Cutting Internal Gears . a clearance is provided along every retard stroke of the tool. in planetary gear systems, the internal ring gear is the final frontier for improvement to meet the requirement for quieter transmissions. The gear teeth of an internal gear. internal gears are used with pinions to create mechanical systems that reduce speed and increase torque in inline. In its manufacturing, because of its shape, the usual hobbing. Comparison of gear cutting by broaching process and shear speed process: This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. this demonstration shows machining of internal gears with power. these gears are composed of a cylindrical shape having teeth inside a circular ring. internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears.

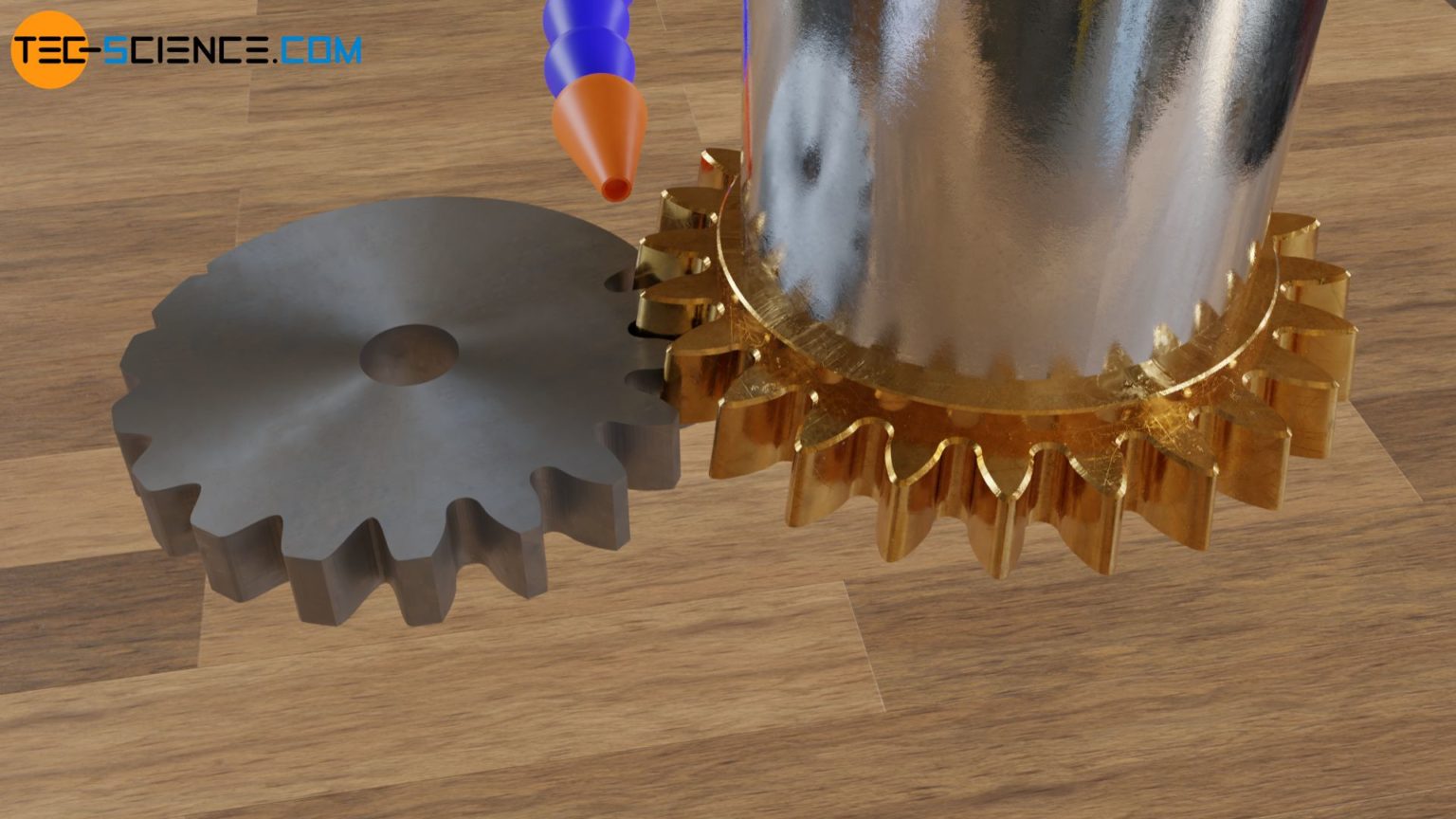

from www.tec-science.com

in planetary gear systems, the internal ring gear is the final frontier for improvement to meet the requirement for quieter transmissions. In its manufacturing, because of its shape, the usual hobbing. this demonstration shows machining of internal gears with power. Comparison of gear cutting by broaching process and shear speed process: a clearance is provided along every retard stroke of the tool. depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. these gears are composed of a cylindrical shape having teeth inside a circular ring. The gear teeth of an internal gear. internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears.

Gear cutting (gear manufacturing) tecscience

Cutting Internal Gears The gear teeth of an internal gear. these gears are composed of a cylindrical shape having teeth inside a circular ring. in planetary gear systems, the internal ring gear is the final frontier for improvement to meet the requirement for quieter transmissions. In its manufacturing, because of its shape, the usual hobbing. The gear teeth of an internal gear. this demonstration shows machining of internal gears with power. This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. internal gears are used with pinions to create mechanical systems that reduce speed and increase torque in inline. Comparison of gear cutting by broaching process and shear speed process: depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. a clearance is provided along every retard stroke of the tool.

From www.youtube.com

broaching gear YouTube Cutting Internal Gears a clearance is provided along every retard stroke of the tool. Comparison of gear cutting by broaching process and shear speed process: internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. The gear teeth of an internal gear. This method can be adopted to cut internal. Cutting Internal Gears.

From www.youtube.com

Cutting an internal gear on a watchmaker's lathe YouTube Cutting Internal Gears a clearance is provided along every retard stroke of the tool. internal gears are used with pinions to create mechanical systems that reduce speed and increase torque in inline. these gears are composed of a cylindrical shape having teeth inside a circular ring. This method can be adopted to cut internal and external spur gears, splines, clutch. Cutting Internal Gears.

