Solder On Aluminum . soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow. Soldering is the process whereby a low melting point metal alloy (solder) is. Don’t let the parts move while soldering, this will result in a poor result; what is soldering aluminium? for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. You can also use tin with zinc. aluminum doesn’t solder well, and that’s because of the oxide layer that rapidly forms on the surface. Review the manufacturers instructions for the right amount of heat; rules of aluminum soldering. If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique. Joint fit must be snug but with a gap for the solder; Before starting any aluminum soldering project, clean the metal to remove grease and oils; [simpletronic] recently showed a method that chemically plates copper. It will be difficult to achieve.

from users.monash.edu.au

what is soldering aluminium? It will be difficult to achieve. Joint fit must be snug but with a gap for the solder; If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique. Soldering is the process whereby a low melting point metal alloy (solder) is. Don’t let the parts move while soldering, this will result in a poor result; You can also use tin with zinc. Review the manufacturers instructions for the right amount of heat; aluminum doesn’t solder well, and that’s because of the oxide layer that rapidly forms on the surface. [simpletronic] recently showed a method that chemically plates copper.

solderaluminium

Solder On Aluminum Review the manufacturers instructions for the right amount of heat; aluminum doesn’t solder well, and that’s because of the oxide layer that rapidly forms on the surface. [simpletronic] recently showed a method that chemically plates copper. Don’t let the parts move while soldering, this will result in a poor result; Review the manufacturers instructions for the right amount of heat; Soldering is the process whereby a low melting point metal alloy (solder) is. rules of aluminum soldering. for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. Before starting any aluminum soldering project, clean the metal to remove grease and oils; Joint fit must be snug but with a gap for the solder; soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow. You can also use tin with zinc. what is soldering aluminium? It will be difficult to achieve. If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique.

From www.instructables.com

How to Solder Aluminum. 3 Steps (with Pictures) Instructables Solder On Aluminum [simpletronic] recently showed a method that chemically plates copper. Soldering is the process whereby a low melting point metal alloy (solder) is. what is soldering aluminium? Review the manufacturers instructions for the right amount of heat; If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique. Joint fit must be. Solder On Aluminum.

From www.electricity-magnetism.org

Aluminum Solder How it works, Application & Advantages Solder On Aluminum You can also use tin with zinc. for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. Review the manufacturers instructions for the right amount of heat; aluminum doesn’t solder well, and that’s because of the oxide layer that rapidly forms on the surface. It will be difficult to achieve. what is soldering. Solder On Aluminum.

From solderingironguide.com

How to Solder Aluminum Guide For Beginners Solderingironguide Solder On Aluminum If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique. Don’t let the parts move while soldering, this will result in a poor result; for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. It will be difficult to achieve. Before starting any aluminum soldering project,. Solder On Aluminum.

From www.youtube.com

How to solder aluminum. YouTube Solder On Aluminum If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique. soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow. Don’t let the parts move while soldering, this will result in a poor result; Before starting any aluminum soldering project,. Solder On Aluminum.

From aluminumpipedzukeoshi.blogspot.com

Aluminum Pipe Can You Solder Aluminum Pipe Solder On Aluminum If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique. aluminum doesn’t solder well, and that’s because of the oxide layer that rapidly forms on the surface. Review the manufacturers instructions for the right amount of heat; [simpletronic] recently showed a method that chemically plates copper. Soldering is the process. Solder On Aluminum.

