Wire Wrap Test . Ductility reflects how easily a conductor can be wound and. The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. The wrapping test assesses the ductility of aluminum wires used in power cables. This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic deformation during wrapping. The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a.

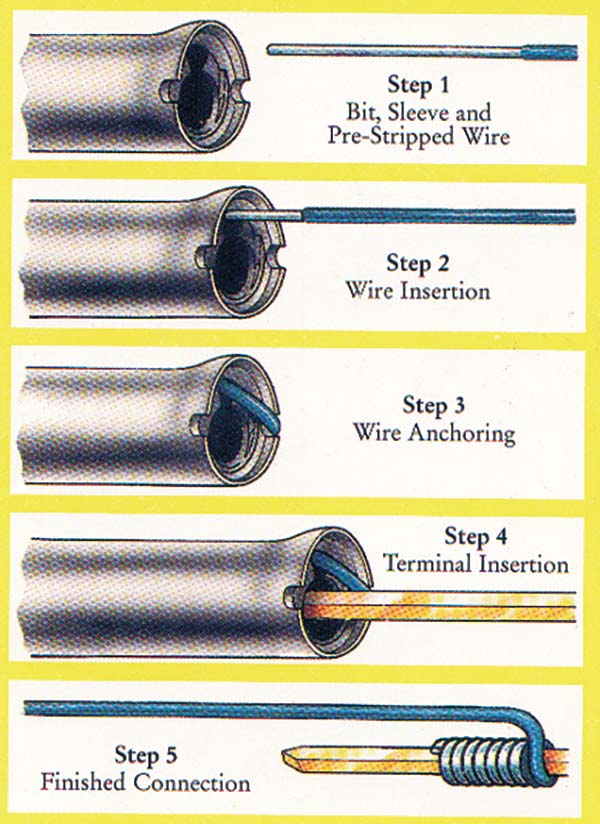

from www.nutsvolts.com

This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic deformation during wrapping. Ductility reflects how easily a conductor can be wound and. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic. The wrapping test assesses the ductility of aluminum wires used in power cables. The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to.

Wire Wrap Is alive And Well! Nuts & Volts Magazine

Wire Wrap Test The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic deformation during wrapping. Ductility reflects how easily a conductor can be wound and. The wrapping test assesses the ductility of aluminum wires used in power cables. The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to.

From www.youtube.com

How to Wrap a Cable The Right Way The Over Under Method YouTube Wire Wrap Test Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic deformation during wrapping. This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. Ductility reflects how easily a conductor can be. Wire Wrap Test.

From dohwaji.or.kr

Strippers Wire Wrapping Tool Unwrapping 22 AWG Gauge Professional Engineer Quick & Easy Wire Wire Wrap Test Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic. The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. Ductility reflects how easily a conductor can be wound. Wire Wrap Test.

From rk.edu.pl

Wire wrapping tool for electronics prototyping with reliable connections Wire Wrap Test This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic deformation during wrapping. The wrapping test assesses the ductility of aluminum. Wire Wrap Test.

From learn.sparkfun.com

Working with Wire Wire Wrap Test The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic. The wrapping test assesses the ductility of aluminum wires. Wire Wrap Test.

From www.electronictestsurplus.com

Bantam Plug To Wire Wrap Terminal Pins Female Grp 400210WP Wire Wrap Test This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. Iso 7802:2013 specifies a method for determining the ability. Wire Wrap Test.

From www.slideserve.com

PPT Operation of FPGAs at Extremely Low Temperatures PowerPoint Presentation ID6311584 Wire Wrap Test The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic deformation during wrapping. Ductility reflects how easily a. Wire Wrap Test.

From www.youtube.com

Wire wrap classes Available YouTube Wire Wrap Test The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. Ductility reflects how easily a conductor can be wound and. The wrapping test assesses the ductility of aluminum wires used in power cables. The test consists of winding a wire to a specified number. Wire Wrap Test.

From learn.sparkfun.com

Working with Wire SparkFun Learn Wire Wrap Test Ductility reflects how easily a conductor can be wound and. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic deformation during wrapping. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive,. Wire Wrap Test.

From www.aliexpress.com

2pcs/lot 8 color Wrapping Wire Wrap Multicolor PCB Test Core Line AWG30 ok wire jumper wire free Wire Wrap Test The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. The wrapping test assesses the ductility of aluminum wires used in power cables. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10. Wire Wrap Test.

From www.gcreurodraw.com

Cable wrapping machines Eurodraw Wire Equipment Site Wire Wrap Test Ductility reflects how easily a conductor can be wound and. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic deformation during wrapping. The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in. Wire Wrap Test.

From www.grainger.com

OK INDUSTRIES Wire Wrap Tool, Green, 1832 AWG, Manual 2RZN5G200/R3278 Grainger Wire Wrap Test This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. Iso 7802:2013 specifies a method for determining the ability of. Wire Wrap Test.

From www.youtube.com

TuffWrap Fabric HeatShrink Wire & Cable Wrap YouTube Wire Wrap Test The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. The wrapping test assesses the ductility of aluminum wires used. Wire Wrap Test.

From www.youtube.com

WIRE WRAPPING TECHNIQUE 1 YouTube Wire Wrap Test The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. The wrapping test assesses the ductility of aluminum wires used in power cables. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm. Wire Wrap Test.

