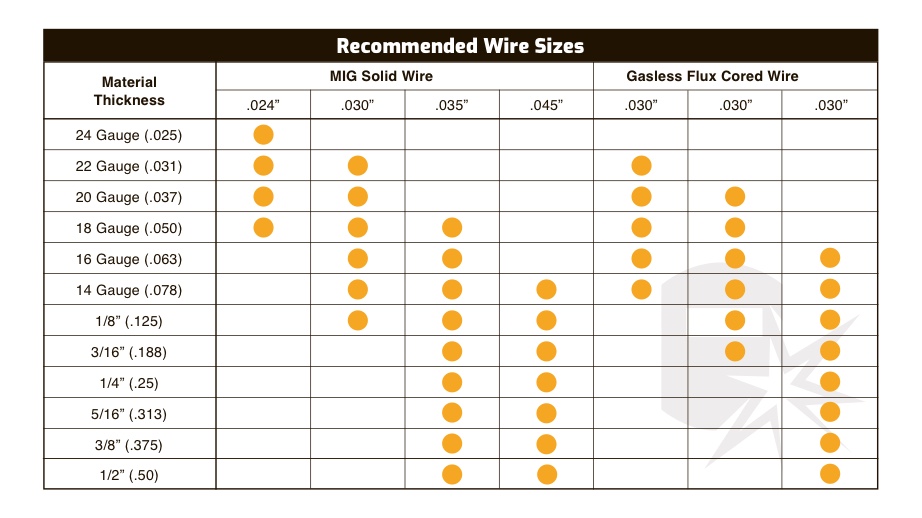

Best Wire Size For Mig Welding Sheet Metal . some wire and gas combinations commonly seen with mig welding are: Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. learn how to select the right mig wire size for different metal thicknesses and welding applications. learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding position, and shielding gas. Also, avoid a 100% co2 shielding gas because it amplifies penetration,. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best.

from weldguru.com

learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. Also, avoid a 100% co2 shielding gas because it amplifies penetration,. some wire and gas combinations commonly seen with mig welding are: the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding position, and shielding gas. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. learn how to select the right mig wire size for different metal thicknesses and welding applications.

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

Best Wire Size For Mig Welding Sheet Metal the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. some wire and gas combinations commonly seen with mig welding are: Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding position, and shielding gas. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. Also, avoid a 100% co2 shielding gas because it amplifies penetration,. learn how to select the right mig wire size for different metal thicknesses and welding applications. learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best.

From www.youtube.com

MIG Welding What Size Wire Should I Use? YouTube Best Wire Size For Mig Welding Sheet Metal Also, avoid a 100% co2 shielding gas because it amplifies penetration,. learn how to select the right mig wire size for different metal thicknesses and welding applications. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and. Best Wire Size For Mig Welding Sheet Metal.

From www.pinterest.ca

Weld Setup and Parts Information Chart Welding set, Welding table Best Wire Size For Mig Welding Sheet Metal learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding position, and shielding gas. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. . Best Wire Size For Mig Welding Sheet Metal.

From weldguru.com

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru Best Wire Size For Mig Welding Sheet Metal learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. Also, avoid a 100% co2 shielding gas because it amplifies penetration,. learn how to select the right mig wire size for. Best Wire Size For Mig Welding Sheet Metal.

From www.instructables.com

Basics of MIG Welding 17 Steps (with Pictures) Instructables Best Wire Size For Mig Welding Sheet Metal learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding position, and shielding gas. learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. using 0.023, 0.024, and 0.030 in mig solid wires for. Best Wire Size For Mig Welding Sheet Metal.

From www.ebay.com

Clarke Mild Steel Mig Welding Wire 0.9mm (Flux Cored No Gas 0.45kg Best Wire Size For Mig Welding Sheet Metal using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. learn how to select the right mig wire size for different metal thicknesses and welding applications. Also, avoid a 100% co2. Best Wire Size For Mig Welding Sheet Metal.

From weldingpros.net

MIG welder settings explained Amperage & Wire Speed Best Wire Size For Mig Welding Sheet Metal learn how to select the right mig wire size for different metal thicknesses and welding applications. learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. learn how to select the right mig wire size for your welding project based on the material thickness, joint. Best Wire Size For Mig Welding Sheet Metal.

