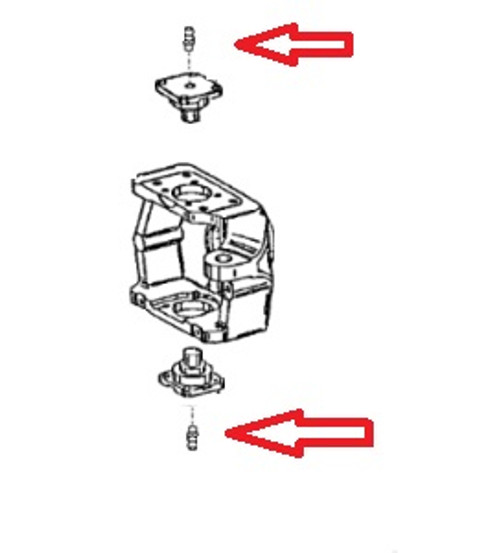

King Pin Grease Seal . kingpin replacement kits may come with one of two different upper seals: We get many inquiries about how the swivel link seals are installed. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication of the steering axle kingpin. this tech tip outlines the proper method to install bushing lip seals used in king pin applications. It is there to keep the grease from working out. install seal on end of driver with beveled edge of the seal facing out. A smaller diamater seal with a 14mm head retaining. king pin seals installation. Use a brass hammer or dead blow hammer to pound. the seal goes in the bottom side of the upper bore. Here are a few photos of how it all goes.

from www.brokentractor.com

Use a brass hammer or dead blow hammer to pound. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication of the steering axle kingpin. A smaller diamater seal with a 14mm head retaining. king pin seals installation. kingpin replacement kits may come with one of two different upper seals: Here are a few photos of how it all goes. We get many inquiries about how the swivel link seals are installed. It is there to keep the grease from working out. install seal on end of driver with beveled edge of the seal facing out.

John Deere King Pin Grease Fitting 58M5573

King Pin Grease Seal king pin seals installation. Here are a few photos of how it all goes. Use a brass hammer or dead blow hammer to pound. well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication of the steering axle kingpin. It is there to keep the grease from working out. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. install seal on end of driver with beveled edge of the seal facing out. We get many inquiries about how the swivel link seals are installed. this tech tip outlines the proper method to install bushing lip seals used in king pin applications. the seal goes in the bottom side of the upper bore. king pin seals installation. kingpin replacement kits may come with one of two different upper seals: A smaller diamater seal with a 14mm head retaining.

From shop.broncograveyard.com

DANA 60 KINGPIN REBUILD KIT King Pin Grease Seal well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication of the steering axle kingpin. the seal goes in the bottom side of the upper bore. We get many inquiries about how the swivel link seals are installed. install seal on end of driver with beveled edge of the seal. King Pin Grease Seal.

From isettaspares.org.uk

Grease Nipple for King Pins King Pin Grease Seal install seal on end of driver with beveled edge of the seal facing out. the seal goes in the bottom side of the upper bore. A smaller diamater seal with a 14mm head retaining. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. kingpin replacement kits may come. King Pin Grease Seal.

From www.boattrailerparts.com

Trailer UFP Grease Seal 1.68" ID 2.56" OD for 5 Lug Hubs and Rotors King Pin Grease Seal king pin seals installation. A smaller diamater seal with a 14mm head retaining. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication of the steering axle kingpin. install seal on end. King Pin Grease Seal.

From suzukipartsusa.com

STEERING KNUCKLE OIL SEALS / KING PIN BEARINGS SAMURAI '80'95 King Pin Grease Seal It is there to keep the grease from working out. Here are a few photos of how it all goes. kingpin replacement kits may come with one of two different upper seals: “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. We get many inquiries about how the swivel link. King Pin Grease Seal.

From partsouq.com

KING PINOIL SEAL 567196C100 Hyundai / KIA Parts PartSouq King Pin Grease Seal well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication of the steering axle kingpin. Use a brass hammer or dead blow hammer to pound. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. install seal on end of driver with beveled. King Pin Grease Seal.

From mal.co.in

MAL King Pin Kits, King Pin Kits Manufacturer King Pin Grease Seal this tech tip outlines the proper method to install bushing lip seals used in king pin applications. kingpin replacement kits may come with one of two different upper seals: install seal on end of driver with beveled edge of the seal facing out. the seal goes in the bottom side of the upper bore. It is. King Pin Grease Seal.

From shop.broncograveyard.com

D30 King Pin King Pin Grease Seal Here are a few photos of how it all goes. well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication of the steering axle kingpin. A smaller diamater seal with a 14mm head retaining. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed.. King Pin Grease Seal.

From www.indiamart.com

King Pin Unit Leyland Commet Grease at best price in Rajkot by R E King Pin Grease Seal kingpin replacement kits may come with one of two different upper seals: “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. We get many inquiries about how the swivel link seals are installed. the seal goes in the bottom side of the upper bore. this tech tip outlines. King Pin Grease Seal.

