How Metal Sheets Are Made . Melting, pouring, pickling and lastly, rolling and annealing. There are four basic stages in the process of making sheet metal: The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal. The article gives an overview of sheet metal. Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. Iron ore, coal, and limestone. This includes standard measurements, materials and different forming methods. Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. Bending (sheet metal process) incremental sheet forming. The family of manufacturing processes used to create sheet metal components encompasses a. Sheet metal is created in just five stages:

from elgalad-gm.com

Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. Bending (sheet metal process) incremental sheet forming. Sheet metal is created in just five stages: Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. There are four basic stages in the process of making sheet metal: Iron ore, coal, and limestone. The family of manufacturing processes used to create sheet metal components encompasses a. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. The article gives an overview of sheet metal.

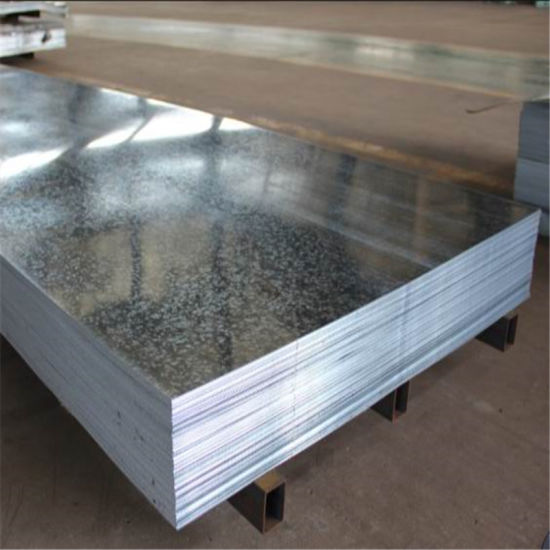

GalvanizedSteelSheetGiSheet GM

How Metal Sheets Are Made Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. Bending (sheet metal process) incremental sheet forming. The family of manufacturing processes used to create sheet metal components encompasses a. Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal. This includes standard measurements, materials and different forming methods. Sheet metal is created in just five stages: There are four basic stages in the process of making sheet metal: Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. Iron ore, coal, and limestone. Melting, pouring, pickling and lastly, rolling and annealing. The article gives an overview of sheet metal.

From in.pinterest.com

Different Types of Sheet Metal Operations [Explained] Sheet metal How Metal Sheets Are Made Sheet metal is created in just five stages: The article gives an overview of sheet metal. The family of manufacturing processes used to create sheet metal components encompasses a. This includes standard measurements, materials and different forming methods. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal.. How Metal Sheets Are Made.

From dedasdesignproduct.blogspot.com

How To Shape Sheet Metal How to Create a Sheet Metal Cone with How Metal Sheets Are Made This includes standard measurements, materials and different forming methods. There are four basic stages in the process of making sheet metal: The family of manufacturing processes used to create sheet metal components encompasses a. Melting, pouring, pickling and lastly, rolling and annealing. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling. How Metal Sheets Are Made.

From proleantech.com

Stainless Steel Sheet Metal Fabrication Process and Applications How Metal Sheets Are Made This includes standard measurements, materials and different forming methods. The family of manufacturing processes used to create sheet metal components encompasses a. Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into. How Metal Sheets Are Made.

From www.brismetal.com.au

Sheet Metal Rolling for Commercial Applications How Metal Sheets Are Made This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal. Sheet metal is created in just five stages: Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. The article gives an overview of sheet metal.. How Metal Sheets Are Made.

From eziil.com

Basics of Metal Forming Process An Ultimate Guide How Metal Sheets Are Made The article gives an overview of sheet metal. Iron ore, coal, and limestone. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the. How Metal Sheets Are Made.

From www.residencestyle.com

The 5 Major Characteristics of Aluminum Sheets » Residence Style How Metal Sheets Are Made There are four basic stages in the process of making sheet metal: The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. The family of manufacturing processes used to create. How Metal Sheets Are Made.

From hlhrapid.com

Sheet Metal Fabrication Techniques, Materials, Applications How Metal Sheets Are Made Bending (sheet metal process) incremental sheet forming. Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. Iron ore, coal, and limestone. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal. Melting, pouring, pickling and. How Metal Sheets Are Made.