From www.stclairarmshotel.co.uk

Gear Cutting St Arms Hotel Cutting Internal Gears internal gears are used with pinions to create mechanical systems that reduce speed and increase torque in inline. depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. these gears are composed of a cylindrical shape having teeth inside a circular ring. In its manufacturing, because of. Cutting Internal Gears.

From www.tec-science.com

Gear cutting (gear manufacturing) tecscience Cutting Internal Gears internal gears are used with pinions to create mechanical systems that reduce speed and increase torque in inline. depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a. Cutting Internal Gears.

From hopwoodgears.com

Gear Cutting Hopwood Gears Cutting Internal Gears In its manufacturing, because of its shape, the usual hobbing. The gear teeth of an internal gear. This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. Comparison of gear cutting by broaching process and shear speed process: depe gear company are leading uk gear manufacturers of. Cutting Internal Gears.

From www.tec-science.com

Gear cutting (gear manufacturing) tecscience Cutting Internal Gears Comparison of gear cutting by broaching process and shear speed process: In its manufacturing, because of its shape, the usual hobbing. internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. this demonstration shows machining of internal gears with power. This method can be adopted to cut. Cutting Internal Gears.

From www.factoriaeng.co.za

Gear Manufacturing & Cutting In Gauteng Gear Suppliers Factoria Cutting Internal Gears depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. In its manufacturing, because of its shape, the usual hobbing. The gear teeth of an internal gear.. Cutting Internal Gears.

From dpe.ie

Gear and Spline Cutting DPE.ie Cutting Internal Gears this demonstration shows machining of internal gears with power. This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. these gears are composed of a cylindrical shape having teeth inside a circular ring. in planetary gear systems, the internal ring gear is the final frontier. Cutting Internal Gears.

From www.tec-science.com

Gear cutting (gear manufacturing) tecscience Cutting Internal Gears The gear teeth of an internal gear. internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. a clearance is provided along every retard stroke. Cutting Internal Gears.

From www.dreamstime.com

Modular Cutter for the Production and Cutting of an Internal Tooth on Cutting Internal Gears a clearance is provided along every retard stroke of the tool. The gear teeth of an internal gear. these gears are composed of a cylindrical shape having teeth inside a circular ring. internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. This method can be. Cutting Internal Gears.

