Klipper Pressure Advance Calibration Pattern . Therefore, one should calibrate pressure advance on each printer and with each spool of filament. You should calibrate your extruder first. This page is compatible with klipper, marlin, and reprapfirmware. Linear advance must be enabled in firmware. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. Printing temperature and extrusion rates can impact. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. Default values apply to standard abs with a 0.4mm nozzle. The parameter involved in the. Not all printers have it.

from ellis3dp.com

Therefore, one should calibrate pressure advance on each printer and with each spool of filament. You should calibrate your extruder first. This page is compatible with klipper, marlin, and reprapfirmware. Default values apply to standard abs with a 0.4mm nozzle. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. Printing temperature and extrusion rates can impact. The parameter involved in the. Linear advance must be enabled in firmware. Not all printers have it. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration.

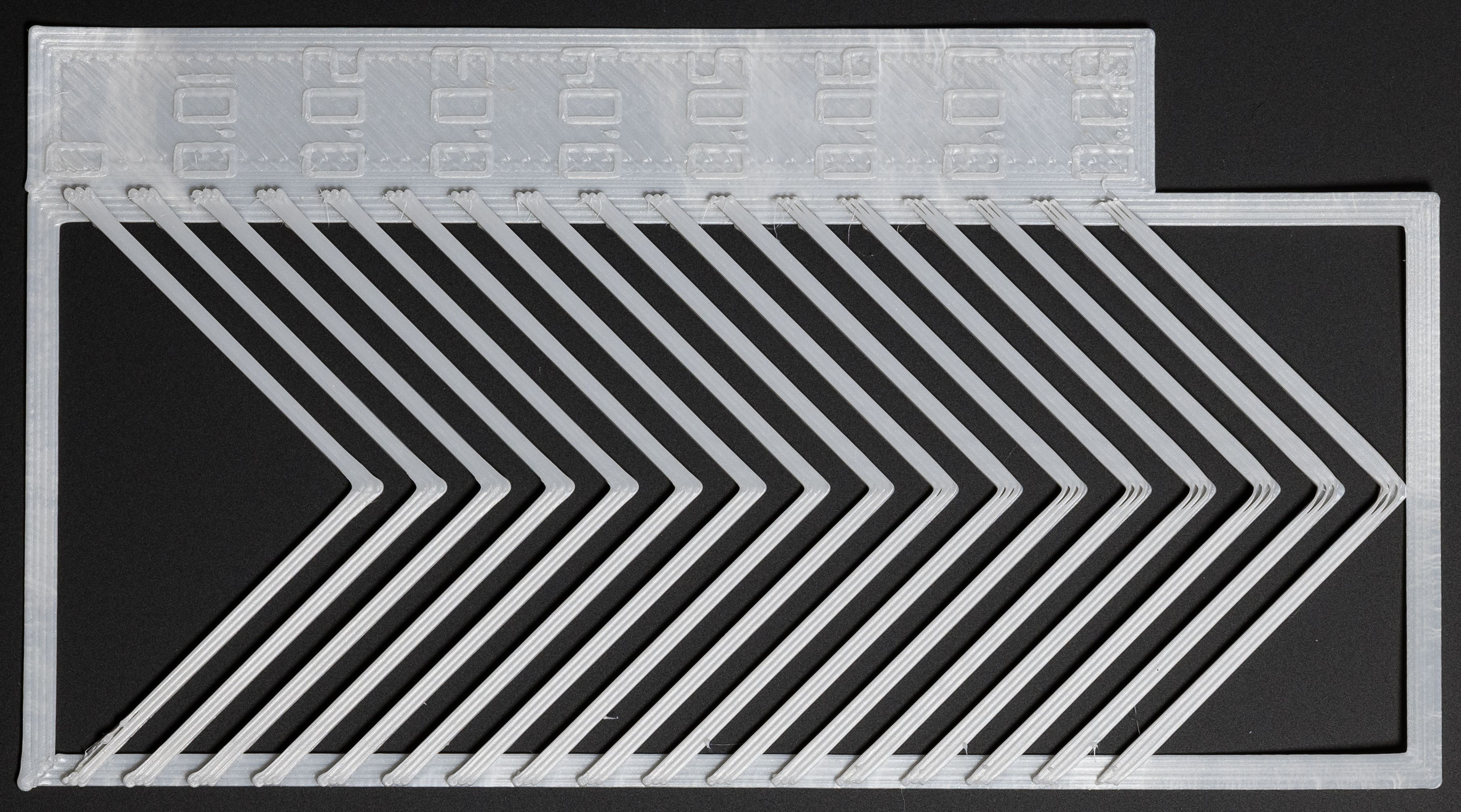

Pattern Method Ellis’ Print Tuning Guide

Klipper Pressure Advance Calibration Pattern Therefore, one should calibrate pressure advance on each printer and with each spool of filament. You should calibrate your extruder first. Printing temperature and extrusion rates can impact. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. The parameter involved in the. This page is compatible with klipper, marlin, and reprapfirmware. Default values apply to standard abs with a 0.4mm nozzle. Not all printers have it. Linear advance must be enabled in firmware.

