Brass Wire Hardness . It has the second highest strength and second lowest ductility. Dead soft, half hard, and full hard. H08 c26000 brass is c26000 brass in the h08 (spring) temper. The significant difference between the two test classifications is in the test forces that are used. This guide is an essential tool for engineers. (wire name artists are an exception.) brass wire and copper wire are often used to. A metal’s hardness is basically a measure of how much it resists bending, so you. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. Most people find full hard too hard to use for wire wrapping. Jewelry wire is typically offered in three hardnesses: Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common. This standard contains a good. For the rockwell hardness test, the preliminary test force is 10 kgf.

from www.mmimports.com

The significant difference between the two test classifications is in the test forces that are used. (wire name artists are an exception.) brass wire and copper wire are often used to. H08 c26000 brass is c26000 brass in the h08 (spring) temper. Most people find full hard too hard to use for wire wrapping. It has the second highest strength and second lowest ductility. This guide is an essential tool for engineers. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. Dead soft, half hard, and full hard. For the rockwell hardness test, the preliminary test force is 10 kgf. Jewelry wire is typically offered in three hardnesses:

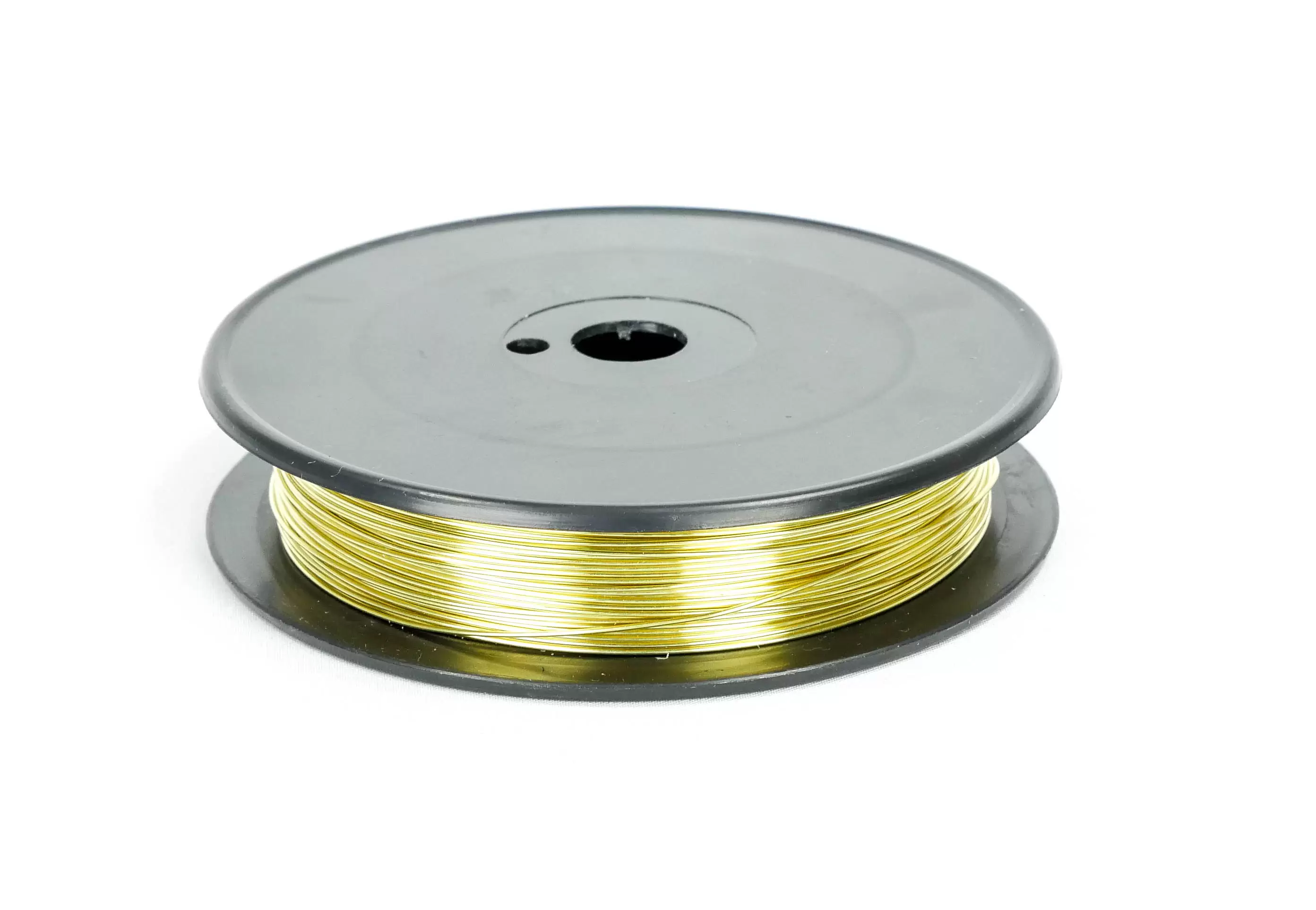

Rieger Brass Wire Midwest Musical Imports

Brass Wire Hardness Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common. H08 c26000 brass is c26000 brass in the h08 (spring) temper. This standard contains a good. A metal’s hardness is basically a measure of how much it resists bending, so you. This guide is an essential tool for engineers. Most people find full hard too hard to use for wire wrapping. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common. It has the second highest strength and second lowest ductility. The significant difference between the two test classifications is in the test forces that are used. Jewelry wire is typically offered in three hardnesses: (wire name artists are an exception.) brass wire and copper wire are often used to. For the rockwell hardness test, the preliminary test force is 10 kgf. Dead soft, half hard, and full hard.

From wuhuchujiang.en.made-in-china.com

65 Copper Low Pb Hardness and Good Wear Resistance Brass Alloy Wire Brass Wire Hardness (wire name artists are an exception.) brass wire and copper wire are often used to. Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common. It has the second highest strength and second lowest ductility. H08 c26000 brass is c26000 brass in the h08 (spring) temper. Most people find full. Brass Wire Hardness.

From www.swkventure.com.my

Avio SWKVenture Brass Wire Hardness A metal’s hardness is basically a measure of how much it resists bending, so you. Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common. Jewelry wire is typically offered in three hardnesses: The significant difference between the two test classifications is in the test forces that are used. For. Brass Wire Hardness.

From liamhowells.z19.web.core.windows.net

