Sheet Metal Cutting Clearance Formula . Cutting, piercing and trimming operations require cutting clearances held within close limits. The shear resistance should be about 80% of the tensile strength as a guide. Please multiply x 1.4 to the calculation result in case of more. This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: Clearance is calculated according to material type and thickness. How to estimate die clearance required for punching mild steel. Determine proper clearance by using these guidelines or click the button below and we'll. Because most stamping features are not symmetrical or totally round,. Clearance is determined by the type and thickness of the material being punched. Mild steel, stainless steel, aluminum. Δ x —plate elongation ratio; A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is.

from proleantech.com

This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: Clearance is determined by the type and thickness of the material being punched. Because most stamping features are not symmetrical or totally round,. Determine proper clearance by using these guidelines or click the button below and we'll. Mild steel, stainless steel, aluminum. The shear resistance should be about 80% of the tensile strength as a guide. Cutting, piercing and trimming operations require cutting clearances held within close limits. How to estimate die clearance required for punching mild steel. Please multiply x 1.4 to the calculation result in case of more. Δ x —plate elongation ratio;

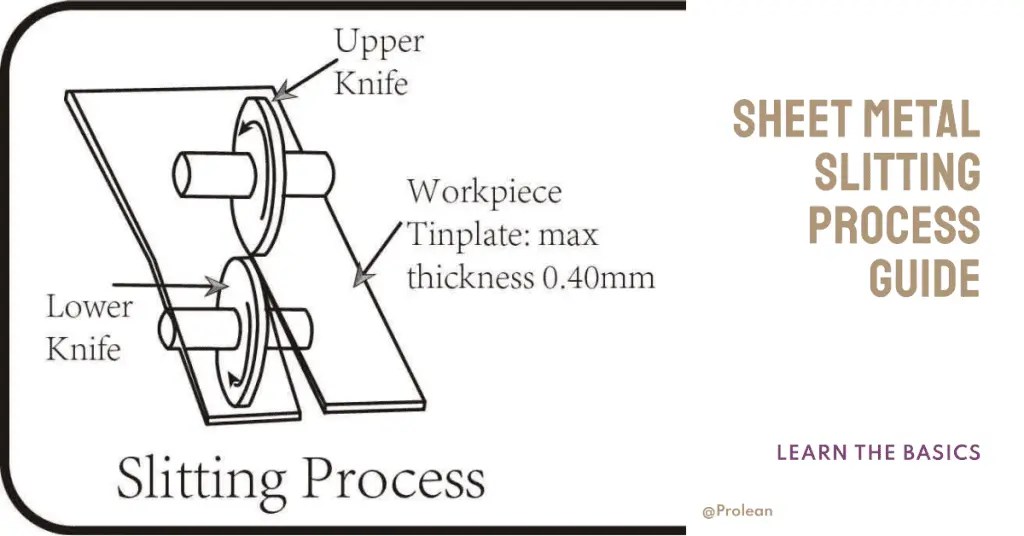

金属板材分切工艺指南

Sheet Metal Cutting Clearance Formula Clearance is calculated according to material type and thickness. Because most stamping features are not symmetrical or totally round,. Determine proper clearance by using these guidelines or click the button below and we'll. Clearance is calculated according to material type and thickness. Mild steel, stainless steel, aluminum. The shear resistance should be about 80% of the tensile strength as a guide. Cutting, piercing and trimming operations require cutting clearances held within close limits. Please multiply x 1.4 to the calculation result in case of more. How to estimate die clearance required for punching mild steel. Δ x —plate elongation ratio; A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is. This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: Clearance is determined by the type and thickness of the material being punched.

From www.steelmama.com

High Performance Automatic 3m Steel Sheet Metal Plate Hydraulic Sheet Metal Cutting Clearance Formula How to estimate die clearance required for punching mild steel. Clearance is determined by the type and thickness of the material being punched. Clearance is calculated according to material type and thickness. A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is. Please multiply x 1.4 to the calculation result in. Sheet Metal Cutting Clearance Formula.

From www.slideserve.com

PPT Manufacturing Engineering Technology SheetMetal Forming Sheet Metal Cutting Clearance Formula How to estimate die clearance required for punching mild steel. Because most stamping features are not symmetrical or totally round,. Clearance is calculated according to material type and thickness. A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is. Cutting, piercing and trimming operations require cutting clearances held within close limits.. Sheet Metal Cutting Clearance Formula.

