Induction Motor+Starting Time Calculation . This calculation is more or. I l = s start / (√3 * v t), where s start = rated hp of the motor * code factor this paper presents the starting time calculation for a squirrel cage induction motor. induction motors are typically designed to start with a terminal voltage >80% when to do the calculation? methods of starting the motor. Making reference to the data of the above table, here is an example of calculation of the starting time of a motor, according to the theoretical treatment previously developed. To get everything out, the following method of starting is generally used: Τ ind = (10 hp * 746 kw/hp) / (1500 r/min * 2 π rad/r * 1 min/60 s) = 47.49 nm. Find the shaft torque of the 10 hp induction motor whose rotor speed is 1500 r/min. in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. the following discussion will describe a common method for calculating the starting time for an induction motor starting full. calculation of the starting time of a motor. The importance of starting time.

from www.chegg.com

This calculation is more or. in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. induction motors are typically designed to start with a terminal voltage >80% when to do the calculation? Making reference to the data of the above table, here is an example of calculation of the starting time of a motor, according to the theoretical treatment previously developed. The importance of starting time. Τ ind = (10 hp * 746 kw/hp) / (1500 r/min * 2 π rad/r * 1 min/60 s) = 47.49 nm. the following discussion will describe a common method for calculating the starting time for an induction motor starting full. I l = s start / (√3 * v t), where s start = rated hp of the motor * code factor Find the shaft torque of the 10 hp induction motor whose rotor speed is 1500 r/min. To get everything out, the following method of starting is generally used:

