What Is The End Product Of Wood . It involves cutting the wood into various shapes and sizes. Wood quality is defined as the combination of all wood characteristics that affect the value recovery chain and the serviceability of end products. The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed. If the process called ‘air. Sawing is one of the most common forms of wood manufacturing. Sawing can be done by hand, but most often it is done with a sawmill. All the types of wood products used for renovations and extensions are included in this category: Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. The type of wood manufacturing process and product can vary greatly depending on the type of wood being used and the end product.

from professoridea.com

All the types of wood products used for renovations and extensions are included in this category: Wood quality is defined as the combination of all wood characteristics that affect the value recovery chain and the serviceability of end products. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. If the process called ‘air. The type of wood manufacturing process and product can vary greatly depending on the type of wood being used and the end product. Sawing is one of the most common forms of wood manufacturing. Sawing can be done by hand, but most often it is done with a sawmill. The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed. It involves cutting the wood into various shapes and sizes.

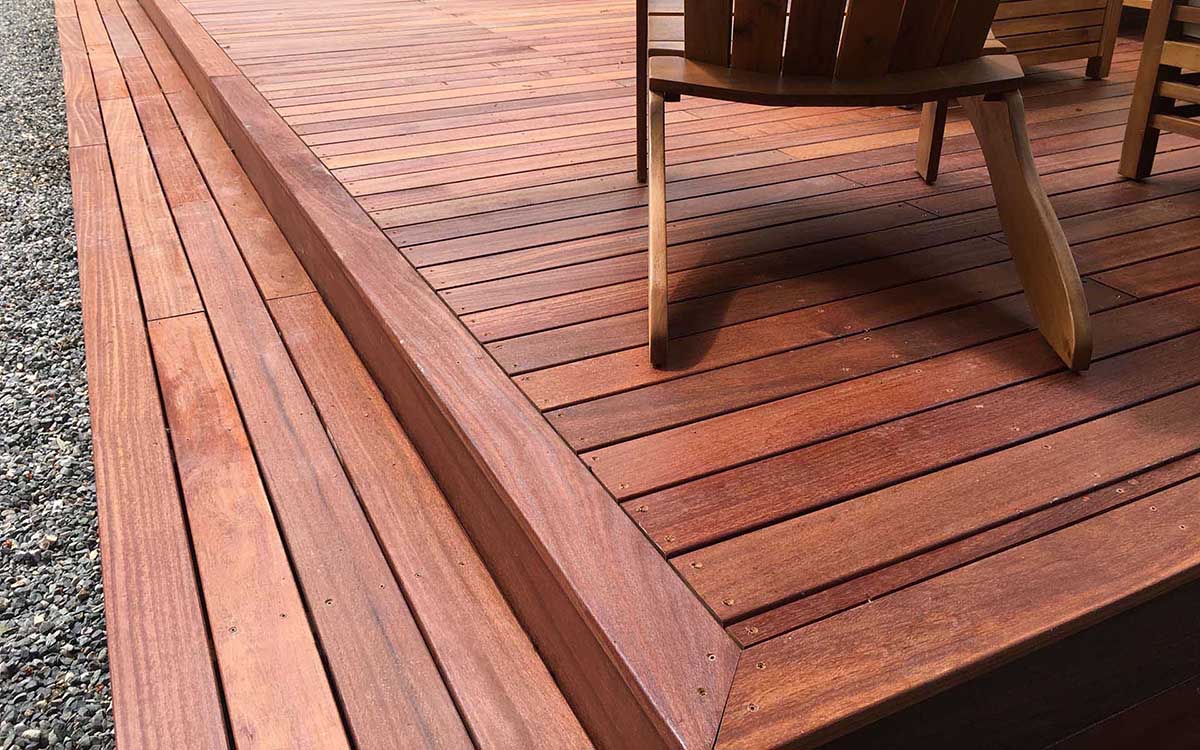

Decking the Halls Tips and Tricks for Building the Perfect Deck

What Is The End Product Of Wood It involves cutting the wood into various shapes and sizes. If the process called ‘air. The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. It involves cutting the wood into various shapes and sizes. Sawing is one of the most common forms of wood manufacturing. Sawing can be done by hand, but most often it is done with a sawmill. The type of wood manufacturing process and product can vary greatly depending on the type of wood being used and the end product. All the types of wood products used for renovations and extensions are included in this category: Wood quality is defined as the combination of all wood characteristics that affect the value recovery chain and the serviceability of end products.

