Mig Welder Burn Back Setting . Burnback control refers to a specific setting in some. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. You are probably here for this reason, so i’ll explain. one of those details is setting the right parameters on your new mig welder for the job at hand. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. I've just added a new red box to my. Run in mode/burn back time. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip.

from weldguru.com

Burnback control refers to a specific setting in some. I've just added a new red box to my. burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. You are probably here for this reason, so i’ll explain. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. Run in mode/burn back time. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. one of those details is setting the right parameters on your new mig welder for the job at hand.

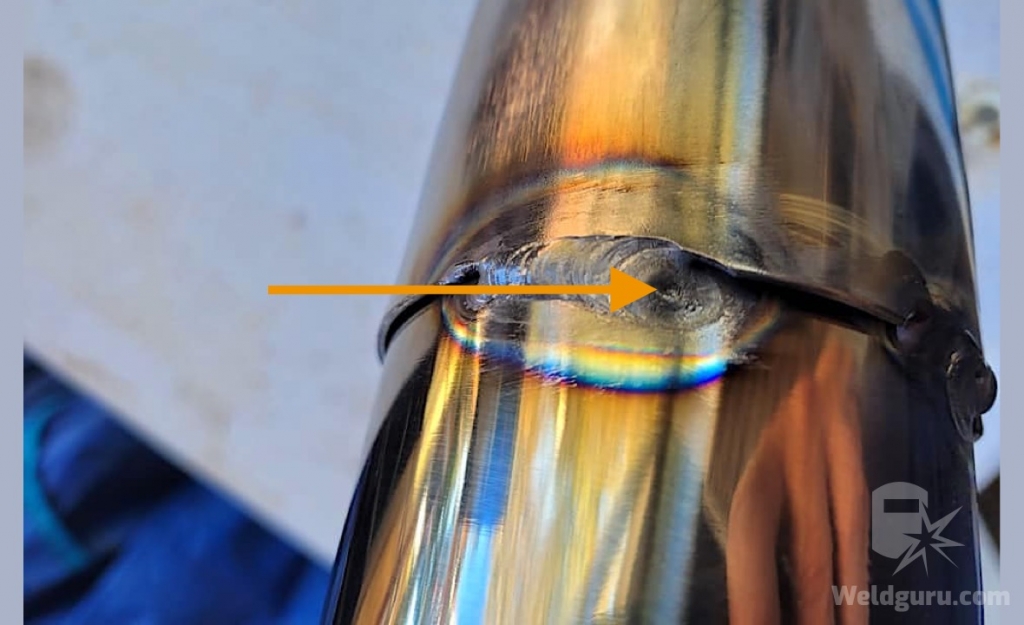

Welding Burn Through Causes & Prevention

Mig Welder Burn Back Setting one of those details is setting the right parameters on your new mig welder for the job at hand. I've just added a new red box to my. one of those details is setting the right parameters on your new mig welder for the job at hand. Burnback control refers to a specific setting in some. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. Run in mode/burn back time. burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. You are probably here for this reason, so i’ll explain.

From www.desertcart.com.kw

Buy ARCCAPTAINMIG Welder, 200Amp 6 in 1 MIG/less Flux Core MIG/Stick Mig Welder Burn Back Setting a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. I've just added a new red box to my. one of those details is setting the right parameters. Mig Welder Burn Back Setting.

From weldguru.com

Welding Burn Through Causes & Prevention Mig Welder Burn Back Setting Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. Run in mode/burn back time. one of those details is setting the right parameters on your new mig. Mig Welder Burn Back Setting.

From weldguru.com

MIG Welder Settings Explained (with Chart) Weld Guru Mig Welder Burn Back Setting You are probably here for this reason, so i’ll explain. Burnback control refers to a specific setting in some. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. I've just added a new red box to my. burnback happens when your wire arcs at. Mig Welder Burn Back Setting.

From www.slideserve.com

PPT Mig Welding PowerPoint Presentation, free download ID5756487 Mig Welder Burn Back Setting Burnback control refers to a specific setting in some. You are probably here for this reason, so i’ll explain. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself. Mig Welder Burn Back Setting.

From www.desertcart.ae

Buy MIG Welder, 200Amp 6 in 1 MIG/less Flux Core MIG/Stick/Lift TIG Mig Welder Burn Back Setting one of those details is setting the right parameters on your new mig welder for the job at hand. burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. Run in mode/burn back time. a 'burnback' control sets the amount of wire. Mig Welder Burn Back Setting.

