Screw Clamp Function . Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications. Clamping screws are mechanical elements which use screw thrust for workpiece fixing and positioning. Their inherently slow clamping speed limits their use in high. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. The basic screw clamp uses the torque developed by a screw thread to hold a part in place. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. This is done by direct pressure or by acting on another. But they also have a drawback. They are designed to hold objects firmly in place. Full ball point contact securely fixes the workpiece. Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp a workpiece in place.

from www.homenish.com

The basic screw clamp uses the torque developed by a screw thread to hold a part in place. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. This is done by direct pressure or by acting on another. Clamping screws are mechanical elements which use screw thrust for workpiece fixing and positioning. They are designed to hold objects firmly in place. Their inherently slow clamping speed limits their use in high. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. Full ball point contact securely fixes the workpiece. But they also have a drawback. Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications.

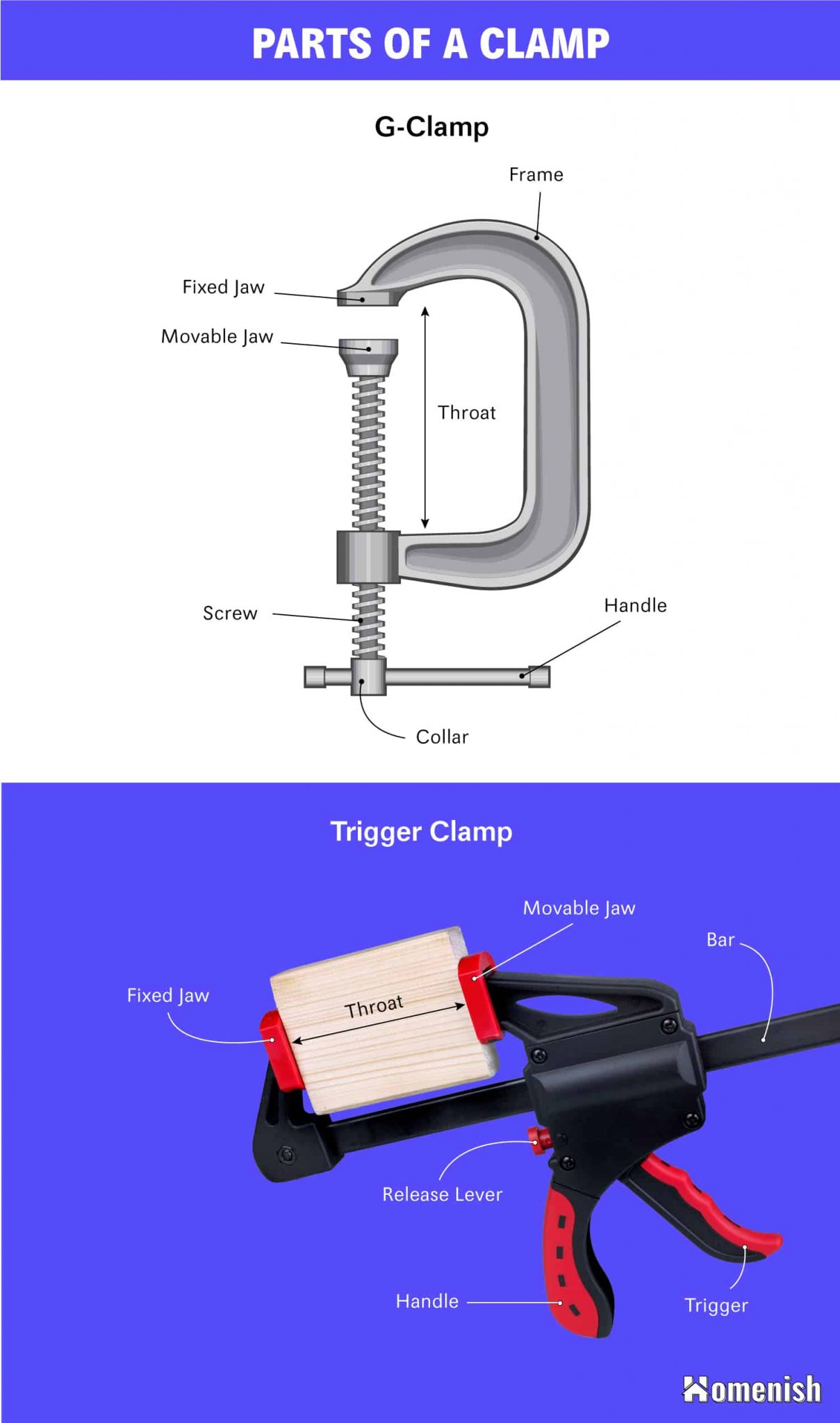

8 Essential Parts of a Clamp (with Diagram) Homenish

Screw Clamp Function Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp a workpiece in place. This is done by direct pressure or by acting on another. They are designed to hold objects firmly in place. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp a workpiece in place. Clamping screws are mechanical elements which use screw thrust for workpiece fixing and positioning. But they also have a drawback. Full ball point contact securely fixes the workpiece. Their inherently slow clamping speed limits their use in high. Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. The basic screw clamp uses the torque developed by a screw thread to hold a part in place.

From www.youtube.com

Lever Type Screw Actuated Clamp Mechanism 5 YouTube Screw Clamp Function They are designed to hold objects firmly in place. But they also have a drawback. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. The basic screw clamp uses the torque developed by a screw thread to hold a part in place. Clamping screws are mechanical elements which use screw. Screw Clamp Function.

From shop.wurth.ca

Screw Clamp Screw Clamp Function But they also have a drawback. This is done by direct pressure or by acting on another. The basic screw clamp uses the torque developed by a screw thread to hold a part in place. Full ball point contact securely fixes the workpiece. Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and. Screw Clamp Function.