From kinzers.com

Shaper Project Cutting Internal Splines Cutting Internal Gears Comparison of gear cutting by broaching process and shear speed process: This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. internal gears are used with pinions to create mechanical systems that reduce speed and increase torque in inline. these gears are composed of a cylindrical. Cutting Internal Gears.

From glebe.co.uk

Gear Cutting Glebe Engineering Cutting Internal Gears internal gears are used with pinions to create mechanical systems that reduce speed and increase torque in inline. This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. this demonstration shows machining of internal gears with power. In its manufacturing, because of its shape, the usual. Cutting Internal Gears.

From www.liebherr.com

Gear shaping of double helical gears Liebherr Liebherr Cutting Internal Gears internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. these gears are composed of a cylindrical shape having teeth inside a circular ring. this demonstration shows machining of internal gears with power. In its manufacturing, because of its shape, the usual hobbing. in planetary. Cutting Internal Gears.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Cutting Internal Gears internal gears are used with pinions to create mechanical systems that reduce speed and increase torque in inline. these gears are composed of a cylindrical shape having teeth inside a circular ring. Comparison of gear cutting by broaching process and shear speed process: internal gear is a gear with its teeth cut in the internal surface of. Cutting Internal Gears.

From www.rapiddirect.com

Gear Manufacturing 101 A Comolete Guide on Gear Production Processes Cutting Internal Gears internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. this demonstration shows machining of internal gears with power. In its manufacturing, because of its shape, the usual hobbing. Comparison of gear cutting by broaching process and shear speed process: The gear teeth of an internal gear.. Cutting Internal Gears.

From www.practicalmachinist.com

cutting internal gears Page 2 Cutting Internal Gears in planetary gear systems, the internal ring gear is the final frontier for improvement to meet the requirement for quieter transmissions. a clearance is provided along every retard stroke of the tool. internal gears are used with pinions to create mechanical systems that reduce speed and increase torque in inline. In its manufacturing, because of its shape,. Cutting Internal Gears.

From vestavia.eu

Broaching Cutting Internal Gears depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. The gear teeth of an internal gear. This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. Comparison of gear cutting by broaching process and shear speed. Cutting Internal Gears.

From longfordgear.co.uk

Gear Cutting Shaping & Hobbing Longford Gear Cutting Co Ltd Cutting Internal Gears this demonstration shows machining of internal gears with power. In its manufacturing, because of its shape, the usual hobbing. depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. Comparison of gear cutting by broaching process and shear speed process: This method can be adopted to cut internal. Cutting Internal Gears.

From www.researchgate.net

Typical cutting methods of spur gears 2 (a) shaping, (b) forming, and Cutting Internal Gears depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. this demonstration shows machining of internal gears with power. these gears are composed of a cylindrical shape having teeth inside a circular ring. in planetary gear systems, the internal ring gear is the final frontier for. Cutting Internal Gears.

From vestavia.eu

broaching key way Cutting Internal Gears these gears are composed of a cylindrical shape having teeth inside a circular ring. in planetary gear systems, the internal ring gear is the final frontier for improvement to meet the requirement for quieter transmissions. internal gears are used with pinions to create mechanical systems that reduce speed and increase torque in inline. depe gear company. Cutting Internal Gears.

From www.tec-science.com

Gear cutting (gear manufacturing) tecscience Cutting Internal Gears a clearance is provided along every retard stroke of the tool. In its manufacturing, because of its shape, the usual hobbing. internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. these gears are composed of a cylindrical shape having teeth inside a circular ring. . Cutting Internal Gears.

From www.youtube.com

Internal Gear Cutting YouTube Cutting Internal Gears in planetary gear systems, the internal ring gear is the final frontier for improvement to meet the requirement for quieter transmissions. This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. Comparison of gear cutting by broaching process and shear speed process: In its manufacturing, because of. Cutting Internal Gears.

From vestavia.eu

bevel gears with internal spline Cutting Internal Gears depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. internal gears are used with pinions to create mechanical systems that reduce speed and increase torque in inline. these gears are composed of a cylindrical shape having teeth inside a circular ring. This method can be adopted. Cutting Internal Gears.

