Sheet Metal Bending Inner Radius . • enter the precise sheet thickness and desired inner bend radius. But if you are air forming, the inside bend radius is produced as a percentage of the die opening. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle,. — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. — in the actual sheet metal processing experience, when the general plate thickness is not more than 6mm, the bending inner radius of. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. — input material thickness and inner radius: — sheet metal bending calculation. — a typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. — in steel between 0.5 and 0.8 in.

from eziil.com

— a typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle,. • enter the precise sheet thickness and desired inner bend radius. But if you are air forming, the inside bend radius is produced as a percentage of the die opening. — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. — in steel between 0.5 and 0.8 in. — in the actual sheet metal processing experience, when the general plate thickness is not more than 6mm, the bending inner radius of. — sheet metal bending calculation.

Sheet Metal Bend Radius Full Guide Chart

Sheet Metal Bending Inner Radius But if you are air forming, the inside bend radius is produced as a percentage of the die opening. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). • enter the precise sheet thickness and desired inner bend radius. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. — in the actual sheet metal processing experience, when the general plate thickness is not more than 6mm, the bending inner radius of. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle,. — a typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. — input material thickness and inner radius: But if you are air forming, the inside bend radius is produced as a percentage of the die opening. — in steel between 0.5 and 0.8 in. — sheet metal bending calculation.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bending Inner Radius — in steel between 0.5 and 0.8 in. — in the actual sheet metal processing experience, when the general plate thickness is not more than 6mm, the bending inner radius of. — sheet metal bending calculation. — input material thickness and inner radius: For example, if the thickness of the sheet is 2mm, the minimum bend. Sheet Metal Bending Inner Radius.

From exozzueaq.blob.core.windows.net

Sheet Metal Bend Radius Calculator at Horace Winfield blog Sheet Metal Bending Inner Radius — a typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. — in the actual sheet metal processing experience, when the general. Sheet Metal Bending Inner Radius.

From dxohfuetc.blob.core.windows.net

Sheet Metal Bend Radius Tolerance at Wade Breeden blog Sheet Metal Bending Inner Radius Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle,. — a typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. — in bottoming or coining, use the punch nose radius as the inside bend. Sheet Metal Bending Inner Radius.

From www.tbkmetal.com

5 Things To Consider When Using The Proper Sheet Metal Bend Radius For Sheet Metal Bending Inner Radius — a typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. — input material thickness and inner radius: Bend allowance (ba) ba. Sheet Metal Bending Inner Radius.

From exovyzyec.blob.core.windows.net

Aluminium Sheet Metal Bend Radius at Jeffrey Crane blog Sheet Metal Bending Inner Radius — input material thickness and inner radius: Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle,. • enter the precise sheet thickness and desired inner bend radius. — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. But if. Sheet Metal Bending Inner Radius.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Bending Inner Radius • enter the precise sheet thickness and desired inner bend radius. — in steel between 0.5 and 0.8 in. — input material thickness and inner radius: — in the actual sheet metal processing experience, when the general plate thickness is not more than 6mm, the bending inner radius of. For example, if the thickness of the sheet. Sheet Metal Bending Inner Radius.

From www.thefabricator.com

Predicting an airformed sheet metal inside bend radius Sheet Metal Bending Inner Radius • enter the precise sheet thickness and desired inner bend radius. — a typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. —. Sheet Metal Bending Inner Radius.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Bending Inner Radius But if you are air forming, the inside bend radius is produced as a percentage of the die opening. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle,. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. — in. Sheet Metal Bending Inner Radius.

From mungfali.com

Sheet Metal Bend Radius Sheet Metal Bending Inner Radius — input material thickness and inner radius: Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). — a typical recommendation is 1t for all sheet metal parts, which means. Sheet Metal Bending Inner Radius.

From www.youtube.com

Making a Radius Bending Fixture for Sheetmetal YouTube Sheet Metal Bending Inner Radius — input material thickness and inner radius: — sheet metal bending calculation. But if you are air forming, the inside bend radius is produced as a percentage of the die opening. — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. Bend allowance (ba) ba = [. Sheet Metal Bending Inner Radius.

