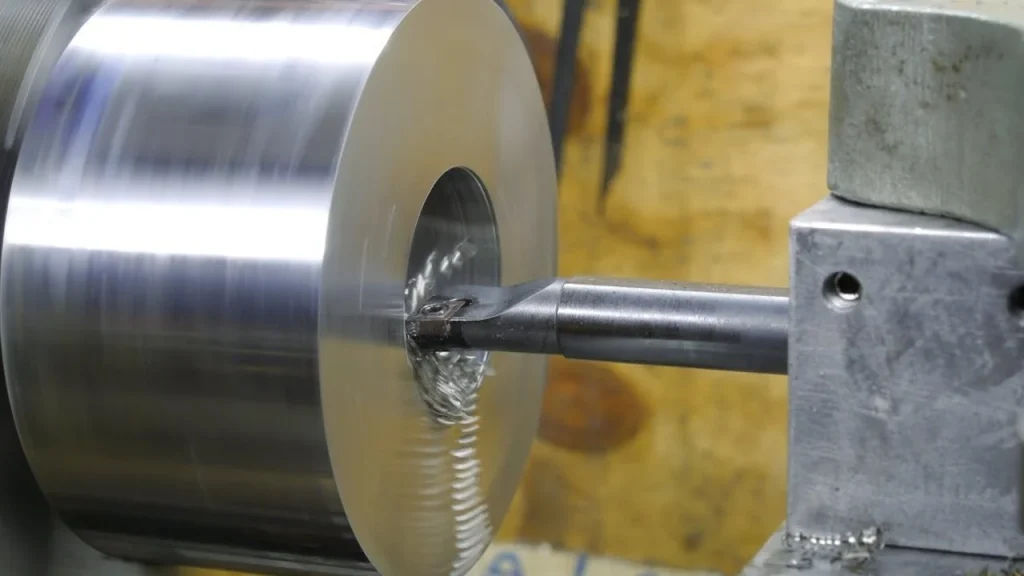

Boring Operation On Machine Tool . The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. This process is compatible with many types of materials, and it can efficiently process holes. This article will review boring machining, discuss its uses, describe its. There are many types of boring including horizontal, vertical, and precision boring machining. Boring machining allows operators to modify holes that already exist in a workpiece. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. Single point boring tools consist of a round shaft with one insert. Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation.

from proleantech.com

Single point boring tools consist of a round shaft with one insert. This process is compatible with many types of materials, and it can efficiently process holes. Boring machining allows operators to modify holes that already exist in a workpiece. This article will review boring machining, discuss its uses, describe its. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. There are many types of boring including horizontal, vertical, and precision boring machining. Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation.

CNC Programming for Boring Operations Unlocking the Full Potential of

Boring Operation On Machine Tool The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. This process is compatible with many types of materials, and it can efficiently process holes. This article will review boring machining, discuss its uses, describe its. Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. Boring machining allows operators to modify holes that already exist in a workpiece. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. Single point boring tools consist of a round shaft with one insert. There are many types of boring including horizontal, vertical, and precision boring machining. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt.

From proleantech.com

CNC Programming for Boring Operations Unlocking the Full Potential of Boring Operation On Machine Tool There are many types of boring including horizontal, vertical, and precision boring machining. This article will review boring machining, discuss its uses, describe its. Boring machining allows operators to modify holes that already exist in a workpiece. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as. Boring Operation On Machine Tool.

From www.penntoolco.com

Precise Indexable Boring Tool Set w/3" Boring Head, R8 Shank & 8 Boring Boring Operation On Machine Tool Single point boring tools consist of a round shaft with one insert. Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. The boring machining process typically unfolds on a lathe or cnc. Boring Operation On Machine Tool.

From www.youtube.com

Boring Operation on Lathe Machine YouTube Boring Operation On Machine Tool Boring machining allows operators to modify holes that already exist in a workpiece. Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. This article will review boring machining, discuss its uses, describe its. This process is compatible with many types of materials, and it can efficiently process holes. Single. Boring Operation On Machine Tool.

From www.youtube.com

BORING LATHE OPERATION YouTube Boring Operation On Machine Tool Single point boring tools consist of a round shaft with one insert. This article will review boring machining, discuss its uses, describe its. Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy. Boring Operation On Machine Tool.

From www.practicalmachinist.com

Tips for Your Boring Operations Practical Machinist Practical Machinist Boring Operation On Machine Tool Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. There are many types of boring including horizontal, vertical, and precision boring machining. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt.. Boring Operation On Machine Tool.