From toptechboy.com

LESSON 26 Wire Wrapping Technology Tutorials Wire Wrap Test The wrapping test assesses the ductility of aluminum wires used in power cables. The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to. Wire Wrap Test.

From www.vtstestingequipment.com

ISO7802 Wire Wrapping Test VTSTesting Equipment Manufacturer Wire Wrap Test Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic. The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. Ductility reflects how easily a conductor can be wound. Wire Wrap Test.

From www.youtube.com

Wire Wrapping Tutorial YouTube Wire Wrap Test The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. Iso 7802:2013 specifies a method for determining the ability of. Wire Wrap Test.

From jonard.com

Insulated Wire Wrapping Tool with Flashlight Jonard Wire Wrap Test The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. The test consists of winding a wire to a specified. Wire Wrap Test.

From www.grainger.com

OK INDUSTRIES Wire Wrap Tool, Silver, 1832 AWG, Manual 2RZN2G100/R3278 Grainger Wire Wrap Test The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. Ductility reflects how easily a conductor can be wound and. This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive,. Wire Wrap Test.

From www.thelabelpeople.co.uk

Cable Wrap PAT Testing Labels Browse and Buy online today Wire Wrap Test The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. Ductility reflects how easily a conductor can be wound and. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. Wire Wrap Test.

From www.youtube.com

Wire Wrapping Tutorial Simple Wire Wrapped Cabochon Pendant Great For Beginners! YouTube Wire Wrap Test The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. The wrapping test assesses the ductility of aluminum wires used in power cables. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10. Wire Wrap Test.

From www.victorytest.com

ISO 7802 Metallic MaterialsWireWrapping Test VTSTesting Equipment Manufacturer Wire Wrap Test Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic deformation during wrapping. The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. Ductility reflects how easily a conductor. Wire Wrap Test.

From www.shoppingsquare.com.au

250m 8Wire Coloured Insulated P/N B301000 30AWG Wire Wrapping Cable Wrap Reel Online Wire Wrap Test This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic deformation during wrapping. Iso 7802:2013 specifies a method for determining the. Wire Wrap Test.

From learn.sparkfun.com

Working with Wire SparkFun Learn Wire Wrap Test Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic deformation during wrapping. Ductility reflects how easily a conductor can be wound and. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive,. Wire Wrap Test.

From www.youtube.com

Wire Wrapping Tutorials Coils Part 2 YouTube Wire Wrap Test Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic. This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. Iso 7802:2013 specifies a method for determining the ability of metallic. Wire Wrap Test.

From www.aliexpress.com

8 Colors 30AWG 0.25mm Electrical Wires Tin Plated Copper Wire Wrapping Insulation Test Cable Wire Wrap Test The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. Ductility reflects how easily a conductor can be wound and. The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the. Wire Wrap Test.

From www.grainger.com

OK INDUSTRIES Manual Wire Wrap Tool w/Light, 1832 AWG 2RZN3G100/R3278FL Grainger Wire Wrap Test This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. The wrapping test assesses the ductility of aluminum wires used in power cables. Ductility reflects how easily a conductor can be wound and. Iso 7802:2013 specifies a method for determining the ability of metallic wire of. Wire Wrap Test.

From www.aliexpress.com

Wire Wrap Test Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic. The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. Iso 7802:2013 specifies a method for determining the. Wire Wrap Test.

From www.patlabelsonline.co.uk

Cable Wrap PAT Test Labels for Testing Portable Appliance Pat Labels Wire Wrap Test This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. Iso 7802:2013 specifies a method for determining the ability. Wire Wrap Test.

From learn.sparkfun.com

Working with Wire SparkFun Learn Wire Wrap Test The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic deformation during wrapping. The test consists of winding a. Wire Wrap Test.

From acroname.com

Getting Started How To Set Up Your Automated Test System Acroname Wire Wrap Test Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic. The wrapping test assesses the ductility of aluminum wires used in power cables. Ductility reflects how easily a conductor can be wound and. This international standard specifies a method for determining the ability of metallic. Wire Wrap Test.

From studylib.net

The WireWrap wrapping technique Wire Wrap Test The wrapping test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic. The wrapping test assesses the ductility of aluminum wires. Wire Wrap Test.

From www.elexp.com

Wire Wrap Solid Kynar Wire 30 Gauge (White, 1000 feet) Electronix Express Wire Wrap Test Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic. This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. The wrapping test consists of winding a wire to a specified. Wire Wrap Test.

From www.youtube.com

Wire Wrapping Tutorial Weave Settings (DOABLE WITH ALL ROUND WIRES!) YouTube Wire Wrap Test The wrapping test assesses the ductility of aluminum wires used in power cables. This international standard specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to. Wire Wrap Test.

From www.unitedtest.com

Metal wire wrapping test ISO 7802_Metal_United Test Wire Wrap Test Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic. The wrapping test assesses the ductility of aluminum wires used in power cables. Ductility reflects how easily a conductor can be wound and. The test consists of winding a wire to a specified number of. Wire Wrap Test.

From www.nutsvolts.com

Wire Wrap Is alive And Well! Nuts & Volts Magazine Wire Wrap Test Iso 7802:2013 specifies a method for determining the ability of metallic wire of diameter or thickness 0,1 mm to 10 mm inclusive, to undergo plastic deformation during wrapping. The test consists of winding a wire to a specified number of turns around a mandrel of the diameter specified in the relevant standard to form a. This international standard specifies a. Wire Wrap Test.