From www.eng-tips.com

Fronius 320i mig welding 0.8mm aluminium wire burn back & bird nesting Mig Welder Burn Back Setting Burnback control refers to a specific setting in some. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. one of those details is setting the right parameters on your new mig welder for the job at hand. burnback happens when your wire arcs at the opening. Mig Welder Burn Back Setting.

From www.amazon.com

ARCCAPTAIN MIG Welder, 200Amp 6 in 1 Gas MIG/Gasless Flux Core MIG Mig Welder Burn Back Setting Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. I've just added a new red box to my. Burnback control refers to a specific setting in some. . Mig Welder Burn Back Setting.

From www.amazon.ca

ARCCAPTAIN MIG Welder, 200Amp 6 in 1 Gas MIG/Gasless Flux Core MIG Mig Welder Burn Back Setting burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. burnback refers to an issue in mig welding in which the filler wire. Mig Welder Burn Back Setting.

From www.amazon.com

ARCCAPTAIN MIG Welder, 200Amp 6 in 1 Gas MIG/Gasless Flux Core MIG Mig Welder Burn Back Setting one of those details is setting the right parameters on your new mig welder for the job at hand. You are probably here for this reason, so i’ll explain. Burnback control refers to a specific setting in some. I've just added a new red box to my. a 'burnback' control sets the amount of wire to 'burn back'. Mig Welder Burn Back Setting.

From welderslab.com

How to MIG Weld Large Gaps A Beginners Guide Welders Lab Mig Welder Burn Back Setting Burnback control refers to a specific setting in some. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. Run in mode/burn back time. I've just added a new red box to my. a 'burnback' control sets the amount of wire to 'burn back' after. Mig Welder Burn Back Setting.

From weldguru.com

Welding Burn Through Causes & Prevention Mig Welder Burn Back Setting Run in mode/burn back time. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. one of those details is setting the right parameters on your new mig welder for the job at hand. Burnback is specifically a mig problem, as it only occurs with. Mig Welder Burn Back Setting.

From www.eng-tips.com

Fronius 320i mig welding 0.8mm aluminium wire burn back & bird nesting Mig Welder Burn Back Setting Burnback control refers to a specific setting in some. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. Run in mode/burn back time. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. . Mig Welder Burn Back Setting.

From www.amazon.co.uk

ARCCAPTAIN MIG Welder, 200Amp 6 in 1 Gas MIG/Gasless Flux Core MIG Mig Welder Burn Back Setting a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. Run in mode/burn back time. Burnback control refers to a specific setting in some. I've just. Mig Welder Burn Back Setting.

From tweld.com.au

Mig Welders Mig Welder Burn Back Setting one of those details is setting the right parameters on your new mig welder for the job at hand. You are probably here for this reason, so i’ll explain. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. burnback refers to an issue in mig welding. Mig Welder Burn Back Setting.

From guidediagramvalerianic.z4.web.core.windows.net

How To Set Up A Mig Welder Mig Welder Burn Back Setting a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. burnback happens when your wire arcs at the opening of the contact tip and burns. Mig Welder Burn Back Setting.

From www.aliexpress.com

Mig Mma Tig 3 In 1 Inverter Welder Welding Machine 270a / 250a /160 Amp Mig Welder Burn Back Setting Burnback control refers to a specific setting in some. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. I've just added a new red box to my. You are probably here for this reason, so i’ll explain. burnback happens when your wire arcs at. Mig Welder Burn Back Setting.

From 2020lidatools.en.made-in-china.com

5kgs Wire MIG/MMA/TIG 3 in 1 Multifunctional Welding Machine BurnBack Mig Welder Burn Back Setting one of those details is setting the right parameters on your new mig welder for the job at hand. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding. Mig Welder Burn Back Setting.

From www.eng-tips.com

Fronius 320i mig welding 0.8mm aluminium wire burn back & bird nesting Mig Welder Burn Back Setting burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. one of those details is setting the right parameters on your new mig welder. Mig Welder Burn Back Setting.

From unimig.com.au

Welding Burnback What Is It and How to Adjust the Controls UNIMIG Mig Welder Burn Back Setting You are probably here for this reason, so i’ll explain. Burnback control refers to a specific setting in some. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a. Mig Welder Burn Back Setting.

From www.scribd.com

Mig Wire Burn Back Details PDF Friction Welding Mig Welder Burn Back Setting one of those details is setting the right parameters on your new mig welder for the job at hand. I've just added a new red box to my. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. You are probably here for this reason, so i’ll explain.. Mig Welder Burn Back Setting.

