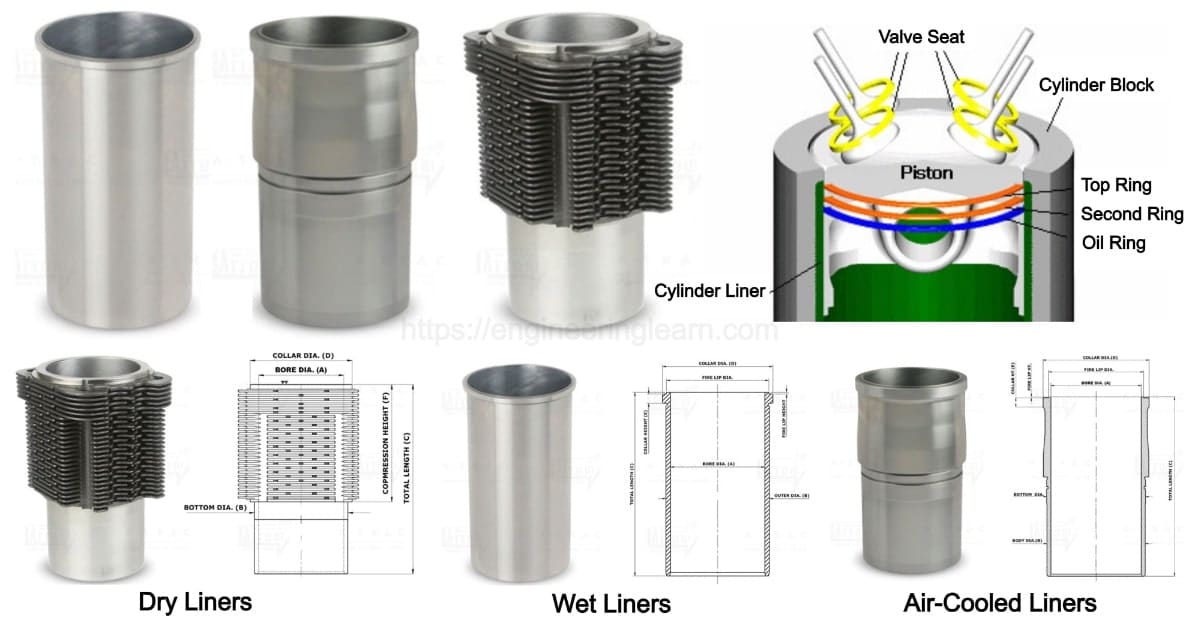

Cylinder Liner Disadvantages . Most aluminum cylinder blocks are fitted with steel, or ductile iron cylinder bore liners. Engine designers can utilise various. Cylinder liners can be made with specific surface treatments and finishes for better lubrication. A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. Dusty atmospherics air is more harmful as it increases friction in the cylinder. The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. Cylinder liners add weight to the engine due to the additional material used. In internal combustion engines, the cylinder liner. An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. Advantage of air cooled/finned type cylinder liner is that it is resistant to corrosion and it has very effective heat dissipation. Compatibility with various piston materials; Here are some of the disadvantages associated with the use of cylinder liners: Cylinder corrosion, a key cylinder liner function, is caused by corrosive products of combustion, which are formed.

from engineeringlearn.com

Here are some of the disadvantages associated with the use of cylinder liners: Compatibility with various piston materials; Advantage of air cooled/finned type cylinder liner is that it is resistant to corrosion and it has very effective heat dissipation. Engine designers can utilise various. In internal combustion engines, the cylinder liner. Dusty atmospherics air is more harmful as it increases friction in the cylinder. Cylinder liners add weight to the engine due to the additional material used. A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. Cylinder corrosion, a key cylinder liner function, is caused by corrosive products of combustion, which are formed.

Cylinder Liner Types and Function Engineering Learn

Cylinder Liner Disadvantages A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. Dusty atmospherics air is more harmful as it increases friction in the cylinder. Compatibility with various piston materials; Cylinder corrosion, a key cylinder liner function, is caused by corrosive products of combustion, which are formed. Advantage of air cooled/finned type cylinder liner is that it is resistant to corrosion and it has very effective heat dissipation. Engine designers can utilise various. Cylinder liners add weight to the engine due to the additional material used. An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. In internal combustion engines, the cylinder liner. Here are some of the disadvantages associated with the use of cylinder liners: Most aluminum cylinder blocks are fitted with steel, or ductile iron cylinder bore liners. Cylinder liners can be made with specific surface treatments and finishes for better lubrication.

