Pvc Pipe Extrusion Mold . Pipe is formed when plastics is extruded through a round shaping die, cooled in a water bath, and either cut and coiled. Pvc pipes are the most common tubing extrusion product, created using dies similar to blow film. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. From raw material preparation to final product testing. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. To understand the process better, it’s important to first understand the extruder and how it works.

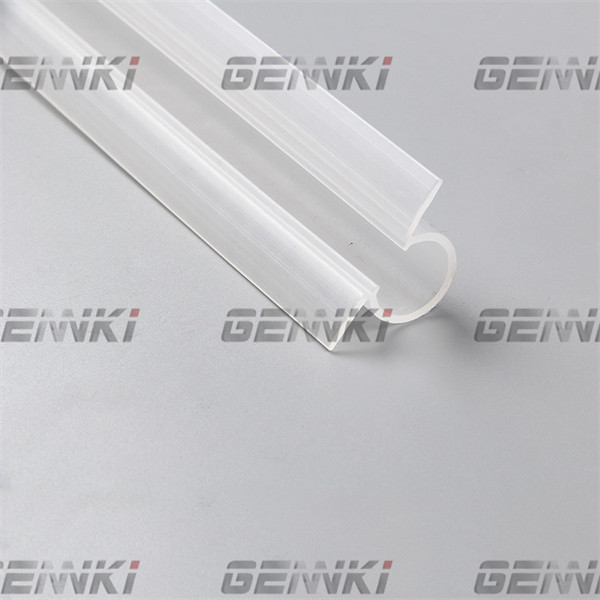

from www.gennkimfg.com

Pipe is formed when plastics is extruded through a round shaping die, cooled in a water bath, and either cut and coiled. This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. From raw material preparation to final product testing. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. Pvc pipes are the most common tubing extrusion product, created using dies similar to blow film. To understand the process better, it’s important to first understand the extruder and how it works. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative.

High Volume UPVC Pvc Plastic Extrusion Mold 2316 Steel Construction Industry

Pvc Pipe Extrusion Mold From raw material preparation to final product testing. This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. Pipe is formed when plastics is extruded through a round shaping die, cooled in a water bath, and either cut and coiled. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Pvc pipes are the most common tubing extrusion product, created using dies similar to blow film. From raw material preparation to final product testing. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. To understand the process better, it’s important to first understand the extruder and how it works.

From bogdamachine.en.made-in-china.com

Plastic Profiles Extrusion Mould PVC Skirting Board Extrusion Mold PVC Baseboard Extrusion Mold Pvc Pipe Extrusion Mold To understand the process better, it’s important to first understand the extruder and how it works. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. In pipe extrusion, selecting or building a complementary set of tooling often poses. Pvc Pipe Extrusion Mold.

From www.vrogue.co

Pvc Extrusion Tutorial Injection Molding vrogue.co Pvc Pipe Extrusion Mold This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. Pvc pipes are the most common tubing extrusion product, created using dies. Pvc Pipe Extrusion Mold.

From lilyindustries.en.made-in-china.com

PVC WPC Plastic Extrusion Mold for Profile PVC Profile Mould and PVC Extrusion Mould Pvc Pipe Extrusion Mold In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. Pipe is formed when plastics is extruded through a round shaping die, cooled in a water bath, and either cut and coiled. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. From raw material. Pvc Pipe Extrusion Mold.

From www.opusplastics.com

What is Plastic Extrusion? Process Guide Opus Plastics Pvc Pipe Extrusion Mold Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables,. Pvc Pipe Extrusion Mold.

From middletech.en.made-in-china.com

PVC Four Pipe Extrusion Line/PVC One Mold Four out Pipe Production Line Four Pipes Extrusion Pvc Pipe Extrusion Mold Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges. Pvc Pipe Extrusion Mold.

From sana-toryextruder.en.made-in-china.com

3cr17 SS Material PVC WPC Plastic Extrusion Mold for Profile WPC Extrusion Mold and Profile Mold Pvc Pipe Extrusion Mold Pvc pipes are the most common tubing extrusion product, created using dies similar to blow film. This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help. Pvc Pipe Extrusion Mold.

From zjgcnlws.en.made-in-china.com

Customize Extrusion Blow Mold /Mould for Plastic HDPE PP PVC PC ABS Hollow Products China Blow Pvc Pipe Extrusion Mold This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. To understand the process better, it’s important to first understand the extruder and how it works. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help. Pvc Pipe Extrusion Mold.

From www.joinzeal.net

Supply PVC moulding extrusion mold for PVC cable trunking profiles Wholesale Factory HUANGSHI Pvc Pipe Extrusion Mold Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Pipe is formed when plastics is extruded through a round shaping die, cooled in a water bath, and either cut and coiled. From raw material preparation to final product testing. To understand the process better, it’s important to first understand the extruder and how it. Pvc Pipe Extrusion Mold.

