Lifting Straps Inspection Checklist . All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. In this article, we present an all. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. 6 monthly thorough sling inspection checklist.

from www.slideshare.net

Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. 6 monthly thorough sling inspection checklist. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. In this article, we present an all. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,.

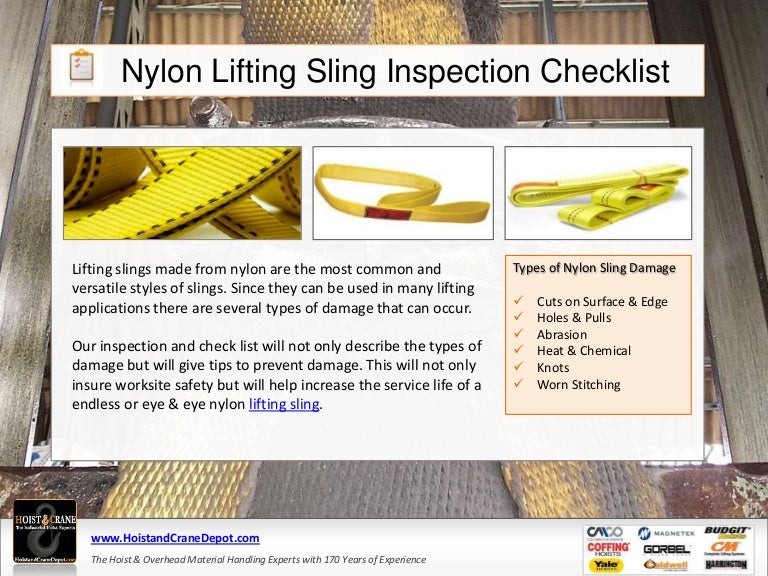

Nylon Slings Inspection Checklist

Lifting Straps Inspection Checklist All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. In this article, we present an all. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. 6 monthly thorough sling inspection checklist. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting.

From www.pinterest.com

best sling inspection form template example in 2021 Workplace safety Lifting Straps Inspection Checklist Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. In this article, we present an all. Regularly inspecting webbing slings. Lifting Straps Inspection Checklist.

From joyfill.io

Rigging Inspection Form Checklist Joyfill Lifting Straps Inspection Checklist Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. In this article, we present an all. All slings (new,. Lifting Straps Inspection Checklist.

From www.scribd.com

FC 4.1.5 Flexible Steel Wire Rope Sling (FSWR) Inspection Checklist Lifting Straps Inspection Checklist In this article, we present an all. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. 6 monthly thorough sling inspection checklist. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,.. Lifting Straps Inspection Checklist.

From www.hsedocuments.com

Inspection Checklist for Lifting Tools & Tackles HSE Documents Lifting Straps Inspection Checklist Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. 6 monthly thorough sling inspection checklist. Regularly inspecting webbing slings is essential to. Lifting Straps Inspection Checklist.

From www.signnow.com

Lifting Gear Inspection Checklist Complete with ease airSlate SignNow Lifting Straps Inspection Checklist Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. Regularly inspecting webbing slings is essential to maintain a safe working environment and. Lifting Straps Inspection Checklist.

From sitemate.com

Lifting Equipment Inspection Checklist (Better than excel and PDF) Lifting Straps Inspection Checklist Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. In this article, we present an all. All slings. Lifting Straps Inspection Checklist.

From sitemate.com

Lifting Gear Inspection Checklist (for better lifting gear inspections) Lifting Straps Inspection Checklist 6 monthly thorough sling inspection checklist. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. In this article,. Lifting Straps Inspection Checklist.

From www.tpsearchtool.com

Sling Inspection Checklist Fill Out And Sign Printable Pdf Template Images Lifting Straps Inspection Checklist 6 monthly thorough sling inspection checklist. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. In this article, we present an all. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and. Lifting Straps Inspection Checklist.

From www.vrogue.co

Rigging And Sling Equipment Inspection Checklist Safe vrogue.co Lifting Straps Inspection Checklist Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to. Lifting Straps Inspection Checklist.

From www.scribd.com

Cranes and Lifting Inspection Checklist PDF Lifting Straps Inspection Checklist 6 monthly thorough sling inspection checklist. In this article, we present an all. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,.. Lifting Straps Inspection Checklist.

From www.scribd.com

Lifting and Slinging Tools Inspection PDF Lifting Straps Inspection Checklist In this article, we present an all. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. All slings. Lifting Straps Inspection Checklist.

From www.signnow.com

Rigging Inspection Checklist Complete with ease airSlate SignNow Lifting Straps Inspection Checklist 6 monthly thorough sling inspection checklist. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. Osha 1910.184, asme b30.9, b30.20, b30.26, &. Lifting Straps Inspection Checklist.

From dremelmicro.com

Printable Rigging Equipment Inspection Checklist For Better Rigging Lifting Straps Inspection Checklist Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. 6 monthly thorough sling inspection checklist. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. All slings (new,. Lifting Straps Inspection Checklist.

From sitemate.com

Lifting equipment inspection frequency The right frequency for you Lifting Straps Inspection Checklist Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. 6 monthly thorough sling inspection checklist. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. Osha 1910.184, asme. Lifting Straps Inspection Checklist.

