Compactor Machine Risk Assessment . What are the main safety risks? Carry out visual checks for fuel leaks and repair before operation. Ensure the fuel cap is properly secured after refuelling. To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that receives the waste. Compactor risk assessment templates are used to identify and assess the risks of compactors. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that. The primary goal is to protect workers from injury or illness through effective.

from www.haspod.com

To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that. Carry out visual checks for fuel leaks and repair before operation. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that receives the waste. Compactor risk assessment templates are used to identify and assess the risks of compactors. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. The primary goal is to protect workers from injury or illness through effective. Ensure the fuel cap is properly secured after refuelling. What are the main safety risks? Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams.

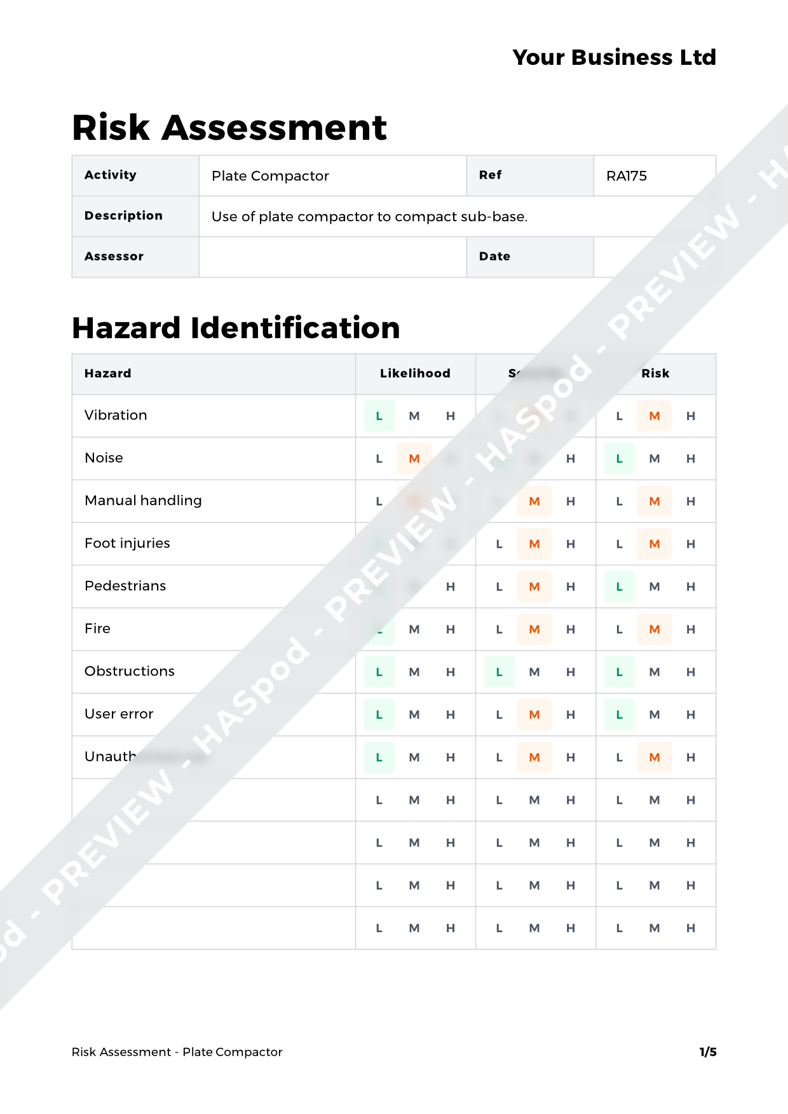

Plate Compactor Risk Assessment Template HASpod

Compactor Machine Risk Assessment Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. The primary goal is to protect workers from injury or illness through effective. Compactor risk assessment templates are used to identify and assess the risks of compactors. Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that receives the waste. Carry out visual checks for fuel leaks and repair before operation. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. What are the main safety risks? To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Ensure the fuel cap is properly secured after refuelling. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that.

From www.chegg.com

Solved Task 6 Showing how the faulty compactor exposed Compactor Machine Risk Assessment Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. Compactor risk assessment templates are used to identify and assess the risks of compactors. Carry out visual checks for fuel leaks and repair before operation. The primary goal is to protect workers from injury or illness through effective. Compactors normally. Compactor Machine Risk Assessment.

From constatech.co.za

Risk Assessment Compactor Machine Risk Assessment What are the main safety risks? To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Carry out visual checks for fuel leaks and repair before operation. Ensure the fuel cap is properly secured after refuelling. Risk assess your work activities and introduce (and maintain) safe systems of work for. Compactor Machine Risk Assessment.

From www.scribd.com

JSA. Compactor Personal Protective Equipment Safety Compactor Machine Risk Assessment To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. Compactors normally include a feed. Compactor Machine Risk Assessment.

From www.rynohire.com.au

How to Prevent Accidents When Using a Compactor Machine Ryno Hire Compactor Machine Risk Assessment Compactor risk assessment templates are used to identify and assess the risks of compactors. Carry out visual checks for fuel leaks and repair before operation. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. Ensure the fuel cap is properly secured after refuelling. Compactors normally include a feed inlet, a. Compactor Machine Risk Assessment.