From www.youtube.com

Klipper Pressure Advance Tuning MADE EASY! YouTube Klipper Pressure Advance Calibration Pattern The parameter involved in the. Not all printers have it. Printing temperature and extrusion rates can impact. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration.. Klipper Pressure Advance Calibration Pattern.

From klipper.discourse.group

Not sure how to interpret this pressure advance calibration print Klipper Pressure Advance Calibration Pattern You should calibrate your extruder first. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. The parameter involved in the. This page is compatible with klipper, marlin, and reprapfirmware. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. The pressure. Klipper Pressure Advance Calibration Pattern.

From github.com

GitHub wigglers/customizableklipperpressureadvancecalibration Klipper Pressure Advance Calibration Pattern The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. Default values apply to standard abs with a 0.4mm nozzle. Not all printers have it. You should calibrate your extruder first. Linear advance must be enabled in firmware. The pressure advance system accounts for pressure by pushing. Klipper Pressure Advance Calibration Pattern.

From www.advanced3dprinting.com

Pressure Advance Tool Klipper Advanced 3D Printing Klipper Pressure Advance Calibration Pattern The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. Linear advance must be enabled in firmware. Printing temperature and extrusion rates can impact. The parameter involved in the. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament. Klipper Pressure Advance Calibration Pattern.

From github.com

Pressure advance smoothing induces eaxis position swings that scale Klipper Pressure Advance Calibration Pattern The parameter involved in the. Default values apply to standard abs with a 0.4mm nozzle. Printing temperature and extrusion rates can impact. Not all printers have it. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. Linear advance must be enabled in firmware. The pressure advance system accounts for pressure by pushing in extra. Klipper Pressure Advance Calibration Pattern.

From www.advanced3dprinting.com

Pressure Advance Tool Klipper Advanced 3D Printing Klipper Pressure Advance Calibration Pattern Printing temperature and extrusion rates can impact. You should calibrate your extruder first. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. This page is compatible with klipper, marlin, and reprapfirmware. Not all printers. Klipper Pressure Advance Calibration Pattern.

From klipper.discourse.group

Pressure_advance_smooth_time skews pressure_advance Developers Klipper Klipper Pressure Advance Calibration Pattern Not all printers have it. Printing temperature and extrusion rates can impact. This page is compatible with klipper, marlin, and reprapfirmware. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. Linear advance must be enabled in firmware. The parameter involved in the. The pressure advance system accounts for pressure by pushing in extra filament. Klipper Pressure Advance Calibration Pattern.

From www.obico.io

Klipper Pressure Advance Tuning How to Guide Obico Knowledge Base Klipper Pressure Advance Calibration Pattern Printing temperature and extrusion rates can impact. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. The parameter involved in the. Default values apply to standard abs with a 0.4mm nozzle. Linear advance must be enabled in firmware. You should calibrate your extruder first. The basic principle is to. Klipper Pressure Advance Calibration Pattern.

From all3dp.com

Klipper Pressure Advance Simply Explained All3DP Klipper Pressure Advance Calibration Pattern The parameter involved in the. Not all printers have it. This page is compatible with klipper, marlin, and reprapfirmware. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. Linear advance must be enabled in firmware. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament,. Klipper Pressure Advance Calibration Pattern.

From forum.duet3d.com

Pattern Pressure Advance Calibration Duet3D Forum Klipper Pressure Advance Calibration Pattern Therefore, one should calibrate pressure advance on each printer and with each spool of filament. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. Default values apply to standard abs with a 0.4mm nozzle. The parameter involved in the. Not all printers have it. You should. Klipper Pressure Advance Calibration Pattern.

From www.youtube.com

Klipper guide Input shaping, pressure advance and macros (manual Klipper Pressure Advance Calibration Pattern The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. You should calibrate your extruder first. Default values apply to standard abs with a 0.4mm nozzle. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. Not all printers have it. The parameter involved in. Klipper Pressure Advance Calibration Pattern.

