Nickel Plating Processes . It results in parts with improved corrosion resistance, wear resistance, and hardness. The basics of electroplating are addressed and it is focussed on the operation of the plating bath. Nickel plating is used for decorative, engineering, and electroforming purposes. The typical base metals for nickel plating are steel, copper alloys,. Control of nickel plating processes. In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so the plating can be applied. The core material or substrate is first cleaned to ensure a spotless. Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. Learn about the difference between electrolytic and electroless nickel plating, common applications for each and our design guide to specify nickel plating for your parts. The electroless nickel plating process consists of a simple chemical chain reaction.

from narodnatribuna.info

The basics of electroplating are addressed and it is focussed on the operation of the plating bath. The electroless nickel plating process consists of a simple chemical chain reaction. Nickel plating is used for decorative, engineering, and electroforming purposes. The core material or substrate is first cleaned to ensure a spotless. Control of nickel plating processes. In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so the plating can be applied. Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. It results in parts with improved corrosion resistance, wear resistance, and hardness. Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. Learn about the difference between electrolytic and electroless nickel plating, common applications for each and our design guide to specify nickel plating for your parts.

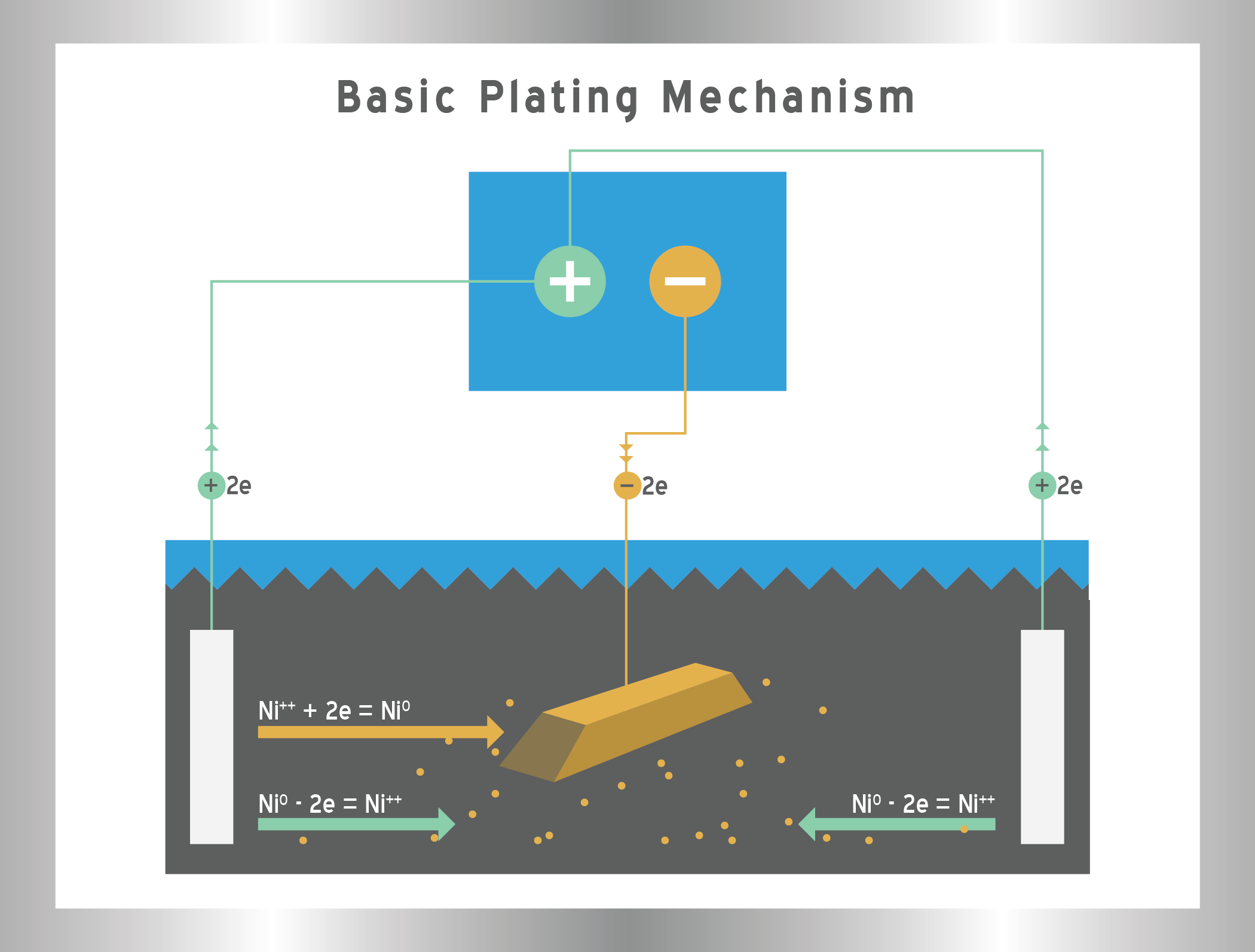

Electroplating Diagram

Nickel Plating Processes Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. Nickel plating is used for decorative, engineering, and electroforming purposes. The basics of electroplating are addressed and it is focussed on the operation of the plating bath. Control of nickel plating processes. Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so the plating can be applied. The electroless nickel plating process consists of a simple chemical chain reaction. It results in parts with improved corrosion resistance, wear resistance, and hardness. Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. The typical base metals for nickel plating are steel, copper alloys,. The core material or substrate is first cleaned to ensure a spotless. Learn about the difference between electrolytic and electroless nickel plating, common applications for each and our design guide to specify nickel plating for your parts.

From flowchart.chartexamples.com

Electroless Nickel Plating Process Flow Chart Flowchart Examples Nickel Plating Processes Nickel plating is used for decorative, engineering, and electroforming purposes. In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so the plating can be applied. The typical base metals for nickel plating are steel, copper alloys,. The electroless nickel plating process consists of a simple chemical chain reaction. The core material. Nickel Plating Processes.

From www.youtube.com

PH Tool's Nickel Plating Process YouTube Nickel Plating Processes The typical base metals for nickel plating are steel, copper alloys,. Nickel plating is used for decorative, engineering, and electroforming purposes. The electroless nickel plating process consists of a simple chemical chain reaction. It results in parts with improved corrosion resistance, wear resistance, and hardness. Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a. Nickel Plating Processes.