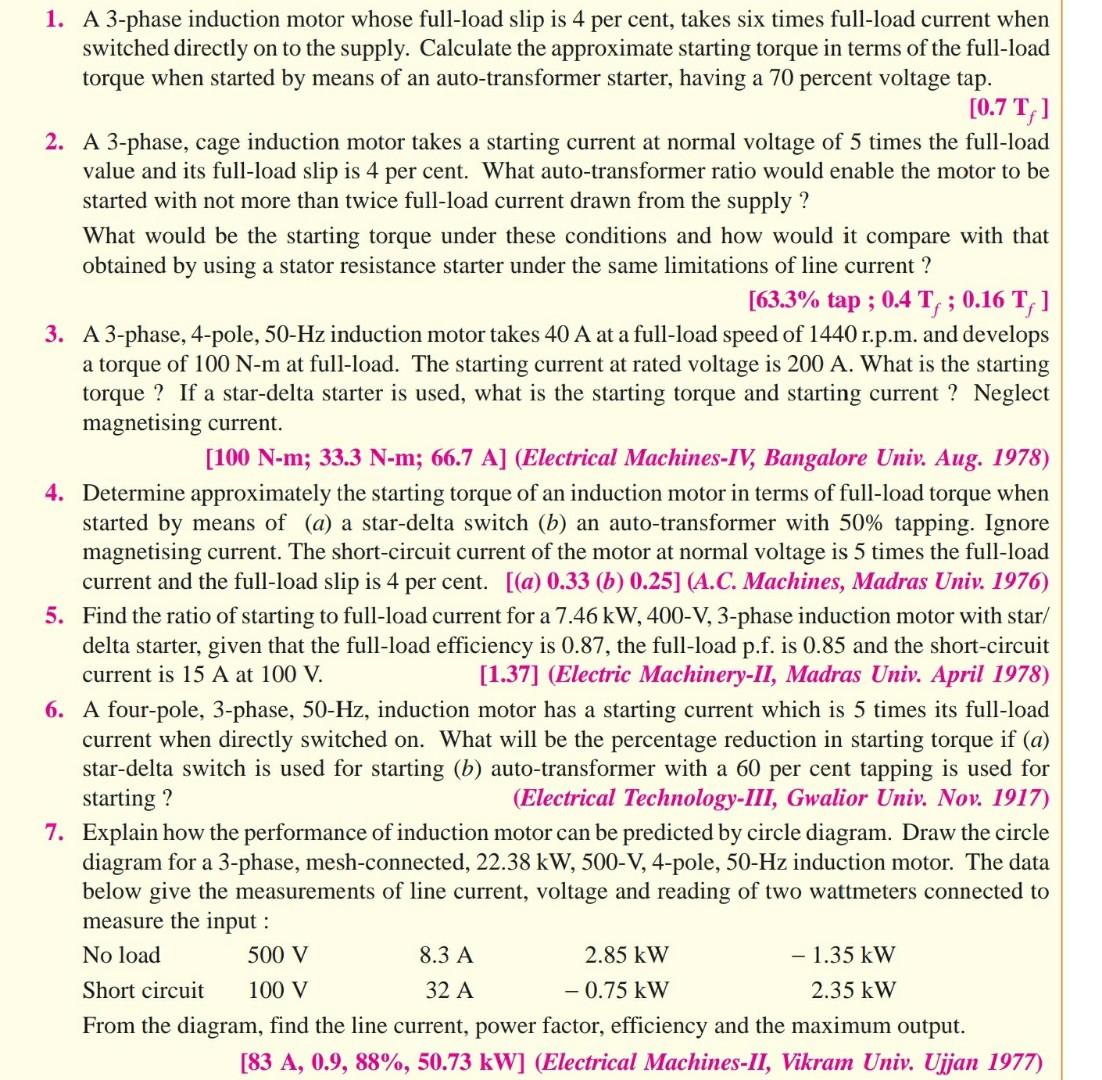

Solved 1. A 3phase induction motor whose fullload slip is

Induction Motor+Starting Time Calculation calculation of the starting time of a motor. the following discussion will describe a common method for calculating the starting time for an induction motor starting full. this paper presents the starting time calculation for a squirrel cage induction motor. induction motors are typically designed to start with a terminal voltage >80% when to do the calculation? The importance of starting time. calculation of the starting time of a motor. To get everything out, the following method of starting is generally used: in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. I l = s start / (√3 * v t), where s start = rated hp of the motor * code factor Find the shaft torque of the 10 hp induction motor whose rotor speed is 1500 r/min. Making reference to the data of the above table, here is an example of calculation of the starting time of a motor, according to the theoretical treatment previously developed. Τ ind = (10 hp * 746 kw/hp) / (1500 r/min * 2 π rad/r * 1 min/60 s) = 47.49 nm. methods of starting the motor. This calculation is more or.

From www.scribd.com

Calculation of Motor Starting Time PDF Electric Motor Torque Induction Motor+Starting Time Calculation Making reference to the data of the above table, here is an example of calculation of the starting time of a motor, according to the theoretical treatment previously developed. the following discussion will describe a common method for calculating the starting time for an induction motor starting full. Τ ind = (10 hp * 746 kw/hp) / (1500 r/min. Induction Motor+Starting Time Calculation.

From www.semanticscholar.org

Figure 4 from Starting time calculation of large induction motors using their manufacturer Induction Motor+Starting Time Calculation in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. I l = s start / (√3 * v t), where s start = rated hp of the motor * code factor This calculation is more or. Τ ind = (10 hp * 746 kw/hp) / (1500 r/min *. Induction Motor+Starting Time Calculation.

From www.slideserve.com

PPT INDUCTION MOTORS 3 PowerPoint Presentation, free download ID1714969 Induction Motor+Starting Time Calculation in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. calculation of the starting time of a motor. induction motors are typically designed to start with a terminal voltage >80% when to do the calculation? I l = s start / (√3 * v t), where s. Induction Motor+Starting Time Calculation.

From www.youtube.com

Torque Equation 3phase Induction Motor Lec33 YouTube Induction Motor+Starting Time Calculation methods of starting the motor. in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. Find the shaft torque of the 10 hp induction motor whose rotor speed is 1500 r/min. I l = s start / (√3 * v t), where s start = rated hp of. Induction Motor+Starting Time Calculation.

From www.coursehero.com

[Solved] A 75 kW, 440 V, 3phase, 6pole, 50 Hz, woundrotor induction motor... Course Hero Induction Motor+Starting Time Calculation calculation of the starting time of a motor. Making reference to the data of the above table, here is an example of calculation of the starting time of a motor, according to the theoretical treatment previously developed. in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. This. Induction Motor+Starting Time Calculation.