From www.obico.io

Klipper Pressure Advance Tuning How to Guide Obico Knowledge Base Klipper Pressure Advance Calibration Pattern The parameter involved in the. This page is compatible with klipper, marlin, and reprapfirmware. Printing temperature and extrusion rates can impact. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. Linear advance must be enabled in firmware. You should calibrate your extruder first. Not all printers have it. Default. Klipper Pressure Advance Calibration Pattern.

From www.advanced3dprinting.com

Pressure Advance Tool Klipper Advanced 3D Printing Klipper Pressure Advance Calibration Pattern Default values apply to standard abs with a 0.4mm nozzle. Linear advance must be enabled in firmware. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. The parameter involved in the. You should calibrate your extruder first. The pressure advance system accounts for pressure by pushing. Klipper Pressure Advance Calibration Pattern.

From www.teamfdm.com

Pressure advance General Discussion Team FDM Klipper Pressure Advance Calibration Pattern The parameter involved in the. You should calibrate your extruder first. Printing temperature and extrusion rates can impact. Default values apply to standard abs with a 0.4mm nozzle. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. The pressure advance system accounts for pressure by pushing. Klipper Pressure Advance Calibration Pattern.

From www.obico.io

Pressure advance calibration in OrcaSlicer A Comprehensive Guide Klipper Pressure Advance Calibration Pattern Default values apply to standard abs with a 0.4mm nozzle. The parameter involved in the. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. Linear advance must be enabled in firmware. This page is compatible with klipper, marlin, and reprapfirmware. Not all printers have it. The basic principle is to increase nozzle pressure during. Klipper Pressure Advance Calibration Pattern.

From 3dprintinggeek.com

Klipper Pressure Advance Setup and Troubleshooting Tips Klipper Pressure Advance Calibration Pattern Therefore, one should calibrate pressure advance on each printer and with each spool of filament. The parameter involved in the. Linear advance must be enabled in firmware. Default values apply to standard abs with a 0.4mm nozzle. Not all printers have it. You should calibrate your extruder first. This page is compatible with klipper, marlin, and reprapfirmware. Printing temperature and. Klipper Pressure Advance Calibration Pattern.

From clevercreations.org

Klipper Pressure Advance Perfect It With These 5 Essential Tips Klipper Pressure Advance Calibration Pattern Default values apply to standard abs with a 0.4mm nozzle. Printing temperature and extrusion rates can impact. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. Not all printers have it. Linear advance must be enabled in firmware. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce. Klipper Pressure Advance Calibration Pattern.

From www.youtube.com

How to set pressure advance klipper? YouTube Klipper Pressure Advance Calibration Pattern Default values apply to standard abs with a 0.4mm nozzle. Linear advance must be enabled in firmware. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. Not all printers have it. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and. Klipper Pressure Advance Calibration Pattern.

From www.youtube.com

3D Print Live Cam Klipper Pressure Advance Calibration Cube YouTube Klipper Pressure Advance Calibration Pattern You should calibrate your extruder first. Linear advance must be enabled in firmware. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. This page is compatible with klipper, marlin, and reprapfirmware. Therefore, one should calibrate pressure advance on each printer and with each spool of filament.. Klipper Pressure Advance Calibration Pattern.

From www.advanced3dprinting.com

Pressure Advance Tool Klipper Advanced 3D Printing Klipper Pressure Advance Calibration Pattern This page is compatible with klipper, marlin, and reprapfirmware. You should calibrate your extruder first. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. Linear advance. Klipper Pressure Advance Calibration Pattern.

From 3dprintinggeek.com

Klipper Pressure Advance Setup and Troubleshooting Tips Klipper Pressure Advance Calibration Pattern The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. Not all printers have it. You should calibrate your extruder first. The parameter involved in the. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. This. Klipper Pressure Advance Calibration Pattern.

From www.youtube.com

Klipper 기초강좌 9 (Pressure Advance) YouTube Klipper Pressure Advance Calibration Pattern You should calibrate your extruder first. This page is compatible with klipper, marlin, and reprapfirmware. Not all printers have it. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. Printing temperature and extrusion rates can impact. Linear advance must be enabled in firmware. The pressure advance. Klipper Pressure Advance Calibration Pattern.

From github.com

Pressure Advance proper calibration · Issue 3958 · Klipper3d/klipper Klipper Pressure Advance Calibration Pattern Printing temperature and extrusion rates can impact. The parameter involved in the. This page is compatible with klipper, marlin, and reprapfirmware. Not all printers have it. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. You should calibrate your extruder first. The basic principle is to increase nozzle pressure. Klipper Pressure Advance Calibration Pattern.