From medium.com

A Brief Guide to Screw Clamps. 🗜️ Screw Clamp by Ritik Chaudhary Medium Screw Clamp Function Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp a workpiece in place. The basic screw clamp uses the torque developed by a screw thread to hold a part in place. They are designed to hold objects firmly in place. Screw clamps, or c or g. Screw Clamp Function.

From emilyfoto.en.made-in-china.com

High Quality Super Clamp Crab Claw Clamp MultiFunction Strong Clip Screw Hole for Photo Screw Clamp Function Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp a workpiece in place. They are designed to hold objects firmly in place. Their inherently slow clamping speed limits their use in high. But they also have a drawback. Clamping screws are mechanical elements which use screw. Screw Clamp Function.

From www.pinterest.com

SmallRig Multifunction Super Clamp with Double Ball Heads & 1/4" Screw 1138 Smallrig, Clamp Screw Clamp Function Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications. They are designed to hold objects firmly in place. Full ball point contact securely fixes the workpiece. Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp a workpiece. Screw Clamp Function.

From www.theengineerspost.com

37 Types of Clamps & Their Uses [How To Use Guide] PDF Screw Clamp Function Their inherently slow clamping speed limits their use in high. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. They are designed to hold objects firmly in place. Full ball point contact securely fixes the workpiece. Clamping screws are mechanical elements which use screw thrust for workpiece fixing and positioning. This is done by direct pressure or by. Screw Clamp Function.

From www.youtube.com

Lever Type Screw Actuated Clamp Mechanism 11 YouTube Screw Clamp Function The basic screw clamp uses the torque developed by a screw thread to hold a part in place. Clamping screws are mechanical elements which use screw thrust for workpiece fixing and positioning. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and. Screw Clamp Function.

From www.fine-tools.com

AllSteel Screw Clamps FINE TOOLS Screw Clamp Function The basic screw clamp uses the torque developed by a screw thread to hold a part in place. Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications. Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp a. Screw Clamp Function.

From www.youtube.com

ScrewActuated Clamp Mechanism YouTube Screw Clamp Function The basic screw clamp uses the torque developed by a screw thread to hold a part in place. Their inherently slow clamping speed limits their use in high. This is done by direct pressure or by acting on another. They are designed to hold objects firmly in place. Clamping screws are mechanical elements which use screw thrust for workpiece fixing. Screw Clamp Function.

