Hobbing Machine Info . Machine concept liebherr hobbing machines are optimized for universal gear applications. Whether compact or large, our gear hobbing machines impress with their flexibility. Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. The lc 280 α is the perfect way for getting started with gear cutting. For the gear cutting process, the hob cutter and the gear are building a pair. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. It offers maximum flexibility thanks to a diverse range of workpieces, well.

from engineeringlearn.com

Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. Machine concept liebherr hobbing machines are optimized for universal gear applications. The lc 280 α is the perfect way for getting started with gear cutting. It offers maximum flexibility thanks to a diverse range of workpieces, well. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. For the gear cutting process, the hob cutter and the gear are building a pair. Whether compact or large, our gear hobbing machines impress with their flexibility. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear.

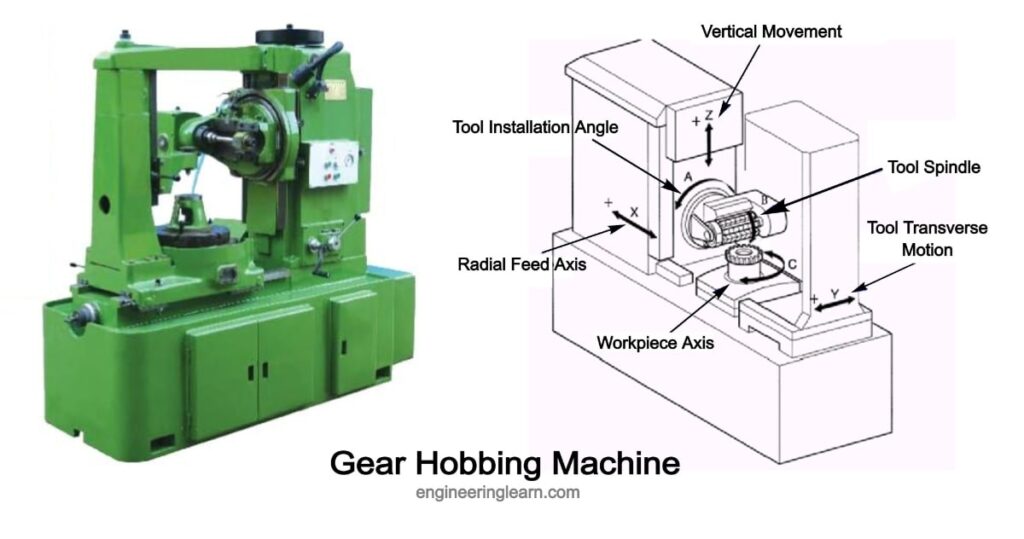

Gear Hobbing Machine Definition, Types, Uses, Working & Construction

Hobbing Machine Info Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. Machine concept liebherr hobbing machines are optimized for universal gear applications. It offers maximum flexibility thanks to a diverse range of workpieces, well. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear. For the gear cutting process, the hob cutter and the gear are building a pair. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. Whether compact or large, our gear hobbing machines impress with their flexibility. The lc 280 α is the perfect way for getting started with gear cutting.

From www.liebherr.com

LC 180 280 Gear hobbing machines Liebherr Liebherr Hobbing Machine Info Whether compact or large, our gear hobbing machines impress with their flexibility. The lc 280 α is the perfect way for getting started with gear cutting. For the gear cutting process, the hob cutter and the gear are building a pair. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process. Hobbing Machine Info.

From www.monnier-zahner.ch

W1000micro Gear hobbing machine Monnier Zahner Hobbing Machine Info Whether compact or large, our gear hobbing machines impress with their flexibility. Machine concept liebherr hobbing machines are optimized for universal gear applications. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear. Gear hobbing is the most productive and economic way to produce gear teeth profiles. Hobbing Machine Info.

From www.liebherr.com

Gear hobbing machines Liebherr Liebherr Hobbing Machine Info For the gear cutting process, the hob cutter and the gear are building a pair. Whether compact or large, our gear hobbing machines impress with their flexibility. It offers maximum flexibility thanks to a diverse range of workpieces, well. The lc 280 α is the perfect way for getting started with gear cutting. Machine concept liebherr hobbing machines are optimized. Hobbing Machine Info.

From nidec-machinetoolamerica.com

Gear Hobbing Machines Nidec Machine Tool America. Hobbing Machine Info The lc 280 α is the perfect way for getting started with gear cutting. It offers maximum flexibility thanks to a diverse range of workpieces, well. Whether compact or large, our gear hobbing machines impress with their flexibility. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the. Hobbing Machine Info.

From www.liebherr.com

LC 300 500 Gear hobbing machines Liebherr Liebherr Hobbing Machine Info Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear. For the gear cutting process, the hob cutter and the gear are building a pair. Gear hobbing is the. Hobbing Machine Info.

From nidec-machinetoolamerica.com

Gear Hobbing Machines Nidec Machine Tool America. Hobbing Machine Info The lc 280 α is the perfect way for getting started with gear cutting. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear. It offers maximum flexibility thanks to a diverse range of workpieces, well. Today’s operators need very few basic inputs of gear geometry, hob. Hobbing Machine Info.

