Thickener Rake Design . The rake arm is then. 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. Thickener rakes fulfil three main functions: Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of the tank to the center cone. Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. Developed for high performance, the patented spiral rake blade solves common issues with. The solids flux curve is used to model the process of continuous sedimentation.

from www.flsmidth.com

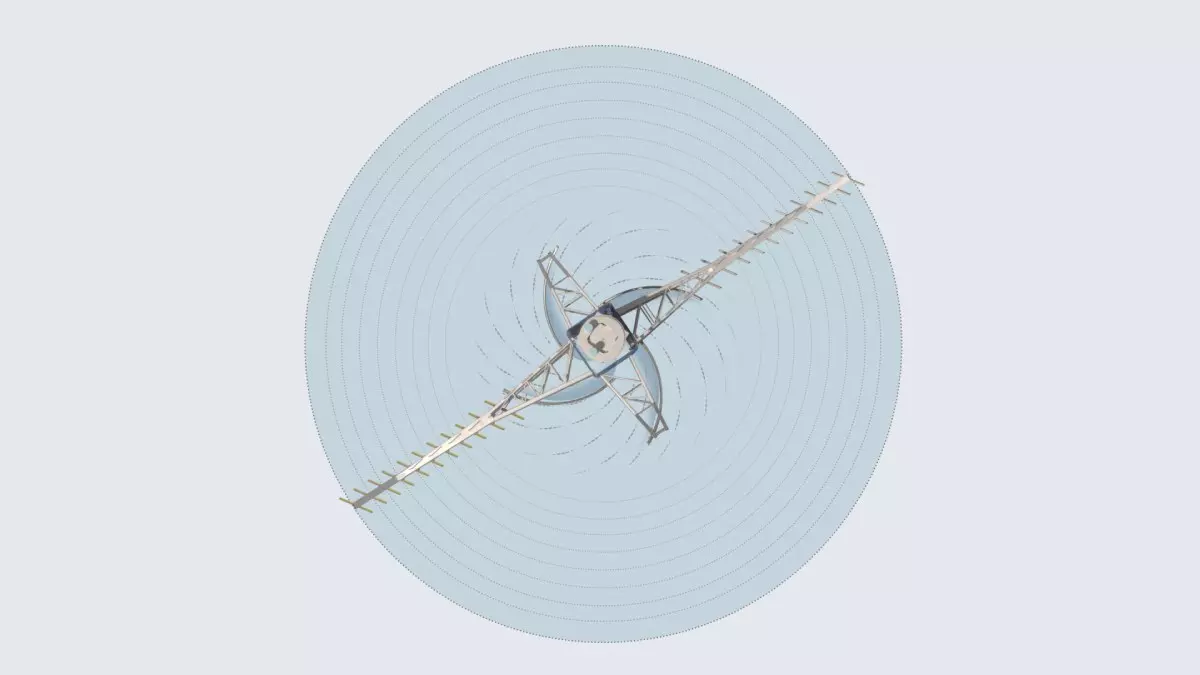

From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of the tank to the center cone. Developed for high performance, the patented spiral rake blade solves common issues with. The solids flux curve is used to model the process of continuous sedimentation. The rake arm is then. Thickener rakes fulfil three main functions: Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. Raked clarifier with advanced feedwell design for a wide range of mining clarification duties.

Thickener Spiral Rake Blade FLSmidth

Thickener Rake Design 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. The solids flux curve is used to model the process of continuous sedimentation. Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. The rake arm is then. Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of the tank to the center cone. Developed for high performance, the patented spiral rake blade solves common issues with. Thickener rakes fulfil three main functions: 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles.

From gestech.net

Thickener Rake Arm Design, Severe Acid Environment Thickener Rake Design Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. The solids flux curve is used to model the process of continuous sedimentation. Developed for high performance, the patented spiral rake blade solves common issues with. Thickener rakes fulfil three main functions: From a metallurgical point, the exclusive design of the spiral rake imparts a continuous. Thickener Rake Design.

From gestech.net

Thickener Rake Arm Design, Severe Acid Environment Thickener Rake Design Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. The solids flux curve is used to model the process of continuous sedimentation. From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of. Thickener Rake Design.

From www.911metallurgist.com

Thickeners Thickener Rake Design Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. Developed for high performance, the patented spiral rake blade solves common issues with. Thickener rakes fulfil three main functions: The. Thickener Rake Design.