From xometry.eu

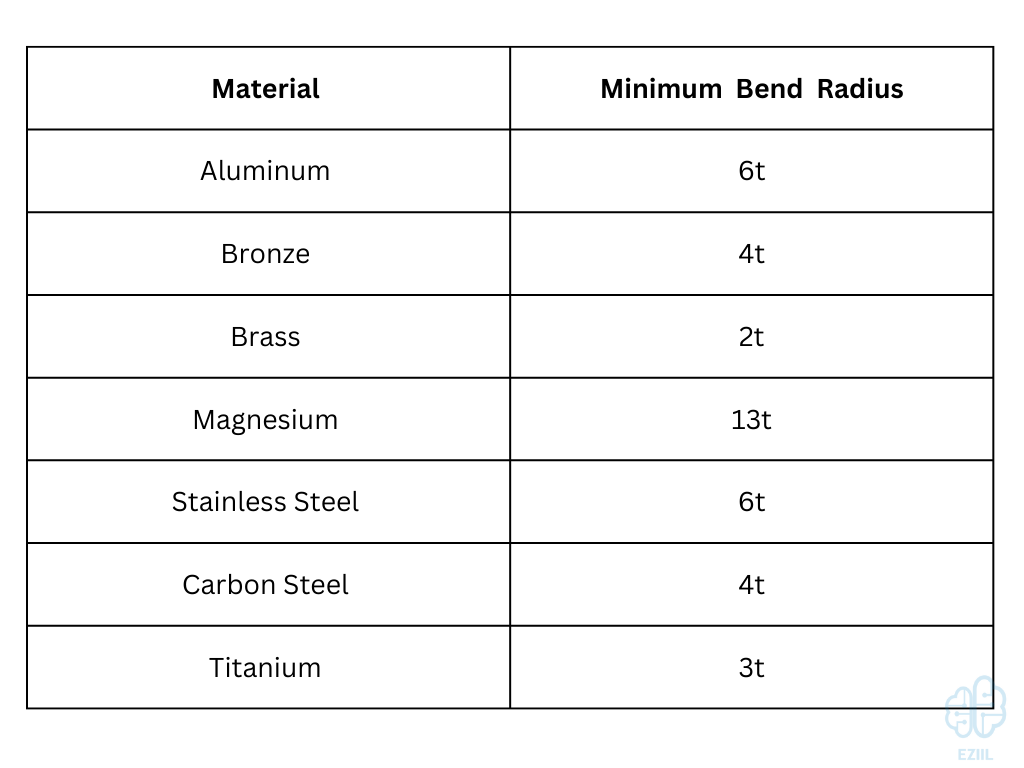

Minimum Bend Radius Reference Table For Sheet Metal Xometry Europe Sheet Metal Bending Inner Radius Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. But if. Sheet Metal Bending Inner Radius.

From www.youtube.com

Common sheet metal design Basic rules or guidelines Minimum Bend Sheet Metal Bending Inner Radius — in steel between 0.5 and 0.8 in. But if you are air forming, the inside bend radius is produced as a percentage of the die opening. • enter the precise sheet thickness and desired inner bend radius. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle,. — a. Sheet Metal Bending Inner Radius.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Bending Inner Radius — in steel between 0.5 and 0.8 in. — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle,. For example, if the thickness of the sheet is 2mm, the minimum. Sheet Metal Bending Inner Radius.

From metalscut4u.com

How To Bend Sheet Metal The Ultimate Guide Sheet Metal Bending Inner Radius — sheet metal bending calculation. — input material thickness and inner radius: — in steel between 0.5 and 0.8 in. — in the actual sheet metal processing experience, when the general plate thickness is not more than 6mm, the bending inner radius of. But if you are air forming, the inside bend radius is produced as. Sheet Metal Bending Inner Radius.

From exovyzyec.blob.core.windows.net

Aluminium Sheet Metal Bend Radius at Jeffrey Crane blog Sheet Metal Bending Inner Radius — in steel between 0.5 and 0.8 in. — sheet metal bending calculation. — input material thickness and inner radius: — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. But if you are air forming, the inside bend radius is produced as a percentage of. Sheet Metal Bending Inner Radius.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Bending Inner Radius — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. — a typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum. Sheet Metal Bending Inner Radius.

From in.pinterest.com

Engineering First Principles (engineering_first_principles) en Sheet Metal Bending Inner Radius — input material thickness and inner radius: — a typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle,. — in bottoming or coining, use. Sheet Metal Bending Inner Radius.

From mungfali.com

Stainless Steel Bend Radius Chart Sheet Metal Bending Inner Radius — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle,. — in steel between 0.5 and 0.8 in. — in the actual sheet metal processing experience, when the general. Sheet Metal Bending Inner Radius.

From www.javelin-tech.com

Learn Sheet Metal Design Terminology including Bend Deduction Sheet Metal Bending Inner Radius — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. — input material thickness and inner radius: But if you are air forming, the inside bend radius is produced as a percentage of the die opening. — a typical recommendation is 1t for all sheet metal parts,. Sheet Metal Bending Inner Radius.

From www.thefabricator.com

Minimum inside sheet metal bend radius vs what's Sheet Metal Bending Inner Radius — input material thickness and inner radius: — a typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. — in steel between 0.5 and 0.8 in. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be. Sheet Metal Bending Inner Radius.