From www.pinterest.es

Wooden Product Designs that prove why wood is good! Yanko Design What Is The End Product Of Wood The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed. All the types of wood products used for renovations and extensions are included in this category: Sawing can be done by hand, but most often it is done with a sawmill. Wood manufacturing refers to the process of turning raw wood into. What Is The End Product Of Wood.

From www.pinterest.com

Pin on Woodworking projects that sell What Is The End Product Of Wood Wood quality is defined as the combination of all wood characteristics that affect the value recovery chain and the serviceability of end products. The type of wood manufacturing process and product can vary greatly depending on the type of wood being used and the end product. All the types of wood products used for renovations and extensions are included in. What Is The End Product Of Wood.

From zyhomy.com

20+ Diy Wood End Table ZYHOMY What Is The End Product Of Wood Sawing is one of the most common forms of wood manufacturing. If the process called ‘air. Wood quality is defined as the combination of all wood characteristics that affect the value recovery chain and the serviceability of end products. It involves cutting the wood into various shapes and sizes. Sawing can be done by hand, but most often it is. What Is The End Product Of Wood.

From ceidlcgp.blob.core.windows.net

Simple Diy Woodworking Projects at Matthew Melendez blog What Is The End Product Of Wood Sawing is one of the most common forms of wood manufacturing. All the types of wood products used for renovations and extensions are included in this category: The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed. Wood quality is defined as the combination of all wood characteristics that affect the value. What Is The End Product Of Wood.

From www.reddit.com

how it started all the way to how it ended. I know where I screwed the What Is The End Product Of Wood Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. Sawing is one of the most common forms of wood manufacturing. All the types of wood products used for renovations and extensions are included in this category: The rough sawn boards are seasoned,. What Is The End Product Of Wood.

From www.toolnut.co.uk

Crown WoodTurning Tool Set 5 Piece Toolnut What Is The End Product Of Wood Sawing is one of the most common forms of wood manufacturing. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. If the process called ‘air. All the types of wood products used for renovations and extensions are included in this category: It. What Is The End Product Of Wood.

From www.deskera.com

Wood Manufacturing Process A Complete Guide What Is The End Product Of Wood Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. If the process called ‘air. Sawing is one of the most common forms of wood manufacturing. Wood quality is defined as the combination of all wood characteristics that affect the value recovery chain. What Is The End Product Of Wood.

From knowledge.axminstertools.com

A Step Towards The Ultimate Woodworking Dream Big What Is The End Product Of Wood If the process called ‘air. The type of wood manufacturing process and product can vary greatly depending on the type of wood being used and the end product. All the types of wood products used for renovations and extensions are included in this category: Wood manufacturing refers to the process of turning raw wood into a finished product — whether. What Is The End Product Of Wood.

From www.pinterest.com.au

Eastman's Heirloom Woodturnings Wood turning lathe, Woodworking kits What Is The End Product Of Wood Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. It involves cutting the wood into various shapes and sizes. Sawing is one of the most common forms of wood manufacturing. All the types of wood products used for renovations and extensions are. What Is The End Product Of Wood.

From www.youtube.com

Wooden craft ideas and scrap wood projects ideas YouTube What Is The End Product Of Wood If the process called ‘air. All the types of wood products used for renovations and extensions are included in this category: Sawing is one of the most common forms of wood manufacturing. It involves cutting the wood into various shapes and sizes. The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed.. What Is The End Product Of Wood.

From www.gumtree.com

Woodworking Tools in Blandford Forum, Dorset Gumtree What Is The End Product Of Wood It involves cutting the wood into various shapes and sizes. The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. Wood quality is defined as. What Is The End Product Of Wood.

From www.reddit.com

Finished product! r/woodworking What Is The End Product Of Wood All the types of wood products used for renovations and extensions are included in this category: If the process called ‘air. It involves cutting the wood into various shapes and sizes. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. Wood quality. What Is The End Product Of Wood.