From klipper.discourse.group

Bambulab Calibration Routine Features Klipper Klipper Pressure Advance Calibration Pattern Not all printers have it. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. Printing temperature and extrusion rates can impact. The parameter involved in the. The pressure advance system accounts. Klipper Pressure Advance Calibration Pattern.

From www.obico.io

Klipper Pressure Advance Tuning How to Guide Obico Knowledge Base Klipper Pressure Advance Calibration Pattern Not all printers have it. Linear advance must be enabled in firmware. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. The basic principle is to increase nozzle pressure during acceleration to extrude extra. Klipper Pressure Advance Calibration Pattern.

From klipper.discourse.group

Pressure_advance_smooth_time skews pressure_advance Developers Klipper Klipper Pressure Advance Calibration Pattern Linear advance must be enabled in firmware. This page is compatible with klipper, marlin, and reprapfirmware. Printing temperature and extrusion rates can impact. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. Not all printers have it. The pressure advance system accounts for pressure by pushing. Klipper Pressure Advance Calibration Pattern.

From www.teamfdm.com

Pressure advance General Discussion Team FDM Klipper Pressure Advance Calibration Pattern The parameter involved in the. Printing temperature and extrusion rates can impact. Not all printers have it. This page is compatible with klipper, marlin, and reprapfirmware. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during. Klipper Pressure Advance Calibration Pattern.

From ellis3dp.com

Pattern Method Ellis’ Print Tuning Guide Klipper Pressure Advance Calibration Pattern Default values apply to standard abs with a 0.4mm nozzle. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. Printing temperature and extrusion rates can impact. Linear advance must be enabled in firmware. The. Klipper Pressure Advance Calibration Pattern.

From www.obico.io

Klipper Pressure Advance Tuning How to Guide Obico Knowledge Base Klipper Pressure Advance Calibration Pattern Default values apply to standard abs with a 0.4mm nozzle. You should calibrate your extruder first. The parameter involved in the. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. Printing. Klipper Pressure Advance Calibration Pattern.

From github.com

Pressure advance smoothing induces eaxis position swings that scale Klipper Pressure Advance Calibration Pattern You should calibrate your extruder first. Printing temperature and extrusion rates can impact. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. Default values apply to standard abs with a 0.4mm nozzle. This page is compatible with klipper, marlin, and reprapfirmware. Not all printers have it.. Klipper Pressure Advance Calibration Pattern.

From www.youtube.com

Pressure Advance (PA) dans Klipper TUTO et explications ! YouTube Klipper Pressure Advance Calibration Pattern This page is compatible with klipper, marlin, and reprapfirmware. Linear advance must be enabled in firmware. You should calibrate your extruder first. The parameter involved in the. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. Printing temperature and extrusion rates can impact. Not all printers. Klipper Pressure Advance Calibration Pattern.

From www.obico.io

Klipper Pressure Advance Tuning How to Guide Obico Knowledge Base Klipper Pressure Advance Calibration Pattern The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. The parameter involved in the. Not all printers have it. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. You should calibrate your extruder first. Linear. Klipper Pressure Advance Calibration Pattern.

From www.youtube.com

Pressure Advance Calibration for your 3d printer (Klipper) YouTube Klipper Pressure Advance Calibration Pattern Printing temperature and extrusion rates can impact. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. Therefore, one should calibrate pressure advance on each printer and with each spool of filament. You should calibrate your extruder first. The parameter involved in the. Default values apply to. Klipper Pressure Advance Calibration Pattern.

From klipper.discourse.group

Pressure_advance_smooth_time on direct extruders with short filament Klipper Pressure Advance Calibration Pattern Therefore, one should calibrate pressure advance on each printer and with each spool of filament. The parameter involved in the. This page is compatible with klipper, marlin, and reprapfirmware. The pressure advance system accounts for pressure by pushing in extra filament during acceleration and retracting that filament during deceleration. The basic principle is to increase nozzle pressure during acceleration to. Klipper Pressure Advance Calibration Pattern.

From www.obico.io

Klipper Pressure Advance Tuning How to Guide Obico Knowledge Base Klipper Pressure Advance Calibration Pattern Printing temperature and extrusion rates can impact. The basic principle is to increase nozzle pressure during acceleration to extrude extra filament, and reduce nozzle pressure to retract filament during deceleration. This page is compatible with klipper, marlin, and reprapfirmware. The parameter involved in the. Linear advance must be enabled in firmware. Default values apply to standard abs with a 0.4mm. Klipper Pressure Advance Calibration Pattern.