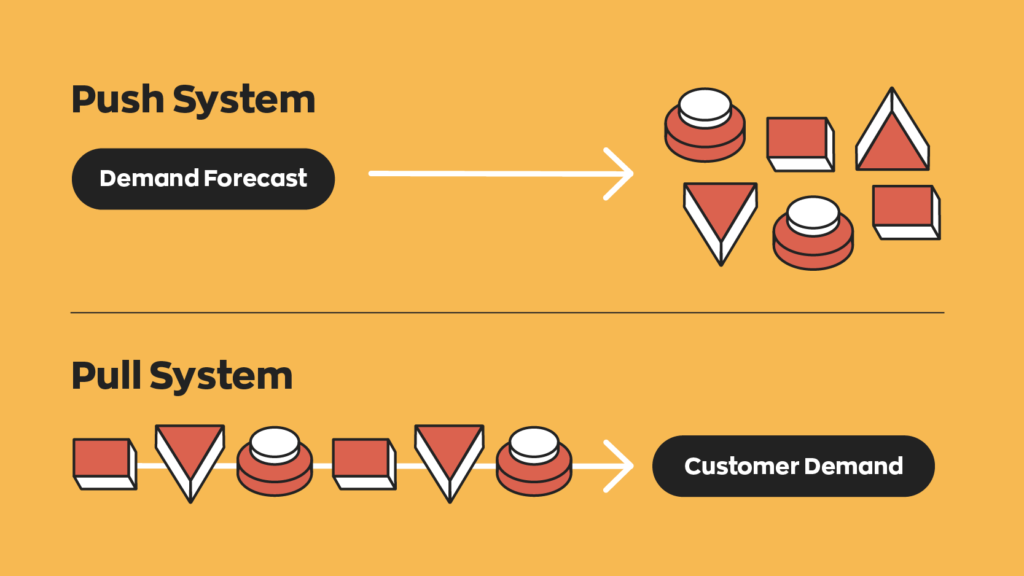

Disadvantages Of A Pull System . It dictates when and how much to produce. Pull system requires reliable suppliers who can deliver materials on time. In a push system, that trigger is predicted market demand. One of the main disadvantages of the push system is the risk of overstocking. It triggers production and movement of goods based on actual customer demand, not on projections. It is easy enough to send the request, but how do you get. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. Disadvantages of the push system. If demand forecasts are inaccurate, or there are unexpected dips in consumer demand, businesses can end up with excess inventory. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. Any delays or inconsistencies from suppliers can. In a pull system, it’s the customer demanding a product. While the pull system offers significant benefits, it also presents certain challenges and vulnerabilities that can impact manufacturing. The biggest problem with pull systems is probably when you have a request/response communication pattern.

from www.inflowinventory.com

It dictates when and how much to produce. Disadvantages of the push system. While the pull system offers significant benefits, it also presents certain challenges and vulnerabilities that can impact manufacturing. One of the main disadvantages of the push system is the risk of overstocking. If demand forecasts are inaccurate, or there are unexpected dips in consumer demand, businesses can end up with excess inventory. Any delays or inconsistencies from suppliers can. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. It triggers production and movement of goods based on actual customer demand, not on projections. It is easy enough to send the request, but how do you get. In a pull system, it’s the customer demanding a product.

Push vs Pull System Manufacturing An InDepth Analysis

Disadvantages Of A Pull System If demand forecasts are inaccurate, or there are unexpected dips in consumer demand, businesses can end up with excess inventory. In a push system, that trigger is predicted market demand. It is easy enough to send the request, but how do you get. It triggers production and movement of goods based on actual customer demand, not on projections. The biggest problem with pull systems is probably when you have a request/response communication pattern. If demand forecasts are inaccurate, or there are unexpected dips in consumer demand, businesses can end up with excess inventory. It dictates when and how much to produce. Any delays or inconsistencies from suppliers can. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. Disadvantages of the push system. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. In a pull system, it’s the customer demanding a product. While the pull system offers significant benefits, it also presents certain challenges and vulnerabilities that can impact manufacturing. Pull system requires reliable suppliers who can deliver materials on time. One of the main disadvantages of the push system is the risk of overstocking.