From life-improver.com

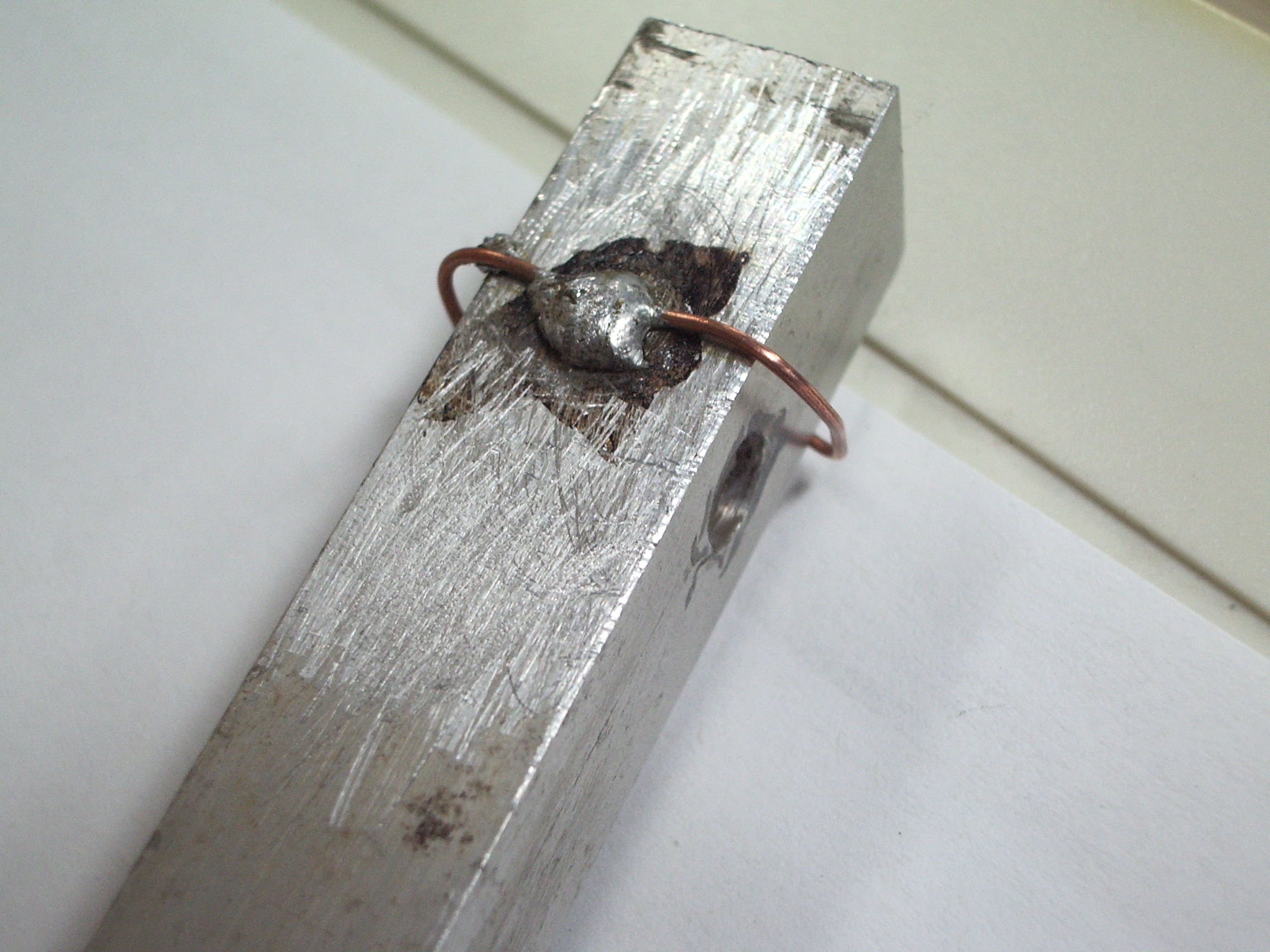

Soldering copper pigtails to aluminum wire Love & Improve Life Solder On Aluminum rules of aluminum soldering. Before starting any aluminum soldering project, clean the metal to remove grease and oils; Soldering is the process whereby a low melting point metal alloy (solder) is. It will be difficult to achieve. what is soldering aluminium? If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of. Solder On Aluminum.

From inductionheater.blogspot.com

induction heating Induction Soldering Wire To Aluminum Lug Solder On Aluminum Before starting any aluminum soldering project, clean the metal to remove grease and oils; If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique. aluminum doesn’t solder well, and that’s because of the oxide layer that rapidly forms on the surface. Soldering is the process whereby a low melting point. Solder On Aluminum.

From laptrinhx.com

How to Solder To Aluminum, Easily LaptrinhX Solder On Aluminum rules of aluminum soldering. what is soldering aluminium? You can also use tin with zinc. soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow. If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique. Soldering is the. Solder On Aluminum.

From www.dreamstime.com

Technician is Welding Aluminium Pipe by Using Soldering Copper Stock Solder On Aluminum It will be difficult to achieve. for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. Joint fit must be snug but with a gap for the solder; Review the manufacturers instructions for the right amount of heat; rules of aluminum soldering. [simpletronic] recently showed a method that chemically plates copper. Soldering is the. Solder On Aluminum.

From www.youtube.com

Soldering Aluminum to Galvanized Steel with Super Alloy 1 MultiMetal Solder On Aluminum for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique. It will be difficult to achieve. [simpletronic] recently showed a method that chemically plates copper. Soldering is the process whereby a low melting point metal alloy. Solder On Aluminum.