From blog.thepipingmart.com

Brush Nickel Plating Process An Brief Overview Nickel Plating Processes The typical base metals for nickel plating are steel, copper alloys,. It results in parts with improved corrosion resistance, wear resistance, and hardness. The core material or substrate is first cleaned to ensure a spotless. Control of nickel plating processes. In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so the. Nickel Plating Processes.

From www.sharrettsplating.com

Electroless Nickel Plating Sharretts Plating Nickel Plating Processes Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. Learn about the difference between electrolytic and electroless nickel plating, common applications for each and our design guide to specify nickel plating for your parts. The electroless nickel plating process consists of a simple chemical chain reaction. Control of nickel plating. Nickel Plating Processes.

From jmmm.material.chula.ac.th

Recovery of nickel from spent electroplating solution by hydrometallurgical and Nickel Plating Processes The electroless nickel plating process consists of a simple chemical chain reaction. The basics of electroplating are addressed and it is focussed on the operation of the plating bath. Nickel plating is used for decorative, engineering, and electroforming purposes. Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. Learn about. Nickel Plating Processes.

From www.youtube.com

Nickel Plating Process. How Perform nickel electroplating. Complete nickel plating process Nickel Plating Processes Learn about the difference between electrolytic and electroless nickel plating, common applications for each and our design guide to specify nickel plating for your parts. Nickel plating is used for decorative, engineering, and electroforming purposes. The core material or substrate is first cleaned to ensure a spotless. The typical base metals for nickel plating are steel, copper alloys,. Nickel electroplating. Nickel Plating Processes.

From www.sunrise-metal.com

Nickel Plating Aluminum Electropalting Aluminum Nickel Plating Processes The typical base metals for nickel plating are steel, copper alloys,. Control of nickel plating processes. Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. It results in parts with improved corrosion resistance, wear resistance, and hardness. The core material or substrate is first cleaned to ensure a spotless. The basics. Nickel Plating Processes.

From blog.thepipingmart.com

Copper Nickel Plating Process An Overview Nickel Plating Processes Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. Nickel plating is used for decorative, engineering, and electroforming purposes. The electroless nickel plating process consists of a simple chemical chain reaction. Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. Control. Nickel Plating Processes.

From www.researchgate.net

Reactions performed during the nickel electroplating process Download Scientific Diagram Nickel Plating Processes Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. The typical base metals for nickel plating are steel, copper alloys,. Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. In order for parts to be plated, they must be clean and. Nickel Plating Processes.

From ar.inspiredpencil.com

Nickel Electroplating Process Nickel Plating Processes Nickel plating is used for decorative, engineering, and electroforming purposes. The electroless nickel plating process consists of a simple chemical chain reaction. The core material or substrate is first cleaned to ensure a spotless. Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. The typical base metals for nickel plating are. Nickel Plating Processes.