From www.gnuttibortolo.com

Screw clamp Screw Clamp Function Full ball point contact securely fixes the workpiece. Clamping screws are mechanical elements which use screw thrust for workpiece fixing and positioning. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. Their inherently slow clamping speed limits their use in high. For clamping effectiveness and size/force ration, screw clamps make. Screw Clamp Function.

From inchbyinch.de

INCH Technical English pictorial screw clamp Screw Clamp Function Clamping screws are mechanical elements which use screw thrust for workpiece fixing and positioning. But they also have a drawback. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. The basic screw clamp uses the torque developed by a screw thread to hold a part in place. Full ball point contact securely fixes the workpiece. Clamping screws include. Screw Clamp Function.

From www.slideserve.com

PPT Power Screw and Springs PowerPoint Presentation, free download ID4843335 Screw Clamp Function Their inherently slow clamping speed limits their use in high. Clamping screws are mechanical elements which use screw thrust for workpiece fixing and positioning. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. Full ball point contact securely fixes the workpiece. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to. Screw Clamp Function.

From www.chegg.com

Solved A screw clamp similar to the one shown in the figure Screw Clamp Function Full ball point contact securely fixes the workpiece. They are designed to hold objects firmly in place. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. The basic screw clamp uses the torque developed by a screw thread to hold a part in place. Screw clamps, or c or g. Screw Clamp Function.

From www.ebay.com

2 Heavy Duty Steel Screw Hold Down Clamps / Toggle Locks Machining Clamp eBay Screw Clamp Function Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. The basic screw clamp uses the torque developed by a screw thread to hold a part in place. Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp. Screw Clamp Function.

From www.carrlane.com

BarLok QuickActing Screw Clamps (Sliding Bar Handle) Carr Lane Screw Clamp Function Clamping screws are mechanical elements which use screw thrust for workpiece fixing and positioning. Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications. Full ball point contact securely fixes the workpiece. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. Screw clamps is the general term given to a. Screw Clamp Function.

From www.kstools.com

Power screw clamp Screw Clamps Construction Tools Hand tools catalogue Products KS Screw Clamp Function They are designed to hold objects firmly in place. But they also have a drawback. Their inherently slow clamping speed limits their use in high. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. The basic screw clamp uses the torque developed by a screw thread to hold a part. Screw Clamp Function.

From www.homenish.com

8 Essential Parts of a Clamp (with Diagram) Homenish Screw Clamp Function Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp a workpiece in place. But they also have a drawback. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. They are designed to hold objects firmly in place. The basic screw clamp uses the torque. Screw Clamp Function.

From www.directindustry.com

Screw clamp classiX GSM series BESSEY Tool GmbH & Co. KG steel / highperformance Screw Clamp Function Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp. Screw Clamp Function.

From www.hubbell.com

Furniture Connectivity Boxes, Thumb Screw Clamp for Table Mount WSB Boxes WSBECLAMP Hubbell Screw Clamp Function For clamping effectiveness and size/force ration, screw clamps make excellent workholders. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. The basic screw clamp uses the torque developed by a screw thread to hold a part in place. They are designed to hold objects firmly in place. This is done. Screw Clamp Function.

From quickmachinerycompany.com

Your Choice of Clamp Style Screw Clamp Function Their inherently slow clamping speed limits their use in high. Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. They are designed to hold objects firmly in place. Full ball point contact securely fixes the workpiece. Screw clamps is the. Screw Clamp Function.

From www.youtube.com

How To make a Hand Screw Clamp YouTube Screw Clamp Function Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications. Their inherently slow clamping speed limits their use in high. Clamping screws are mechanical elements which use screw thrust for workpiece fixing and positioning. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the. Screw Clamp Function.

From www.distrelec.de

XB5AK123B5 Schneider Electric Illuminated Selector Switch, 90°, Latching Function, Screw Clamp Screw Clamp Function Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp a workpiece in place. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. The basic screw clamp uses the torque developed by a screw thread to hold a part in place. Their inherently slow clamping. Screw Clamp Function.

From mechanicaljungle.com

What Is a Clamp Used? How Does a Clamp Work? 38 Different Types of Clamps Screw Clamp Function This is done by direct pressure or by acting on another. Their inherently slow clamping speed limits their use in high. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. They are designed to hold objects firmly in place. For clamping effectiveness and size/force ration, screw clamps make excellent workholders.. Screw Clamp Function.