From finemetalworking.com

Drill Press 101. Types of Drill Press and Their Uses Boring Operation On Machine Tool This article will review boring machining, discuss its uses, describe its. Boring machining allows operators to modify holes that already exist in a workpiece. Single point boring tools consist of a round shaft with one insert. There are many types of boring including horizontal, vertical, and precision boring machining. Internal single point turning is referred to as boring, and can. Boring Operation On Machine Tool.

From proleantech.com

Boring Vs. Drilling Understanding the Processes, Differences, and Boring Operation On Machine Tool There are many types of boring including horizontal, vertical, and precision boring machining. Boring machining allows operators to modify holes that already exist in a workpiece. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. This article will review boring machining, discuss its uses, describe its. Internal single point turning is referred. Boring Operation On Machine Tool.

From www.youtube.com

How to do boring operation on CNC turning machine boring and turning Boring Operation On Machine Tool Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. Boring machining is a subtractive manufacturing process that uses a. Boring Operation On Machine Tool.

From www.youtube.com

Drilling,Boring & Reaming(Difference) YouTube Boring Operation On Machine Tool Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. Single point boring tools consist of a round shaft with one insert. There are many types of boring including horizontal, vertical, and precision boring machining. The boring machining process typically unfolds on a lathe or cnc milling machine, both of. Boring Operation On Machine Tool.

From www.researchgate.net

1 shows an example of boring operation. The tool and the workpiece have Boring Operation On Machine Tool Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. Single point boring tools consist of a round shaft with one insert. This article will review boring machining, discuss its uses, describe its. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy. Boring Operation On Machine Tool.

From www.youtube.com

All Lathe Machine Operations Turning, Facing, Taper Turning, Boring Boring Operation On Machine Tool The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. This process is compatible with many types of materials, and it can efficiently process holes. This article will review boring machining, discuss its uses, describe its. Single point boring tools. Boring Operation On Machine Tool.

From www.ctemag.com

Boring with a milling machine Cutting Tool Engineering Boring Operation On Machine Tool There are many types of boring including horizontal, vertical, and precision boring machining. Single point boring tools consist of a round shaft with one insert. Boring machining allows operators to modify holes that already exist in a workpiece. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known. Boring Operation On Machine Tool.

From www.youtube.com

boring operation on a jig borar YouTube Boring Operation On Machine Tool This article will review boring machining, discuss its uses, describe its. There are many types of boring including horizontal, vertical, and precision boring machining. Single point boring tools consist of a round shaft with one insert. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. Internal single point turning is referred to. Boring Operation On Machine Tool.

From www.researchgate.net

Schematic diagram of drilling tool operation Download Scientific Diagram Boring Operation On Machine Tool Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. This process is compatible with many types of materials, and it can efficiently. Boring Operation On Machine Tool.

From www.youtube.com

Boring Drilling Operation Machining Operations Manufacturing Boring Operation On Machine Tool There are many types of boring including horizontal, vertical, and precision boring machining. Single point boring tools consist of a round shaft with one insert. Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. This article will review boring machining, discuss its uses, describe its. Boring machining allows operators. Boring Operation On Machine Tool.

From www.researchgate.net

Schematic diagram of a precision horizontal boring machine tool Boring Operation On Machine Tool This article will review boring machining, discuss its uses, describe its. There are many types of boring including horizontal, vertical, and precision boring machining. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. Boring machining is a subtractive manufacturing. Boring Operation On Machine Tool.

From www.youtube.com

Metal Lathe 112 Operation Basics, Boring Holes YouTube Boring Operation On Machine Tool Single point boring tools consist of a round shaft with one insert. This process is compatible with many types of materials, and it can efficiently process holes. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which. Boring Operation On Machine Tool.

From www.americanmachinist.com

Chapter 10 Boring Operations and Machines Cutting Tool Applications Boring Operation On Machine Tool Single point boring tools consist of a round shaft with one insert. This article will review boring machining, discuss its uses, describe its. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. Boring machining allows operators to modify holes. Boring Operation On Machine Tool.

From www.rapidenterprises.ca

Tips For Your Boring Operation Boring Operation On Machine Tool This article will review boring machining, discuss its uses, describe its. There are many types of boring including horizontal, vertical, and precision boring machining. Single point boring tools consist of a round shaft with one insert. Boring machining allows operators to modify holes that already exist in a workpiece. The boring machining process typically unfolds on a lathe or cnc. Boring Operation On Machine Tool.

From www.mechanicalbooster.com

operationsrelatedtodrilling Mechanical Booster Boring Operation On Machine Tool The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. There are many types of boring including horizontal, vertical, and precision boring machining. Boring machining allows operators to modify holes that already exist in a workpiece. Single point boring tools. Boring Operation On Machine Tool.

From www.bdmfg.com

Portable Line Boring Machine AM1424 B&D Manufacturing Boring Operation On Machine Tool Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. Single point boring tools consist of a round shaft with. Boring Operation On Machine Tool.