From www.electricaldesks.com

Starting Methods of a Single Phase Induction Motor Induction Motor+Starting Time Calculation the following discussion will describe a common method for calculating the starting time for an induction motor starting full. calculation of the starting time of a motor. Find the shaft torque of the 10 hp induction motor whose rotor speed is 1500 r/min. To get everything out, the following method of starting is generally used: Making reference to. Induction Motor+Starting Time Calculation.

From www.semanticscholar.org

Figure 2 from Large Induction Motor Starting Time Determination for The Purpose of Protection Induction Motor+Starting Time Calculation I l = s start / (√3 * v t), where s start = rated hp of the motor * code factor induction motors are typically designed to start with a terminal voltage >80% when to do the calculation? this paper presents the starting time calculation for a squirrel cage induction motor. methods of starting the motor.. Induction Motor+Starting Time Calculation.

From wiringdecastich.z21.web.core.windows.net

Starting Methods Of 1 Phase Induction Motor Induction Motor+Starting Time Calculation This calculation is more or. the following discussion will describe a common method for calculating the starting time for an induction motor starting full. this paper presents the starting time calculation for a squirrel cage induction motor. I l = s start / (√3 * v t), where s start = rated hp of the motor * code. Induction Motor+Starting Time Calculation.

From dokumen.tips

(PDF) Calculation of Induction Motor Starting parameters Using Matlab DOKUMEN.TIPS Induction Motor+Starting Time Calculation The importance of starting time. Τ ind = (10 hp * 746 kw/hp) / (1500 r/min * 2 π rad/r * 1 min/60 s) = 47.49 nm. this paper presents the starting time calculation for a squirrel cage induction motor. the following discussion will describe a common method for calculating the starting time for an induction motor starting. Induction Motor+Starting Time Calculation.

From quovadismonxdschematic.z21.web.core.windows.net

Starting Methods Of 3 Phase Induction Motor Induction Motor+Starting Time Calculation Find the shaft torque of the 10 hp induction motor whose rotor speed is 1500 r/min. methods of starting the motor. The importance of starting time. in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. Τ ind = (10 hp * 746 kw/hp) / (1500 r/min *. Induction Motor+Starting Time Calculation.

From electricalbaba.com

Starting Methods of Single Phase Induction Motors Electrical Concepts Induction Motor+Starting Time Calculation this paper presents the starting time calculation for a squirrel cage induction motor. in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. To get everything out, the following method of starting is generally used: This calculation is more or. Making reference to the data of the above. Induction Motor+Starting Time Calculation.

From engineeringlearner.com

Operation of Induction Motor Engineering Learner Induction Motor+Starting Time Calculation calculation of the starting time of a motor. the following discussion will describe a common method for calculating the starting time for an induction motor starting full. This calculation is more or. induction motors are typically designed to start with a terminal voltage >80% when to do the calculation? Τ ind = (10 hp * 746 kw/hp). Induction Motor+Starting Time Calculation.

From webmotor.org

3 Phase Induction Motor Winding Calculation Pdf Induction Motor+Starting Time Calculation To get everything out, the following method of starting is generally used: calculation of the starting time of a motor. in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. this paper presents the starting time calculation for a squirrel cage induction motor. Making reference to the. Induction Motor+Starting Time Calculation.

From electricalbaba.com

or DOL Starting of Induction Motor Electrical Concepts Induction Motor+Starting Time Calculation Making reference to the data of the above table, here is an example of calculation of the starting time of a motor, according to the theoretical treatment previously developed. To get everything out, the following method of starting is generally used: Τ ind = (10 hp * 746 kw/hp) / (1500 r/min * 2 π rad/r * 1 min/60 s). Induction Motor+Starting Time Calculation.

From www.youtube.com

Starting Torque Electrical factors Induction Motor Lec37 YouTube Induction Motor+Starting Time Calculation Find the shaft torque of the 10 hp induction motor whose rotor speed is 1500 r/min. I l = s start / (√3 * v t), where s start = rated hp of the motor * code factor induction motors are typically designed to start with a terminal voltage >80% when to do the calculation? calculation of the. Induction Motor+Starting Time Calculation.