From www.slideserve.com

PPT Types of Cylinder Liners and The Advantages PowerPoint Cylinder Liner Disadvantages A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. In internal combustion engines, the cylinder liner. An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. Here are some of the disadvantages associated with the use of cylinder liners: Most aluminum cylinder blocks are fitted with steel, or. Cylinder Liner Disadvantages.

From www.semanticscholar.org

Figure 2 from Failure Investigation and ThermoMechanical Analysis of Cylinder Liner Disadvantages The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. Engine designers can utilise various. In internal combustion engines, the cylinder liner. Advantage of air cooled/finned type cylinder liner is that it is resistant to corrosion and it has very effective heat dissipation. Cylinder liners can be made with specific surface treatments. Cylinder Liner Disadvantages.

From anandliners.com

Understanding the difference between dry and wet cylinder liners Cylinder Liner Disadvantages Dusty atmospherics air is more harmful as it increases friction in the cylinder. Advantage of air cooled/finned type cylinder liner is that it is resistant to corrosion and it has very effective heat dissipation. Cylinder liners can be made with specific surface treatments and finishes for better lubrication. Cylinder corrosion, a key cylinder liner function, is caused by corrosive products. Cylinder Liner Disadvantages.

From www.hars.com.tr

What are the types of Cylinder Liner? HARS Cylinder Liner Disadvantages An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. Cylinder liners add weight to the engine due to the additional material used. Cylinder corrosion, a key cylinder liner function, is caused by corrosive products of combustion, which are formed. A cylinder liner is a cylindrical component that is inserted into an engine block to form a. Cylinder Liner Disadvantages.

From www.exportersindia.com

Cylinder Liner R R Industries, Rajkot, Gujarat Cylinder Liner Disadvantages Cylinder liners can be made with specific surface treatments and finishes for better lubrication. Here are some of the disadvantages associated with the use of cylinder liners: Most aluminum cylinder blocks are fitted with steel, or ductile iron cylinder bore liners. An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. The main disadvantage of iron being. Cylinder Liner Disadvantages.

From www.researchgate.net

Boundary constraints of cylinder liner. Download Scientific Diagram Cylinder Liner Disadvantages Compatibility with various piston materials; Engine designers can utilise various. Cylinder liners can be made with specific surface treatments and finishes for better lubrication. Cylinder corrosion, a key cylinder liner function, is caused by corrosive products of combustion, which are formed. An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. Most aluminum cylinder blocks are fitted. Cylinder Liner Disadvantages.

From www.slideshare.net

How to know when you need to change your cylinder liners points that Cylinder Liner Disadvantages Dusty atmospherics air is more harmful as it increases friction in the cylinder. Advantage of air cooled/finned type cylinder liner is that it is resistant to corrosion and it has very effective heat dissipation. Compatibility with various piston materials; The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. In internal combustion. Cylinder Liner Disadvantages.

From www.pinterest.co.uk

Distinguish Between Dry Cylinder Liners And Wet Cylinder Liners Cylinder Liner Disadvantages In internal combustion engines, the cylinder liner. The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. Engine designers can utilise various. A cylinder liner is a cylindrical component that is inserted into an engine block to form a. Cylinder Liner Disadvantages.

From www.researchgate.net

(PDF) Thermo Mechanical analysis of Cylinder Liner Cylinder Liner Disadvantages Engine designers can utilise various. Cylinder corrosion, a key cylinder liner function, is caused by corrosive products of combustion, which are formed. Dusty atmospherics air is more harmful as it increases friction in the cylinder. Cylinder liners add weight to the engine due to the additional material used. Here are some of the disadvantages associated with the use of cylinder. Cylinder Liner Disadvantages.

From www.atracparts.com

Different Types of Cylinder Liner Dry Cylinder Liners vs. Wet Cylinder Liner Disadvantages Cylinder liners can be made with specific surface treatments and finishes for better lubrication. Here are some of the disadvantages associated with the use of cylinder liners: Dusty atmospherics air is more harmful as it increases friction in the cylinder. An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. Cylinder liners add weight to the engine. Cylinder Liner Disadvantages.

From mechanicaljungle.com

What Is Cylinder Liner? Material for Cylinder Liner Function of Cylinder Liner Disadvantages Cylinder liners can be made with specific surface treatments and finishes for better lubrication. Here are some of the disadvantages associated with the use of cylinder liners: The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. A cylinder liner is a cylindrical component that is inserted into an engine block to. Cylinder Liner Disadvantages.