From www.compliantindustriesgroup.com.au

COMPACTOR ROLLER RISK & HAZARD ASSESSMENT HAZARD ANALYSIS Compactor Machine Risk Assessment Carry out visual checks for fuel leaks and repair before operation. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that receives the waste. To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Ensure the fuel cap is properly secured after refuelling. Compactor. Compactor Machine Risk Assessment.

From sitemate.com

Roller Compactor Inspection Checklist Template Better Than PDF Compactor Machine Risk Assessment Compactor risk assessment templates are used to identify and assess the risks of compactors. Carry out visual checks for fuel leaks and repair before operation. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by. Compactor Machine Risk Assessment.

From constatech.co.za

Risk Assessment Compactor Machine Risk Assessment Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that. Carry out visual checks for fuel leaks and repair before operation. Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. To reduce the risk of injury, all operators and maintenance personnel must read. Compactor Machine Risk Assessment.

From www.etsy.com

Roller Compactor Inspection Checklist, Health Safety Policy Compactor Machine Risk Assessment Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that receives the waste. To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that. What are the main safety. Compactor Machine Risk Assessment.

From www.scribd.com

Washer Compactor and Grit Classifier Cleaning PDF Risk Risk Compactor Machine Risk Assessment Ensure the fuel cap is properly secured after refuelling. Compactor risk assessment templates are used to identify and assess the risks of compactors. Carry out visual checks for fuel leaks and repair before operation. What are the main safety risks? The primary goal is to protect workers from injury or illness through effective. Compactors normally include a feed inlet, a. Compactor Machine Risk Assessment.

From www.safetysticker.com

Compactor Safety Sheet Safety Stickers Safety Decals Compactor Machine Risk Assessment Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Carry out visual checks for fuel leaks and repair before operation. Compactor risk assessment templates are used to identify and assess. Compactor Machine Risk Assessment.

From www.scribd.com

Roller Compactor Inspection Checklist PDF Wheeled Vehicles Car Compactor Machine Risk Assessment Carry out visual checks for fuel leaks and repair before operation. Compactor risk assessment templates are used to identify and assess the risks of compactors. To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip. Compactor Machine Risk Assessment.

From www.haspod.com

Plate Compactor Risk Assessment Template HASpod Compactor Machine Risk Assessment To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that receives the waste. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. Compacting and. Compactor Machine Risk Assessment.

From sitemate.com

Roller Compactor Inspection Checklist Template Better Than PDF Compactor Machine Risk Assessment To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Compactor risk assessment templates are used to identify and assess the risks of compactors. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that receives the waste. What are the main safety risks? Carry. Compactor Machine Risk Assessment.

From constatech.co.za

Risk Assessment Compactor Machine Risk Assessment Carry out visual checks for fuel leaks and repair before operation. Compactor risk assessment templates are used to identify and assess the risks of compactors. Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. To reduce the risk of injury, all operators and maintenance personnel must read and understand. Compactor Machine Risk Assessment.

From www.etsy.com

Roller Compactor Inspection Checklist, Health Safety Policy Compactor Machine Risk Assessment To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. The primary goal is to protect workers from injury or illness through effective. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that receives the waste. Carry out visual checks for fuel leaks and. Compactor Machine Risk Assessment.

From www.scribd.com

23. Jumping Compactor Inspection Checklist PDF Compactor Machine Risk Assessment To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that. Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. The primary goal is. Compactor Machine Risk Assessment.

From onlinenzsigns.co.nz

Earthworks Compactor Checklist Online NZ Signs Compactor Machine Risk Assessment Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that. Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. To reduce the risk of. Compactor Machine Risk Assessment.

From www.compliantindustriesgroup.com.au

PLATE COMPACTOR RISK & HAZARD ASSESSMENT HAZARD ANALYSIS Compactor Machine Risk Assessment The primary goal is to protect workers from injury or illness through effective. Compactor risk assessment templates are used to identify and assess the risks of compactors. Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. Compactors normally include a feed inlet, a compaction chamber and an outlet to. Compactor Machine Risk Assessment.

From www.hsedocuments.com

CompactorDailyInspectionChecklist HSE Documents Compactor Machine Risk Assessment Compactor risk assessment templates are used to identify and assess the risks of compactors. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. What are the main safety risks? Carry out visual checks for fuel leaks and repair before operation. Compactors normally include a feed inlet, a compaction chamber and. Compactor Machine Risk Assessment.

From www.scribd.com

ES_Safety & Maintenance ChecklistPneumatic Soil Compactors_V08102E1 Compactor Machine Risk Assessment Carry out visual checks for fuel leaks and repair before operation. What are the main safety risks? Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Ensure the fuel. Compactor Machine Risk Assessment.

From www.haspod.com

Plate Compactor Risk Assessment Template HASpod Compactor Machine Risk Assessment Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Ensure the fuel cap is properly secured after refuelling. Compactors normally include a feed inlet, a compaction chamber and an. Compactor Machine Risk Assessment.