From www.snmhi.com

NZY25 Centre Drive Lift Rake Thickener Shenyang Northern Metso Heavy Industry Machinery Co., Ltd. Thickener Rake Design Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. The solids flux curve is used to model the process of continuous sedimentation. Developed for high performance, the patented spiral rake blade solves common issues with. From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the. Thickener Rake Design.

From www.tikal-co.com

Thickner Tikal Water & Irrigation Systems Thickener Rake Design Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. The rake arm is then. Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. The solids flux curve is used to model. Thickener Rake Design.

From graver.com

RotaRake® Solids Thickener WW Graver Water Systems Thickener Rake Design Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. The rake arm is then. Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. Raked clarifier with advanced feedwell design for. Thickener Rake Design.

From nelsonmachinery.com

100' DIA. FLSMIDTH DORROLIVER THICKENER RAKE DRIVE MECHANISM Nelson Machinery & Equipment Ltd. Thickener Rake Design Thickener rakes fulfil three main functions: The solids flux curve is used to model the process of continuous sedimentation. Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. From a metallurgical point, the exclusive design of. Thickener Rake Design.

From www.terex.com

Rake Thickener Tanks Terex Washing Systems Thickener Rake Design Developed for high performance, the patented spiral rake blade solves common issues with. Thickener rakes fulfil three main functions: Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. The solids flux curve is used to model. Thickener Rake Design.

From www.911metallurgist.com

How to Operate a Thickener Thickener Rake Design From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of the tank to the center cone. 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. The solids flux curve is used to model the process of continuous sedimentation. Starting. Thickener Rake Design.

From www.toncin.com

Automatic Rake Tailing Thickener Gold Thickening Equipment, Gold Sludge Mining Thickener Buy Thickener Rake Design The solids flux curve is used to model the process of continuous sedimentation. Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. Thickener rakes fulfil three main functions: Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. Developed. Thickener Rake Design.

From gestech.net

Thickener Rake Arm Design, Severe Acid Environment Thickener Rake Design Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. The solids flux curve is used to model the process of continuous sedimentation. From a metallurgical point, the exclusive design of the spiral rake imparts a continuous. Thickener Rake Design.

From www.snmhi.com

NZY25 Centre Drive Lift Rake Thickener Shenyang Northern Metso Heavy Industry Machinery Co., Ltd. Thickener Rake Design 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. The rake arm is then. The solids flux curve is used to model the process of continuous sedimentation. Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. Thickener rakes and supports metallurgically,. Thickener Rake Design.

From www.slideshare.net

Gravity thickener Thickener Rake Design Developed for high performance, the patented spiral rake blade solves common issues with. Thickener rakes fulfil three main functions: From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of the tank to the center cone. Raked clarifier with advanced feedwell design for a wide range. Thickener Rake Design.

From graver.com

RotaRake® Solids Thickener Pretreat Graver Water Systems Thickener Rake Design Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. Developed for high performance, the patented spiral rake blade solves common issues with. Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. From a metallurgical point, the exclusive design. Thickener Rake Design.

From www.youtube.com

Spiral Rake Blade for thickeners the optimal design YouTube Thickener Rake Design Thickener rakes fulfil three main functions: The rake arm is then. Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of the tank to the center cone. Developed for high performance,. Thickener Rake Design.

From www.911metallurgist.com

Thickeners Thickener Rake Design Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of the tank to the center cone. Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. Thickener rakes fulfil three. Thickener Rake Design.

From www.flsmidth.com

Thickener Spiral Rake Blade FLSmidth Thickener Rake Design 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. Thickener rakes fulfil three main functions: Developed for high performance, the patented. Thickener Rake Design.

From www.flsmidth.com

Thickener Spiral Rake Blade FLSmidth Thickener Rake Design Developed for high performance, the patented spiral rake blade solves common issues with. Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. Thickener rakes fulfil three main functions: Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. The rake arm is then. Starting with the basics of thickener theory, key elements of the. Thickener Rake Design.

From gestech.net

Thickener Rake Arm Design, Severe Acid Environment Thickener Rake Design Developed for high performance, the patented spiral rake blade solves common issues with. From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of the tank to the center cone. Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. Thickener rakes. Thickener Rake Design.

From www.911metallurgist.com

Thickeners Thickener Rake Design The solids flux curve is used to model the process of continuous sedimentation. Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of. Thickener Rake Design.

From makprocess.com.au

RakeLifting Mechanism Mak Process Thickener Rake Design 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. The solids flux curve is used to model the process of continuous sedimentation. The rake arm is then. Developed for high performance, the patented spiral rake blade solves common issues with. Thickener rakes fulfil three main functions: Thickener rakes and supports metallurgically, and mechanically, rakes. Thickener Rake Design.

