Helical Gear Standard Sizes . Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. The teeth are angled and appear as a segment of a helix. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. Helical gears can transmit power between parallel or right angle axes. Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy, surface finish and quiet running. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The maximum bore size should be 60% to 70% of the hub.

from www.youtube.com

Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy, surface finish and quiet running. Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. Helical gears can transmit power between parallel or right angle axes. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. The maximum bore size should be 60% to 70% of the hub. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. The teeth are angled and appear as a segment of a helix. The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth.

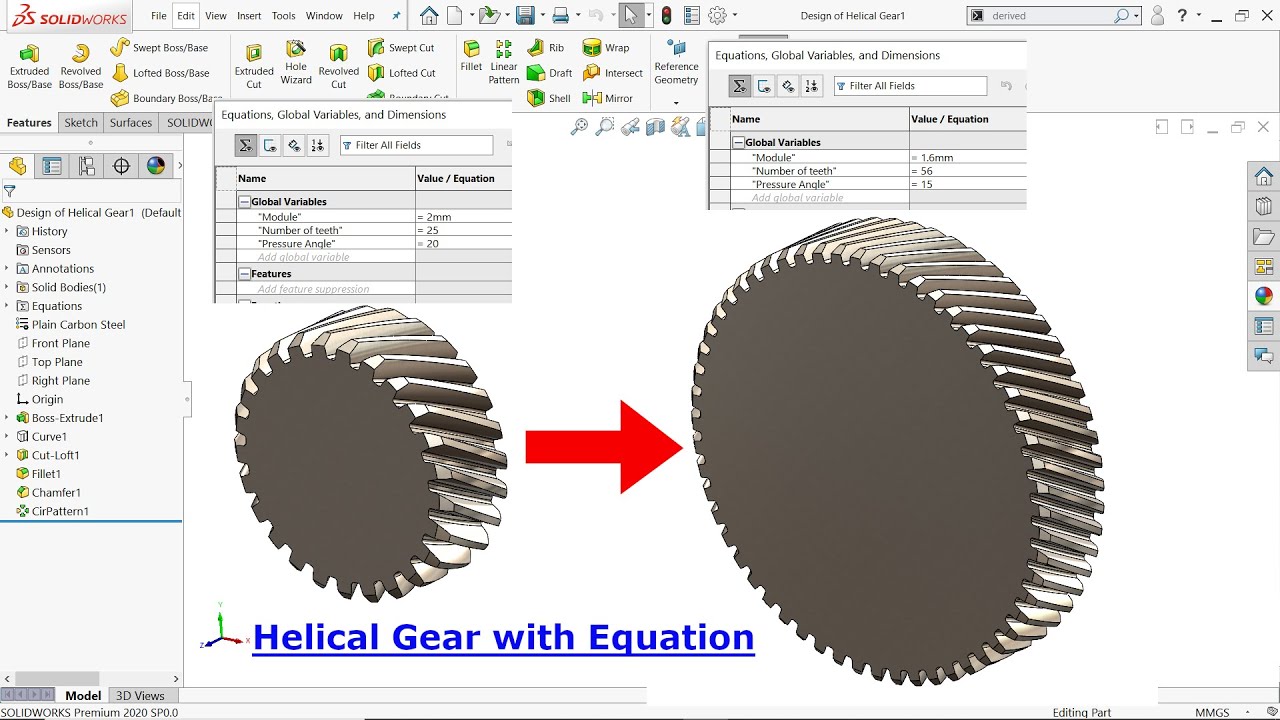

Design Of Helical Gear with Equation in SolidWorks YouTube

Helical Gear Standard Sizes Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy, surface finish and quiet running. Helical gears can transmit power between parallel or right angle axes. Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy, surface finish and quiet running. The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. The teeth are angled and appear as a segment of a helix. The maximum bore size should be 60% to 70% of the hub.

From www.youtube.com

catia Helical gear design with formula explanation,How to make helical Helical Gear Standard Sizes The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The maximum bore size should be 60% to 70% of the hub. Helical gears can. Helical Gear Standard Sizes.

From www.researchgate.net

Specification of spur and helical gears. Download Table Helical Gear Standard Sizes The teeth are angled and appear as a segment of a helix. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Helical gears can transmit power between parallel or right angle axes. The maximum bore size should be 60% to 70% of the hub. The maximum bore size is. Helical Gear Standard Sizes.