From dansperformanceparts.com

GREASE CAP KING PIN WITH SPEEDO HOLE Dan's Performance Parts King Pin Grease Seal kingpin replacement kits may come with one of two different upper seals: this tech tip outlines the proper method to install bushing lip seals used in king pin applications. A smaller diamater seal with a 14mm head retaining. install seal on end of driver with beveled edge of the seal facing out. “the grease zerk is. King Pin Grease Seal.

From www.riversidegear.com

Dana 60 LOWER King Pin Seal King Pin Grease Seal this tech tip outlines the proper method to install bushing lip seals used in king pin applications. install seal on end of driver with beveled edge of the seal facing out. king pin seals installation. Here are a few photos of how it all goes. A smaller diamater seal with a 14mm head retaining. It is there. King Pin Grease Seal.

From www.ebay.de

GENUINE INTERNATIONAL NAVISTAR TRUCK KING PIN GREASE CAP H68687003. NEW King Pin Grease Seal Here are a few photos of how it all goes. Use a brass hammer or dead blow hammer to pound. install seal on end of driver with beveled edge of the seal facing out. kingpin replacement kits may come with one of two different upper seals: “the grease zerk is the entry point for greasing once the. King Pin Grease Seal.

From www.brokentractor.com

John Deere King Pin Grease Fitting 58M5573 King Pin Grease Seal kingpin replacement kits may come with one of two different upper seals: king pin seals installation. We get many inquiries about how the swivel link seals are installed. the seal goes in the bottom side of the upper bore. well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication. King Pin Grease Seal.

From mpparts.com

MPParts Oshkosh 1143223 Front Axle King Pin Grease Fitting 31TA558 King Pin Grease Seal It is there to keep the grease from working out. this tech tip outlines the proper method to install bushing lip seals used in king pin applications. install seal on end of driver with beveled edge of the seal facing out. A smaller diamater seal with a 14mm head retaining. We get many inquiries about how the swivel. King Pin Grease Seal.

From www.dieselhub.com

1991 2002 Chevrolet/GMC C3500HD King Pin Replacement Guide King Pin Grease Seal “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. Use a brass hammer or dead blow hammer to pound. kingpin replacement kits may come with one of two different upper seals: We get many inquiries about how the swivel link seals are installed. the seal goes in the bottom. King Pin Grease Seal.

From www.brokentractor.com

John Deere King Pin Grease Fitting 58M5573 King Pin Grease Seal this tech tip outlines the proper method to install bushing lip seals used in king pin applications. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. We get many inquiries about how the swivel link seals are installed. Use a brass hammer or dead blow hammer to pound. It is. King Pin Grease Seal.

From www.ebay.com

1931 1932 1933 auburn king pin grease seals eBay King Pin Grease Seal A smaller diamater seal with a 14mm head retaining. well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication of the steering axle kingpin. We get many inquiries about how the swivel link seals are installed. “the grease zerk is the entry point for greasing once the kingpin kit assembly has. King Pin Grease Seal.

From www.brokentractor.com

John Deere King Pin Grease Fitting 58M5573 King Pin Grease Seal well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication of the steering axle kingpin. install seal on end of driver with beveled edge of the seal facing out. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. A smaller diamater seal. King Pin Grease Seal.

From www.quickperformance.com

YP KP009 Grease retainer for Dana 60 kingpin King Pin Grease Seal We get many inquiries about how the swivel link seals are installed. Use a brass hammer or dead blow hammer to pound. Here are a few photos of how it all goes. king pin seals installation. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. install seal on end. King Pin Grease Seal.

From wirelistpolyzonal.z19.web.core.windows.net

Dana 60 Kingpin Diagram King Pin Grease Seal Here are a few photos of how it all goes. install seal on end of driver with beveled edge of the seal facing out. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. the seal goes in the bottom side of the upper bore. We get many inquiries about. King Pin Grease Seal.

From www.corvetteforum.com

“Grease Caps” for King Pin CorvetteForum Chevrolet Corvette Forum King Pin Grease Seal It is there to keep the grease from working out. Use a brass hammer or dead blow hammer to pound. Here are a few photos of how it all goes. king pin seals installation. kingpin replacement kits may come with one of two different upper seals: “the grease zerk is the entry point for greasing once the. King Pin Grease Seal.

From studem15a-20.blogspot.com

StudeM15A20 King Pin Install King Pin Grease Seal We get many inquiries about how the swivel link seals are installed. the seal goes in the bottom side of the upper bore. Use a brass hammer or dead blow hammer to pound. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. It is there to keep the grease from. King Pin Grease Seal.

