Gear Motor Shaft Coupling . Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. Considering the peak load as. They are normally made up of two flexible joints, one fixed to each shaft, and linked by a spindle, or third shaft. This is a heavy duty coupling with incredible design flexibility, making. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. Skf gear couplings are rated up to 1 310 knm with a maximum bore of 525 mm. Due to their damping properties, the powergrip® couplings from. Torsionally flexible shaft powergrip couplings.

from mechstuff.com

Torsionally flexible shaft powergrip couplings. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. This is a heavy duty coupling with incredible design flexibility, making. Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. Due to their damping properties, the powergrip® couplings from. They are normally made up of two flexible joints, one fixed to each shaft, and linked by a spindle, or third shaft. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. Considering the peak load as. Skf gear couplings are rated up to 1 310 knm with a maximum bore of 525 mm.

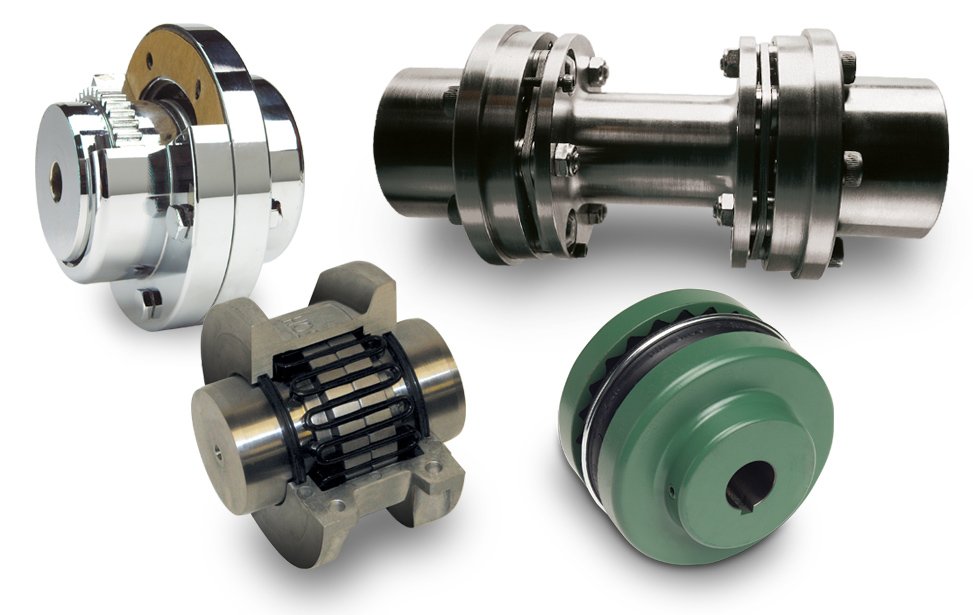

What are Couplings? Types of Couplings and their application MechStuff

Gear Motor Shaft Coupling This is a heavy duty coupling with incredible design flexibility, making. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. This is a heavy duty coupling with incredible design flexibility, making. Skf gear couplings are rated up to 1 310 knm with a maximum bore of 525 mm. Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. Torsionally flexible shaft powergrip couplings. Considering the peak load as. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. Due to their damping properties, the powergrip® couplings from. They are normally made up of two flexible joints, one fixed to each shaft, and linked by a spindle, or third shaft.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Gear Motor Shaft Coupling Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. Torsionally flexible shaft powergrip couplings. Due to their damping properties, the powergrip® couplings from. This is a heavy duty coupling. Gear Motor Shaft Coupling.

From engineeringlearn.com

Shaft Coupling Definition, Types, Uses, Working Principle & Advantages Gear Motor Shaft Coupling Torsionally flexible shaft powergrip couplings. Due to their damping properties, the powergrip® couplings from. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. Considering the peak load as. This is a heavy duty coupling with incredible design flexibility, making. They are normally. Gear Motor Shaft Coupling.

From www.linquip.com

Types of Gear Coupling With Working Principles Linquip Gear Motor Shaft Coupling Considering the peak load as. This is a heavy duty coupling with incredible design flexibility, making. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak. Gear Motor Shaft Coupling.

From www.sydensen.com

Densen customized GICLZ type gear motor shaft coupling,curved teeth Gear Motor Shaft Coupling Considering the peak load as. This is a heavy duty coupling with incredible design flexibility, making. Due to their damping properties, the powergrip® couplings from. Torsionally flexible shaft powergrip couplings. They are normally made up of two flexible joints, one fixed to each shaft, and linked by a spindle, or third shaft. Brakewheel and disc brake couplings accommodate misalignment between. Gear Motor Shaft Coupling.

From mechstuff.com

What are Couplings? Types of Couplings and their application MechStuff Gear Motor Shaft Coupling This is a heavy duty coupling with incredible design flexibility, making. Skf gear couplings are rated up to 1 310 knm with a maximum bore of 525 mm. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. Brakewheel and disc brake couplings accommodate misalignment between connected equipment and. Gear Motor Shaft Coupling.