Material Hardness Comparison Chart Brass Wire Hardness H08 c26000 brass is c26000 brass in the h08 (spring) temper. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. It has the second highest strength and second lowest ductility. For the rockwell hardness test, the preliminary test force is 10 kgf. This guide is an essential tool. Brass Wire Hardness.

From www.sakysteel.com

Hardness Stainless Steel Wire Saky Steel Brass Wire Hardness Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common. The significant difference between the two test classifications is in the test forces that are used. Jewelry wire is typically offered in three hardnesses: For the rockwell hardness test, the preliminary test force is 10 kgf. In this article, you’ll. Brass Wire Hardness.

From htwelding888.en.made-in-china.com

Brass Welding Wire Good Strength and Hardness Brass Rod China Brass Brass Wire Hardness For the rockwell hardness test, the preliminary test force is 10 kgf. A metal’s hardness is basically a measure of how much it resists bending, so you. (wire name artists are an exception.) brass wire and copper wire are often used to. This standard contains a good. It has the second highest strength and second lowest ductility. Dead soft, half. Brass Wire Hardness.

From www.copper.org

Standards & Properties Mechanical Properties of Copper and Copper Brass Wire Hardness H08 c26000 brass is c26000 brass in the h08 (spring) temper. Dead soft, half hard, and full hard. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. This guide is an essential tool for engineers. For the rockwell hardness test, the preliminary test force is 10 kgf. Jewelry. Brass Wire Hardness.

From dir.indiamart.com

Brass Wires at Best Price in India Brass Wire Hardness A metal’s hardness is basically a measure of how much it resists bending, so you. This guide is an essential tool for engineers. Dead soft, half hard, and full hard. This standard contains a good. (wire name artists are an exception.) brass wire and copper wire are often used to. Most people find full hard too hard to use for. Brass Wire Hardness.

From www.buckcopper.com

China High Hardness Aluminum Brass Wire factory and manufacturers Buck Brass Wire Hardness It has the second highest strength and second lowest ductility. For the rockwell hardness test, the preliminary test force is 10 kgf. Dead soft, half hard, and full hard. The significant difference between the two test classifications is in the test forces that are used. A metal’s hardness is basically a measure of how much it resists bending, so you.. Brass Wire Hardness.

From zytcstainless.en.made-in-china.com

1/2 Hardness Copper on Stock Price Brass C46400 Coil Pipe for Pressure Brass Wire Hardness This guide is an essential tool for engineers. Dead soft, half hard, and full hard. Jewelry wire is typically offered in three hardnesses: In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. A metal’s hardness is basically a measure of how much it resists bending, so you. The. Brass Wire Hardness.

From www.researchgate.net

Results of tensile test of brass Download Table Brass Wire Hardness It has the second highest strength and second lowest ductility. Most people find full hard too hard to use for wire wrapping. This standard contains a good. The significant difference between the two test classifications is in the test forces that are used. Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties. Brass Wire Hardness.