From www.dochub.com

Elevator inspection checklist pdf Fill out & sign online DocHub Lifting Straps Inspection Checklist Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. 6 monthly thorough sling inspection checklist. All slings (new, altered,. Lifting Straps Inspection Checklist.

From www.scribd.com

HSE 0XXX Sling Inspection Checklist PDF Lifting Straps Inspection Checklist Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. 6 monthly thorough sling inspection checklist. In this article, we present an all. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings,. Lifting Straps Inspection Checklist.

From www.lift-it.com

Wire Rope Sling Inspection Criteria LiftIt® Manufacturing Lifting Straps Inspection Checklist Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. In this article, we present an all. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. All slings. Lifting Straps Inspection Checklist.

From www.tpsearchtool.com

Sling Inspection Checklist Fill Out And Sign Printable Pdf Template Images Lifting Straps Inspection Checklist 6 monthly thorough sling inspection checklist. In this article, we present an all. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. All slings (new, altered, modified, or repaired) should be inspected by a competent person. Lifting Straps Inspection Checklist.

From mavink.com

Lifting Sling Inspection Form Lifting Straps Inspection Checklist 6 monthly thorough sling inspection checklist. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. Osha 1910.184, asme b30.9, b30.20,. Lifting Straps Inspection Checklist.

From www.scribd.com

BR Lifting Sling Inspection Criteria R2 PDF Rope Knot Lifting Straps Inspection Checklist Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. In this article, we present an all. 6 monthly. Lifting Straps Inspection Checklist.

From www.inpaspages.com

Belt & sling inspection checklist Lifting Straps Inspection Checklist Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. In this article, we present an all. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. All slings. Lifting Straps Inspection Checklist.

From www.hsedocuments.com

Sling Inspection Checklist HSE Documents Lifting Straps Inspection Checklist Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. 6 monthly thorough sling inspection checklist. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to. Lifting Straps Inspection Checklist.

From www.worksafeforlife.ca

Safety Matters Seaview Manor uses PACE to inspire new safety pr Lifting Straps Inspection Checklist 6 monthly thorough sling inspection checklist. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. Regularly inspecting webbing slings is essential. Lifting Straps Inspection Checklist.

From www.lift-it.com

TwinPath Extra Slings Information LiftIt® Manufacturing Lifting Straps Inspection Checklist Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. In this article, we present an all. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. Regularly inspecting webbing slings is. Lifting Straps Inspection Checklist.

From www.scribd.com

FC 4.1.6 Synthetic Sling Inspection Checklist Form PDF Lifting Straps Inspection Checklist Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. In this article, we present an all. 6 monthly thorough sling inspection checklist. All slings (new, altered, modified, or repaired) should be inspected by a competent person before. Lifting Straps Inspection Checklist.

From www.lift-it.com

Sling Inspection Sling Repair Services Sling Replacement Lift Lifting Straps Inspection Checklist In this article, we present an all. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. Factory trained professionals inspect. Lifting Straps Inspection Checklist.

From mungfali.com

Lifting Sling Inspection Form Lifting Straps Inspection Checklist Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. In this article, we present an all. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. 6 monthly thorough sling inspection checklist. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on. Lifting Straps Inspection Checklist.

From sitemate.com

Hoist Inspection Checklist (Better than word, excel, PDF) Lifting Straps Inspection Checklist In this article, we present an all. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used. Lifting Straps Inspection Checklist.

From www.dochub.com

Scissor lift inspection form Fill out & sign online DocHub Lifting Straps Inspection Checklist Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic,. Lifting Straps Inspection Checklist.

From mungfali.com

Lifting Sling Inspection Form Lifting Straps Inspection Checklist All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. In this article, we present an all. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. Osha 1910.184, asme b30.9,. Lifting Straps Inspection Checklist.

From www.lift-it.com

RoundSling Safety Information LiftIt® Manufacturing Lifting Straps Inspection Checklist In this article, we present an all. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. Factory trained professionals. Lifting Straps Inspection Checklist.

From www.vrogue.co

Sling Inspection Checklist Template Fill Online Print vrogue.co Lifting Straps Inspection Checklist Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. In this article, we present an all. Osha 1910.184, asme b30.9, b30.20, b30.26,. Lifting Straps Inspection Checklist.

From www.slideshare.net

Nylon Slings Inspection Checklist Lifting Straps Inspection Checklist In this article, we present an all. Factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. 6 monthly thorough sling inspection checklist. Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent. Lifting Straps Inspection Checklist.

From dokumen.tips

(PDF) AERIAL LIFT PRE USE INSPECTION CHECKLIST · PDF file · 201802 Lifting Straps Inspection Checklist Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. 6 monthly thorough sling inspection checklist. Factory trained professionals inspect all types of. Lifting Straps Inspection Checklist.

From www.scribd.com

Sling Belt & Wire Rope Inspection Checklist Lifting Straps Inspection Checklist Regularly inspecting webbing slings is essential to maintain a safe working environment and prevent potential accidents. All slings (new, altered, modified, or repaired) should be inspected by a competent person before they are used in the workplace to make sure they are built to specifications, not damaged,. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections. Lifting Straps Inspection Checklist.