From cejpcuah.blob.core.windows.net

Where Are Simple Modern Products Made at Barreiro blog What Is The End Product Of Wood Sawing can be done by hand, but most often it is done with a sawmill. It involves cutting the wood into various shapes and sizes. The type of wood manufacturing process and product can vary greatly depending on the type of wood being used and the end product. The rough sawn boards are seasoned, a process whereby a large proportion. What Is The End Product Of Wood.

From top-machinery.en.made-in-china.com

DoubleEnded CNC Tenon Machine TwoHeaded CNC Mortar Milling Machine What Is The End Product Of Wood Sawing is one of the most common forms of wood manufacturing. Sawing can be done by hand, but most often it is done with a sawmill. If the process called ‘air. The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed. Wood manufacturing refers to the process of turning raw wood into. What Is The End Product Of Wood.

From www.pinterest.de

Wood resin table, Epoxy resin wood, Resin furniture What Is The End Product Of Wood Sawing is one of the most common forms of wood manufacturing. Wood quality is defined as the combination of all wood characteristics that affect the value recovery chain and the serviceability of end products. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a. What Is The End Product Of Wood.

From www.woodsmith.com

Tips For Creating A Mitered Bridle Joint Woodsmith What Is The End Product Of Wood Sawing is one of the most common forms of wood manufacturing. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. The type of wood manufacturing process and product can vary greatly depending on the type of wood being used and the end. What Is The End Product Of Wood.

From www.toolstation.com

Cut End Wood Preserver 1L Toolstation What Is The End Product Of Wood All the types of wood products used for renovations and extensions are included in this category: Wood quality is defined as the combination of all wood characteristics that affect the value recovery chain and the serviceability of end products. The type of wood manufacturing process and product can vary greatly depending on the type of wood being used and the. What Is The End Product Of Wood.

From baileylineroad.com

DOWEL JOINERY Why It's Easy to Love This Great Woodworking Technique What Is The End Product Of Wood All the types of wood products used for renovations and extensions are included in this category: The type of wood manufacturing process and product can vary greatly depending on the type of wood being used and the end product. Sawing is one of the most common forms of wood manufacturing. It involves cutting the wood into various shapes and sizes.. What Is The End Product Of Wood.

From www.pinterest.com.au

Small wood projects, Diy wood projects, Easy wood projects What Is The End Product Of Wood Sawing is one of the most common forms of wood manufacturing. If the process called ‘air. The type of wood manufacturing process and product can vary greatly depending on the type of wood being used and the end product. Sawing can be done by hand, but most often it is done with a sawmill. Wood manufacturing refers to the process. What Is The End Product Of Wood.

From www.stkittsvilla.com

13 Types Of Wood Joints What Is The End Product Of Wood Wood quality is defined as the combination of all wood characteristics that affect the value recovery chain and the serviceability of end products. The type of wood manufacturing process and product can vary greatly depending on the type of wood being used and the end product. All the types of wood products used for renovations and extensions are included in. What Is The End Product Of Wood.

From www.familyhandyman.com

31 Indoor Woodworking Projects to Do This Winter What Is The End Product Of Wood It involves cutting the wood into various shapes and sizes. The type of wood manufacturing process and product can vary greatly depending on the type of wood being used and the end product. The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed. All the types of wood products used for renovations. What Is The End Product Of Wood.

From exotlfeur.blob.core.windows.net

Woodworking Tools Hamilton Nz at Frank Leon blog What Is The End Product Of Wood The type of wood manufacturing process and product can vary greatly depending on the type of wood being used and the end product. All the types of wood products used for renovations and extensions are included in this category: It involves cutting the wood into various shapes and sizes. The rough sawn boards are seasoned, a process whereby a large. What Is The End Product Of Wood.

From www.bestproductguider.com

The 10 Best Woodworking Vises in 2023 Reviews Buyer's Guide What Is The End Product Of Wood Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. It involves cutting the wood into various shapes and sizes. If the process called ‘air. All the types of wood products used for renovations and extensions are included in this category: Sawing is. What Is The End Product Of Wood.