From www.indiamart.com

Brass Zipper Wire, Hardness 90 HV at Rs 580/kilogram in Jamnagar ID Brass Wire Hardness In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. H08 c26000 brass is c26000 brass in the h08 (spring) temper. (wire name artists are an exception.) brass wire and copper wire are often used to. This standard contains a good. Here we collect the metal strength chart (tensile,. Brass Wire Hardness.

From web.calce.umd.edu

Hardness Brass Wire Hardness Most people find full hard too hard to use for wire wrapping. Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common. Jewelry wire is typically offered in three hardnesses: For the rockwell hardness test, the preliminary test force is 10 kgf. This guide is an essential tool for engineers.. Brass Wire Hardness.

From www.mmimports.com

Rieger Brass Wire Midwest Musical Imports Brass Wire Hardness Most people find full hard too hard to use for wire wrapping. A metal’s hardness is basically a measure of how much it resists bending, so you. (wire name artists are an exception.) brass wire and copper wire are often used to. This standard contains a good. H08 c26000 brass is c26000 brass in the h08 (spring) temper. For the. Brass Wire Hardness.

From www.buckcopper.com

China High Hardness Aluminum Brass Wire factory and manufacturers Buck Brass Wire Hardness For the rockwell hardness test, the preliminary test force is 10 kgf. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. Jewelry wire is typically offered in three hardnesses: This guide is an essential tool for engineers. Dead soft, half hard, and full hard. This standard contains a. Brass Wire Hardness.

From blog.thepipingmart.com

Brass vs. Stainless Steel Hardness and Strength Brass Wire Hardness In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. A metal’s hardness is basically a measure of how much it resists bending, so you. The significant difference between the two test classifications is in the test forces that are used. H08 c26000 brass is c26000 brass in the. Brass Wire Hardness.

From studio73designsnb.com

Jewelry Wire for Wrapping Stones [Beginner's Guide] Studio 73 Designs Brass Wire Hardness This guide is an essential tool for engineers. The significant difference between the two test classifications is in the test forces that are used. Most people find full hard too hard to use for wire wrapping. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. It has the. Brass Wire Hardness.

From amesportablehardnesstesters.com

Raised Flat 1/8" Brass Wire Hardness This standard contains a good. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. Most people find full hard too hard to use for wire wrapping. For the rockwell hardness test, the preliminary test force is 10 kgf. A metal’s hardness is basically a measure of how much. Brass Wire Hardness.

From www.alibaba.com

Brass Rod Wire C2700 C2600 C3604 Buy Brass Rod Wire C2700 C2600 C3604 Brass Wire Hardness This guide is an essential tool for engineers. Most people find full hard too hard to use for wire wrapping. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. For the rockwell hardness test, the preliminary test force is 10 kgf. This standard contains a good. (wire name. Brass Wire Hardness.

From allsteelchoices.blogspot.com

Stainless Steel Hardness Scale Steel Choices Brass Wire Hardness Jewelry wire is typically offered in three hardnesses: A metal’s hardness is basically a measure of how much it resists bending, so you. (wire name artists are an exception.) brass wire and copper wire are often used to. Dead soft, half hard, and full hard. Most people find full hard too hard to use for wire wrapping. This guide is. Brass Wire Hardness.

From www.youtube.com

What Do Dead Soft, Half Hard and Full Hard Mean? All About Wire Brass Wire Hardness A metal’s hardness is basically a measure of how much it resists bending, so you. Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common. This guide is an essential tool for engineers. It has the second highest strength and second lowest ductility. (wire name artists are an exception.) brass. Brass Wire Hardness.

From www.brooksforgings.co.uk

Steel Hardness & Tensile Comparisons ©2022 Brooks Ltd. Brass Wire Hardness In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. (wire name artists are an exception.) brass wire and copper wire are often used to. The significant difference between the two test classifications is in the test forces that are used. It has the second highest strength and second. Brass Wire Hardness.

From shchangjin.en.made-in-china.com

99.9 Purity Straight Copper Tube 1/2 AC Copper Pipe for Air Brass Wire Hardness It has the second highest strength and second lowest ductility. For the rockwell hardness test, the preliminary test force is 10 kgf. This guide is an essential tool for engineers. Jewelry wire is typically offered in three hardnesses: This standard contains a good. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass. Brass Wire Hardness.

From payscalechart.z28.web.core.windows.net

rockwell scale chart Metal hardness scale Brass Wire Hardness Most people find full hard too hard to use for wire wrapping. This guide is an essential tool for engineers. Jewelry wire is typically offered in three hardnesses: For the rockwell hardness test, the preliminary test force is 10 kgf. (wire name artists are an exception.) brass wire and copper wire are often used to. H08 c26000 brass is c26000. Brass Wire Hardness.