From fashioncoached.com

Learning Push & Pull System with their Advantage, Disadvantage & the Disadvantages Of A Pull System The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. Pull system requires reliable suppliers who can deliver materials on time. In a push system, that trigger is predicted market demand. If. Disadvantages Of A Pull System.

From en.ppt-online.org

Basic Elements of Lean Production. Benefits of Lean Production Disadvantages Of A Pull System It triggers production and movement of goods based on actual customer demand, not on projections. Pull system requires reliable suppliers who can deliver materials on time. Disadvantages of the push system. The biggest problem with pull systems is probably when you have a request/response communication pattern. A pull system is an essential lean management technique that can help you reduce. Disadvantages Of A Pull System.

From elsmar.com

Benefits of Pull Systems Disadvantages Of A Pull System One of the main disadvantages of the push system is the risk of overstocking. The biggest problem with pull systems is probably when you have a request/response communication pattern. It is easy enough to send the request, but how do you get. In a pull system, it’s the customer demanding a product. Disadvantages of the push system. Pull system requires. Disadvantages Of A Pull System.

From businessmap.io

What Is a Pull System? A Practical Guide to Increasing Process Efficiency Disadvantages Of A Pull System Disadvantages of the push system. It triggers production and movement of goods based on actual customer demand, not on projections. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. It dictates. Disadvantages Of A Pull System.

From www.velaction.com

Pull System Disadvantages Of A Pull System The biggest problem with pull systems is probably when you have a request/response communication pattern. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. Any delays or inconsistencies from suppliers can.. Disadvantages Of A Pull System.

From reiv-engineering.com

Just in Time REIV Disadvantages Of A Pull System A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. In a pull system, it’s the customer demanding a product. The biggest problem with pull systems is probably when you have a request/response communication pattern. It is easy enough to send the request, but how do. Disadvantages Of A Pull System.

From www.inflowinventory.com

Push vs Pull System Manufacturing An InDepth Analysis Disadvantages Of A Pull System The biggest problem with pull systems is probably when you have a request/response communication pattern. It triggers production and movement of goods based on actual customer demand, not on projections. It is easy enough to send the request, but how do you get. A pull system is an essential lean management technique that can help you reduce waste and production. Disadvantages Of A Pull System.

From www.slideserve.com

PPT JustinTime PowerPoint Presentation, free download ID1572249 Disadvantages Of A Pull System In a pull system, it’s the customer demanding a product. It is easy enough to send the request, but how do you get. It triggers production and movement of goods based on actual customer demand, not on projections. Pull system requires reliable suppliers who can deliver materials on time. In a push system, that trigger is predicted market demand. It. Disadvantages Of A Pull System.

From elsmar.com

Pull System Disadvantages Of A Pull System The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve. Disadvantages Of A Pull System.

From www.slideshare.net

Lean DL Arsene Disadvantages Of A Pull System One of the main disadvantages of the push system is the risk of overstocking. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. Pull system requires reliable suppliers who can deliver. Disadvantages Of A Pull System.

From gomingo.io

Push vs. Pull System Mingo Manufacturing Productivity Disadvantages Of A Pull System Disadvantages of the push system. One of the main disadvantages of the push system is the risk of overstocking. It is easy enough to send the request, but how do you get. Pull system requires reliable suppliers who can deliver materials on time. A pull system is an essential lean management technique that can help you reduce waste and production. Disadvantages Of A Pull System.

From www.slideshare.net

Push vs pull Advantages & Disadvantages Disadvantages Of A Pull System In a pull system, it’s the customer demanding a product. It dictates when and how much to produce. One of the main disadvantages of the push system is the risk of overstocking. If demand forecasts are inaccurate, or there are unexpected dips in consumer demand, businesses can end up with excess inventory. Pull system requires reliable suppliers who can deliver. Disadvantages Of A Pull System.

From bitrebels.com

Push vs. Pull System Understanding The Basics And How It Affects Your Disadvantages Of A Pull System The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. Pull system requires reliable suppliers who can deliver materials on time. One of the main disadvantages of the push system is the. Disadvantages Of A Pull System.