From www.alibaba.com

Factory Supply Pvc Plastic Pipe Extrusion Mold Die Buy Plastic Pipe Extrusion Mold,Pvc Pipe Pvc Pipe Extrusion Mold From raw material preparation to final product testing. Pvc pipes are the most common tubing extrusion product, created using dies similar to blow film. To understand the process better, it’s important to first understand the extruder and how it works. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a process. Pvc Pipe Extrusion Mold.

From www.rutlandplastics.co.uk

How does injection moulding work Rutland Plastics Pvc Pipe Extrusion Mold In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. Pvc pipes are the most common tubing extrusion product, created using dies similar to blow film. Pipe is formed when plastics is extruded through a round shaping die, cooled in a water bath, and either cut and coiled. To understand. Pvc Pipe Extrusion Mold.

From jada.com.co

EXTRUSIÓN DE PVC RÍGIDO • JADA INDUSTRY Pvc Pipe Extrusion Mold In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. Pvc pipes are the most common tubing extrusion. Pvc Pipe Extrusion Mold.

From plastex.en.made-in-china.com

ODM/OEM PVC Pipe Extrusion Processing Plastic Extrusion Mold China Tooling and Extrusion Tooling Pvc Pipe Extrusion Mold Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. To understand the process better, it’s important to first understand the extruder and how it works. Pipe is formed when plastics is extruded through a round shaping die, cooled in a water bath, and either cut and coiled. This video explain extrusion molding for the. Pvc Pipe Extrusion Mold.

From bogdamachine.en.made-in-china.com

Bogda Plastic Trunking Extrusion Mold Die PVC Cable Ducts Moulds China Extrusion Mould and Pvc Pipe Extrusion Mold Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. Pipe is formed when plastics is extruded through a round shaping die,. Pvc Pipe Extrusion Mold.

From www.wanhan-plastic.com

Cooling process of extrusion molding process Pvc Pipe Extrusion Mold To understand the process better, it’s important to first understand the extruder and how it works. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. Pvc pipes are the most common tubing extrusion product, created using dies similar. Pvc Pipe Extrusion Mold.

From www.alibaba.com

Pvc Tube Pipe Extrusion Mold Profile Extruder Buy Tube Pipe Extrusion Mould,Pvc Profile Pvc Pipe Extrusion Mold From raw material preparation to final product testing. To understand the process better, it’s important to first understand the extruder and how it works. Pvc pipes are the most common tubing extrusion product, created using dies similar to blow film. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. This video explain extrusion molding. Pvc Pipe Extrusion Mold.

From www.pipefittingsmould.com

OEM PVC Pipe Extrusion Processing Plastic Extrusion Mould/Die Service Pvc Pipe Extrusion Mold This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. Pipe is formed when plastics is extruded through a round shaping die, cooled in a water bath, and either cut and coiled. Pvc pipes are the most common tubing extrusion product, created using dies similar to blow film. In pipe extrusion, selecting or. Pvc Pipe Extrusion Mold.

From www.wanrooerecycle.com

PVC Mould of PVC Pipe Profile Production LineWANROOETECH Pvc Pipe Extrusion Mold Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with. Pvc Pipe Extrusion Mold.

From maximuschillers.com

Plastic Extrusion Moulding Chillers Service, Maintenance & Repair Pvc Pipe Extrusion Mold From raw material preparation to final product testing. Pipe is formed when plastics is extruded through a round shaping die, cooled in a water bath, and either cut and coiled. This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. Pvc pipes are the most common tubing extrusion product, created using dies similar. Pvc Pipe Extrusion Mold.

From www.alibaba.com

Pvc Upvc Double Pipe Extruder Machine /plastic One Mold Two Pipe Extrusion Line Buy Pvc Pipe Pvc Pipe Extrusion Mold Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. From raw material preparation to final product testing. Pipe is formed when plastics is extruded through a round shaping die, cooled in a water bath, and either cut and coiled. Pvc pipes are the most common tubing extrusion product, created using dies similar to blow. Pvc Pipe Extrusion Mold.

From www.csssld.com

Custom Plastic Extrusion Molding Manufacturing Csssld Pvc Pipe Extrusion Mold This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. Pvc pipes are the most common tubing extrusion product, created using dies similar to blow film. From raw material preparation to final product. Pvc Pipe Extrusion Mold.

From www.plasticrecycling-machines.com

HDPE PVC Plastic Pipe Extrusion Line Die Head With Extrusion Mold And Calibration Tools Pvc Pipe Extrusion Mold Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. From raw material preparation to final product testing. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Pipe is formed when plastics is. Pvc Pipe Extrusion Mold.