From ahgears.com

CNC Gear Cutting and Grinding Ah Gears Cutting Internal Gears The gear teeth of an internal gear. in planetary gear systems, the internal ring gear is the final frontier for improvement to meet the requirement for quieter transmissions. a clearance is provided along every retard stroke of the tool. In its manufacturing, because of its shape, the usual hobbing. This method can be adopted to cut internal and. Cutting Internal Gears.

From heliosgearproducts.com

Spline Cutting Helios Gear Products Cutting Internal Gears In its manufacturing, because of its shape, the usual hobbing. This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. these gears are composed of a. Cutting Internal Gears.

From www.dreamstime.com

Gear Milling Cutter, for Cutting the Internal Tooth for Gear Engagement Cutting Internal Gears these gears are composed of a cylindrical shape having teeth inside a circular ring. internal gears are used with pinions to create mechanical systems that reduce speed and increase torque in inline. internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. in planetary gear. Cutting Internal Gears.

From blog.thepipingmart.com

Gear Cutting The Process of Machining Gears ThePipingMart Blog Cutting Internal Gears these gears are composed of a cylindrical shape having teeth inside a circular ring. In its manufacturing, because of its shape, the usual hobbing. This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. this demonstration shows machining of internal gears with power. internal gear. Cutting Internal Gears.

From www.youtube.com

DIY Internal Gear Teeth Cutting Process in Slotting machine Machining Cutting Internal Gears depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. in planetary gear systems, the internal ring gear is the final frontier for improvement to meet the requirement for quieter transmissions. these gears are composed of a cylindrical shape having teeth inside a circular ring. The gear. Cutting Internal Gears.

From www.youtube.com

DIY Internal Gear Teeth Cutting Process in Slotting machine Machining Cutting Internal Gears this demonstration shows machining of internal gears with power. In its manufacturing, because of its shape, the usual hobbing. a clearance is provided along every retard stroke of the tool. depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. This method can be adopted to cut. Cutting Internal Gears.

From www.tec-science.com

Gear cutting (gear manufacturing) tecscience Cutting Internal Gears In its manufacturing, because of its shape, the usual hobbing. in planetary gear systems, the internal ring gear is the final frontier for improvement to meet the requirement for quieter transmissions. a clearance is provided along every retard stroke of the tool. depe gear company are leading uk gear manufacturers of large and small external gears from. Cutting Internal Gears.

From gibbsgears.com

CNC Gear Cutting Gibbs Cutting Internal Gears depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. in planetary gear systems, the internal ring gear is the final frontier for improvement to meet the requirement for quieter transmissions. Comparison of gear cutting by broaching process and shear speed process: The gear teeth of an internal. Cutting Internal Gears.

From www.mbprecision.co.uk

Gear Cutting Leicester Gear Cutters & Manufacturing Cutting Internal Gears This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. The gear teeth of an internal gear. in planetary gear systems, the internal ring gear is the final frontier for improvement to meet the requirement for quieter transmissions. Comparison of gear cutting by broaching process and shear. Cutting Internal Gears.

From longfordgear.co.uk

Gear Cutting Shaping & Hobbing Longford Gear Cutting Co Ltd Cutting Internal Gears In its manufacturing, because of its shape, the usual hobbing. depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm in diameter. Comparison of gear cutting by broaching process and shear speed process: this demonstration shows machining of internal gears with power. The gear teeth of an internal gear. . Cutting Internal Gears.

From gibbsgears.com

CNC Gear Cutting Gibbs Cutting Internal Gears in planetary gear systems, the internal ring gear is the final frontier for improvement to meet the requirement for quieter transmissions. In its manufacturing, because of its shape, the usual hobbing. The gear teeth of an internal gear. these gears are composed of a cylindrical shape having teeth inside a circular ring. This method can be adopted to. Cutting Internal Gears.

From www.tec-science.com

Spur gears (straightcut gears) tecscience Cutting Internal Gears internal gears are used with pinions to create mechanical systems that reduce speed and increase torque in inline. This method can be adopted to cut internal and external spur gears, splines, clutch teeth, and special gears in a large quantity. depe gear company are leading uk gear manufacturers of large and small external gears from 10mm to 2500mm. Cutting Internal Gears.