Cooling System For Injection Molding Machine . Minimize use of sealing rings: Explore different options for efficient mold cooling systems. Air cooling system and water cooling system. The injection mold cooling system is a critical aspect of mold design that significantly impacts the quality of molded parts and the. Chiller, corrosion, scale, or leaks in the mold itself. Use rapid cooling for standard molds to shorten the molding cycle and gradual cooling for precision molds, incorporating mold thermometers. Learn how to optimize cooling in injection mold to improve cycle time and quality of plastic parts. Key considerations in cooling system design 1. There are two standard methods for injection molding machine cooling systems: Efficient cooling systems help overcome these realities, enabling mold designers to balance. Cooling methods for different molds: The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to.

from alphadescaler.com

Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. The injection mold cooling system is a critical aspect of mold design that significantly impacts the quality of molded parts and the. There are two standard methods for injection molding machine cooling systems: Efficient cooling systems help overcome these realities, enabling mold designers to balance. Minimize use of sealing rings: Cooling methods for different molds: Learn how to optimize cooling in injection mold to improve cycle time and quality of plastic parts. Air cooling system and water cooling system. Key considerations in cooling system design 1. The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with.

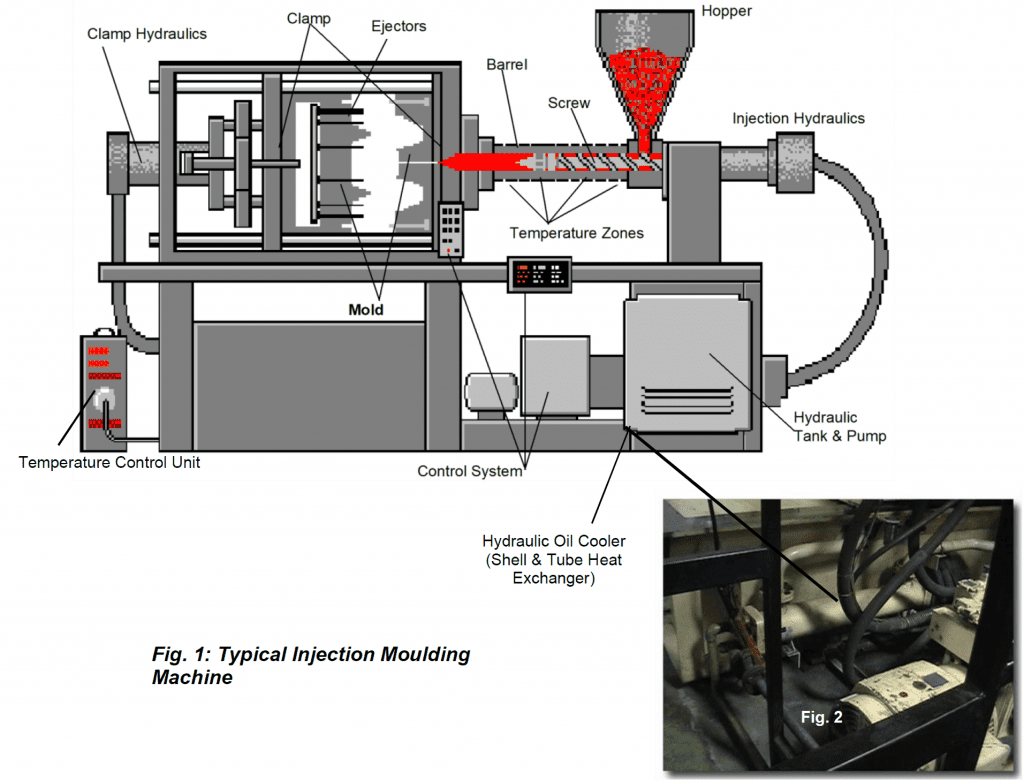

Injection Moulding & The Plastics Industry

Cooling System For Injection Molding Machine The injection mold cooling system is a critical aspect of mold design that significantly impacts the quality of molded parts and the. Learn how to optimize cooling in injection mold to improve cycle time and quality of plastic parts. Air cooling system and water cooling system. The injection mold cooling system is a critical aspect of mold design that significantly impacts the quality of molded parts and the. Chiller, corrosion, scale, or leaks in the mold itself. Key considerations in cooling system design 1. Minimize use of sealing rings: Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. Use rapid cooling for standard molds to shorten the molding cycle and gradual cooling for precision molds, incorporating mold thermometers. Explore different options for efficient mold cooling systems. Cooling methods for different molds: Efficient cooling systems help overcome these realities, enabling mold designers to balance. There are two standard methods for injection molding machine cooling systems: The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with.