From www.slideshare.net

Shearing metal Sheet Metal Cutting Clearance Formula This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: Δ x —plate elongation ratio; Cutting, piercing and trimming operations require cutting clearances held within close limits. Clearance is calculated according to material type and thickness. Please multiply x 1.4 to the calculation result in case of more. Because most. Sheet Metal Cutting Clearance Formula.

From proleantech.com

金属板材分切工艺指南 Sheet Metal Cutting Clearance Formula Cutting, piercing and trimming operations require cutting clearances held within close limits. Clearance is determined by the type and thickness of the material being punched. Determine proper clearance by using these guidelines or click the button below and we'll. Please multiply x 1.4 to the calculation result in case of more. Δ x —plate elongation ratio; A correct clearance produces. Sheet Metal Cutting Clearance Formula.

From www.slideserve.com

PPT Sheet Metal Forming PowerPoint Presentation, free download ID Sheet Metal Cutting Clearance Formula Mild steel, stainless steel, aluminum. Cutting, piercing and trimming operations require cutting clearances held within close limits. Clearance is determined by the type and thickness of the material being punched. Please multiply x 1.4 to the calculation result in case of more. Clearance is calculated according to material type and thickness. A correct clearance produces (on a mild steel sheet). Sheet Metal Cutting Clearance Formula.

From www.slideshare.net

1 Basic Punching Tt 2010 Sheet Metal Cutting Clearance Formula Determine proper clearance by using these guidelines or click the button below and we'll. This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is. Mild steel, stainless steel, aluminum. Clearance is. Sheet Metal Cutting Clearance Formula.

From www.slideserve.com

PPT ME 350 Lecture 18 Chapter 20 PowerPoint Presentation, free Sheet Metal Cutting Clearance Formula A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is. Mild steel, stainless steel, aluminum. The shear resistance should be about 80% of the tensile strength as a guide. Please multiply x 1.4 to the calculation result in case of more. Cutting, piercing and trimming operations require cutting clearances held within. Sheet Metal Cutting Clearance Formula.

From www.thelibraryofmanufacturing.com

Sheet Metal Cutting Sheet Metal Cutting Clearance Formula Clearance is calculated according to material type and thickness. A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is. Determine proper clearance by using these guidelines or click the button below and we'll. The shear resistance should be about 80% of the tensile strength as a guide. Because most stamping features. Sheet Metal Cutting Clearance Formula.

From www.thelibraryofmanufacturing.com

Sheet Metal Cutting Sheet Metal Cutting Clearance Formula This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: Clearance is calculated according to material type and thickness. Δ x —plate elongation ratio; Mild steel, stainless steel, aluminum. Cutting, piercing and trimming operations require cutting clearances held within close limits. Clearance is determined by the type and thickness of. Sheet Metal Cutting Clearance Formula.

From www.slideserve.com

PPT ME 350 Lecture 18 Chapter 20 PowerPoint Presentation, free Sheet Metal Cutting Clearance Formula The shear resistance should be about 80% of the tensile strength as a guide. Cutting, piercing and trimming operations require cutting clearances held within close limits. This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: Clearance is determined by the type and thickness of the material being punched. Mild. Sheet Metal Cutting Clearance Formula.

From www.pinterest.com

Ever wanted to figure out the pattern to cut out a cone shaped object Sheet Metal Cutting Clearance Formula Because most stamping features are not symmetrical or totally round,. Determine proper clearance by using these guidelines or click the button below and we'll. Δ x —plate elongation ratio; How to estimate die clearance required for punching mild steel. This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: A. Sheet Metal Cutting Clearance Formula.

From www.slideserve.com

PPT Sheet Metal Forming PowerPoint Presentation, free download ID Sheet Metal Cutting Clearance Formula Please multiply x 1.4 to the calculation result in case of more. A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is. Mild steel, stainless steel, aluminum. Determine proper clearance by using these guidelines or click the button below and we'll. Clearance is calculated according to material type and thickness. Because. Sheet Metal Cutting Clearance Formula.

From www.animalia-life.club

Punch And Die Clearance Sheet Metal Cutting Clearance Formula Mild steel, stainless steel, aluminum. Δ x —plate elongation ratio; Cutting, piercing and trimming operations require cutting clearances held within close limits. How to estimate die clearance required for punching mild steel. Please multiply x 1.4 to the calculation result in case of more. Determine proper clearance by using these guidelines or click the button below and we'll. This die. Sheet Metal Cutting Clearance Formula.

From www.slideserve.com

PPT Chapter 20 SHEET METALWORKING PowerPoint Presentation, free Sheet Metal Cutting Clearance Formula Determine proper clearance by using these guidelines or click the button below and we'll. Please multiply x 1.4 to the calculation result in case of more. Because most stamping features are not symmetrical or totally round,. Cutting, piercing and trimming operations require cutting clearances held within close limits. Clearance is determined by the type and thickness of the material being. Sheet Metal Cutting Clearance Formula.