From www.yash.com

Digital Pull System Material flow Operations SAP Disadvantages Of A Pull System If demand forecasts are inaccurate, or there are unexpected dips in consumer demand, businesses can end up with excess inventory. In a pull system, it’s the customer demanding a product. The biggest problem with pull systems is probably when you have a request/response communication pattern. Disadvantages of the push system. A pull system is an essential lean management technique that. Disadvantages Of A Pull System.

From hogonext.com

A Comprehensive and InDepth Guide to Pull System HogoNext Disadvantages Of A Pull System While the pull system offers significant benefits, it also presents certain challenges and vulnerabilities that can impact manufacturing. The biggest problem with pull systems is probably when you have a request/response communication pattern. If demand forecasts are inaccurate, or there are unexpected dips in consumer demand, businesses can end up with excess inventory. One of the main disadvantages of the. Disadvantages Of A Pull System.

From www.dozuki.com

Push vs. Pull System in Manufacturing A Complete Overview for Disadvantages Of A Pull System Any delays or inconsistencies from suppliers can. While the pull system offers significant benefits, it also presents certain challenges and vulnerabilities that can impact manufacturing. One of the main disadvantages of the push system is the risk of overstocking. Pull system requires reliable suppliers who can deliver materials on time. The main difference between push and pull manufacturing is that. Disadvantages Of A Pull System.

From www.dozuki.com

Push vs. Pull System in Manufacturing A Complete Overview for Disadvantages Of A Pull System It dictates when and how much to produce. One of the main disadvantages of the push system is the risk of overstocking. If demand forecasts are inaccurate, or there are unexpected dips in consumer demand, businesses can end up with excess inventory. Pull system requires reliable suppliers who can deliver materials on time. It is easy enough to send the. Disadvantages Of A Pull System.

From www.projectpractical.com

Pull System Explained With Examples Disadvantages Of A Pull System In a pull system, it’s the customer demanding a product. Disadvantages of the push system. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. It dictates when and how much to. Disadvantages Of A Pull System.

From brainly.in

Advantage and disadvantage of pull ans push process in supply chain Disadvantages Of A Pull System Any delays or inconsistencies from suppliers can. It triggers production and movement of goods based on actual customer demand, not on projections. In a push system, that trigger is predicted market demand. In a pull system, it’s the customer demanding a product. While the pull system offers significant benefits, it also presents certain challenges and vulnerabilities that can impact manufacturing.. Disadvantages Of A Pull System.

From www.slideserve.com

PPT Chapter 5 Distribution Strategies PowerPoint Presentation, free Disadvantages Of A Pull System It is easy enough to send the request, but how do you get. The biggest problem with pull systems is probably when you have a request/response communication pattern. One of the main disadvantages of the push system is the risk of overstocking. In a pull system, it’s the customer demanding a product. Any delays or inconsistencies from suppliers can. The. Disadvantages Of A Pull System.

From www.slideshare.net

Pull Systems Disadvantages Of A Pull System The biggest problem with pull systems is probably when you have a request/response communication pattern. While the pull system offers significant benefits, it also presents certain challenges and vulnerabilities that can impact manufacturing. Disadvantages of the push system. It is easy enough to send the request, but how do you get. It triggers production and movement of goods based on. Disadvantages Of A Pull System.

From www.manufactus.com

PUSH vs. PULL System advantages / disadvantages Disadvantages Of A Pull System It triggers production and movement of goods based on actual customer demand, not on projections. The biggest problem with pull systems is probably when you have a request/response communication pattern. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. It is easy enough to send. Disadvantages Of A Pull System.

From www.slideserve.com

PPT Chapter 7 JustinTime and Lean Systems PowerPoint Presentation Disadvantages Of A Pull System One of the main disadvantages of the push system is the risk of overstocking. It dictates when and how much to produce. While the pull system offers significant benefits, it also presents certain challenges and vulnerabilities that can impact manufacturing. Pull system requires reliable suppliers who can deliver materials on time. In a push system, that trigger is predicted market. Disadvantages Of A Pull System.

From elsmar.com

Pull System Example Disadvantages Of A Pull System A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. It triggers production and movement of goods based on actual customer demand, not on projections. Any delays or inconsistencies from suppliers can. The main difference between push and pull manufacturing is that in a push system,. Disadvantages Of A Pull System.