From chinaplasticmoulding.blogspot.com

the installation process for injection mold Cooling System For Injection Molding Machine Minimize use of sealing rings: Use rapid cooling for standard molds to shorten the molding cycle and gradual cooling for precision molds, incorporating mold thermometers. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. There are two standard methods for injection molding machine cooling systems: Chiller, corrosion, scale, or leaks. Cooling System For Injection Molding Machine.

From www.youtube.com

Balance and Optimize Mold Cooling for Improved Molded Part Quality Cooling System For Injection Molding Machine Air cooling system and water cooling system. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. Key considerations in cooling system design 1. Use rapid cooling for standard molds to shorten the molding cycle and gradual cooling for precision molds, incorporating mold thermometers. Explore different options for efficient mold cooling. Cooling System For Injection Molding Machine.

From www.linkedin.com

The Role of Cooling Towers in Injection Molding Machine Cooling System For Injection Molding Machine Learn how to optimize cooling in injection mold to improve cycle time and quality of plastic parts. The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. Key considerations in cooling system design 1. There are two standard methods for injection molding machine cooling systems: Minimize use of sealing rings: Air cooling system and. Cooling System For Injection Molding Machine.

From www.redsant.com

Injection Molding Machine Barrel Cooling System with RedsAnt Aerogel Cooling System For Injection Molding Machine Use rapid cooling for standard molds to shorten the molding cycle and gradual cooling for precision molds, incorporating mold thermometers. There are two standard methods for injection molding machine cooling systems: Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. Minimize use of sealing rings: The present paper has highlighted. Cooling System For Injection Molding Machine.

From www.linearams.com

Conformal Cooling Transforms Injection Molding Processes and Part Cooling System For Injection Molding Machine The injection mold cooling system is a critical aspect of mold design that significantly impacts the quality of molded parts and the. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. Minimize use of sealing rings: Cooling methods for different molds: The present paper has highlighted aspects of injection mold. Cooling System For Injection Molding Machine.

From cooling-tower.my

Injection molding working principle JH Cooling Machine Cooling System For Injection Molding Machine Cooling methods for different molds: The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. Air cooling system and water cooling system. Efficient cooling systems help overcome these realities, enabling mold designers to balance. Explore. Cooling System For Injection Molding Machine.

From cooling-tower.my

Injection molding working principle JH Cooling Machine Cooling System For Injection Molding Machine Learn how to optimize cooling in injection mold to improve cycle time and quality of plastic parts. Chiller, corrosion, scale, or leaks in the mold itself. The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. Minimize use of sealing rings: Explore different options for efficient mold cooling systems. Air cooling system and water. Cooling System For Injection Molding Machine.

From www.coowor.com

Closed 600kw cooling tower for injection molding machine Cooling System For Injection Molding Machine There are two standard methods for injection molding machine cooling systems: Learn how to optimize cooling in injection mold to improve cycle time and quality of plastic parts. The injection mold cooling system is a critical aspect of mold design that significantly impacts the quality of molded parts and the. Efficient cooling systems aid in overcoming these realities, allowing mold. Cooling System For Injection Molding Machine.

From www.oumalchiller.com

Cooling water circulation system in injection molding Cooling System For Injection Molding Machine The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. Air cooling system and water cooling system. Chiller, corrosion, scale, or leaks in the mold itself. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. Cooling methods for different molds: Explore different options for. Cooling System For Injection Molding Machine.

From www.hansenplastics.com

Cooling Rate in Injection Molding A Comprehensive Guide Cooling System For Injection Molding Machine Minimize use of sealing rings: Explore different options for efficient mold cooling systems. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. Key considerations in cooling system design 1. Air cooling system and water cooling system. There are two standard methods for injection molding machine cooling systems: Cooling methods for. Cooling System For Injection Molding Machine.

From www.hensim-life.com

Understanding Injection Molding Process Control Cooling System For Injection Molding Machine Key considerations in cooling system design 1. Use rapid cooling for standard molds to shorten the molding cycle and gradual cooling for precision molds, incorporating mold thermometers. The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time. Cooling System For Injection Molding Machine.

From ibcplastic.ru

Cooling by working systems of injection molding machines, PET and Cooling System For Injection Molding Machine Cooling methods for different molds: Air cooling system and water cooling system. The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. Explore different options for efficient mold cooling systems. Minimize use of sealing rings: There are two standard methods for injection molding machine cooling systems: Efficient cooling systems help overcome these realities, enabling. Cooling System For Injection Molding Machine.

From vrcoolertech.en.made-in-china.com

Economical Natural Cooling System for Injection Molding Machine China Cooling System For Injection Molding Machine Air cooling system and water cooling system. Minimize use of sealing rings: Explore different options for efficient mold cooling systems. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. Efficient cooling systems help overcome these realities, enabling mold designers to balance. Key considerations in cooling system design 1. Learn how. Cooling System For Injection Molding Machine.