From www.alibaba.com

Pvc Pipe Extrusion Mold / Plastic Pipe Extrusion Die Mould Buy Pvc Pipe Extrusion Mould Pvc Pipe Extrusion Mold In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. To understand the process better, it’s important to first understand the extruder and how it works. From raw material preparation to final product testing. Pipe is formed when plastics is extruded through a round shaping die, cooled in a water. Pvc Pipe Extrusion Mold.

From www.alibaba.com

Pvc Pipe Extrusion Mold / Plastic Pipe Extrusion Die Mould Buy Pvc Pipe Extrusion Mould Pvc Pipe Extrusion Mold Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. From raw material preparation to final product testing. Pvc. Pvc Pipe Extrusion Mold.

From www.gennkimfg.com

High Volume UPVC Pvc Plastic Extrusion Mold 2316 Steel Construction Industry Pvc Pipe Extrusion Mold Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. To understand the process better, it’s important to first understand the extruder and how it works. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat. Pvc Pipe Extrusion Mold.

From www.youtube.com

PVC PIPES EXTRUSION LINE YouTube Pvc Pipe Extrusion Mold This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous. Pvc Pipe Extrusion Mold.

From www.alibaba.com

Pvc Pipe Extrusion Mold / Plastic Pipe Extrusion Die Mould Buy Pvc Pipe Extrusion Mould Pvc Pipe Extrusion Mold Pipe is formed when plastics is extruded through a round shaping die, cooled in a water bath, and either cut and coiled. From raw material preparation to final product testing. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Pvc pipes are the most common tubing extrusion product, created using dies similar to blow. Pvc Pipe Extrusion Mold.

From plastex.en.made-in-china.com

PVC Pipe Extrusion Mold / Plastic Pipe Extrusion Die Mould China Tooling and Extrusion Tooling Pvc Pipe Extrusion Mold Pvc pipes are the most common tubing extrusion product, created using dies similar to blow film. This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help. Pvc Pipe Extrusion Mold.

From www.alibaba.com

Factory Supply Pvc Plastic Pipe Extrusion Mold Die Buy Plastic Pipe Extrusion Mold,Pvc Pipe Pvc Pipe Extrusion Mold Pipe is formed when plastics is extruded through a round shaping die, cooled in a water bath, and either cut and coiled. Pvc pipes are the most common tubing extrusion product, created using dies similar to blow film. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a process where granular. Pvc Pipe Extrusion Mold.

From bogdamachine.en.made-in-china.com

Making High Speed HDPE PVC Pipe Extrusion Mold Tooling Die Extrusion Mould and Extrusion Die Pvc Pipe Extrusion Mold Pvc pipes are the most common tubing extrusion product, created using dies similar to blow film. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. Explore the world of plastic extrusion —. Pvc Pipe Extrusion Mold.

From www.alibaba.com

Pvc Pipe Extrusion Mold / Plastic Pipe Extrusion Die Mould Buy Pvc Pipe Extrusion Mould Pvc Pipe Extrusion Mold Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. From raw material preparation to final product testing. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder. Pvc Pipe Extrusion Mold.

From lilyindustries.en.made-in-china.com

China Manufacturer Supply PVC Extrusion Mould Pipe Extrusion Plastic Mould PVC Door and Window Pvc Pipe Extrusion Mold From raw material preparation to final product testing. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. Pipe. Pvc Pipe Extrusion Mold.

From www.pipefittingsmould.com

OEM PVC Pipe Extrusion Processing Plastic Extrusion Mould/Die Service Pvc Pipe Extrusion Mold Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. To understand the process better, it’s important to first understand the extruder. Pvc Pipe Extrusion Mold.

From www.made-in-china.com

China PVC Extrusion Mold Die Photos & Pictures Pvc Pipe Extrusion Mold To understand the process better, it’s important to first understand the extruder and how it works. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. From raw material preparation to final product testing. Pipe is formed when plastics is extruded through a round shaping die, cooled in a water. Pvc Pipe Extrusion Mold.

From plastex.en.made-in-china.com

OEM PVC HDPE Pipe Extrusion Processing Plastic Extrusion Mold / Mould Service China Plastic Pvc Pipe Extrusion Mold Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Pipe is formed when plastics is extruded through a round shaping die, cooled in a water bath, and either cut and coiled. From raw material preparation to final product testing. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due. Pvc Pipe Extrusion Mold.

From www.ztextrusion.com

PVC Extrusion MoldPVC Profile MoldPlastic Extrusion MoldPVC Profile MouldWPC Extrusion Mold Pvc Pipe Extrusion Mold This video explain extrusion molding for the manufacture of pvc pipes, electrical wires, cables, and various long. In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative. From raw material preparation to final product testing. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications.. Pvc Pipe Extrusion Mold.