From www.liebherr.com

LC 300 500 Gear hobbing machines Liebherr Liebherr Hobbing Machine Info Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. For the gear cutting process, the hob cutter and the gear are building a pair. The lc 280 α is the perfect way for getting started with gear cutting. Whether compact or large, our gear hobbing machines impress with their flexibility. Machine. Hobbing Machine Info.

From nidec-machinetoolamerica.com

Gear Hobbing Machines Gear Machines Nidec Machine Tool America Hobbing Machine Info The lc 280 α is the perfect way for getting started with gear cutting. It offers maximum flexibility thanks to a diverse range of workpieces, well. Whether compact or large, our gear hobbing machines impress with their flexibility. Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. Machine concept liebherr hobbing. Hobbing Machine Info.

From www.liebherr.com

LC 180 280 Gear hobbing machines Liebherr Liebherr Hobbing Machine Info The lc 280 α is the perfect way for getting started with gear cutting. Whether compact or large, our gear hobbing machines impress with their flexibility. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear. For the gear cutting process, the hob cutter and the gear. Hobbing Machine Info.

From www.monnier-zahner.ch

W90 CNC Fine pitch gear hobbing machine Monnier Zahner Hobbing Machine Info Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. Machine concept liebherr hobbing machines are optimized for universal gear applications. The lc 280 α is the perfect way for getting started with gear cutting. Whether compact or large, our gear hobbing machines impress with their flexibility. Gear hobbing is a mechanical. Hobbing Machine Info.

From www.youtube.com

Gear hobbing machine Pfauter P 251 infoemuk.info YouTube Hobbing Machine Info Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear. Machine. Hobbing Machine Info.

From www.indiamart.com

TOS FO 6 Gear Hobbing Machine at Rs 8500/piece Gear Hobbing Machine Hobbing Machine Info It offers maximum flexibility thanks to a diverse range of workpieces, well. Whether compact or large, our gear hobbing machines impress with their flexibility. Machine concept liebherr hobbing machines are optimized for universal gear applications. The lc 280 α is the perfect way for getting started with gear cutting. For the gear cutting process, the hob cutter and the gear. Hobbing Machine Info.

From www.star-su.com

H 250400 Vertical Gear Hobbing Machine StarSU Hobbing Machine Info The lc 280 α is the perfect way for getting started with gear cutting. It offers maximum flexibility thanks to a diverse range of workpieces, well. Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. Gear hobbing is a mechanical process of production of gears in which gears are cut by. Hobbing Machine Info.

From www.emag.com

Gear Hobbing Machine K 160 Gear Hobbing at the Highest Level Hobbing Machine Info Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. It offers maximum flexibility thanks to a diverse range of workpieces, well. Whether compact or large, our gear hobbing machines impress with their flexibility. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating. Hobbing Machine Info.

From engineeringlearn.com

Gear Hobbing Machine Definition, Types, Uses, Working & Construction Hobbing Machine Info Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. For the gear cutting process, the hob cutter and the gear are building a pair. Whether compact or large, our gear hobbing machines impress. Hobbing Machine Info.

From www.youtube.com

Mechanism of Gear Hobbing Machine YouTube Hobbing Machine Info Machine concept liebherr hobbing machines are optimized for universal gear applications. For the gear cutting process, the hob cutter and the gear are building a pair. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and. Hobbing Machine Info.

From www.pli-international.com

CNC Gear Hobbing Machine LIEBHERR LC802 PLI International Hobbing Machine Info It offers maximum flexibility thanks to a diverse range of workpieces, well. For the gear cutting process, the hob cutter and the gear are building a pair. The lc 280 α is the perfect way for getting started with gear cutting. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process. Hobbing Machine Info.

From www.emag.com

VL 4 H Gear Hobbing Machine for Fast Gear Cutting Hobbing Machine Info Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. The lc 280 α is the perfect way for getting started with gear cutting. Machine concept liebherr hobbing machines are optimized for universal gear. Hobbing Machine Info.

From www.liebherr.com

LC 180 280 Gear hobbing machines Liebherr Liebherr Hobbing Machine Info It offers maximum flexibility thanks to a diverse range of workpieces, well. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. For the gear cutting process, the hob cutter and the gear are building a pair. Whether compact or large, our gear hobbing machines impress with their flexibility. Gear hobbing is. Hobbing Machine Info.

From cdvictor.en.made-in-china.com

Horizontal Gear Hobbing Machine (WL3603A) China Horizontal Gear Hobbing Machine Info Whether compact or large, our gear hobbing machines impress with their flexibility. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. The lc 280 α is the perfect way for getting started with gear cutting. It offers maximum flexibility thanks to a diverse range of workpieces, well. Today’s operators need very. Hobbing Machine Info.

From presstoolindustries.com

Hobbing Machine Press Tool Industries Hobbing Machine Info For the gear cutting process, the hob cutter and the gear are building a pair. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. Machine concept liebherr hobbing machines are optimized for universal gear applications. The lc 280 α is the perfect way for getting started with gear cutting. Whether compact. Hobbing Machine Info.