From www.ehsdb.com

machine and equipment safety1 Compactor Machine Risk Assessment The primary goal is to protect workers from injury or illness through effective. Carry out visual checks for fuel leaks and repair before operation. Ensure the fuel cap is properly secured after refuelling. Compactor risk assessment templates are used to identify and assess the risks of compactors. What are the main safety risks? Compactors normally include a feed inlet, a. Compactor Machine Risk Assessment.

From www.scribd.com

Risk Assessment SML Plate Compactor PDF Throttle Risk Compactor Machine Risk Assessment Compactor risk assessment templates are used to identify and assess the risks of compactors. Carry out visual checks for fuel leaks and repair before operation. What are the main safety risks? Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that receives the waste. Ensure the fuel cap is properly secured after refuelling. Compacting. Compactor Machine Risk Assessment.

From hsa.ie

PostPrimary Guidelines Part C Risk Assessment Templates Health Compactor Machine Risk Assessment Carry out visual checks for fuel leaks and repair before operation. Ensure the fuel cap is properly secured after refuelling. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that receives the waste. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. To reduce. Compactor Machine Risk Assessment.

From www.hseinfoservice.com

Roller Compactor inspection checklist Inspection checklist of Roller Compactor Machine Risk Assessment Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that. Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. The primary goal is to protect workers from injury or illness through effective. Ensure the fuel cap is properly secured after refuelling. Risk assess. Compactor Machine Risk Assessment.

From testbook.com

Road Roller Compactor Hazards Risk and Different Safety Measures Compactor Machine Risk Assessment The primary goal is to protect workers from injury or illness through effective. What are the main safety risks? Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that receives the waste. Carry out visual checks for fuel leaks and repair before operation. Compactor risk assessment templates are used to identify and assess the. Compactor Machine Risk Assessment.

From www.compliantindustriesgroup.com.au

PLATE COMPACTOR RISK & HAZARD ASSESSMENT HAZARD ANALYSIS Compactor Machine Risk Assessment What are the main safety risks? Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that. Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. Carry out visual checks for fuel leaks and repair before operation. Ensure the fuel cap is properly secured. Compactor Machine Risk Assessment.

From www.scribd.com

Checklist For Equipment Inspection EARTH COMPACTOR (ROLLER) PDF Compactor Machine Risk Assessment Compactor risk assessment templates are used to identify and assess the risks of compactors. The primary goal is to protect workers from injury or illness through effective. Ensure the fuel cap is properly secured after refuelling. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that. Risk assess your work activities and introduce (and. Compactor Machine Risk Assessment.

From globalehs.co.in

Earth Compactor Inspection Checklist Compactor Machine Risk Assessment Compactor risk assessment templates are used to identify and assess the risks of compactors. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that. Carry out visual checks for fuel leaks and repair before operation.. Compactor Machine Risk Assessment.

From www.civil-engineers-2020.com

Excavation & Back Filling Risk Assessment Template Compactor Machine Risk Assessment What are the main safety risks? Ensure the fuel cap is properly secured after refuelling. Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. Compactor risk assessment templates are used to identify and assess the risks of compactors. Compactors normally include a feed inlet, a compaction chamber and an. Compactor Machine Risk Assessment.

From www.scribd.com

Plate Compactor Inspection Checklist PDF Compactor Machine Risk Assessment What are the main safety risks? The primary goal is to protect workers from injury or illness through effective. Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that. Ensure the fuel cap is properly secured after refuelling. To reduce the risk of injury, all operators and maintenance personnel must read and understand this. Compactor Machine Risk Assessment.

From www.compliantindustriesgroup.com.au

PLATE COMPACTOR RISK & HAZARD ASSESSMENT HAZARD ANALYSIS Compactor Machine Risk Assessment What are the main safety risks? Compactor risk assessment templates are used to identify and assess the risks of compactors. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. Carry. Compactor Machine Risk Assessment.

From bahamas.desertcart.com

Buy Roller Compactor Daily Inspection Checklist Compactor Safety Compactor Machine Risk Assessment What are the main safety risks? To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting,. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. Compactor risk assessment templates are used to identify and assess the risks of compactors. Ensure. Compactor Machine Risk Assessment.

From spiresafety.com.au

Free Compactor Risk Assessment Template Spire Safety Consultants Compactor Machine Risk Assessment Compactors normally include a feed inlet, a compaction chamber and an outlet to a container/skip that receives the waste. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. Compacting and baling equipment reduces large amounts of solid waste to smaller, more manageable units by means of powered rams. The primary. Compactor Machine Risk Assessment.

From www.lhthealthandsafety.co.uk

Excavations Risk Assessment Template LHT Health & Safety Compactor Machine Risk Assessment Ensure the fuel cap is properly secured after refuelling. Carry out visual checks for fuel leaks and repair before operation. Compactor risk assessment templates are used to identify and assess the risks of compactors. Risk assess your work activities and introduce (and maintain) safe systems of work for all the machinery in use. What are the main safety risks? Compacting. Compactor Machine Risk Assessment.