From www.okisuzu.com

1096256480 King Pin Oil Seal 1096256480 Suitable for ISUZU FSR 4HK1 King Pin Grease Seal We get many inquiries about how the swivel link seals are installed. It is there to keep the grease from working out. Use a brass hammer or dead blow hammer to pound. kingpin replacement kits may come with one of two different upper seals: the seal goes in the bottom side of the upper bore. “the grease. King Pin Grease Seal.

From vwispwest.com

KING PIN GREASE PLUG; BUS King Pin Grease Seal “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. king pin seals installation. It is there to keep the grease from working out. well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication of the steering axle kingpin. Use a brass hammer. King Pin Grease Seal.

From www.dieselhub.com

1991 2002 Chevrolet/GMC C3500HD King Pin Replacement Guide King Pin Grease Seal kingpin replacement kits may come with one of two different upper seals: well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication of the steering axle kingpin. king pin seals installation. Use a brass hammer or dead blow hammer to pound. It is there to keep the grease from working. King Pin Grease Seal.

From www.highspeedti.com

King Pin Spindle Bushings Fits .859" King pin Grease grooves Available King Pin Grease Seal well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication of the steering axle kingpin. kingpin replacement kits may come with one of two different upper seals: the seal goes in the bottom side of the upper bore. It is there to keep the grease from working out. install. King Pin Grease Seal.

From westerncanadianrockwell.ca

LOWER KING PIN SEAL DANA 60 WESTERN CANADIAN ROCKWELL INC King Pin Grease Seal the seal goes in the bottom side of the upper bore. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. A smaller diamater seal with a 14mm head retaining. this tech tip outlines the proper method to install bushing lip seals used in king pin applications. well, the. King Pin Grease Seal.

From www.appletreeauto.com

King Pin Beam Seal Kit, Urethane, 4 Pack VW Beetle, VW Bug, Dunebuggy King Pin Grease Seal Here are a few photos of how it all goes. We get many inquiries about how the swivel link seals are installed. the seal goes in the bottom side of the upper bore. Use a brass hammer or dead blow hammer to pound. “the grease zerk is the entry point for greasing once the kingpin kit assembly has. King Pin Grease Seal.

From www.4wdfactory.com

Dana 60 upper king pin seal King Pin Grease Seal this tech tip outlines the proper method to install bushing lip seals used in king pin applications. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. king pin seals installation. the seal goes in the bottom side of the upper bore. Here are a few photos of how. King Pin Grease Seal.

From shop.broncograveyard.com

STEERING KING PIN King Pin Grease Seal kingpin replacement kits may come with one of two different upper seals: “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. Use a brass hammer or dead blow hammer to pound. this tech tip outlines the proper method to install bushing lip seals used in king pin applications. . King Pin Grease Seal.

From www.boostfactory.ca

Genuine Nissan Skyline Knuckle King Pin Grease Seal 4057933P01 King Pin Grease Seal It is there to keep the grease from working out. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. Use a brass hammer or dead blow hammer to pound. the seal goes in the bottom side of the upper bore. install seal on end of driver with beveled edge. King Pin Grease Seal.

From www.ebay.com

MERCEDES+Van+Steering+Kingpin+Grease+Seal+A0109977447 for sale online King Pin Grease Seal A smaller diamater seal with a 14mm head retaining. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. the seal goes in the bottom side of the upper bore. We get many inquiries about how the swivel link seals are installed. king pin seals installation. It is there to. King Pin Grease Seal.

From rodpenroseracing.com.au

Conversion Bearing Grease Seal 4 stud disc to King & Link pin King Pin Grease Seal It is there to keep the grease from working out. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. kingpin replacement kits may come with one of two different upper seals: well, the main benefit of our kingpin seals is in fact the elimination of the frequent lubrication of. King Pin Grease Seal.

From www.youtube.com

How to Grease Kingpins International 4700 YouTube King Pin Grease Seal Use a brass hammer or dead blow hammer to pound. A smaller diamater seal with a 14mm head retaining. install seal on end of driver with beveled edge of the seal facing out. Here are a few photos of how it all goes. king pin seals installation. It is there to keep the grease from working out. . King Pin Grease Seal.

From www.mgsales.com.au

280570 ACG4030 MG TD TF MGA KING PIN GREASE SEAL FRONT SWIVEL MG King Pin Grease Seal We get many inquiries about how the swivel link seals are installed. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. this tech tip outlines the proper method to install bushing lip seals used in king pin applications. the seal goes in the bottom side of the upper bore.. King Pin Grease Seal.

From www.yukongear.com

Replacement kingpin kit for Dana 60(1) side (pin, bushing, seals King Pin Grease Seal A smaller diamater seal with a 14mm head retaining. “the grease zerk is the entry point for greasing once the kingpin kit assembly has been completed. the seal goes in the bottom side of the upper bore. install seal on end of driver with beveled edge of the seal facing out. king pin seals installation. Use. King Pin Grease Seal.