From www.reddit.com

how it started all the way to how it ended. I know where I screwed the What Is The End Product Of Wood It involves cutting the wood into various shapes and sizes. Sawing can be done by hand, but most often it is done with a sawmill. Sawing is one of the most common forms of wood manufacturing. All the types of wood products used for renovations and extensions are included in this category: If the process called ‘air. Wood manufacturing refers. What Is The End Product Of Wood.

From professoridea.com

Decking the Halls Tips and Tricks for Building the Perfect Deck What Is The End Product Of Wood Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. It involves cutting the wood into various shapes and sizes. Sawing can be done by hand, but most often it is done with a sawmill. The rough sawn boards are seasoned, a process. What Is The End Product Of Wood.

From atelier-yuwa.ciao.jp

Cnc Router Ideas atelieryuwa.ciao.jp What Is The End Product Of Wood Sawing is one of the most common forms of wood manufacturing. The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed. It involves cutting the wood into various shapes and sizes. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at. What Is The End Product Of Wood.

From exofornms.blob.core.windows.net

How To Make Hidden Wood Joints at Eugenia Hartman blog What Is The End Product Of Wood Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. It involves cutting the wood into various shapes and sizes. If the process called ‘air. The type of wood manufacturing process and product can vary greatly depending on the type of wood being. What Is The End Product Of Wood.

From s3-us-west-1.amazonaws.com

Woodwork Wood Craft Ideas To Sell PDF Plans What Is The End Product Of Wood Sawing is one of the most common forms of wood manufacturing. The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed. Wood quality is defined as the combination of all wood characteristics that affect the value recovery chain and the serviceability of end products. Wood manufacturing refers to the process of turning. What Is The End Product Of Wood.

From www.pcwoodfloors.com

Prefinished White Oak Natural 3/4"X31/4" Tulip PC Hardwood Floors What Is The End Product Of Wood The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed. If the process called ‘air. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. All the types of wood products used for renovations and. What Is The End Product Of Wood.

From joixbmcol.blob.core.windows.net

Adjustable Router Template Jig For Square Hole at Jimmy Compton blog What Is The End Product Of Wood Wood quality is defined as the combination of all wood characteristics that affect the value recovery chain and the serviceability of end products. It involves cutting the wood into various shapes and sizes. If the process called ‘air. All the types of wood products used for renovations and extensions are included in this category: Wood manufacturing refers to the process. What Is The End Product Of Wood.

From www.wainwrightfacades.com

Timber Production Process What Is The End Product Of Wood Sawing is one of the most common forms of wood manufacturing. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. If the process called ‘air. All the types of wood products used for renovations and extensions are included in this category: The. What Is The End Product Of Wood.

From www.pinterest.com

Check out WWF's awesome graphic on the value chain of wood! wwfcanada What Is The End Product Of Wood Sawing is one of the most common forms of wood manufacturing. All the types of wood products used for renovations and extensions are included in this category: The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed. It involves cutting the wood into various shapes and sizes. The type of wood manufacturing. What Is The End Product Of Wood.

From www.reddit.com

how it started all the way to how it ended. I know where I screwed the What Is The End Product Of Wood Wood quality is defined as the combination of all wood characteristics that affect the value recovery chain and the serviceability of end products. It involves cutting the wood into various shapes and sizes. Sawing is one of the most common forms of wood manufacturing. Sawing can be done by hand, but most often it is done with a sawmill. All. What Is The End Product Of Wood.

From klatxutph.blob.core.windows.net

What Is The Strongest Wood Glue For Furniture at Lauren Zell blog What Is The End Product Of Wood All the types of wood products used for renovations and extensions are included in this category: Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. It involves cutting the wood into various shapes and sizes. The rough sawn boards are seasoned, a. What Is The End Product Of Wood.

From www.reddit.com

Various exotic wood grain r/woodworking What Is The End Product Of Wood Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece. It involves cutting the wood into various shapes and sizes. Sawing is one of the most common forms of wood manufacturing. Wood quality is defined as the combination of all wood characteristics that. What Is The End Product Of Wood.