From www.slideserve.com

PPT Cylinder Liners PowerPoint Presentation, free download ID2134219 Cylinder Liner Disadvantages Cylinder corrosion, a key cylinder liner function, is caused by corrosive products of combustion, which are formed. Cylinder liners can be made with specific surface treatments and finishes for better lubrication. The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. A cylinder liner is a cylindrical component that is inserted into. Cylinder Liner Disadvantages.

From marineprogress.com

Two Stroke Engine Cylinder Liner Marine Progress Cylinder Liner Disadvantages Engine designers can utilise various. Dusty atmospherics air is more harmful as it increases friction in the cylinder. Compatibility with various piston materials; Here are some of the disadvantages associated with the use of cylinder liners: Advantage of air cooled/finned type cylinder liner is that it is resistant to corrosion and it has very effective heat dissipation. Cylinder corrosion, a. Cylinder Liner Disadvantages.

From medium.com

What is the Cylinder Liner? Types and Function. by Technical Cylinder Liner Disadvantages Most aluminum cylinder blocks are fitted with steel, or ductile iron cylinder bore liners. In internal combustion engines, the cylinder liner. The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. Advantage of air. Cylinder Liner Disadvantages.

From www.slideserve.com

PPT Cylinder liner PowerPoint Presentation, free download ID9196633 Cylinder Liner Disadvantages Cylinder liners add weight to the engine due to the additional material used. A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. Advantage of air cooled/finned type cylinder liner is that it is resistant to corrosion and it. Cylinder Liner Disadvantages.

From www.ijraset.com

Design and Analysis of Cylinder Liner with Different Coatings Cylinder Liner Disadvantages Here are some of the disadvantages associated with the use of cylinder liners: Compatibility with various piston materials; Cylinder corrosion, a key cylinder liner function, is caused by corrosive products of combustion, which are formed. Most aluminum cylinder blocks are fitted with steel, or ductile iron cylinder bore liners. Cylinder liners can be made with specific surface treatments and finishes. Cylinder Liner Disadvantages.

From slideplayer.com

A New Test Rig for Simulation of Piston Ring Friction ppt video Cylinder Liner Disadvantages The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. Cylinder liners add weight to the engine due to the additional material used. Compatibility with various piston materials; An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. Engine designers can utilise various. Advantage of air cooled/finned type cylinder. Cylinder Liner Disadvantages.

From www.youtube.com

Cylinder Liners Remove and Fit YouTube Cylinder Liner Disadvantages Dusty atmospherics air is more harmful as it increases friction in the cylinder. In internal combustion engines, the cylinder liner. Advantage of air cooled/finned type cylinder liner is that it is resistant to corrosion and it has very effective heat dissipation. A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. Most. Cylinder Liner Disadvantages.

From engineeringlearn.com

Cylinder Liner Types and Function Engineering Learn Cylinder Liner Disadvantages Here are some of the disadvantages associated with the use of cylinder liners: An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. Compatibility with various piston materials; Engine designers can utilise various. Cylinder liners add weight to the. Cylinder Liner Disadvantages.

From www.mdpi.com

Energies Free FullText Structural Performance of Additively Cylinder Liner Disadvantages An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. Advantage of air cooled/finned type cylinder liner is that it is resistant to corrosion and it has very effective heat dissipation. Dusty atmospherics air is more harmful as it increases friction in the cylinder. Most aluminum cylinder blocks are fitted with steel, or ductile iron cylinder bore. Cylinder Liner Disadvantages.

From www.slideserve.com

PPT Cylinder liner PowerPoint Presentation, free download ID9196633 Cylinder Liner Disadvantages Advantage of air cooled/finned type cylinder liner is that it is resistant to corrosion and it has very effective heat dissipation. Dusty atmospherics air is more harmful as it increases friction in the cylinder. The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. Here are some of the disadvantages associated with. Cylinder Liner Disadvantages.

From aspiringyouths.com

Advantages and Disadvantages of Cylinder Liners Cylinder Liner Disadvantages Cylinder liners can be made with specific surface treatments and finishes for better lubrication. Cylinder corrosion, a key cylinder liner function, is caused by corrosive products of combustion, which are formed. Compatibility with various piston materials; A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. Dusty atmospherics air is more harmful. Cylinder Liner Disadvantages.

From www.slideserve.com

PPT All you need to Know about Cylinder Liners PowerPoint Cylinder Liner Disadvantages The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. Cylinder liners add weight to the engine due to the additional. Cylinder Liner Disadvantages.