From www.slideshare.net

Push vs pull Advantages & Disadvantages Disadvantages Of A Pull System It dictates when and how much to produce. Pull system requires reliable suppliers who can deliver materials on time. In a pull system, it’s the customer demanding a product. It is easy enough to send the request, but how do you get. Any delays or inconsistencies from suppliers can. One of the main disadvantages of the push system is the. Disadvantages Of A Pull System.

From elsmar.com

Implementation of a Pull System Is Affected by Many Factors Disadvantages Of A Pull System Any delays or inconsistencies from suppliers can. In a pull system, it’s the customer demanding a product. It triggers production and movement of goods based on actual customer demand, not on projections. Disadvantages of the push system. One of the main disadvantages of the push system is the risk of overstocking. The biggest problem with pull systems is probably when. Disadvantages Of A Pull System.

From meksmart.com

WHAT IS PULL SYSTEM? PULL STRATEGY IN INVENTORY MANAGEMENT Disadvantages Of A Pull System While the pull system offers significant benefits, it also presents certain challenges and vulnerabilities that can impact manufacturing. It triggers production and movement of goods based on actual customer demand, not on projections. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. It is easy. Disadvantages Of A Pull System.

From alexsibaja.blogspot.com

Lean Manufacturing & Six Sigma Pull Production Systems 生産システムを引いて Disadvantages Of A Pull System The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. Any delays or inconsistencies from suppliers can. Pull system requires reliable suppliers who can deliver materials on time. If demand forecasts are. Disadvantages Of A Pull System.

From www.impactfirst.co

Pull System Definition, Its 3 Types & Differences with Push Disadvantages Of A Pull System It triggers production and movement of goods based on actual customer demand, not on projections. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. The biggest problem with pull systems is probably when you have a request/response communication pattern. It dictates when and how much. Disadvantages Of A Pull System.

From www.impactfirst.co

Lean Manufacturing Impact. Disadvantages Of A Pull System In a pull system, it’s the customer demanding a product. One of the main disadvantages of the push system is the risk of overstocking. The biggest problem with pull systems is probably when you have a request/response communication pattern. While the pull system offers significant benefits, it also presents certain challenges and vulnerabilities that can impact manufacturing. If demand forecasts. Disadvantages Of A Pull System.

From www.slideshare.net

Pull Systems Disadvantages Of A Pull System If demand forecasts are inaccurate, or there are unexpected dips in consumer demand, businesses can end up with excess inventory. One of the main disadvantages of the push system is the risk of overstocking. While the pull system offers significant benefits, it also presents certain challenges and vulnerabilities that can impact manufacturing. It triggers production and movement of goods based. Disadvantages Of A Pull System.

From www.slideshare.net

Push vs pull Advantages & Disadvantages Disadvantages Of A Pull System While the pull system offers significant benefits, it also presents certain challenges and vulnerabilities that can impact manufacturing. One of the main disadvantages of the push system is the risk of overstocking. It triggers production and movement of goods based on actual customer demand, not on projections. Pull system requires reliable suppliers who can deliver materials on time. It dictates. Disadvantages Of A Pull System.

From www.deskera.com

Push System vs. Pull System in Manufacturing Management Disadvantages Of A Pull System A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. Any delays or inconsistencies from suppliers can. Disadvantages of the push system. If demand forecasts are inaccurate, or there are unexpected dips in consumer demand, businesses can end up with excess inventory. The main difference between. Disadvantages Of A Pull System.

From www.slideserve.com

PPT JustinTime PowerPoint Presentation, free download ID1572249 Disadvantages Of A Pull System In a push system, that trigger is predicted market demand. Disadvantages of the push system. It dictates when and how much to produce. If demand forecasts are inaccurate, or there are unexpected dips in consumer demand, businesses can end up with excess inventory. One of the main disadvantages of the push system is the risk of overstocking. The biggest problem. Disadvantages Of A Pull System.

From quickcreator.io

Push vs Pull System in Manufacturing Advantages and Disadvantages Disadvantages Of A Pull System A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. While the pull system offers significant benefits, it also presents certain challenges and vulnerabilities that can impact manufacturing. In a pull system, it’s the customer demanding a product. Pull system requires reliable suppliers who can deliver. Disadvantages Of A Pull System.