From alphadescaler.com

Injection Moulding & The Plastics Industry Cooling System For Injection Molding Machine Air cooling system and water cooling system. There are two standard methods for injection molding machine cooling systems: Efficient cooling systems help overcome these realities, enabling mold designers to balance. Chiller, corrosion, scale, or leaks in the mold itself. Cooling methods for different molds: Use rapid cooling for standard molds to shorten the molding cycle and gradual cooling for precision. Cooling System For Injection Molding Machine.

From www.myplasticmold.com

Injection Molding Machine Components And Its Function Cooling System For Injection Molding Machine Key considerations in cooling system design 1. Efficient cooling systems help overcome these realities, enabling mold designers to balance. Learn how to optimize cooling in injection mold to improve cycle time and quality of plastic parts. Air cooling system and water cooling system. Explore different options for efficient mold cooling systems. There are two standard methods for injection molding machine. Cooling System For Injection Molding Machine.

From www.dreamstime.com

Close Up Cooling System or Water Hose of Plastic Injection Mold for Cooling System For Injection Molding Machine Minimize use of sealing rings: Cooling methods for different molds: Efficient cooling systems help overcome these realities, enabling mold designers to balance. Air cooling system and water cooling system. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. The injection mold cooling system is a critical aspect of mold design. Cooling System For Injection Molding Machine.

From china-plastic-injection-molding.com

How Does Plastic Injection Molding Work? Cooling System For Injection Molding Machine Use rapid cooling for standard molds to shorten the molding cycle and gradual cooling for precision molds, incorporating mold thermometers. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. The injection mold cooling system is a critical aspect of mold design that significantly impacts the quality of molded parts and. Cooling System For Injection Molding Machine.

From www.rjcmold.com

What Is Cooling System In Injection Molding RJC Mold Cooling System For Injection Molding Machine Learn how to optimize cooling in injection mold to improve cycle time and quality of plastic parts. Efficient cooling systems help overcome these realities, enabling mold designers to balance. There are two standard methods for injection molding machine cooling systems: Air cooling system and water cooling system. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage. Cooling System For Injection Molding Machine.

From cooling-towers.com.tw

Information Closed Circuit Cooling Tower Cooling System For Injection Molding Machine Learn how to optimize cooling in injection mold to improve cycle time and quality of plastic parts. The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. Cooling methods for different molds: Minimize use of sealing rings: The injection mold cooling system is a critical aspect of mold design that significantly impacts the quality. Cooling System For Injection Molding Machine.

From upmold.com

Plastic Injection Mold Cooling System Design Guideline Upmold Cooling System For Injection Molding Machine Key considerations in cooling system design 1. There are two standard methods for injection molding machine cooling systems: Efficient cooling systems help overcome these realities, enabling mold designers to balance. Explore different options for efficient mold cooling systems. Learn how to optimize cooling in injection mold to improve cycle time and quality of plastic parts. Minimize use of sealing rings:. Cooling System For Injection Molding Machine.

From www.coowor.com

25 ton FRP cooling tower for injection molding machine Cooling System For Injection Molding Machine Air cooling system and water cooling system. The injection mold cooling system is a critical aspect of mold design that significantly impacts the quality of molded parts and the. Chiller, corrosion, scale, or leaks in the mold itself. The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. Explore different options for efficient mold. Cooling System For Injection Molding Machine.

From www.redsant.com

Injection Molding Machine Barrel Cooling System with RedsAnt Aerogel Cooling System For Injection Molding Machine Efficient cooling systems help overcome these realities, enabling mold designers to balance. Explore different options for efficient mold cooling systems. Key considerations in cooling system design 1. Learn how to optimize cooling in injection mold to improve cycle time and quality of plastic parts. The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with.. Cooling System For Injection Molding Machine.

From winday.en.made-in-china.com

Air Cooled Water Chiller for Injection Moulding Machine China Chiller Cooling System For Injection Molding Machine Chiller, corrosion, scale, or leaks in the mold itself. There are two standard methods for injection molding machine cooling systems: Minimize use of sealing rings: Air cooling system and water cooling system. Learn how to optimize cooling in injection mold to improve cycle time and quality of plastic parts. Explore different options for efficient mold cooling systems. The present paper. Cooling System For Injection Molding Machine.

From www.echosupply.com

Injection Molding Basics Hot Runner Systems Echo Supply Cooling System For Injection Molding Machine Efficient cooling systems help overcome these realities, enabling mold designers to balance. Use rapid cooling for standard molds to shorten the molding cycle and gradual cooling for precision molds, incorporating mold thermometers. Key considerations in cooling system design 1. Minimize use of sealing rings: The injection mold cooling system is a critical aspect of mold design that significantly impacts the. Cooling System For Injection Molding Machine.