From www.youtube.com

AlumSolder Alu Flux use solder and soldering iron to soldering Solder On Aluminum Joint fit must be snug but with a gap for the solder; rules of aluminum soldering. You can also use tin with zinc. aluminum doesn’t solder well, and that’s because of the oxide layer that rapidly forms on the surface. [simpletronic] recently showed a method that chemically plates copper. Soldering is the process whereby a low melting point. Solder On Aluminum.

From www.wikihow.com

How to Solder Aluminum 13 Steps (with Pictures) wikiHow Solder On Aluminum aluminum doesn’t solder well, and that’s because of the oxide layer that rapidly forms on the surface. [simpletronic] recently showed a method that chemically plates copper. for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. Review the manufacturers instructions for the right amount of heat; soldering is a metal joining technique where. Solder On Aluminum.

From solderingironguide.com

How to Solder Aluminum Guide For Beginners Solder On Aluminum for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. Review the manufacturers instructions for the right amount of heat; [simpletronic] recently showed a method that chemically plates copper. Soldering is the process whereby a low melting point metal alloy (solder) is. what is soldering aluminium? soldering is a metal joining technique where. Solder On Aluminum.

From wikihow.com

How to Solder Aluminum 13 Steps (with Pictures) wikiHow Solder On Aluminum for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. Before starting any aluminum soldering project, clean the metal to remove grease and oils; [simpletronic] recently showed a method that chemically plates copper. Soldering is the process whereby a low melting point metal alloy (solder) is. If you’ve ever tried to solder to aluminum, you. Solder On Aluminum.

From pcbtoolexpert.com

How To Solder Aluminum With Soldering Iron? PCB Tool Expert Solder On Aluminum rules of aluminum soldering. Before starting any aluminum soldering project, clean the metal to remove grease and oils; for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow. what is soldering aluminium?. Solder On Aluminum.

From electronicshacks.com

3 Steps to Solder Wires to Connectors ElectronicsHacks Solder On Aluminum aluminum doesn’t solder well, and that’s because of the oxide layer that rapidly forms on the surface. for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow. Joint fit must be snug but. Solder On Aluminum.

From www.youtube.com

AlumSolder Alu Flux use solder and soldering iron to join aluminium Solder On Aluminum Joint fit must be snug but with a gap for the solder; rules of aluminum soldering. Review the manufacturers instructions for the right amount of heat; for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. Don’t let the parts move while soldering, this will result in a poor result; what is soldering. Solder On Aluminum.

From solderingironguide.com

How to Solder Aluminum Guide For Beginners Solderingironguide Solder On Aluminum soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow. It will be difficult to achieve. [simpletronic] recently showed a method that chemically plates copper. Before starting any aluminum soldering project, clean the metal to remove grease and oils; aluminum doesn’t solder well, and that’s because of the. Solder On Aluminum.

From silvertumbledtravertinetilenbikoka.blogspot.com

Silver Tumbled Travertine Tile Can You Silver Solder Aluminum Solder On Aluminum for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. Review the manufacturers instructions for the right amount of heat; Soldering is the process whereby a low melting point metal alloy (solder) is. soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow. Don’t. Solder On Aluminum.

From www.s-bond.com

Applications For Aluminum Soldering Solder On Aluminum Soldering is the process whereby a low melting point metal alloy (solder) is. soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow. Don’t let the parts move while soldering, this will result in a poor result; [simpletronic] recently showed a method that chemically plates copper. Review the manufacturers. Solder On Aluminum.

From hackaday.com

How To Solder To Aluminum, Easily Hackaday Solder On Aluminum If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique. You can also use tin with zinc. soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow. Review the manufacturers instructions for the right amount of heat; Joint fit must. Solder On Aluminum.

From www.stxaviersschooljaipur.com

Sale > silver solder aluminum > in stock Solder On Aluminum rules of aluminum soldering. for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. You can also use tin with zinc. [simpletronic] recently showed a method that chemically plates copper. what is soldering aluminium? Review the manufacturers instructions for the right amount of heat; Don’t let the parts move while soldering, this will. Solder On Aluminum.

From solderingironguide.com

How to Solder Aluminum Guide For Beginners Solderingironguide Solder On Aluminum Soldering is the process whereby a low melting point metal alloy (solder) is. [simpletronic] recently showed a method that chemically plates copper. Review the manufacturers instructions for the right amount of heat; Don’t let the parts move while soldering, this will result in a poor result; for soldering aluminum parts, you can use solders consisting of bismuth and tin. Solder On Aluminum.