From mechathon.com

What is Cylinder Block and Cylinder Liner? Types of Liners Cylinder Liner Disadvantages Cylinder liners can be made with specific surface treatments and finishes for better lubrication. A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. Compatibility with various piston materials; Engine designers can utilise various. The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum.. Cylinder Liner Disadvantages.

From www.hc-enginepart.com

Cylinder liner failure reasons Cylinder Liner Disadvantages Dusty atmospherics air is more harmful as it increases friction in the cylinder. Cylinder liners can be made with specific surface treatments and finishes for better lubrication. A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. Engine designers can utilise various. An aluminum piston skin rubbing against an aluminum cylinder wall. Cylinder Liner Disadvantages.

From www.youtube.com

Cylinder liner honing INJEGOV SA YouTube Cylinder Liner Disadvantages An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. Engine designers can utilise various. Here are some of the disadvantages associated with the use of cylinder liners: Dusty atmospherics air is more harmful as it increases friction in the cylinder. Compatibility with various piston materials; Cylinder liners can be made with specific surface treatments and finishes. Cylinder Liner Disadvantages.

From www.atracparts.com

Atrac Engineering Company Blog Cylinder Liner Disadvantages The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. Here are some of the disadvantages associated with the use of cylinder liners: Cylinder liners add weight to the engine due to the additional material used. Cylinder corrosion, a key cylinder liner function, is caused by corrosive products of combustion, which are. Cylinder Liner Disadvantages.

From www.engineeringchoice.com

What is Cylinder Liner? Function and Types Engineering Choice Cylinder Liner Disadvantages An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. Most aluminum cylinder blocks are fitted with steel, or ductile iron cylinder bore liners. Cylinder liners add weight to the engine due to the additional material used. Here are some of the disadvantages associated with the use of cylinder liners: The main disadvantage of iron being is. Cylinder Liner Disadvantages.

From dokumen.tips

(PPT) Cylinder liners DOKUMEN.TIPS Cylinder Liner Disadvantages Dusty atmospherics air is more harmful as it increases friction in the cylinder. Here are some of the disadvantages associated with the use of cylinder liners: In internal combustion engines, the cylinder liner. Most aluminum cylinder blocks are fitted with steel, or ductile iron cylinder bore liners. Engine designers can utilise various. Advantage of air cooled/finned type cylinder liner is. Cylinder Liner Disadvantages.

From ghaemg.com

?What is Cylinder Liner/Material cylinder liner گروه صنعتی قائم Cylinder Liner Disadvantages Cylinder liners add weight to the engine due to the additional material used. Engine designers can utilise various. Dusty atmospherics air is more harmful as it increases friction in the cylinder. In internal combustion engines, the cylinder liner. A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. Advantage of air cooled/finned. Cylinder Liner Disadvantages.

From tk.ghaemg.com

Liner Failure Analysis and key points for how to work and repair the Cylinder Liner Disadvantages Most aluminum cylinder blocks are fitted with steel, or ductile iron cylinder bore liners. Dusty atmospherics air is more harmful as it increases friction in the cylinder. The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly. A cylinder. Cylinder Liner Disadvantages.

From mechanicaljungle.com

What Is Cylinder Liner? Material for Cylinder Liner Function of Cylinder Liner Disadvantages Cylinder corrosion, a key cylinder liner function, is caused by corrosive products of combustion, which are formed. Advantage of air cooled/finned type cylinder liner is that it is resistant to corrosion and it has very effective heat dissipation. A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. Engine designers can utilise. Cylinder Liner Disadvantages.

From www.youtube.com

HOW TO REMOVE CYLINDER LINER YouTube Cylinder Liner Disadvantages A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. Here are some of the disadvantages associated with the use of cylinder liners: The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. Compatibility with various piston materials; Most aluminum cylinder blocks are fitted. Cylinder Liner Disadvantages.

From mechanicaljungle.com

What Is Cylinder Liner? Material for Cylinder Liner Function of Cylinder Liner Disadvantages In internal combustion engines, the cylinder liner. Most aluminum cylinder blocks are fitted with steel, or ductile iron cylinder bore liners. A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. Compatibility with various piston materials; Advantage of air cooled/finned type cylinder liner is that it is resistant to corrosion and it. Cylinder Liner Disadvantages.

From themechanicalengineering.com

Cylinder Liner Definition, Function, Types, Material [Notes & PDF] Cylinder Liner Disadvantages A cylinder liner is a cylindrical component that is inserted into an engine block to form a cylinder. The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum. Cylinder corrosion, a key cylinder liner function, is caused by corrosive products of combustion, which are formed. In internal combustion engines, the cylinder liner.. Cylinder Liner Disadvantages.