From www.pinterest.com

Bending of sheet metal is a common and vital process in manufacturing How Metal Sheets Are Made This includes standard measurements, materials and different forming methods. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal. Iron ore, coal, and limestone. Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. Sheet metal is created in just five stages: The 4 primary steps are. How Metal Sheets Are Made.

From blog.thepipingmart.com

How Aluminium Sheets Are Made? How Metal Sheets Are Made Bending (sheet metal process) incremental sheet forming. There are four basic stages in the process of making sheet metal: Sheet metal is created in just five stages: The family of manufacturing processes used to create sheet metal components encompasses a. This includes standard measurements, materials and different forming methods. The article gives an overview of sheet metal. Iron ore, coal,. How Metal Sheets Are Made.

From www.youtube.com

Perforated Metal Sheet Production YouTube How Metal Sheets Are Made Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. There are four basic stages in the process of making sheet metal: The article gives an overview of sheet metal. This includes standard measurements, materials and different forming methods. Sheet metal is created in just five stages: Iron. How Metal Sheets Are Made.

From dewilddieidee101.blogspot.com

Aluminum Sheet Metal Forming sheetmetal forming/ shaping with wooden How Metal Sheets Are Made Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. Bending (sheet metal process) incremental sheet forming. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. There are. How Metal Sheets Are Made.

From www.atlanticstainless.com

Stainless Steel Sheet and Plate Products Atlantic Stainless How Metal Sheets Are Made Bending (sheet metal process) incremental sheet forming. Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. Melting, pouring, pickling and lastly, rolling and annealing. The article gives an overview of sheet metal. There are four basic. How Metal Sheets Are Made.

From blog.thepipingmart.com

How to Join Stainless Steel Sheets A StepByStep Guide How Metal Sheets Are Made The article gives an overview of sheet metal. Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. Bending (sheet metal process) incremental sheet forming. Sheet metal is created in just five stages: The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal. How Metal Sheets Are Made.

From blog.thepipingmart.com

How to Weld Steel Sheet? How Metal Sheets Are Made The article gives an overview of sheet metal. There are four basic stages in the process of making sheet metal: Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the. How Metal Sheets Are Made.

From www.hardwareinterviews.fyi

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI How Metal Sheets Are Made Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. This includes standard measurements, materials and different forming methods. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet.. How Metal Sheets Are Made.

From www.stainlessshapes.net

Stainless Steel Sheets Cold Rolled Sheet How Metal Sheets Are Made The family of manufacturing processes used to create sheet metal components encompasses a. Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the. How Metal Sheets Are Made.

From www.zainaluminium.ae

Aluminium Sheet Suppliers Zain Aluminum Services in Dubai 0502526638 How Metal Sheets Are Made The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. The article gives an overview of sheet metal. This includes standard measurements, materials and different forming methods. Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. Melting, pouring, pickling. How Metal Sheets Are Made.

From www.metafab.com

Common Types of Sheet Metal Meta Fab, Inc. How Metal Sheets Are Made Iron ore, coal, and limestone. This includes standard measurements, materials and different forming methods. Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. The article gives an overview of sheet metal. There are four basic stages in the process of making sheet metal: Melting, pouring, pickling, oxidisation. How Metal Sheets Are Made.

From eziil.com

Sheet Metal Fabrication 101 Types, Materials, Finishes How Metal Sheets Are Made Bending (sheet metal process) incremental sheet forming. Iron ore, coal, and limestone. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. Sheet metal is created in just five stages: There are four basic stages in the process of making sheet. How Metal Sheets Are Made.

From studentlesson.com

Everything you need to know about sheet metals studentlesson How Metal Sheets Are Made Bending (sheet metal process) incremental sheet forming. Iron ore, coal, and limestone. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal. There are four basic stages in the process of making sheet metal: Sheet metal is made for a wide range of purposes, from automotive parts to. How Metal Sheets Are Made.

From elgalad-gm.com

GalvanizedSteelSheetGiSheet GM How Metal Sheets Are Made Melting, pouring, pickling and lastly, rolling and annealing. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. Sheet metal is created in just five stages: This includes standard measurements, materials and different forming methods. The article gives an overview of. How Metal Sheets Are Made.

From ar.inspiredpencil.com

Sheet Metal Bending Techniques How Metal Sheets Are Made There are four basic stages in the process of making sheet metal: The article gives an overview of sheet metal. Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. Iron ore, coal, and limestone. This includes standard measurements, materials and different forming methods. Bending (sheet metal process) incremental sheet forming. Sheet metal is made for a wide range. How Metal Sheets Are Made.