From www.fabbaloo.com

Design of the Week HandScrew Clamp « Fabbaloo Screw Clamp Function Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications. Full ball point contact securely fixes the workpiece. This is done by direct pressure or by acting on another. For clamping effectiveness and. Screw Clamp Function.

From www.ebay.com

2 Heavy Duty Steel Screw Hold Down Clamps / Toggle Locks Machining Clamp eBay Screw Clamp Function This is done by direct pressure or by acting on another. Full ball point contact securely fixes the workpiece. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. But they also have a drawback. Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications. Clamping screws are mechanical elements which. Screw Clamp Function.

From www.chegg.com

Solved The screw of the clamp exerts a compressive force of Screw Clamp Function But they also have a drawback. Their inherently slow clamping speed limits their use in high. Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp a workpiece in place. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to. Screw Clamp Function.

From engineeringlearn.com

Toggle Clamp Definition, Types, Uses, Mechanism, Parts, Working, Applications & Advantages Screw Clamp Function But they also have a drawback. They are designed to hold objects firmly in place. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. This is done by direct pressure or by acting on another. Screw clamps, or c or g clamps, are versatile and widely used tools in various. Screw Clamp Function.

From www.frankclark.ie

BESSEY Screw Clamp (200mm) Frank Clark Ltd Screw Clamp Function Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp a workpiece in place. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. But they also have a drawback. Full ball point contact securely fixes the workpiece.. Screw Clamp Function.

From www.hilti.co.uk

Screw clamp WAGS Z Accessories for Circular and CutOff Saws Hilti GB Screw Clamp Function But they also have a drawback. Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp a workpiece in place. Full ball point contact securely fixes the workpiece. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. This is done by direct pressure or by. Screw Clamp Function.

From www.electrician-1.com

28 Types of Clamps & Their Uses electrical and electronics technology degree Screw Clamp Function For clamping effectiveness and size/force ration, screw clamps make excellent workholders. Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications. Clamping screws include several varieties of ball tip shapes and materials, which can be selected according to the application. This is done by direct pressure or by acting on another. Screw. Screw Clamp Function.

From technologystudent.com

THE TRADITIONAL FCLAMP Screw Clamp Function They are designed to hold objects firmly in place. Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and. Screw Clamp Function.

From mipromet.eu

Screw plate clamp Screw Clamp Function Their inherently slow clamping speed limits their use in high. This is done by direct pressure or by acting on another. Clamping screws are mechanical elements which use screw thrust for workpiece fixing and positioning. The basic screw clamp uses the torque developed by a screw thread to hold a part in place. For clamping effectiveness and size/force ration, screw. Screw Clamp Function.

From eureka.patsnap.com

Connection structure for screw clamp terminal Eureka Patsnap Screw Clamp Function The basic screw clamp uses the torque developed by a screw thread to hold a part in place. This is done by direct pressure or by acting on another. Screw clamps, or c or g clamps, are versatile and widely used tools in various industries and applications. They are designed to hold objects firmly in place. Their inherently slow clamping. Screw Clamp Function.

From www.theengineerspost.com

37 Types of Clamps & Their Uses [How To Use Guide] PDF Screw Clamp Function Full ball point contact securely fixes the workpiece. This is done by direct pressure or by acting on another. Their inherently slow clamping speed limits their use in high. For clamping effectiveness and size/force ration, screw clamps make excellent workholders. But they also have a drawback. They are designed to hold objects firmly in place. Screw clamps, or c or. Screw Clamp Function.

From justinfozone.blogspot.com

Basic Elements of jigs and fixtures(Clamping & Bushes) Informational Encyclopedia Screw Clamp Function Screw clamps is the general term given to a group of clamps which use a screw mechanism to adjust the jaws and clamp a workpiece in place. This is done by direct pressure or by acting on another. Clamping screws are mechanical elements which use screw thrust for workpiece fixing and positioning. The basic screw clamp uses the torque developed. Screw Clamp Function.