From mavink.com

Sheet Metal Minimum Bend Radius Chart Sheet Metal Bending Inner Radius — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. — sheet metal bending calculation. • enter the precise sheet thickness and desired inner bend radius. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. Sheet Metal Bending Inner Radius.

From www.researchgate.net

The sheet metal stretchbending with bending radius R die (a) the Sheet Metal Bending Inner Radius • enter the precise sheet thickness and desired inner bend radius. But if you are air forming, the inside bend radius is produced as a percentage of the die opening. — input material thickness and inner radius: Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. Sheet Metal Bending Inner Radius.

From www.approvedsheetmetal.com

Sheet Metal Bend Radius Best Practices (Updated for 2024) ASM Sheet Metal Bending Inner Radius — in the actual sheet metal processing experience, when the general plate thickness is not more than 6mm, the bending inner radius of. — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. — in steel between 0.5 and 0.8 in. — sheet metal bending calculation.. Sheet Metal Bending Inner Radius.

From tipseri.com

How to calculate the bending radius for sheet metal? Tipseri Sheet Metal Bending Inner Radius — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. • enter the precise sheet thickness and desired inner bend radius. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. — sheet metal bending calculation. Thick, grade. Sheet Metal Bending Inner Radius.

From mungfali.com

Steel Bend Radius Chart Sheet Metal Bending Inner Radius — sheet metal bending calculation. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). For example, if the thickness of the sheet is 2mm, the minimum bend radius should be. Sheet Metal Bending Inner Radius.

From materialschoollavonne.z21.web.core.windows.net

Bend Radius Chart Sheet Metal Sheet Metal Bending Inner Radius — in steel between 0.5 and 0.8 in. — input material thickness and inner radius: Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). But if you are air. Sheet Metal Bending Inner Radius.

From www.youtube.com

Sheet Metal Properties Thickness & Bend Radius Solidworks Tutorial Sheet Metal Bending Inner Radius — input material thickness and inner radius: — sheet metal bending calculation. — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. — in steel between 0.5 and 0.8 in. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material. Sheet Metal Bending Inner Radius.

From classcampustommie.z21.web.core.windows.net

Sheet Metal Bend Radius Chart Sheet Metal Bending Inner Radius Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). — sheet metal bending calculation. — in the actual sheet metal processing experience, when the general plate thickness is not. Sheet Metal Bending Inner Radius.

From exozzueaq.blob.core.windows.net

Sheet Metal Bend Radius Calculator at Horace Winfield blog Sheet Metal Bending Inner Radius — sheet metal bending calculation. — a typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. — input material thickness and inner radius: Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse. Sheet Metal Bending Inner Radius.

From aaronconnolly.z19.web.core.windows.net

Aluminum Sheet Metal Bend Radius Sheet Metal Bending Inner Radius But if you are air forming, the inside bend radius is produced as a percentage of the die opening. — input material thickness and inner radius: Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the. Sheet Metal Bending Inner Radius.

From www.thefabricator.com

Have problems calculating the flat in sheet metal bending? Sheet Metal Bending Inner Radius — sheet metal bending calculation. • enter the precise sheet thickness and desired inner bend radius. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). For example, if the thickness. Sheet Metal Bending Inner Radius.

From xometry.eu

Minimum Bend Radius Reference Table For Sheet Metal Xometry Europe Sheet Metal Bending Inner Radius — input material thickness and inner radius: For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. — in steel between 0.5 and 0.8 in. But if you are air forming, the inside bend radius is produced as a percentage of the die opening. Bend allowance (ba) ba. Sheet Metal Bending Inner Radius.

From www.indiamart.com

MS Sheet Metal Radius Bending, Bend Radius 3D at Rs 15/kg in Ahmedabad Sheet Metal Bending Inner Radius • enter the precise sheet thickness and desired inner bend radius. — in steel between 0.5 and 0.8 in. — a typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. — in bottoming or coining, use the punch nose radius as the. Sheet Metal Bending Inner Radius.

From www.approvedsheetmetal.com

Sheet Metal Bend Radius Best Practices Approved Sheet Metal Sheet Metal Bending Inner Radius — in the actual sheet metal processing experience, when the general plate thickness is not more than 6mm, the bending inner radius of. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see. Sheet Metal Bending Inner Radius.

From dxohfuetc.blob.core.windows.net

Sheet Metal Bend Radius Tolerance at Wade Breeden blog Sheet Metal Bending Inner Radius — sheet metal bending calculation. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. — in bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. Thick, grade 350 and 400 may have a minimum bend radius of 2.5. Sheet Metal Bending Inner Radius.