From arnoldsupply.com

Hytrol Shaft Coupling Arnold Supply, Inc. Gear Motor Shaft Coupling They are normally made up of two flexible joints, one fixed to each shaft, and linked by a spindle, or third shaft. Considering the peak load as. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. This is a heavy duty coupling. Gear Motor Shaft Coupling.

From www.reddit.com

Different Types of Couplings r/coolguides Gear Motor Shaft Coupling A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. Due to their damping properties, the powergrip® couplings from. Skf gear couplings are rated up to 1 310 knm with a maximum bore of 525 mm. Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the. Gear Motor Shaft Coupling.

From www.guardiancouplings.com

Gear Grip Flexible Shaft Coupling Guardian Couplings Gear Motor Shaft Coupling Considering the peak load as. This is a heavy duty coupling with incredible design flexibility, making. Skf gear couplings are rated up to 1 310 knm with a maximum bore of 525 mm. Torsionally flexible shaft powergrip couplings. Due to their damping properties, the powergrip® couplings from. A gear coupling is required to transmit 250 kw from an electric motor. Gear Motor Shaft Coupling.

From www.drive-couplings.com

Rexnord Gear Motor Shaft Coupling 1010G 1070G Falk Steelflex Grid Couplings Gear Motor Shaft Coupling Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. Considering the peak load as. Torsionally flexible shaft powergrip couplings. Skf gear couplings are. Gear Motor Shaft Coupling.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Gear Motor Shaft Coupling Considering the peak load as. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. They are normally made up of two flexible joints, one fixed to each shaft, and linked by a spindle, or third shaft. Due to their damping properties, the powergrip® couplings from. The gear coupling. Gear Motor Shaft Coupling.

From www.sydensen.com

Densen customized GICLZ type gear motor shaft coupling,curved teeth Gear Motor Shaft Coupling Due to their damping properties, the powergrip® couplings from. Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. They are normally made up. Gear Motor Shaft Coupling.

From www.sydensen.com

Densen customized GICLZ type gear motor shaft coupling,curved teeth Gear Motor Shaft Coupling This is a heavy duty coupling with incredible design flexibility, making. They are normally made up of two flexible joints, one fixed to each shaft, and linked by a spindle, or third shaft. Due to their damping properties, the powergrip® couplings from. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to. Gear Motor Shaft Coupling.

From pto-shaft.com

shaft coupling Agricultual PTO Shaft Gear Motor Shaft Coupling Considering the peak load as. This is a heavy duty coupling with incredible design flexibility, making. Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. Due to their damping. Gear Motor Shaft Coupling.

From electronicspanga.com

5.3X6.3mm Bore Aluminum Motor Shaft Flexible Coupling C91 Star Gear Motor Shaft Coupling Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. Considering the peak load as. Skf gear couplings are rated up to 1 310 knm with a maximum bore of 525 mm. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a. Gear Motor Shaft Coupling.

From www.engineeringtribe.com

Types of shaft keys and their definition. EngineeringTribe Gear Motor Shaft Coupling A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. Due to their damping properties, the powergrip® couplings from. Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. This is a heavy duty coupling with incredible design flexibility, making.. Gear Motor Shaft Coupling.

From www.exportersindia.com

Steel Full Gear Coupling, Shape Round at Rs 6,500 / Piece in Bhiwadi Gear Motor Shaft Coupling Due to their damping properties, the powergrip® couplings from. Considering the peak load as. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. This is a heavy duty coupling with incredible design flexibility, making. The gear coupling is the most power intensive coupling as it is designed, but. Gear Motor Shaft Coupling.

From motorrewindingsolutions.com

removing the coupling, gear,or pulley (sheave) from an electric motor Gear Motor Shaft Coupling Torsionally flexible shaft powergrip couplings. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. Considering the peak load as. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. Brakewheel and. Gear Motor Shaft Coupling.

From www.theengineerspost.com

13 Types of Coupling Definition, Drawings, Uses & (PDF) Gear Motor Shaft Coupling This is a heavy duty coupling with incredible design flexibility, making. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. Skf gear couplings are rated up to 1 310 knm with a maximum bore of 525 mm. They are normally made up. Gear Motor Shaft Coupling.

From www.youtube.com

Types of Shaft Coupling, Animation, Machine Design Solidworks YouTube Gear Motor Shaft Coupling A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. Due to their damping properties, the powergrip® couplings from. Torsionally flexible shaft powergrip couplings. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of. Gear Motor Shaft Coupling.

From atindustry.en.made-in-china.com

Aluminum Metal Tapered Spline Drive Shaft Coupling, Quick Release Gear Motor Shaft Coupling A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. They are normally made up of two flexible joints, one fixed to each shaft, and linked by a spindle, or third shaft. Torsionally flexible shaft powergrip couplings. This is a heavy duty coupling with incredible design flexibility, making. Skf. Gear Motor Shaft Coupling.