From peregrinemetalfinishing.com

Zinc Nickel Plating Services Zinc Nickel Plating Company Nickel Plating Processes The typical base metals for nickel plating are steel, copper alloys,. The electroless nickel plating process consists of a simple chemical chain reaction. Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external.. Nickel Plating Processes.

From www.researchgate.net

Schematic of the nickel electrodeposition process Download Scientific Diagram Nickel Plating Processes Control of nickel plating processes. The basics of electroplating are addressed and it is focussed on the operation of the plating bath. Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. It results in parts with improved corrosion resistance, wear resistance, and hardness. Learn about the difference between electrolytic and electroless. Nickel Plating Processes.

From www.iqsdirectory.com

Electroless Nickel Plating Variations, Types, Applications, and Benefits Nickel Plating Processes Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. Control of nickel plating processes. The electroless nickel plating process consists of a simple chemical chain reaction. The typical base metals for nickel plating are steel, copper alloys,. The basics of electroplating are addressed and it is focussed on the operation of. Nickel Plating Processes.

From www.youtube.com

Electroless Nickel Plating Process for Aluminum Parts YouTube Nickel Plating Processes Nickel plating is used for decorative, engineering, and electroforming purposes. The basics of electroplating are addressed and it is focussed on the operation of the plating bath. The electroless nickel plating process consists of a simple chemical chain reaction. The typical base metals for nickel plating are steel, copper alloys,. Control of nickel plating processes. Nickel electroplating is a process. Nickel Plating Processes.

From www.sharrettsplating.com

5 Unique Electroless Nickel Plating Processes SPC Blog Nickel Plating Processes Control of nickel plating processes. The electroless nickel plating process consists of a simple chemical chain reaction. Nickel plating is used for decorative, engineering, and electroforming purposes. It results in parts with improved corrosion resistance, wear resistance, and hardness. In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so the plating. Nickel Plating Processes.

From www.wikihow.com

How to Do At Home Nickel Plating Everything You Need to Know Nickel Plating Processes In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so the plating can be applied. The basics of electroplating are addressed and it is focussed on the operation of the plating bath. The core material or substrate is first cleaned to ensure a spotless. Learn about the difference between electrolytic and. Nickel Plating Processes.

From www.mdpi.com

Free FullText Finishing of Chemically Treated Nickel Plating Processes Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. The basics of electroplating are addressed and it is focussed on the operation of the plating bath. Nickel plating is used for decorative, engineering, and electroforming purposes. It results in parts with improved corrosion resistance, wear resistance, and hardness. Learn about. Nickel Plating Processes.

From ar.inspiredpencil.com

Nickel Electroplating Process Nickel Plating Processes Control of nickel plating processes. Learn about the difference between electrolytic and electroless nickel plating, common applications for each and our design guide to specify nickel plating for your parts. The typical base metals for nickel plating are steel, copper alloys,. Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition.. Nickel Plating Processes.

From narodnatribuna.info

Electroplating Diagram Nickel Plating Processes Learn about the difference between electrolytic and electroless nickel plating, common applications for each and our design guide to specify nickel plating for your parts. The electroless nickel plating process consists of a simple chemical chain reaction. In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so the plating can be. Nickel Plating Processes.

From www.youtube.com

Chemical Stripping Nickel Plating Process Automated Deplating Nickel from Brass YouTube Nickel Plating Processes Nickel plating is used for decorative, engineering, and electroforming purposes. The electroless nickel plating process consists of a simple chemical chain reaction. In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so the plating can be applied. Control of nickel plating processes. Electroless nickel plating is an autocatalytic process that deposits. Nickel Plating Processes.

From myportal.dixonvalve.com

Nickel Plating Process Dixon Nickel Plating Processes The basics of electroplating are addressed and it is focussed on the operation of the plating bath. It results in parts with improved corrosion resistance, wear resistance, and hardness. The electroless nickel plating process consists of a simple chemical chain reaction. In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so. Nickel Plating Processes.

From www.youtube.com

Nickel plating on brass. Complete nickel plating process on brass parts. how nickel plating on Nickel Plating Processes Learn about the difference between electrolytic and electroless nickel plating, common applications for each and our design guide to specify nickel plating for your parts. Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. The basics of electroplating are addressed and it is focussed on the operation of the plating bath.. Nickel Plating Processes.

From www.youtube.com

Metal Plating Process A Complete Guide To Its Types And Technique. YouTube Nickel Plating Processes In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so the plating can be applied. The electroless nickel plating process consists of a simple chemical chain reaction. Learn about the difference between electrolytic and electroless nickel plating, common applications for each and our design guide to specify nickel plating for your. Nickel Plating Processes.