From www.theengineeringknowledge.com

Starting Method of Induction Motors The Engineering Knowledge Induction Motor+Starting Time Calculation methods of starting the motor. I l = s start / (√3 * v t), where s start = rated hp of the motor * code factor Making reference to the data of the above table, here is an example of calculation of the starting time of a motor, according to the theoretical treatment previously developed. calculation of. Induction Motor+Starting Time Calculation.

From itecnotes.com

Electronic How to an induction motor be “self starting” Valuable Tech Notes Induction Motor+Starting Time Calculation This calculation is more or. methods of starting the motor. Τ ind = (10 hp * 746 kw/hp) / (1500 r/min * 2 π rad/r * 1 min/60 s) = 47.49 nm. Find the shaft torque of the 10 hp induction motor whose rotor speed is 1500 r/min. induction motors are typically designed to start with a terminal. Induction Motor+Starting Time Calculation.

From circuitbebsonir.z13.web.core.windows.net

What Is An Ac Induction Motor Induction Motor+Starting Time Calculation in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. I l = s start / (√3 * v t), where s start = rated hp of the motor * code factor the following discussion will describe a common method for calculating the starting time for an induction. Induction Motor+Starting Time Calculation.

From electricalacademia.com

Starting Methods of Three Phase Induction Motor Electrical Academia Induction Motor+Starting Time Calculation I l = s start / (√3 * v t), where s start = rated hp of the motor * code factor Find the shaft torque of the 10 hp induction motor whose rotor speed is 1500 r/min. This calculation is more or. Making reference to the data of the above table, here is an example of calculation of the. Induction Motor+Starting Time Calculation.

From www.youtube.com

Circle Diagram of Induction Motor Part 1 Calculations AC Machines Electrical Machines Induction Motor+Starting Time Calculation induction motors are typically designed to start with a terminal voltage >80% when to do the calculation? the following discussion will describe a common method for calculating the starting time for an induction motor starting full. The importance of starting time. Making reference to the data of the above table, here is an example of calculation of the. Induction Motor+Starting Time Calculation.

From webmotor.org

How To Calculate Input Power Of Induction Motor Induction Motor+Starting Time Calculation this paper presents the starting time calculation for a squirrel cage induction motor. Τ ind = (10 hp * 746 kw/hp) / (1500 r/min * 2 π rad/r * 1 min/60 s) = 47.49 nm. This calculation is more or. calculation of the starting time of a motor. I l = s start / (√3 * v t),. Induction Motor+Starting Time Calculation.

From webmotor.org

How To Calculate Power Factor Of Three Phase Induction Motor Induction Motor+Starting Time Calculation Τ ind = (10 hp * 746 kw/hp) / (1500 r/min * 2 π rad/r * 1 min/60 s) = 47.49 nm. To get everything out, the following method of starting is generally used: the following discussion will describe a common method for calculating the starting time for an induction motor starting full. The importance of starting time. Making. Induction Motor+Starting Time Calculation.

From www.semanticscholar.org

Figure 1 from Large Induction Motor Starting Time Determination for The Purpose of Protection Induction Motor+Starting Time Calculation induction motors are typically designed to start with a terminal voltage >80% when to do the calculation? This calculation is more or. The importance of starting time. calculation of the starting time of a motor. To get everything out, the following method of starting is generally used: Τ ind = (10 hp * 746 kw/hp) / (1500 r/min. Induction Motor+Starting Time Calculation.

From www.electricalengineering.xyz

Induction Motor Formulas with Calculations Induction Motor+Starting Time Calculation calculation of the starting time of a motor. methods of starting the motor. Find the shaft torque of the 10 hp induction motor whose rotor speed is 1500 r/min. I l = s start / (√3 * v t), where s start = rated hp of the motor * code factor the following discussion will describe a. Induction Motor+Starting Time Calculation.

From studylib.net

Starting Time Calculation for Induction Motor Induction Motor+Starting Time Calculation To get everything out, the following method of starting is generally used: I l = s start / (√3 * v t), where s start = rated hp of the motor * code factor Τ ind = (10 hp * 746 kw/hp) / (1500 r/min * 2 π rad/r * 1 min/60 s) = 47.49 nm. induction motors are. Induction Motor+Starting Time Calculation.