From weldguru.com

Welding Burn Through Causes & Prevention Mig Welder Burn Back Setting Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. one of those details is setting the right parameters on your new mig welder for the job at hand. burnback happens when your wire arcs at the opening of the contact tip and burns back into it,. Mig Welder Burn Back Setting.

From www.youtube.com

How to Setup a MIG Welding Machine to Weld with ER70S6 Wire Quick Mig Welder Burn Back Setting Run in mode/burn back time. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. burnback refers to an issue in mig welding in which the filler wire. Mig Welder Burn Back Setting.

From www.youtube.com

Preventing Burnthrough When MIG Welding Aluminum YouTube Mig Welder Burn Back Setting You are probably here for this reason, so i’ll explain. one of those details is setting the right parameters on your new mig welder for the job at hand. Run in mode/burn back time. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. Burnback. Mig Welder Burn Back Setting.

From unimig.com.au

Welding Burnback What Is It and How to Adjust the Controls UNIMIG Mig Welder Burn Back Setting one of those details is setting the right parameters on your new mig welder for the job at hand. burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. You are probably here for this reason, so i’ll explain. burnback refers to. Mig Welder Burn Back Setting.

From www.mig-welding.co.uk

Burn back / wire feed issues??? MIG Welding Forum Mig Welder Burn Back Setting burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. Run in mode/burn back time. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. a 'burnback' control sets the amount of wire to. Mig Welder Burn Back Setting.

From www.lsxmag.com

MIGWelding Basics To Help You Correctly Melt Metal Mig Welder Burn Back Setting Burnback control refers to a specific setting in some. Run in mode/burn back time. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. You are probably here for this reason, so i’ll explain. Burnback is specifically a mig problem, as it only occurs with a. Mig Welder Burn Back Setting.

From 2020lidatools.en.made-in-china.com

5kgs Wire MIG/MMA/TIG 3 in 1 Multifunctional Welding Machine BurnBack Mig Welder Burn Back Setting Run in mode/burn back time. Burnback control refers to a specific setting in some. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. I've just added a new. Mig Welder Burn Back Setting.

From weldguru.com

Welding Burn Through Causes & Prevention Mig Welder Burn Back Setting Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. I've just added a new red box to my. Run in mode/burn back time. Burnback control refers to a. Mig Welder Burn Back Setting.

From www.youtube.com

MIG Welder Burn Back Controls, Most Common MIG Welding Mistakes, MIG Mig Welder Burn Back Setting Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. burnback refers to an issue in mig welding in which the filler wire burns back to the contact tip and melts on it. Run in mode/burn back time. one of those details is setting the right parameters. Mig Welder Burn Back Setting.

From joshuawest.z13.web.core.windows.net

Mig Welder Chart Settings Mig Welder Burn Back Setting I've just added a new red box to my. You are probably here for this reason, so i’ll explain. Burnback control refers to a specific setting in some. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. burnback refers to an issue in mig welding in which the. Mig Welder Burn Back Setting.

From maisiefrancis.z19.web.core.windows.net

Lincoln 180 Mig Welder Settings Chart Mig Welder Burn Back Setting burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. burnback refers to an issue in mig welding in which the filler wire. Mig Welder Burn Back Setting.

From www.hotrod.com

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks Mig Welder Burn Back Setting a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. I've just added a new red box to my. one of those details is setting the right parameters on your new mig welder for the job at hand. burnback happens when your wire arcs at the opening of. Mig Welder Burn Back Setting.

From www.youtube.com

Millermatic® 252 MIG welder burnback YouTube Mig Welder Burn Back Setting a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. You are probably here for this reason, so i’ll explain. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. I've just added a new red box to my.. Mig Welder Burn Back Setting.

From www.amazon.com

ARCCAPTAIN MIG Welder, 200Amp 6 in 1 Gas MIG/Gasless Flux Core MIG Mig Welder Burn Back Setting Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. I've just added a new red box to my. burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. You are probably here. Mig Welder Burn Back Setting.

From www.eng-tips.com

Fronius 320i mig welding 0.8mm aluminium wire burn back & bird nesting Mig Welder Burn Back Setting burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. a 'burnback' control sets the amount of wire to 'burn back' after you release the trigger of your torch. Run in mode/burn back time. You are probably here for this reason, so i’ll. Mig Welder Burn Back Setting.