From www.youtube.com

Terminology of Helical Gears Design of Spur, Helical, Bevel and Worm Helical Gear Standard Sizes The maximum bore size should be 60% to 70% of the hub. Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy, surface finish and quiet running. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. A helical gear is a type of. Helical Gear Standard Sizes.

From www.automotioncomponents.co.uk

Automotion Components Spur Gears Technical Page Automotion Helical Gear Standard Sizes The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. The teeth are angled and appear as a segment of a helix. Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. A helical gear is a type. Helical Gear Standard Sizes.

From khkgears.net

Basic Gear Terminology and Calculation KHK Helical Gear Standard Sizes Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. The maximum bore size should be 60% to. Helical Gear Standard Sizes.

From selmec.org.uk

The Theory of Meccano Gears Part 2 — Helical Gears — South East London Helical Gear Standard Sizes Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The teeth are angled and appear as a segment of a helix. Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. The maximum bore size should be 60% to 70% of the. Helical Gear Standard Sizes.

From www.chegg.com

All gears are helical gears Use standards in Tables Helical Gear Standard Sizes Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy, surface finish and quiet running. Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear. Helical Gear Standard Sizes.

From www.youtube.com

Terminology of helical gear YouTube Helical Gear Standard Sizes Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. The teeth are angled and appear as a segment of a helix. Profile ground single helical gears and hard finished. Helical Gear Standard Sizes.

From cnhfgear.en.made-in-china.com

Standard Size Stainless Steel Processing Grinding Precision Helical Helical Gear Standard Sizes Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The teeth are angled and appear as a segment of a helix. The maximum bore size is dictated by the requirement that the. Helical Gear Standard Sizes.

From studylib.net

Gears Helical Gear Standard Sizes The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy, surface finish and quiet running. Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational. Helical Gear Standard Sizes.

From agricultural-gearbox.en.made-in-china.com

Standard Sizes Steel Gear Rack Helical Gear Set Rack and Aluminum Helical Gear Standard Sizes Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy, surface finish and quiet running. The teeth are angled and appear as a segment of a helix. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Helical gears can transmit power between parallel. Helical Gear Standard Sizes.

From www.youtube.com

Design Of Helical Gear with Equation in SolidWorks YouTube Helical Gear Standard Sizes Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The teeth are angled and appear as a segment of a helix. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of. Helical Gear Standard Sizes.

From khkgears.net

Calculation of Gear Dimensions KHK Helical Gear Standard Sizes The maximum bore size should be 60% to 70% of the hub. Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy, surface finish and quiet running. The teeth are angled and appear as a segment of a helix. The maximum bore size is dictated by the requirement that the strength of the hub. Helical Gear Standard Sizes.

From news.thomasnet.com

Ondrives Commercial Crossed Axis Helical Gears Helical Gear Standard Sizes A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. Helical gears can transmit power between parallel or right angle axes. The teeth are angled and. Helical Gear Standard Sizes.

From www.zakgear.com

Order online high quality 3D CAD models of helical and spur gears for Helical Gear Standard Sizes Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. The maximum bore size should be 60% to 70% of the hub. Helical gears. Helical Gear Standard Sizes.

From www.iqsdirectory.com

Gear Drive What Is It? Types, Uses, Components, Design Helical Gear Standard Sizes The teeth are angled and appear as a segment of a helix. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The maximum bore size should be 60% to 70% of the hub. Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. The. Helical Gear Standard Sizes.

From btprecision.com.au

Rack and Pinion (Helical and Straight Cut) BT Precision Helical Gear Standard Sizes The maximum bore size should be 60% to 70% of the hub. The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. The teeth are angled and appear as a segment of a helix. Gear size, pressure angle, number of teeth…we introduce the basic terminology,. Helical Gear Standard Sizes.

From www.transmissionspareparts.com

Helical Gear Rack, type DP1 ,DP2 ,DP3 ,DP4 ,DP5 ,DP6 ,DP7 ,DP8 ,DP9 Helical Gear Standard Sizes Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. The teeth are angled and appear as a segment of a helix. The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. The maximum bore size should be. Helical Gear Standard Sizes.

From hourz.info

HELICOIL CHART PDF Helical Gear Standard Sizes The maximum bore size should be 60% to 70% of the hub. Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Helical gears can transmit power between parallel or right angle axes.. Helical Gear Standard Sizes.

From www.tbksoft.com

TBK Straight and helical bevel gears Helical Gear Standard Sizes Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy, surface finish and quiet running. Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. The maximum bore size should be 60% to 70% of the hub. Gear dimensions are determined in accordance with their specifications, such. Helical Gear Standard Sizes.