From thelibraryofmanufacturing.com

Sheet Metal Cutting Sheet Metal Cutting Clearance Formula Determine proper clearance by using these guidelines or click the button below and we'll. Cutting, piercing and trimming operations require cutting clearances held within close limits. Because most stamping features are not symmetrical or totally round,. Mild steel, stainless steel, aluminum. Δ x —plate elongation ratio; The shear resistance should be about 80% of the tensile strength as a guide.. Sheet Metal Cutting Clearance Formula.

From ar.inspiredpencil.com

Sheet Metal Bending Techniques Sheet Metal Cutting Clearance Formula Please multiply x 1.4 to the calculation result in case of more. This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: How to estimate die clearance required for punching mild steel. Clearance is calculated according to material type and thickness. Mild steel, stainless steel, aluminum. Cutting, piercing and trimming. Sheet Metal Cutting Clearance Formula.

From tristatefabricators.com

Sheet Metal Cutting TriState Fabricators Sheet Metal Cutting Clearance Formula Clearance is calculated according to material type and thickness. Mild steel, stainless steel, aluminum. Please multiply x 1.4 to the calculation result in case of more. Cutting, piercing and trimming operations require cutting clearances held within close limits. Δ x —plate elongation ratio; The shear resistance should be about 80% of the tensile strength as a guide. How to estimate. Sheet Metal Cutting Clearance Formula.

From www.slideserve.com

PPT Chapter 20 SHEET METALWORKING PowerPoint Presentation, free Sheet Metal Cutting Clearance Formula A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is. Clearance is determined by the type and thickness of the material being punched. Clearance is calculated according to material type and thickness. Determine proper clearance by using these guidelines or click the button below and we'll. Δ x —plate elongation ratio;. Sheet Metal Cutting Clearance Formula.

From www.animalia-life.club

Punch And Die Clearance Sheet Metal Cutting Clearance Formula This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: The shear resistance should be about 80% of the tensile strength as a guide. A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is. How to estimate die clearance required for. Sheet Metal Cutting Clearance Formula.

From www.thelibraryofmanufacturing.com

Sheet Metal Cutting Sheet Metal Cutting Clearance Formula Please multiply x 1.4 to the calculation result in case of more. Determine proper clearance by using these guidelines or click the button below and we'll. Δ x —plate elongation ratio; How to estimate die clearance required for punching mild steel. A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is.. Sheet Metal Cutting Clearance Formula.

From www.slideshare.net

Shearing Sheet Metal Cutting Clearance Formula How to estimate die clearance required for punching mild steel. Clearance is calculated according to material type and thickness. Because most stamping features are not symmetrical or totally round,. This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: Mild steel, stainless steel, aluminum. Clearance is determined by the type. Sheet Metal Cutting Clearance Formula.

From toolnotes.com

Sheet Metal Shearing ToolNotes Sheet Metal Cutting Clearance Formula Clearance is calculated according to material type and thickness. Cutting, piercing and trimming operations require cutting clearances held within close limits. Determine proper clearance by using these guidelines or click the button below and we'll. Clearance is determined by the type and thickness of the material being punched. A correct clearance produces (on a mild steel sheet) holes in which. Sheet Metal Cutting Clearance Formula.

From www.youtube.com

03_02_P6 Calculating Cutting Forces in Sheet Metal Cutting Operations Sheet Metal Cutting Clearance Formula Clearance is determined by the type and thickness of the material being punched. Determine proper clearance by using these guidelines or click the button below and we'll. Because most stamping features are not symmetrical or totally round,. Clearance is calculated according to material type and thickness. Δ x —plate elongation ratio; Please multiply x 1.4 to the calculation result in. Sheet Metal Cutting Clearance Formula.

From sheetmetalshiijin.blogspot.com

Sheet Metal Formula For Bending Sheet Metal Sheet Metal Cutting Clearance Formula Clearance is determined by the type and thickness of the material being punched. This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: Cutting, piercing and trimming operations require cutting clearances held within close limits. A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3. Sheet Metal Cutting Clearance Formula.

From www.scribd.com

Die Clearance Chart and Metal Gages Card Crafts Building Materials Sheet Metal Cutting Clearance Formula Cutting, piercing and trimming operations require cutting clearances held within close limits. Determine proper clearance by using these guidelines or click the button below and we'll. Clearance is calculated according to material type and thickness. Because most stamping features are not symmetrical or totally round,. Please multiply x 1.4 to the calculation result in case of more. How to estimate. Sheet Metal Cutting Clearance Formula.