From www.desertcart.ae

Buy Veloraa Grounding Bar, Ground Bar Easy To Wire Brass Strong Brass Wire Hardness (wire name artists are an exception.) brass wire and copper wire are often used to. This standard contains a good. Most people find full hard too hard to use for wire wrapping. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. For the rockwell hardness test, the preliminary. Brass Wire Hardness.

From www.researchgate.net

Investigations of the mechanical properties of brass (Cu30Zn) after Brass Wire Hardness Jewelry wire is typically offered in three hardnesses: This standard contains a good. For the rockwell hardness test, the preliminary test force is 10 kgf. Dead soft, half hard, and full hard. Most people find full hard too hard to use for wire wrapping. A metal’s hardness is basically a measure of how much it resists bending, so you. Here. Brass Wire Hardness.

From www.qsfullmetal.com

EDM Brass Wire Quanshuo Metal Materials Brass Wire Hardness Most people find full hard too hard to use for wire wrapping. Jewelry wire is typically offered in three hardnesses: Dead soft, half hard, and full hard. This standard contains a good. This guide is an essential tool for engineers. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze. Brass Wire Hardness.

From www.hardnessgauge.com

What is the Rockwell Scale? Hardness Tester Brass Wire Hardness Jewelry wire is typically offered in three hardnesses: This guide is an essential tool for engineers. This standard contains a good. Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common. H08 c26000 brass is c26000 brass in the h08 (spring) temper. The significant difference between the two test classifications. Brass Wire Hardness.

From www.lazada.com.ph

WEEGUBENG 1000mm x100mm Brass Sheet Roll 1000mm x50mm Gold Film Wire Brass Wire Hardness H08 c26000 brass is c26000 brass in the h08 (spring) temper. A metal’s hardness is basically a measure of how much it resists bending, so you. It has the second highest strength and second lowest ductility. For the rockwell hardness test, the preliminary test force is 10 kgf. In this article, you’ll discover a detailed conversion chart for the hardness. Brass Wire Hardness.

From www.buckcopper.com

China High Hardness Aluminum Brass Wire factory and manufacturers Buck Brass Wire Hardness (wire name artists are an exception.) brass wire and copper wire are often used to. This guide is an essential tool for engineers. Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common. This standard contains a good. In this article, you’ll discover a detailed conversion chart for the hardness. Brass Wire Hardness.

From www.indiamart.com

Brass Wire at Rs 570/kg Brass Wires in Rajkot ID 2851559441848 Brass Wire Hardness It has the second highest strength and second lowest ductility. Most people find full hard too hard to use for wire wrapping. H08 c26000 brass is c26000 brass in the h08 (spring) temper. (wire name artists are an exception.) brass wire and copper wire are often used to. This guide is an essential tool for engineers. A metal’s hardness is. Brass Wire Hardness.

From www.tradeindia.com

Brass Wire Brushes Hardness Hard at Best Price in Mumbai Rajhans Brass Wire Hardness This standard contains a good. Jewelry wire is typically offered in three hardnesses: Most people find full hard too hard to use for wire wrapping. This guide is an essential tool for engineers. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. Here we collect the metal strength. Brass Wire Hardness.

From sciencenotes.org

Mohs Hardness Scale Brass Wire Hardness A metal’s hardness is basically a measure of how much it resists bending, so you. This standard contains a good. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. Dead soft, half hard, and full hard. Most people find full hard too hard to use for wire wrapping.. Brass Wire Hardness.

From www.researchgate.net

4 Hardness of Copper Zinc alloy and copper zinc alloy with 3 wt. and Brass Wire Hardness The significant difference between the two test classifications is in the test forces that are used. A metal’s hardness is basically a measure of how much it resists bending, so you. For the rockwell hardness test, the preliminary test force is 10 kgf. Most people find full hard too hard to use for wire wrapping. In this article, you’ll discover. Brass Wire Hardness.

From www.gempacked.com

Should I use Soft, HalfHard or Hard Wire? Wire Wrapping 101 Brass Wire Hardness (wire name artists are an exception.) brass wire and copper wire are often used to. Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common. Jewelry wire is typically offered in three hardnesses: This guide is an essential tool for engineers. It has the second highest strength and second lowest. Brass Wire Hardness.

From www.buckcopper.com

China High Hardness Aluminum Brass Wire factory and manufacturers Buck Brass Wire Hardness Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common. In this article, you’ll discover a detailed conversion chart for the hardness and tensile strength of brass and beryllium bronze alloys. This guide is an essential tool for engineers. H08 c26000 brass is c26000 brass in the h08 (spring) temper.. Brass Wire Hardness.