Centrifugal Pump Max Viscosity . Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps successfully pumping fluids in excess of 1000 centipoise. Depending on the pump type, the impact of liquid viscosity is different. Efficiency is reduced when pumping viscous fluids. We will look at three types of pumps specifically:. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific gravity@15°c/60°f. As illustrated in figure 13, two identical centrifugal pumps operating at. Centrifugal pumps work best with water and other low viscosity fluids. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected.

from www.ogj.com

Depending on the pump type, the impact of liquid viscosity is different. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific gravity@15°c/60°f. As illustrated in figure 13, two identical centrifugal pumps operating at. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps successfully pumping fluids in excess of 1000 centipoise. Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. Efficiency is reduced when pumping viscous fluids. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Centrifugal pumps work best with water and other low viscosity fluids. We will look at three types of pumps specifically:.

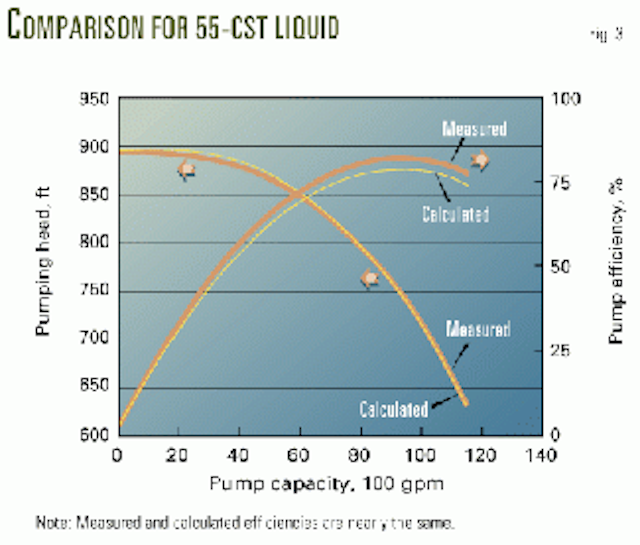

Equations correct centrifugal pump curves for viscosity Oil & Gas Journal

Centrifugal Pump Max Viscosity Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Depending on the pump type, the impact of liquid viscosity is different. Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. We will look at three types of pumps specifically:. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps successfully pumping fluids in excess of 1000 centipoise. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific gravity@15°c/60°f. As illustrated in figure 13, two identical centrifugal pumps operating at. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Centrifugal pumps work best with water and other low viscosity fluids. Efficiency is reduced when pumping viscous fluids.

From www.jeepumps.com

Centrifugal Pump Performance How Fluid Temperature Impact Centrifugal Pump Max Viscosity We will look at three types of pumps specifically:. Depending on the pump type, the impact of liquid viscosity is different. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps successfully pumping fluids in excess of 1000 centipoise. Gravity viscosity. Centrifugal Pump Max Viscosity.

From www.industrialchemicalpump.com

High Pressure High Viscosity Horizontal Chemical Pumps, Chemical Resistant Centrifugal Pump Centrifugal Pump Max Viscosity Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps successfully pumping fluids in excess of 1000 centipoise. Gravity viscosity at. Centrifugal Pump Max Viscosity.

From extrudesign.com

Characteristic Curves of Centrifugal Pumps ExtruDesign Centrifugal Pump Max Viscosity Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. As illustrated in figure 13, two identical centrifugal pumps operating at. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps. Centrifugal Pump Max Viscosity.

From www.pumps.org

How Viscosity Affects Pumping Centrifugal Pump Max Viscosity Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific gravity@15°c/60°f. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps successfully pumping fluids in excess of 1000 centipoise. Centrifugal pump published performance curves. Centrifugal Pump Max Viscosity.

From ingermax.com.my

Centrifugal Pump For Low Viscosity Liquid Ingermax Engineering Centrifugal Pump Max Viscosity Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Efficiency is reduced when pumping viscous fluids. Depending on the pump type, the impact of liquid viscosity is different. Centrifugal pumps work best with water and other low viscosity fluids. Centrifugal pump published performance curves are based on water and. Centrifugal Pump Max Viscosity.

From www.scribd.com

Fluid Viscosity Effects in Centrifugal Pump Centrifugal Pump Max Viscosity Efficiency is reduced when pumping viscous fluids. Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown. Centrifugal Pump Max Viscosity.

From www.ogj.com

Equations correct centrifugal pump curves for viscosity Oil & Gas Journal Centrifugal Pump Max Viscosity We will look at three types of pumps specifically:. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps successfully pumping fluids in excess of 1000 centipoise. Efficiency is reduced when pumping viscous fluids. Centrifugal pump published performance curves are based. Centrifugal Pump Max Viscosity.

From www.researchgate.net

(PDF) An Experimental Study on the Effect of Oil Viscosity and WearRing Clearance on the Centrifugal Pump Max Viscosity As illustrated in figure 13, two identical centrifugal pumps operating at. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps. Centrifugal Pump Max Viscosity.