From www.scribd.com

Cutting Clearance PDF Mechanical Engineering Materials Sheet Metal Cutting Clearance Formula Mild steel, stainless steel, aluminum. Clearance is determined by the type and thickness of the material being punched. A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is. Please multiply x 1.4 to the calculation result in case of more. Cutting, piercing and trimming operations require cutting clearances held within close. Sheet Metal Cutting Clearance Formula.

From www.slideserve.com

PPT Manufacturing Engineering Technology SheetMetal Forming Sheet Metal Cutting Clearance Formula Clearance is determined by the type and thickness of the material being punched. Please multiply x 1.4 to the calculation result in case of more. Δ x —plate elongation ratio; Because most stamping features are not symmetrical or totally round,. How to estimate die clearance required for punching mild steel. Determine proper clearance by using these guidelines or click the. Sheet Metal Cutting Clearance Formula.

From www.youtube.com

03_02_P4 Clearance in Sheet Metal Cutting YouTube Sheet Metal Cutting Clearance Formula This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is. Cutting, piercing and trimming operations require cutting clearances held within close limits. The shear resistance should be about 80% of the. Sheet Metal Cutting Clearance Formula.

From formtekgroup.com

Blog Rotary Slitting Principles and Applications, Part 1 Sheet Metal Cutting Clearance Formula This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: Clearance is calculated according to material type and thickness. Δ x —plate elongation ratio; Because most stamping features are not symmetrical or totally round,. Cutting, piercing and trimming operations require cutting clearances held within close limits. How to estimate die. Sheet Metal Cutting Clearance Formula.

From ar.inspiredpencil.com

Punch And Die Clearance Sheet Metal Cutting Clearance Formula Clearance is determined by the type and thickness of the material being punched. A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is. The shear resistance should be about 80% of the tensile strength as a guide. Δ x —plate elongation ratio; Clearance is calculated according to material type and thickness.. Sheet Metal Cutting Clearance Formula.

From vortool-tool-and-die-design.blogspot.com

Vortool Manufacturing Ltd. Optimum cutting clearance for blanking Sheet Metal Cutting Clearance Formula Clearance is calculated according to material type and thickness. Δ x —plate elongation ratio; The shear resistance should be about 80% of the tensile strength as a guide. Clearance is determined by the type and thickness of the material being punched. Mild steel, stainless steel, aluminum. How to estimate die clearance required for punching mild steel. Cutting, piercing and trimming. Sheet Metal Cutting Clearance Formula.

From www.slideserve.com

PPT Sheet Metalworking Chapter 20 Part 1 PowerPoint Presentation Sheet Metal Cutting Clearance Formula Cutting, piercing and trimming operations require cutting clearances held within close limits. The shear resistance should be about 80% of the tensile strength as a guide. Because most stamping features are not symmetrical or totally round,. Clearance is calculated according to material type and thickness. How to estimate die clearance required for punching mild steel. Clearance is determined by the. Sheet Metal Cutting Clearance Formula.

From www.youtube.com

Sheet Metal Working Cutting Force Analysis YouTube Sheet Metal Cutting Clearance Formula Mild steel, stainless steel, aluminum. Cutting, piercing and trimming operations require cutting clearances held within close limits. Δ x —plate elongation ratio; How to estimate die clearance required for punching mild steel. This die clearance calculator allows you to quickly and easily know the correct die clearance for the most common materials: Determine proper clearance by using these guidelines or. Sheet Metal Cutting Clearance Formula.

From www.tbkmetal.com

7 Best Common Types Of Sheet Metal Joints (Sheet Metal Joining Techniques) Sheet Metal Cutting Clearance Formula Determine proper clearance by using these guidelines or click the button below and we'll. Mild steel, stainless steel, aluminum. Please multiply x 1.4 to the calculation result in case of more. The shear resistance should be about 80% of the tensile strength as a guide. A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3. Sheet Metal Cutting Clearance Formula.

From xometry.eu

eBook Sheet Metal Cutting Design Guide Xometry Europe Sheet Metal Cutting Clearance Formula A correct clearance produces (on a mild steel sheet) holes in which the upper 1/3 of the height is. How to estimate die clearance required for punching mild steel. Determine proper clearance by using these guidelines or click the button below and we'll. Please multiply x 1.4 to the calculation result in case of more. Because most stamping features are. Sheet Metal Cutting Clearance Formula.