From www.semanticscholar.org

Figure 2 from Starting Time Calculation for Induction Motor Semantic Scholar Induction Motor+Starting Time Calculation Τ ind = (10 hp * 746 kw/hp) / (1500 r/min * 2 π rad/r * 1 min/60 s) = 47.49 nm. calculation of the starting time of a motor. this paper presents the starting time calculation for a squirrel cage induction motor. Making reference to the data of the above table, here is an example of calculation. Induction Motor+Starting Time Calculation.

From www.youtube.com

Starting Torque in Three phase induction motor and relation between torque and rotor power Induction Motor+Starting Time Calculation Τ ind = (10 hp * 746 kw/hp) / (1500 r/min * 2 π rad/r * 1 min/60 s) = 47.49 nm. I l = s start / (√3 * v t), where s start = rated hp of the motor * code factor The importance of starting time. To get everything out, the following method of starting is generally. Induction Motor+Starting Time Calculation.

From www.academia.edu

(PDF) Starting Time Calculation for Induction Motor Abhishek Garg Academia.edu Induction Motor+Starting Time Calculation methods of starting the motor. Making reference to the data of the above table, here is an example of calculation of the starting time of a motor, according to the theoretical treatment previously developed. The importance of starting time. This calculation is more or. in this paper, the starting time is accurately evaluated from a newly proposed technique. Induction Motor+Starting Time Calculation.

From www.semanticscholar.org

Figure 2 from Starting time calculation of large induction motors using their manufacturer Induction Motor+Starting Time Calculation Making reference to the data of the above table, here is an example of calculation of the starting time of a motor, according to the theoretical treatment previously developed. the following discussion will describe a common method for calculating the starting time for an induction motor starting full. I l = s start / (√3 * v t), where. Induction Motor+Starting Time Calculation.

From www.caretxdigital.com

how to calculate full load current of induction motor Wiring Diagram and Schematics Induction Motor+Starting Time Calculation Τ ind = (10 hp * 746 kw/hp) / (1500 r/min * 2 π rad/r * 1 min/60 s) = 47.49 nm. Making reference to the data of the above table, here is an example of calculation of the starting time of a motor, according to the theoretical treatment previously developed. induction motors are typically designed to start with. Induction Motor+Starting Time Calculation.

From www.semanticscholar.org

Figure 4 from Large Induction Motor Starting Time Determination for The Purpose of Protection Induction Motor+Starting Time Calculation this paper presents the starting time calculation for a squirrel cage induction motor. induction motors are typically designed to start with a terminal voltage >80% when to do the calculation? To get everything out, the following method of starting is generally used: The importance of starting time. Find the shaft torque of the 10 hp induction motor whose. Induction Motor+Starting Time Calculation.

From www.semanticscholar.org

Figure 2 from Starting time calculation of large induction motors using their manufacturer Induction Motor+Starting Time Calculation This calculation is more or. Find the shaft torque of the 10 hp induction motor whose rotor speed is 1500 r/min. The importance of starting time. in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. methods of starting the motor. I l = s start / (√3. Induction Motor+Starting Time Calculation.

From avsld.com.sg

Typical TorqueSpeed Curve of a Cage Induction Motor AVSLD International Induction Motor+Starting Time Calculation To get everything out, the following method of starting is generally used: the following discussion will describe a common method for calculating the starting time for an induction motor starting full. calculation of the starting time of a motor. this paper presents the starting time calculation for a squirrel cage induction motor. Making reference to the data. Induction Motor+Starting Time Calculation.

From www.chegg.com

Solved 1. A 3phase induction motor whose fullload slip is Induction Motor+Starting Time Calculation in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. I l = s start / (√3 * v t), where s start = rated hp of the motor * code factor methods of starting the motor. the following discussion will describe a common method for calculating. Induction Motor+Starting Time Calculation.

From www.numerade.com

SOLVED Using the simple equivalent circuit of an induction motor, derive the starting torque Induction Motor+Starting Time Calculation in this paper, the starting time is accurately evaluated from a newly proposed technique that is employed to estimate electrical. The importance of starting time. the following discussion will describe a common method for calculating the starting time for an induction motor starting full. methods of starting the motor. this paper presents the starting time calculation. Induction Motor+Starting Time Calculation.