From chempedia.info

Viscosity correction, centrifugal pumps Chart Big Chemical Encyclopedia Centrifugal Pump Max Viscosity Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps successfully pumping fluids in excess of 1000 centipoise. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Depending on the. Centrifugal Pump Max Viscosity.

From www.numerade.com

SOLVED 28. 13.2 Myers Experiments show that the fluid viscosity actually has little Centrifugal Pump Max Viscosity As illustrated in figure 13, two identical centrifugal pumps operating at. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific gravity@15°c/60°f. Depending on the pump type, the impact of liquid viscosity is different. We will look at three types of pumps specifically:. Centrifugal pumps are used in series to overcome a larger. Centrifugal Pump Max Viscosity.

From www.nuclear-power.com

How Does Centrifugal Pump Work Nuclear Power Centrifugal Pump Max Viscosity Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps successfully pumping fluids in excess of 1000 centipoise. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. We will look. Centrifugal Pump Max Viscosity.

From www.northridgepumps.com

Varisco J3 Series Self Priming Centrifugal Pump Centrifugal Pump Max Viscosity Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. We will look at three types of pumps specifically:. Efficiency is reduced when pumping viscous fluids. Depending on the pump type, the impact of liquid viscosity is different. As illustrated in figure 13, two identical centrifugal pumps operating at. Centrifugal. Centrifugal Pump Max Viscosity.

From www.researchgate.net

Effect of pumped fluid viscosity on the performance of centrifugal pump. Download Scientific Centrifugal Pump Max Viscosity We will look at three types of pumps specifically:. Centrifugal pumps work best with water and other low viscosity fluids. As illustrated in figure 13, two identical centrifugal pumps operating at. Depending on the pump type, the impact of liquid viscosity is different. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can. Centrifugal Pump Max Viscosity.

From pumpfocus.com

3.1.6 Centrifugal pump curves Pumpfocus Centrifugal Pump Max Viscosity Efficiency is reduced when pumping viscous fluids. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific gravity@15°c/60°f. As illustrated in figure 13, two identical centrifugal pumps operating at. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Depending on the pump. Centrifugal Pump Max Viscosity.

From www.northridgepumps.com

North Ridge MB Centrifugal Chemical Pump Centrifugal Pump Max Viscosity Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific gravity@15°c/60°f. We will look at three types of pumps specifically:. Efficiency is reduced when pumping viscous fluids. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Centrifugal pumps work best with water. Centrifugal Pump Max Viscosity.

From kingengineering.pk

Centrifugal Pump types, definition and features King Engineering Centrifugal Pump Max Viscosity We will look at three types of pumps specifically:. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps successfully pumping fluids in excess of 1000 centipoise. Efficiency is reduced when pumping viscous fluids. Gravity viscosity at 20°c/68°f and 50°c/122°f for. Centrifugal Pump Max Viscosity.

From www.northridgepumps.com

XTO Single Stage Centrifugal Thermal Oil Pump Centrifugal Pump Max Viscosity Depending on the pump type, the impact of liquid viscosity is different. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific gravity@15°c/60°f. Centrifugal pumps work best with water and other low viscosity fluids. As illustrated in figure 13, two identical centrifugal pumps operating at. Efficiency is reduced when pumping viscous fluids. Depending. Centrifugal Pump Max Viscosity.

From www.tapflopumps.co.uk

Benefits And Uses Of A Centrifugal Pump Tapflo Pumps UK Centrifugal Pump Max Viscosity Depending on the pump type, the impact of liquid viscosity is different. Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many. Centrifugal Pump Max Viscosity.

From www.northridgepumps.com

XRVIL Vertical Inline Self Priming Centrifugal Pump Centrifugal Pump Max Viscosity Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. Efficiency is reduced when pumping viscous fluids. We will look at three types of pumps specifically:. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific gravity@15°c/60°f. Centrifugal pumps are used in series. Centrifugal Pump Max Viscosity.

From www.northridgepumps.com

Varisco J2 Series Self Priming Centrifugal Pump Centrifugal Pump Max Viscosity Efficiency is reduced when pumping viscous fluids. Depending on the pump type, the impact of liquid viscosity is different. We will look at three types of pumps specifically:. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps successfully pumping fluids. Centrifugal Pump Max Viscosity.

From www.youtube.com

Can we use Centrifugal pump for high viscosity. YouTube Centrifugal Pump Max Viscosity We will look at three types of pumps specifically:. Efficiency is reduced when pumping viscous fluids. As illustrated in figure 13, two identical centrifugal pumps operating at. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific gravity@15°c/60°f. Centrifugal pumps work best with water and other low viscosity fluids. Depending on the pump. Centrifugal Pump Max Viscosity.