From www.youtube.com

Gear Hobbing Machine (हिन्दी ) YouTube Hobbing Machine Info Whether compact or large, our gear hobbing machines impress with their flexibility. For the gear cutting process, the hob cutter and the gear are building a pair. Machine concept liebherr hobbing machines are optimized for universal gear applications. It offers maximum flexibility thanks to a diverse range of workpieces, well. Today’s operators need very few basic inputs of gear geometry,. Hobbing Machine Info.

From www.liebherr.com

LC 300 500 Gear hobbing machines Liebherr Liebherr Hobbing Machine Info For the gear cutting process, the hob cutter and the gear are building a pair. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear. Machine concept liebherr hobbing machines are optimized for universal gear applications. It offers maximum flexibility thanks to a diverse range of workpieces,. Hobbing Machine Info.

From boruigearmachine.com

CNC Gear Hobbing Machine YS3180 CNC6 BORUI CNC Hobbing Machine Info For the gear cutting process, the hob cutter and the gear are building a pair. Whether compact or large, our gear hobbing machines impress with their flexibility. The lc 280 α is the perfect way for getting started with gear cutting. Machine concept liebherr hobbing machines are optimized for universal gear applications. Gear hobbing is the most productive and economic. Hobbing Machine Info.

From www.emag.com

Gear Hobbing Machines for Precise Gear Hobbing Hobbing Machine Info Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. Machine concept liebherr hobbing machines are optimized for universal gear applications. It offers maximum flexibility thanks to a diverse range of workpieces, well. For the gear cutting process, the hob cutter and the gear are building a pair. The lc 280 α. Hobbing Machine Info.

From nidec-machinetoolamerica.com

Gear Hobbing Machines Nidec Machine Tool America. Hobbing Machine Info The lc 280 α is the perfect way for getting started with gear cutting. Machine concept liebherr hobbing machines are optimized for universal gear applications. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. It offers maximum flexibility thanks to a diverse range of workpieces, well. Today’s operators need very few. Hobbing Machine Info.

From www.liebherr.com

LC 60 130 Gear hobbing machines Liebherr Liebherr Hobbing Machine Info For the gear cutting process, the hob cutter and the gear are building a pair. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear. Machine concept liebherr hobbing. Hobbing Machine Info.

From www.pli-international.com

CNC Gear Hobbing Machine LIEBHERR LC802 PLI International Hobbing Machine Info Machine concept liebherr hobbing machines are optimized for universal gear applications. Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. For the gear cutting process, the hob cutter and the gear are building a pair. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a. Hobbing Machine Info.

From www.liebherr.com

Gear hobbing machines Liebherr Liebherr Hobbing Machine Info Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. It offers maximum flexibility thanks to a diverse range of workpieces, well. Whether compact or large, our gear hobbing machines impress with their flexibility. Machine concept liebherr hobbing machines are optimized for universal gear applications. Today’s operators need very few basic inputs. Hobbing Machine Info.

From www.youtube.com

Amazing Hobbing Machine Process Gear Manufacturing YouTube Hobbing Machine Info For the gear cutting process, the hob cutter and the gear are building a pair. Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear. Gear hobbing is the. Hobbing Machine Info.

From nidec-machinetoolamerica.com

Gear Hobbing Machines Gear Machines NIDEC MACHINE TOOL AMERICA Hobbing Machine Info The lc 280 α is the perfect way for getting started with gear cutting. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a outer diameter. For the gear cutting process,. Hobbing Machine Info.

From www.machineryoffers.com

Y3150 gear hobbing machine large module hobbing machine for sale Hobbing Machine Info Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. The lc 280 α is the perfect way for getting started with gear cutting. It offers maximum flexibility thanks to a diverse range of workpieces, well. Gear hobbing is the most productive and economic way to produce gear teeth profiles on a. Hobbing Machine Info.

From products.pmtmachines.com

CNC GEAR HOBBING MACHINE pmtproducts Hobbing Machine Info Today’s operators need very few basic inputs of gear geometry, hob cutter information, process cycles, and speeds and. For the gear cutting process, the hob cutter and the gear are building a pair. It offers maximum flexibility thanks to a diverse range of workpieces, well. The lc 280 α is the perfect way for getting started with gear cutting. Whether. Hobbing Machine Info.

From www.liebherr.com

LC 60 130 Gear hobbing machines Liebherr Liebherr Hobbing Machine Info It offers maximum flexibility thanks to a diverse range of workpieces, well. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear. For the gear cutting process, the hob cutter and the gear are building a pair. Whether compact or large, our gear hobbing machines impress with. Hobbing Machine Info.

From www.tlpathakgroup.com

Universal Gear Hobbing Machine Manufacturer in Kolkata, West Bengal Hobbing Machine Info Whether compact or large, our gear hobbing machines impress with their flexibility. It offers maximum flexibility thanks to a diverse range of workpieces, well. Machine concept liebherr hobbing machines are optimized for universal gear applications. Gear hobbing is a mechanical process of production of gears in which gears are cut by a generating process of rotating the gear. For the. Hobbing Machine Info.