From www.transmissionspareparts.com

Helical Gear Rack, type M0.5 , M1 , M1.5 , M2 , M2.5 , M3 , M4 , M5 Helical Gear Standard Sizes The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. The teeth are angled and appear as a segment of a helix. Helical gears can transmit power between parallel or right angle axes. Profile ground single helical gears and hard finished spiral bevel gears ensure. Helical Gear Standard Sizes.

From www.iqsdirectory.com

Types of Gears Design, Types, Applications, and Materials Helical Gear Standard Sizes Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. The teeth are angled and appear as a segment of a helix. Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy, surface finish and quiet running. The maximum bore size is dictated by the requirement that the strength. Helical Gear Standard Sizes.

From dsaeavatar.weebly.com

Helical gear design calculation dsaeavatar Helical Gear Standard Sizes The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. The maximum bore size should be 60% to 70% of the hub. Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. The teeth are angled and appear. Helical Gear Standard Sizes.

From www.mechanicalbooster.com

Types of Gears Spur Gear, Helical Gear, Bevel Gear etc. Mechanical Helical Gear Standard Sizes Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. Helical gears can transmit power between parallel or right angle axes. The teeth are. Helical Gear Standard Sizes.

From gearspec.blogspot.com

Gear Specification and Standard Helical Gear Standard Sizes The teeth are angled and appear as a segment of a helix. The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. The maximum bore size should be 60% to 70% of the hub. Profile ground single helical gears and hard finished spiral bevel gears. Helical Gear Standard Sizes.

From www.researchgate.net

Assembly of the helicalgear set (a) layout sketch;(b) mating of teeth Helical Gear Standard Sizes A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. Helical gears can transmit power between parallel or right angle axes. Gear dimensions are. Helical Gear Standard Sizes.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Helical Gear Standard Sizes Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. The teeth are angled and appear as a segment of a helix. Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy,. Helical Gear Standard Sizes.

From www.youtube.com

Helix Angle Calculation How to Calculate Helix Angle of Helical Gears Helical Gear Standard Sizes The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and.. Helical Gear Standard Sizes.

From elmechengg.com

ELMECH ENGINEERING COMPANY Helical Gear Standard Sizes Helical gears can transmit power between parallel or right angle axes. Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy, surface finish and quiet running. The teeth are angled and appear as a segment of a helix. The maximum bore size should be 60% to 70% of the hub. The maximum bore size. Helical Gear Standard Sizes.

From www.drivetrainhub.com

Helical Gears Geometry of helical gears and gear meshes Helical Gear Standard Sizes The maximum bore size should be 60% to 70% of the hub. Profile ground single helical gears and hard finished spiral bevel gears ensure high standards of accuracy, surface finish and quiet running. Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. A helical gear is a type of cylindrical gear on which the. Helical Gear Standard Sizes.

From www.researchgate.net

Dimensions of a helical gear. Download Scientific Diagram Helical Gear Standard Sizes Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. The teeth are angled and appear as a segment of a helix. Helical gears are cylindrical gears whose. Helical Gear Standard Sizes.

From ar.inspiredpencil.com

Helical Gear Drawing Helical Gear Standard Sizes The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. The teeth are angled and appear as a segment of a helix. Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. The maximum bore size should be 60% to. Helical Gear Standard Sizes.

From www.motioncontroltips.com

How to Size and Select a Gearbox A Motion Engineer's Guide Helical Gear Standard Sizes Helical gears can transmit power between parallel or right angle axes. The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. The maximum bore size should be 60% to 70% of the hub. Profile ground single helical gears and hard finished spiral bevel gears ensure. Helical Gear Standard Sizes.

From khkgears.net

Bending Strength of Spur and Helical Gears KHK Helical Gear Standard Sizes Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. Helical gears can transmit power between parallel or right angle axes. The maximum bore size should be 60% to 70% of the hub. The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than. Helical Gear Standard Sizes.

From gearspec.blogspot.com

Gear Specification and Standard JGMA Standard and Specfication Helical Gear Standard Sizes The maximum bore size should be 60% to 70% of the hub. Gear size, pressure angle, number of teeth…we introduce the basic terminology, measurement, and relational expressions necessary to. The maximum bore size is dictated by the requirement that the strength of the hub is to be higher than that of the gear teeth. Gear dimensions are determined in accordance. Helical Gear Standard Sizes.