From gowelding.org

MIG Welding How to MIG Weld, Process Overview and Machine Set Up Best Wire Size For Mig Welding Sheet Metal some wire and gas combinations commonly seen with mig welding are: Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. using 0.023, 0.024, and 0.030 in mig solid wires. Best Wire Size For Mig Welding Sheet Metal.

From ratemywelder.com

Best MIG Welding Wire Reviews (2023) For Mild Steel & More Best Wire Size For Mig Welding Sheet Metal the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. learn how to select the right mig wire size for different metal thicknesses and welding applications.. Best Wire Size For Mig Welding Sheet Metal.

From www.pinterest.ca

Welding Wire Size Chart Welding wire, Welding cable, Welding Best Wire Size For Mig Welding Sheet Metal learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding position, and shielding gas. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which. Best Wire Size For Mig Welding Sheet Metal.

From www.collisionblast.com

Auto Welding Lesson 6 Basic Auto Body and Paint Training Best Wire Size For Mig Welding Sheet Metal learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. Find a. Best Wire Size For Mig Welding Sheet Metal.

From www.youtube.com

Sheet metal MIG Welding 101 YouTube Best Wire Size For Mig Welding Sheet Metal learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. learn how to. Best Wire Size For Mig Welding Sheet Metal.

From weldingdirect.com

MIG Welding Wire Output Amperage & Selection Chart Best Wire Size For Mig Welding Sheet Metal learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding position, and shielding gas. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is. Best Wire Size For Mig Welding Sheet Metal.

From www.welspring.com

MIG Wire — Welspring Universal Best Wire Size For Mig Welding Sheet Metal using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. some wire and gas combinations commonly seen with mig welding are: learn how to select the right mig wire size for your welding. Best Wire Size For Mig Welding Sheet Metal.

From www.millerwelds.com

Tips for Welding Sheet Metal With MIG or TIG MillerWelds Best Wire Size For Mig Welding Sheet Metal the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. Also, avoid a 100% co2 shielding gas because it amplifies penetration,. learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding position, and shielding gas. learn how. Best Wire Size For Mig Welding Sheet Metal.

From exoplejih.blob.core.windows.net

Arc Welding Sheet Metal at Rhonda Frost blog Best Wire Size For Mig Welding Sheet Metal Also, avoid a 100% co2 shielding gas because it amplifies penetration,. learn how to select the right mig wire size for different metal thicknesses and welding applications. some wire and gas combinations commonly seen with mig welding are: the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is.. Best Wire Size For Mig Welding Sheet Metal.

From www.youtube.com

How To Weld Sheet Metal With Flux Core Wire For Beginners Flux Core Best Wire Size For Mig Welding Sheet Metal learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. learn how to select the right mig wire size for your welding project based on the material thickness,. Best Wire Size For Mig Welding Sheet Metal.

From weldguru.com

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru Best Wire Size For Mig Welding Sheet Metal the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. some wire and gas combinations commonly seen with mig welding are: Also, avoid a 100% co2 shielding gas because it amplifies penetration,. learn how to select the right mig wire size for your welding project based on the. Best Wire Size For Mig Welding Sheet Metal.

From ratemywelder.com

Best MIG Welding Wire Reviews (2023) For Mild Steel & More Best Wire Size For Mig Welding Sheet Metal Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. learn how to select the right. Best Wire Size For Mig Welding Sheet Metal.

From weldguru.com

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru Best Wire Size For Mig Welding Sheet Metal Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. learn how to select the right mig wire size for different metal thicknesses and welding applications. Also, avoid a 100% co2 shielding gas because it amplifies penetration,. some wire and gas combinations commonly seen with mig welding are: the. Best Wire Size For Mig Welding Sheet Metal.

From weldingpros.net

MIG Welding Wire Types & Specification Best Wire Size For Mig Welding Sheet Metal learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. Also, avoid a 100% co2 shielding gas because it amplifies penetration,. the most commonly used aluminum mig wires are er5056, a. Best Wire Size For Mig Welding Sheet Metal.

From www.youtube.com

How to MIG Weld Aluminum The Complete Guide YouTube Best Wire Size For Mig Welding Sheet Metal using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. some wire and gas combinations commonly seen with mig welding are: learn how to select the right mig wire size. Best Wire Size For Mig Welding Sheet Metal.

From jodiebarnes.z21.web.core.windows.net

Mig Welding Amps To Metal Thickness Chart Best Wire Size For Mig Welding Sheet Metal learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding position, and shielding gas. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. learn how to select the right mig wire size for different metal thicknesses and welding applications. some. Best Wire Size For Mig Welding Sheet Metal.