From www.researchgate.net

Schematic of the boring operation Download Scientific Diagram Boring Operation On Machine Tool This article will review boring machining, discuss its uses, describe its. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. Boring machining allows operators to modify holes that already exist in a workpiece. This process is compatible with many types of materials, and it can efficiently process holes. The boring machining process. Boring Operation On Machine Tool.

From www.theengineerspost.com

Jig Boring Machine Parts, Types, Working Principle & Operations Boring Operation On Machine Tool Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. There are many types of boring including horizontal, vertical, and precision boring machining. Single point boring tools consist of a round shaft with. Boring Operation On Machine Tool.

From www.youtube.com

Drilling MachineOperations, MRR, Design Considerations for Drilling Boring Operation On Machine Tool This article will review boring machining, discuss its uses, describe its. Boring machining allows operators to modify holes that already exist in a workpiece. There are many types of boring including horizontal, vertical, and precision boring machining. This process is compatible with many types of materials, and it can efficiently process holes. Internal single point turning is referred to as. Boring Operation On Machine Tool.

From www.youtube.com

The Facing, boring chamfering and turning by Nine9 cutting tool on CNC Boring Operation On Machine Tool There are many types of boring including horizontal, vertical, and precision boring machining. Boring machining allows operators to modify holes that already exist in a workpiece. This process is compatible with many types of materials, and it can efficiently process holes. Single point boring tools consist of a round shaft with one insert. Internal single point turning is referred to. Boring Operation On Machine Tool.

From www.youtube.com

Operations Performed on Boring Machines YouTube Boring Operation On Machine Tool Single point boring tools consist of a round shaft with one insert. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. This article will review boring machining, discuss its uses, describe its. Boring machining allows operators to modify holes that already exist in a workpiece. This process is compatible with many types. Boring Operation On Machine Tool.

From www.exportersindia.com

Boring Operations Drill Machine at Best Price in Ahmedabad bhavya Boring Operation On Machine Tool Boring machining allows operators to modify holes that already exist in a workpiece. There are many types of boring including horizontal, vertical, and precision boring machining. Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. This process is compatible with many types of materials, and it can efficiently process. Boring Operation On Machine Tool.

From www.researchgate.net

Horizontal boring operations with (a) rotating workpiece and (b Boring Operation On Machine Tool Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. This process is compatible with many types of materials, and it can efficiently process holes. Single point boring tools consist of a round shaft with one insert. The boring machining process typically unfolds on a lathe or cnc milling machine,. Boring Operation On Machine Tool.

From www.youtube.com

Internal Boring Operation on Lathe machine YouTube Boring Operation On Machine Tool There are many types of boring including horizontal, vertical, and precision boring machining. This article will review boring machining, discuss its uses, describe its. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. This process is compatible with many types of materials, and it can efficiently process holes. Single point boring tools. Boring Operation On Machine Tool.

From www.youtube.com

jig boring machine working jig boring machine working principle Boring Operation On Machine Tool Boring machining allows operators to modify holes that already exist in a workpiece. Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. This article will review boring machining, discuss its uses, describe its. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge. Boring Operation On Machine Tool.

From www.theengineerspost.com

Horizontal Boring Machine Types, Parts, Operations with PDF Boring Operation On Machine Tool The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. This article will review boring machining, discuss its uses, describe its. Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing. Boring Operation On Machine Tool.

From www.youtube.com

Drilling Machine Operations Boring, Reaming, Counter Sinking, Spot Boring Operation On Machine Tool Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an. Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. This process is compatible with many types of materials, and it can efficiently process holes. The boring machining process typically unfolds on a. Boring Operation On Machine Tool.

From 4mechtech.blogspot.com

Mechanical Technology Vertical Boring Machine Boring Operation On Machine Tool The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. Internal single point turning is referred to as boring, and can be utilized for either a roughing or finishing operation. There are many types of boring including horizontal, vertical, and. Boring Operation On Machine Tool.

From www.researchgate.net

1 shows an example of boring operation. The tool and the workpiece have Boring Operation On Machine Tool Boring machining allows operators to modify holes that already exist in a workpiece. This process is compatible with many types of materials, and it can efficiently process holes. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. This article. Boring Operation On Machine Tool.

From www.theengineerspost.com

Jig Boring Machine Parts, Types, Working Principle & Operations Boring Operation On Machine Tool There are many types of boring including horizontal, vertical, and precision boring machining. The boring machining process typically unfolds on a lathe or cnc milling machine, both of which deploy a specialized boring tool known as a boring bar, fitted with an apt. This process is compatible with many types of materials, and it can efficiently process holes. This article. Boring Operation On Machine Tool.