From www.slideserve.com

PPT Pumps PowerPoint Presentation, free download ID6736538 Centrifugal Pump Max Viscosity As illustrated in figure 13, two identical centrifugal pumps operating at. Depending on the pump type, the impact of liquid viscosity is different. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. We will look at three types of pumps specifically:. Depending on the pump size and impeller geometry,. Centrifugal Pump Max Viscosity.

From www.abset.com

Centrifugal Plastic Pumps ABS Engineering & Trading Sdn. Bhd. Centrifugal Pump Max Viscosity Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps successfully pumping fluids in excess of 1000 centipoise. Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. Efficiency is reduced. Centrifugal Pump Max Viscosity.

From www.theengineersperspectives.com

What Is A Centrifugal Pump? The Engineer's Perspective Centrifugal Pump Max Viscosity As illustrated in figure 13, two identical centrifugal pumps operating at. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps. Centrifugal Pump Max Viscosity.

From www.scribd.com

Chapter 4 Centrifugal Pumps PDF Pump Viscosity Centrifugal Pump Max Viscosity Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific gravity@15°c/60°f. We will look at three types of pumps specifically:. As illustrated in figure 13, two identical centrifugal pumps operating at. Depending on. Centrifugal Pump Max Viscosity.

From pumpfocus.com

2.2 Pump selection for viscous liquids Pumpfocus Centrifugal Pump Max Viscosity Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. Depending on the pump type, the impact of liquid viscosity is different. Efficiency is reduced when pumping viscous fluids. Depending. Centrifugal Pump Max Viscosity.

From www.scribd.com

Centrifugal Pumps PDF Viscosity Atmospheric Pressure Centrifugal Pump Max Viscosity As illustrated in figure 13, two identical centrifugal pumps operating at. Depending on the pump type, the impact of liquid viscosity is different. Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. Efficiency is reduced when pumping viscous fluids. Centrifugal pumps are used in series to overcome a larger. Centrifugal Pump Max Viscosity.

From www.rotechpumps.com

Understanding Centrifugal Pump Flow Rate Formula and Calculation Centrifugal Pump Max Viscosity Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. As illustrated in figure 13, two identical centrifugal pumps operating at. Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. Depending on the pump size and impeller geometry, the. Centrifugal Pump Max Viscosity.

From www.semanticscholar.org

Figure 1 from The Influence of Viscosity on CentrifugalPump Performance Semantic Scholar Centrifugal Pump Max Viscosity Centrifugal pumps work best with water and other low viscosity fluids. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific gravity@15°c/60°f. Depending on the pump size and impeller geometry, the viscosity limits. Centrifugal Pump Max Viscosity.

From suotopump.en.made-in-china.com

Universal Cam Rotor Pump Can Transfer Max Viscosity 500000cp Liquid China Pump and Centrifugal Centrifugal Pump Max Viscosity We will look at three types of pumps specifically:. Centrifugal pumps work best with water and other low viscosity fluids. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250. Centrifugal Pump Max Viscosity.

From yongyipump.en.made-in-china.com

High Viscosity Single Stage Fgd Pump Centrifugal Mixed Flow Pump China AntiWearing Pump and Centrifugal Pump Max Viscosity Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. Centrifugal pumps work best with water and other low viscosity fluids. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than. Centrifugal Pump Max Viscosity.

From www.northridgepumps.com

Varisco J2 Series Self Priming Centrifugal Pump Centrifugal Pump Max Viscosity As illustrated in figure 13, two identical centrifugal pumps operating at. Efficiency is reduced when pumping viscous fluids. We will look at three types of pumps specifically:. Centrifugal pumps work best with water and other low viscosity fluids. Depending on the pump type, the impact of liquid viscosity is different. Centrifugal pump published performance curves are based on water and. Centrifugal Pump Max Viscosity.

From www.youtube.com

Centrifugal Pump Basics How centrifugal pumps work working principle hvacr YouTube Centrifugal Pump Max Viscosity As illustrated in figure 13, two identical centrifugal pumps operating at. Efficiency is reduced when pumping viscous fluids. We will look at three types of pumps specifically:. Depending on the pump type, the impact of liquid viscosity is different. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific gravity@15°c/60°f. Depending on the. Centrifugal Pump Max Viscosity.

From shuanghaijt.en.made-in-china.com

Stainless Steel SingleStage High Viscosity Chemical Circulating Drive Pump China Centrifugal Pump Max Viscosity Centrifugal pump published performance curves are based on water and so when moving viscous fluids the performance must be corrected. Depending on the pump type, the impact of liquid viscosity is different. We will look at three types of pumps specifically:. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from. Centrifugal Pump Max Viscosity.

From amarineblog.com

CENTRIFUGAL PUMP (Introduction) AMARINE Centrifugal Pump Max Viscosity Depending on the pump type, the impact of liquid viscosity is different. Depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary from 250 to 700 centipoise, and i have witnessed many pumps successfully pumping fluids in excess of 1000 centipoise. Centrifugal pumps work best with water and other low viscosity fluids.. Centrifugal Pump Max Viscosity.