From users.monash.edu.au

solderaluminium Solder On Aluminum If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique. what is soldering aluminium? rules of aluminum soldering. Don’t let the parts move while soldering, this will result in a poor result; Before starting any aluminum soldering project, clean the metal to remove grease and oils; Review the manufacturers. Solder On Aluminum.

From www.wikihow.com

How to Solder Aluminum 13 Steps (with Pictures) wikiHow Solder On Aluminum Don’t let the parts move while soldering, this will result in a poor result; Soldering is the process whereby a low melting point metal alloy (solder) is. Review the manufacturers instructions for the right amount of heat; aluminum doesn’t solder well, and that’s because of the oxide layer that rapidly forms on the surface. Before starting any aluminum soldering. Solder On Aluminum.

From solderingironguide.com

How to Solder Aluminum Guide For Beginners Solder On Aluminum what is soldering aluminium? You can also use tin with zinc. If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique. [simpletronic] recently showed a method that chemically plates copper. Review the manufacturers instructions for the right amount of heat; Soldering is the process whereby a low melting point metal. Solder On Aluminum.

From www.wikihow.com

How to Solder Aluminum 13 Steps (with Pictures) wikiHow Solder On Aluminum If you’ve ever tried to solder to aluminum, you know it isn’t easy without some kind of special technique. what is soldering aluminium? aluminum doesn’t solder well, and that’s because of the oxide layer that rapidly forms on the surface. for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. It will be. Solder On Aluminum.

From blog.thepipingmart.com

How to Solder Aluminum Wire An Overview Solder On Aluminum rules of aluminum soldering. what is soldering aluminium? Soldering is the process whereby a low melting point metal alloy (solder) is. Before starting any aluminum soldering project, clean the metal to remove grease and oils; Don’t let the parts move while soldering, this will result in a poor result; soldering is a metal joining technique where filler. Solder On Aluminum.

From www.youtube.com

Solder on Aluminum YouTube Solder On Aluminum rules of aluminum soldering. It will be difficult to achieve. Don’t let the parts move while soldering, this will result in a poor result; Soldering is the process whereby a low melting point metal alloy (solder) is. You can also use tin with zinc. If you’ve ever tried to solder to aluminum, you know it isn’t easy without some. Solder On Aluminum.

From blog.thepipingmart.com

How to Solder Aluminum with a Soldering Iron Solder On Aluminum soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow. what is soldering aluminium? Joint fit must be snug but with a gap for the solder; aluminum doesn’t solder well, and that’s because of the oxide layer that rapidly forms on the surface. Review the manufacturers instructions. Solder On Aluminum.

From www.youtube.com

Can I solder on aluminium? YouTube Solder On Aluminum Review the manufacturers instructions for the right amount of heat; Joint fit must be snug but with a gap for the solder; aluminum doesn’t solder well, and that’s because of the oxide layer that rapidly forms on the surface. [simpletronic] recently showed a method that chemically plates copper. If you’ve ever tried to solder to aluminum, you know it. Solder On Aluminum.

From www.indiamart.com

Aluminum Solder Wire, सोल्डर वायर Khosla Engineering Private Limited Solder On Aluminum It will be difficult to achieve. Soldering is the process whereby a low melting point metal alloy (solder) is. Review the manufacturers instructions for the right amount of heat; Don’t let the parts move while soldering, this will result in a poor result; Joint fit must be snug but with a gap for the solder; [simpletronic] recently showed a method. Solder On Aluminum.

From www.soldercorp.com

Soldering Flux,China Aluminum Solder Exporter Solder On Aluminum soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow. Don’t let the parts move while soldering, this will result in a poor result; rules of aluminum soldering. for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. aluminum doesn’t solder well,. Solder On Aluminum.

From users.monash.edu.au

solderaluminium Solder On Aluminum You can also use tin with zinc. It will be difficult to achieve. [simpletronic] recently showed a method that chemically plates copper. soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow. Before starting any aluminum soldering project, clean the metal to remove grease and oils; Soldering is the. Solder On Aluminum.

From users.monash.edu.au

solderaluminium Solder On Aluminum Soldering is the process whereby a low melting point metal alloy (solder) is. You can also use tin with zinc. rules of aluminum soldering. Don’t let the parts move while soldering, this will result in a poor result; for soldering aluminum parts, you can use solders consisting of bismuth and tin alloys. what is soldering aluminium? If. Solder On Aluminum.