From www.autoinjectionmoldingmachine.com

Professional 300T Water Cooling Tower For Plastic Injection Molding Machine Cooling System For Injection Molding Machine Chiller, corrosion, scale, or leaks in the mold itself. Key considerations in cooling system design 1. Minimize use of sealing rings: Explore different options for efficient mold cooling systems. Use rapid cooling for standard molds to shorten the molding cycle and gradual cooling for precision molds, incorporating mold thermometers. The injection mold cooling system is a critical aspect of mold. Cooling System For Injection Molding Machine.

From mstcooling.en.made-in-china.com

200ton Water Chiller Systems Cooling Tower for Injection Molding Cooling System For Injection Molding Machine Explore different options for efficient mold cooling systems. The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. Air cooling system and water cooling system. Cooling methods for different molds: Key considerations in cooling system design 1. Chiller, corrosion, scale, or leaks in the mold itself. Efficient cooling systems help overcome these realities, enabling. Cooling System For Injection Molding Machine.

From www.elastron.com

Vent, Screw and Cooling Designs Injection Molding Elastron TPE Cooling System For Injection Molding Machine The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. The injection mold cooling system is a critical aspect of mold design that significantly impacts the quality of molded parts and the. There are two standard methods for injection molding machine cooling systems: Air cooling system and water cooling system. Efficient cooling systems help. Cooling System For Injection Molding Machine.

From www.rnaautomation.com

Robotics in Injection Moulding RNA Automation Cooling System For Injection Molding Machine Air cooling system and water cooling system. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. Minimize use of sealing rings: There are two standard methods for injection molding machine cooling systems: Cooling methods for different molds: The present paper has highlighted aspects of injection mold cooling where opportunities for. Cooling System For Injection Molding Machine.

From www.coowor.com

8hp industry cooling system for injection molding machine Cooling System For Injection Molding Machine Use rapid cooling for standard molds to shorten the molding cycle and gradual cooling for precision molds, incorporating mold thermometers. Efficient cooling systems help overcome these realities, enabling mold designers to balance. Key considerations in cooling system design 1. Chiller, corrosion, scale, or leaks in the mold itself. Learn how to optimize cooling in injection mold to improve cycle time. Cooling System For Injection Molding Machine.

From info.crescentind.com

Cooling Methods and Design in Injection Molding Cooling System For Injection Molding Machine The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. Cooling methods for different molds: Air cooling system and water cooling system. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. Minimize use of sealing rings: Key considerations in cooling system design 1. Efficient. Cooling System For Injection Molding Machine.

From www.indiamart.com

WINDX FRP Cooling Tower For Injection Moulding Machine, Induced Draft Cooling System For Injection Molding Machine Air cooling system and water cooling system. Learn how to optimize cooling in injection mold to improve cycle time and quality of plastic parts. Efficient cooling systems help overcome these realities, enabling mold designers to balance. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. Minimize use of sealing rings:. Cooling System For Injection Molding Machine.

From www.basilius.com

Understanding the Injection Mold Process Basilius Inc. Cooling System For Injection Molding Machine Chiller, corrosion, scale, or leaks in the mold itself. Key considerations in cooling system design 1. Cooling methods for different molds: The injection mold cooling system is a critical aspect of mold design that significantly impacts the quality of molded parts and the. Air cooling system and water cooling system. Minimize use of sealing rings: Efficient cooling systems aid in. Cooling System For Injection Molding Machine.

From www.redsant.com

Injection Molding Machine Barrel Cooling System with RedsAnt Aerogel Cooling System For Injection Molding Machine Key considerations in cooling system design 1. Use rapid cooling for standard molds to shorten the molding cycle and gradual cooling for precision molds, incorporating mold thermometers. Efficient cooling systems help overcome these realities, enabling mold designers to balance. Minimize use of sealing rings: Chiller, corrosion, scale, or leaks in the mold itself. There are two standard methods for injection. Cooling System For Injection Molding Machine.

From www.wsmcmold.com

mold Cooling System Composites compression molding and plastic Cooling System For Injection Molding Machine Key considerations in cooling system design 1. The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. Efficient cooling systems aid in overcoming these realities, allowing mold designers to manage temperature, pressure, and time tradeoffs to. Chiller, corrosion, scale, or leaks in the mold itself. The injection mold cooling system is a critical aspect. Cooling System For Injection Molding Machine.

From www.arptech.com.au

Injection Moulding Process Explained ArpTechBlog Cooling System For Injection Molding Machine Key considerations in cooling system design 1. The present paper has highlighted aspects of injection mold cooling where opportunities for optimization exist with. There are two standard methods for injection molding machine cooling systems: Cooling methods for different molds: Minimize use of sealing rings: The injection mold cooling system is a critical aspect of mold design that significantly impacts the. Cooling System For Injection Molding Machine.