From www.youtube.com

Electroless plating process/Electroless deposition Corrosion Control YouTube Nickel Plating Processes The core material or substrate is first cleaned to ensure a spotless. Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. Learn about the difference between electrolytic and electroless nickel plating, common applications for each and our design guide to specify nickel plating for your parts. The basics of electroplating. Nickel Plating Processes.

From www.semanticscholar.org

[PDF] NICKEL PLATING HANDBOOK Semantic Scholar Nickel Plating Processes It results in parts with improved corrosion resistance, wear resistance, and hardness. The core material or substrate is first cleaned to ensure a spotless. Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. The typical base metals for nickel plating are steel, copper alloys,. In order for parts to be plated,. Nickel Plating Processes.

From www.researchgate.net

Schematic illustration of the nickel plating process. Download Scientific Diagram Nickel Plating Processes Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. Learn about the difference between electrolytic and electroless nickel plating, common applications for each and our design guide to specify nickel plating for your parts. It results in parts with improved corrosion resistance, wear resistance, and hardness. The basics of electroplating are. Nickel Plating Processes.

From www.youtube.com

How to Nickel Electroplate at Home bittech Modding YouTube Nickel Plating Processes It results in parts with improved corrosion resistance, wear resistance, and hardness. In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so the plating can be applied. The typical base metals for nickel plating are steel, copper alloys,. Nickel electroplating is a process of applying a nickel coating onto a metal. Nickel Plating Processes.

From www.worthyhardware.com

Nickel Electroplating CNC Precision Machining Service Nickel Plating Processes Control of nickel plating processes. Nickel plating is used for decorative, engineering, and electroforming purposes. The electroless nickel plating process consists of a simple chemical chain reaction. Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. It results in parts with improved corrosion resistance, wear resistance, and hardness. The core. Nickel Plating Processes.

From www.researchgate.net

Flowchart of the electroplating process Download Scientific Diagram Nickel Plating Processes Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. The core material or substrate is first cleaned to ensure a spotless. Learn about the difference between electrolytic and electroless nickel plating, common applications for each and our design guide to specify nickel plating for your parts. The typical base metals for. Nickel Plating Processes.

From www.researchgate.net

Schematic illustration of the nickel plating process. Download Scientific Diagram Nickel Plating Processes Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. Control of nickel plating processes. The basics of electroplating are addressed and it is focussed on the operation of the plating bath. The typical base metals for nickel plating are steel, copper alloys,. Learn about the difference between electrolytic and electroless. Nickel Plating Processes.

From www.researchgate.net

Process flow chart for electroless nickel plating on copper substrate Download Scientific Diagram Nickel Plating Processes The basics of electroplating are addressed and it is focussed on the operation of the plating bath. Nickel plating is used for decorative, engineering, and electroforming purposes. The typical base metals for nickel plating are steel, copper alloys,. The electroless nickel plating process consists of a simple chemical chain reaction. In order for parts to be plated, they must be. Nickel Plating Processes.

From www.sciencephoto.com

Electroless nickel plating factory Stock Image C038/8907 Science Photo Library Nickel Plating Processes It results in parts with improved corrosion resistance, wear resistance, and hardness. In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so the plating can be applied. Control of nickel plating processes. The electroless nickel plating process consists of a simple chemical chain reaction. Nickel electroplating is a process of applying. Nickel Plating Processes.

From ar.inspiredpencil.com

Nickel Electroplating Process Nickel Plating Processes The basics of electroplating are addressed and it is focussed on the operation of the plating bath. Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external. Control of nickel plating processes. The core material or substrate is first cleaned to ensure a spotless. Learn about the difference between electrolytic and electroless. Nickel Plating Processes.

From blog.thepipingmart.com

Nickel Plating Process An Overview Nickel Plating Processes Control of nickel plating processes. Learn about the difference between electrolytic and electroless nickel plating, common applications for each and our design guide to specify nickel plating for your parts. The basics of electroplating are addressed and it is focussed on the operation of the plating bath. In order for parts to be plated, they must be clean and free. Nickel Plating Processes.

From www.embee.com

Electroless Nickel Plating Nickel Plating Processes Nickel plating is used for decorative, engineering, and electroforming purposes. Nickel electroplating is a process of applying a nickel coating onto a metal surface by means of electrolytic deposition. In order for parts to be plated, they must be clean and free of dirt, corrosion, and defects so the plating can be applied. Control of nickel plating processes. It results. Nickel Plating Processes.