From www.hotrod.com

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks Best Wire Size For Mig Welding Sheet Metal Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. learn how to select the right mig wire size for different metal thicknesses and welding applications. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. some wire and gas combinations commonly seen with mig. Best Wire Size For Mig Welding Sheet Metal.

From weldguru.com

How To MIG Weld Aluminum Beginners Guide (with Chart) Best Wire Size For Mig Welding Sheet Metal the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. some wire and gas combinations commonly seen with mig welding are: learn how to choose the right wire size for. Best Wire Size For Mig Welding Sheet Metal.

From brandonkss.github.io

Mig Welding Settings Chart Best Wire Size For Mig Welding Sheet Metal some wire and gas combinations commonly seen with mig welding are: learn how to select the right mig wire size for different metal thicknesses and welding applications. learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. using 0.023, 0.024, and 0.030 in mig. Best Wire Size For Mig Welding Sheet Metal.

From joshuawest.z13.web.core.windows.net

Mig Welder Chart Settings Best Wire Size For Mig Welding Sheet Metal some wire and gas combinations commonly seen with mig welding are: using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. learn how to select the right mig wire size for different metal thicknesses and welding applications. learn how to choose the right wire size for mig and flux core welding based. Best Wire Size For Mig Welding Sheet Metal.

From garage.grumpysperformance.com

mig wire selection Grumpys Performance Garage Best Wire Size For Mig Welding Sheet Metal learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding position, and shielding gas. using 0.023, 0.024, and 0.030 in mig solid wires for. Best Wire Size For Mig Welding Sheet Metal.

From niamhgould.z13.web.core.windows.net

Lincoln 140 Mig Welder Settings Chart Best Wire Size For Mig Welding Sheet Metal learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is best. learn how to select the right mig wire size for different metal thicknesses and welding applications. learn how to select. Best Wire Size For Mig Welding Sheet Metal.

From weldguru.com

MIG Welder Settings Explained (with Chart) Weld Guru Best Wire Size For Mig Welding Sheet Metal learn how to select the right mig wire size for different metal thicknesses and welding applications. some wire and gas combinations commonly seen with mig welding are: Also, avoid a 100% co2 shielding gas because it amplifies penetration,. learn how to choose the right wire size for mig and flux core welding based on material thickness, joint. Best Wire Size For Mig Welding Sheet Metal.

From brandonkss.github.io

Mig Welding Settings Chart Best Wire Size For Mig Welding Sheet Metal learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. Also, avoid a 100% co2 shielding gas because it amplifies penetration,. Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. learn how to select the right mig. Best Wire Size For Mig Welding Sheet Metal.

From lessonzoneoster.z19.web.core.windows.net

Mig Welding Chart Settings And Guides Best Wire Size For Mig Welding Sheet Metal Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and. Best Wire Size For Mig Welding Sheet Metal.

From www.youtube.com

Amazing TIPS to Mig Welding Sheet Metal like a PRO! YouTube Best Wire Size For Mig Welding Sheet Metal the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. learn how to select the right mig wire size for different metal thicknesses and welding applications. Also, avoid a 100% co2. Best Wire Size For Mig Welding Sheet Metal.

From blog.thepipingmart.com

3 Best MIG Welding Wire for Mild Steel Projects Best Wire Size For Mig Welding Sheet Metal the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. learn how to select the right mig wire size for different metal thicknesses and welding applications.. Best Wire Size For Mig Welding Sheet Metal.

From makemoneywelding.com

MIG Welding Wire Essentials A Guide to Types & Uses Best Wire Size For Mig Welding Sheet Metal learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. Find a mig wire size chart with common wire sizes and their applications for different metals and thicknesses. learn how to select the right mig wire size for your welding project based on the material thickness,. Best Wire Size For Mig Welding Sheet Metal.

From makemoneywelding.com

MIG Welding Wire Essentials A Guide to Types & Uses Best Wire Size For Mig Welding Sheet Metal Also, avoid a 100% co2 shielding gas because it amplifies penetration,. some wire and gas combinations commonly seen with mig welding are: learn how to choose the right wire size for mig and flux core welding based on material thickness, joint design, and amperage. using 0.023, 0.024, and 0.030 in mig solid wires for sheet metal is. Best Wire Size For Mig Welding Sheet Metal.