From 123.design

Manufacturing Sheet Metal Forming 123 DESIGN How Metal Sheets Are Made Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. Sheet metal is created in just five stages: The family of manufacturing processes used to create sheet metal components encompasses a. Iron ore, coal, and limestone. There are four basic stages in the process of making sheet metal: Melting, pouring, pickling and lastly, rolling and annealing. Sheet metal is. How Metal Sheets Are Made.

From www.instructables.com

How to Make a Sheet Metal Box Instructables How Metal Sheets Are Made Melting, pouring, pickling and lastly, rolling and annealing. Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. Sheet metal is created in just five stages: Iron ore, coal, and limestone. The family of manufacturing processes used to create sheet metal components encompasses a. The 4 primary steps. How Metal Sheets Are Made.

From hlhrapid.com

Sheet Metal Fabrication Techniques, Materials, Applications How Metal Sheets Are Made There are four basic stages in the process of making sheet metal: Iron ore, coal, and limestone. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and. How Metal Sheets Are Made.

From proleantech.com

Sheet Metal Drawing Optimize Your Metal Fabrication Process How Metal Sheets Are Made The article gives an overview of sheet metal. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. Melting, pouring, pickling and lastly, rolling and annealing. The family of manufacturing processes used to create sheet metal components encompasses a. Sheet metal. How Metal Sheets Are Made.

From primebldg.com

Choosing the Right Sheet Metal for Your Metal Building Prime Metal How Metal Sheets Are Made Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. Sheet metal is created in just five stages: Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. This includes standard measurements, materials and different forming methods. The article gives an overview of sheet metal. The family. How Metal Sheets Are Made.

From www.protoexpedited.com

4 Tips of Sheet Metal Fabrication Proto Expedited How Metal Sheets Are Made The article gives an overview of sheet metal. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal. There are four basic stages in the process of making sheet metal: Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. The 4 primary steps are the melting. How Metal Sheets Are Made.

From www.madearia.com

Sheet Metal Fabrication 101 everything you need to know How Metal Sheets Are Made Melting, pouring, pickling and lastly, rolling and annealing. The article gives an overview of sheet metal. Bending (sheet metal process) incremental sheet forming. The family of manufacturing processes used to create sheet metal components encompasses a. Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. This includes standard measurements, materials and different forming methods. Iron ore, coal, and. How Metal Sheets Are Made.

From wirefab.com

How to Find the Best Sheet Metal Fabrication Company Wirefab How Metal Sheets Are Made This includes standard measurements, materials and different forming methods. The article gives an overview of sheet metal. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. The family of manufacturing processes used to create sheet metal components encompasses a. Melting,. How Metal Sheets Are Made.

From ar.inspiredpencil.com

Sheet Metal Projects Ideas How Metal Sheets Are Made The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. Melting, pouring, pickling and lastly, rolling and annealing. The. How Metal Sheets Are Made.

From www.youtube.com

Solidworks Sheet Metal Gusset How to Add Strength To Sheet Metal How Metal Sheets Are Made The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. The article gives an overview of sheet metal. This includes standard measurements, materials and different forming methods. Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. Melting, pouring, pickling. How Metal Sheets Are Made.

From www.hordrt.com

Sheet Metal Fabrication Transforming Metal into Precise Creations How Metal Sheets Are Made This includes standard measurements, materials and different forming methods. Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. The family of manufacturing processes used to create sheet metal components encompasses a. The article gives an overview of sheet metal. Sheet metal is created in just five stages: The 4 primary steps are the melting of your chosen material,. How Metal Sheets Are Made.

From www.youtube.com

How to install Roof of sheets. How to install a metal roof. YouTube How Metal Sheets Are Made The article gives an overview of sheet metal. There are four basic stages in the process of making sheet metal: Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components. Bending (sheet metal process) incremental sheet forming. The family of manufacturing processes used to create sheet metal components. How Metal Sheets Are Made.

From www.youtube.com

Aluminum Fabrication Sheet Metal Forming and Punching Blanking dies How Metal Sheets Are Made There are four basic stages in the process of making sheet metal: Melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. The article gives an overview of sheet metal.. How Metal Sheets Are Made.