From graver.com

RotaRake® Solids Thickener Pretreat Graver Water Systems Thickener Rake Design The rake arm is then. Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. The solids flux curve is used to model the process of continuous sedimentation. Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. From a metallurgical point, the exclusive design of the. Thickener Rake Design.

From gestech.net

Thickener Rake Arm Design, Severe Acid Environment Thickener Rake Design Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. Thickener rakes fulfil three main functions: 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. The solids flux curve is used to model the process of continuous sedimentation. From a metallurgical point,. Thickener Rake Design.

From gestech.net

Thickener Rake Arm Design, Severe Acid Environment Thickener Rake Design Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. Developed for high performance, the patented spiral rake blade solves common issues with. The solids flux curve is used to model the process of continuous sedimentation. From a metallurgical point, the exclusive design of the. Thickener Rake Design.

From video.flsmidth.com

Spiral Rake Blade for thickeners the optimal design Thickener Rake Design Developed for high performance, the patented spiral rake blade solves common issues with. 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. The rake arm is then. The solids flux curve is used to model the process of continuous sedimentation. Raked clarifier with advanced feedwell design for a wide range of mining clarification duties.. Thickener Rake Design.

From www.flsmidth.com

Thickener Spiral Rake Blade FLSmidth Thickener Rake Design Developed for high performance, the patented spiral rake blade solves common issues with. From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of the tank to the center cone. Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. Raked clarifier with advanced feedwell. Thickener Rake Design.

From powerscreenofcalifornia.my.invictuslocal.com

Rake Thickener Tanks Powerscreen of California & Hawaii Thickener Rake Design Thickener rakes fulfil three main functions: The solids flux curve is used to model the process of continuous sedimentation. Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. The rake arm is then. From a metallurgical point, the exclusive design of the spiral rake imparts a continuous. Thickener Rake Design.

From nelsonmachinery.com

6' dia x 5' Denver Rake Type Thickener Nelson Machinery & Equipment Thickener Rake Design Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. The rake arm is then. 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. Developed for high performance,. Thickener Rake Design.

From www.terex.com

Rake Thickener Tanks Terex Washing Systems Thickener Rake Design The solids flux curve is used to model the process of continuous sedimentation. From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of the tank to the center cone. The rake arm is then. Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed.. Thickener Rake Design.

From gestech.net

Thickener Rake Arm Design, Severe Acid Environment Thickener Rake Design Raked clarifier with advanced feedwell design for a wide range of mining clarification duties. From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of the tank to the center cone. Thickener rakes fulfil three main functions: The solids flux curve is used to model the. Thickener Rake Design.

From nelsonmachinery.com

6' dia x 5' Denver Rake Type Thickener Nelson Machinery & Equipment Thickener Rake Design From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of the tank to the center cone. 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. The solids flux curve is used to model the process of continuous sedimentation. Thickener. Thickener Rake Design.

From www.filtaquip.com

Rake Drives Filtaquip Mineral Processing Solutions Thickener Rake Design Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. The solids flux curve is used to model the process of continuous sedimentation. Thickener rakes fulfil three main functions: 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. Developed for high performance,. Thickener Rake Design.

From www.matecindustries.com

Rake Thickener Matec Industries Thickener Rake Design Developed for high performance, the patented spiral rake blade solves common issues with. Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. The solids flux curve is used to model the process of continuous sedimentation. The rake arm is then. Thickener rakes and supports metallurgically, and mechanically,. Thickener Rake Design.

From www.emeraldequipmentsystems.com

Rake Thickener Emerald Equipment Systems Inc Thickener Rake Design From a metallurgical point, the exclusive design of the spiral rake imparts a continuous turning motion which conveys the thickened pulp from the outside of the tank to the center cone. Thickener rakes fulfil three main functions: 1) to move sediment to the underflow, 2) to assist in dewatering sediment that settles. Raked clarifier with advanced feedwell design for a. Thickener Rake Design.

From www.westech-inc.com

EvenFlo™ Feedwell Thickener Rake Design Thickener rakes and supports metallurgically, and mechanically, rakes are correctly designed. Developed for high performance, the patented spiral rake blade solves common issues with. Starting with the basics of thickener theory, key elements of the sedimentation process and options for thickener selection are explored, as well. The rake arm is then. Thickener rakes fulfil three main functions: Raked clarifier with. Thickener Rake Design.