From www.zeushydratech.com

DCND108B OMT Drive Coupling, Motor Half, 11kw (42mm, 12mm key) Zeus Gear Motor Shaft Coupling Due to their damping properties, the powergrip® couplings from. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. Torsionally flexible shaft powergrip couplings. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of. Gear Motor Shaft Coupling.

From b2bmap.com

Gear Motor Shaft Coupling Flexible & Efficient Connection Solution Gear Motor Shaft Coupling They are normally made up of two flexible joints, one fixed to each shaft, and linked by a spindle, or third shaft. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. Due to their damping properties, the powergrip® couplings from. Torsionally flexible. Gear Motor Shaft Coupling.

From megadynegroup.com

Shaft Couplings Megadyne Group Gear Motor Shaft Coupling This is a heavy duty coupling with incredible design flexibility, making. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. Torsionally flexible shaft powergrip couplings. Skf gear couplings are rated up to 1 310 knm with a maximum bore of 525 mm.. Gear Motor Shaft Coupling.

From www.dreamstime.com

Motor Shaft Coupling, Industrial Stock Image Image of rotate Gear Motor Shaft Coupling They are normally made up of two flexible joints, one fixed to each shaft, and linked by a spindle, or third shaft. Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. Torsionally flexible shaft powergrip couplings. Due to their damping properties, the powergrip® couplings from. The gear coupling is the. Gear Motor Shaft Coupling.

From mechanicaljungle.com

What Is a Coupling? How Does a Shaft Coupling Work? Types of Shaft Gear Motor Shaft Coupling The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. Due to their damping properties, the powergrip® couplings from. This is a heavy duty coupling with incredible design flexibility, making. Skf gear couplings are rated up to 1 310 knm with a maximum. Gear Motor Shaft Coupling.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Gear Motor Shaft Coupling A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. This is a heavy duty coupling with incredible design flexibility, making. Considering the peak load as. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak. Gear Motor Shaft Coupling.

From www.designworldonline.com

What are gear couplings and how do they work? Gear Motor Shaft Coupling A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. Due to their damping properties, the powergrip® couplings from. This is a heavy duty coupling with incredible design flexibility, making.. Gear Motor Shaft Coupling.

From www.drive-couplings.com

Nylon Gear Motor Shaft Coupling Bowex B48 High Precision Gear Motor Shaft Coupling Due to their damping properties, the powergrip® couplings from. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. This is a heavy duty coupling with incredible design flexibility, making. Torsionally flexible shaft powergrip couplings. Considering the peak load as. A gear coupling. Gear Motor Shaft Coupling.

From www.gearcouplingsindia.com

Gear Coupling What it is and How it Works? Sahara Engineers Gear Motor Shaft Coupling Considering the peak load as. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. This is a heavy duty coupling with. Gear Motor Shaft Coupling.

From www.drive-couplings.com

Rexnord Gear Motor Shaft Coupling 1010G 1070G Falk Steelflex Grid Couplings Gear Motor Shaft Coupling Torsionally flexible shaft powergrip couplings. This is a heavy duty coupling with incredible design flexibility, making. Skf gear couplings are rated up to 1 310 knm with a maximum bore of 525 mm. Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. Considering the peak load as. Due to their. Gear Motor Shaft Coupling.

From www.mrosupply.com

The Main Types of Shaft Couplings and their Applications Gear Motor Shaft Coupling This is a heavy duty coupling with incredible design flexibility, making. Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. Skf gear couplings are rated up to 1 310 knm with a maximum bore of 525 mm. They are normally made up of two flexible joints, one fixed to each. Gear Motor Shaft Coupling.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Gear Motor Shaft Coupling Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. Considering the peak load as. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. Due to their damping properties, the powergrip® couplings from.. Gear Motor Shaft Coupling.

From www.mtsindustrial.com

Gear Couplings Gear Motor Shaft Coupling Due to their damping properties, the powergrip® couplings from. Considering the peak load as. They are normally made up of two flexible joints, one fixed to each shaft, and linked by a spindle, or third shaft. Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. The gear coupling is the. Gear Motor Shaft Coupling.

From b2bmap.com

Gear Motor Shaft Coupling Flexible & Efficient Connection Solution Gear Motor Shaft Coupling Torsionally flexible shaft powergrip couplings. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. A gear coupling is required to transmit 250 kw from an electric motor running at 730 rev/min to a pulper machine. They are normally made up of two. Gear Motor Shaft Coupling.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Gear Motor Shaft Coupling Brakewheel and disc brake couplings accommodate misalignment between connected equipment and eliminate the need for double shaft extensions on. The gear coupling is the most power intensive coupling as it is designed, but the shaft to hub connection can be the weak point of the coupling. Torsionally flexible shaft powergrip couplings. Due to their damping properties, the powergrip® couplings from.. Gear Motor Shaft Coupling.