Soldering Issues . Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc tests or, worse, fail in the field. The most 7 common soldering mistakes. We’ll explore the reasons behind. This movement can be an unstable work surface or human error which will cause the solder to become distressed before it has completely solidified. Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Read some practical pointers on how to ensure quality solder joints that will endure. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder.

from www.qhsmt.com

Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc tests or, worse, fail in the field. Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. We’ll explore the reasons behind. The most 7 common soldering mistakes. Read some practical pointers on how to ensure quality solder joints that will endure. This movement can be an unstable work surface or human error which will cause the solder to become distressed before it has completely solidified.

SMT pick and place machine &Solder problems in PCB Soldering

Soldering Issues Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc tests or, worse, fail in the field. Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc tests or, worse, fail in the field. We’ll explore the reasons behind. This movement can be an unstable work surface or human error which will cause the solder to become distressed before it has completely solidified. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. The most 7 common soldering mistakes. Read some practical pointers on how to ensure quality solder joints that will endure.

From rushpcb.com

What is a Solder Joint? RushPcb Soldering Issues Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Read some practical pointers on how to ensure quality solder joints that will endure. Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc tests or, worse, fail in the field. Cold joints, characterized by. Soldering Issues.

From www.pinterest.com

⭐⭐ Common soldering problems 👥 Tag your friends who do soldering Soldering Issues Read some practical pointers on how to ensure quality solder joints that will endure. The most 7 common soldering mistakes. Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc tests or, worse, fail in the field. This movement can be an unstable work surface or human error which will cause. Soldering Issues.

From www.youtube.com

Best solution soldering issues YouTube Soldering Issues Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. The most 7 common soldering mistakes. Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc. Soldering Issues.

From stock.adobe.com

Failed solder joints. Cracked or broken solder joints, due to stress Soldering Issues We’ll explore the reasons behind. This movement can be an unstable work surface or human error which will cause the solder to become distressed before it has completely solidified. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering. Soldering Issues.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Soldering Issues Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc tests or, worse, fail in the field. The most 7 common soldering mistakes. We’ll explore the reasons behind. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Disturbed joints arise when there is. Soldering Issues.

From www.ourpcb.com

Insufficient Solder What It Is and What to Do About It Soldering Issues Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Read some practical pointers on how to ensure quality solder joints that will endure. Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. Get tips on causes, inspection methods, repair techniques, and. Soldering Issues.

From www.atetool.com

9 most common problems and mistakes in soldering Soldering Issues The most 7 common soldering mistakes. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Read some practical pointers on how to ensure quality solder joints that will endure. Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. Learn how to identify and. Soldering Issues.

From www.kernowcraft.com

Common Soldering Problems & Solutions For Jewellers Soldering Issues Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. This movement can be an unstable work surface or human error which. Soldering Issues.

From www.finepowertools.com

9 Types of Soldering Defects and Their Solutions Soldering Issues Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. The most 7 common soldering mistakes. Read some practical pointers on how. Soldering Issues.

From electronicshacks.com

Solder Not Sticking How to Fix That? ElectronicsHacks Soldering Issues Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc tests or, worse, fail in the field. Read some practical pointers on how to ensure quality solder joints that will endure. Cold joints, characterized by. Soldering Issues.

From youtube.com

Repair cracked solder joints What is a "Dry" or "Cracked Solder Joint Soldering Issues Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Read some practical pointers on how to ensure quality solder joints that will endure. The most 7 common soldering mistakes. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Get tips on causes, inspection methods, repair. Soldering Issues.

From www.circuits-diy.com

Bad Solder PCB Soldering Issues and their Solution Soldering Issues Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. The most 7 common soldering mistakes. Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Learn how to. Soldering Issues.

From www.vse.com

How to Avoid Common Soldering Problems With DFM Principles VSE Soldering Issues Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. We’ll explore the reasons behind. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Despite being a. Soldering Issues.

From www.digitaltrends.com

How to Solder A Complete Noob's Guide to Melting Metal Digital Trends Soldering Issues Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc tests or, worse, fail in the field. Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. We’ll. Soldering Issues.

From www.qhsmt.com

SMT pick and place machine &Solder problems in PCB Soldering Soldering Issues Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. Read some practical pointers on how to ensure quality solder joints that will endure. Get tips on causes, inspection methods, repair techniques, and best. Soldering Issues.

From www.pcbaaa.com

Mastering Solder Bridge Prevention Essential Tips and Techniques Soldering Issues Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. The most 7 common soldering mistakes. Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Cold joints, characterized by a dull. Soldering Issues.

From www.pcbaservices.com

Solder Melting Point Guide Understanding The Basics Soldering Issues Read some practical pointers on how to ensure quality solder joints that will endure. Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. The most 7 common soldering mistakes. Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Learn how to identify. Soldering Issues.

From learn.adafruit.com

Common Soldering Problems Adafruit Guide To Excellent Soldering Soldering Issues We’ll explore the reasons behind. The most 7 common soldering mistakes. Read some practical pointers on how to ensure quality solder joints that will endure. Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the. Soldering Issues.

From www.youtube.com

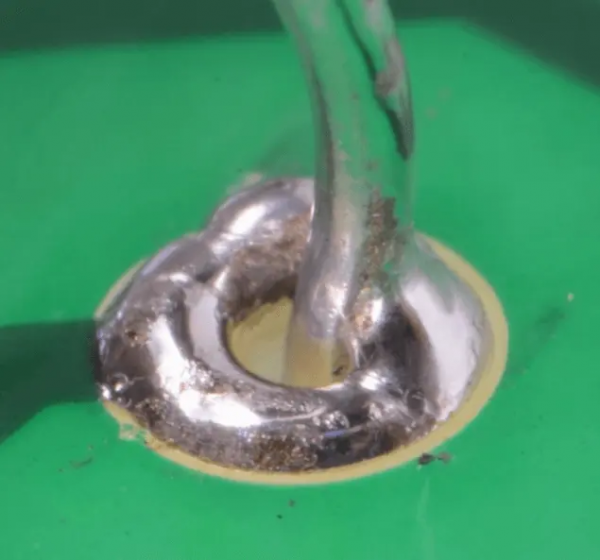

Soldering 101 6. Soldering a Wire to a Terminal YouTube Soldering Issues Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. This movement can be an unstable work surface or human error which will cause the solder to become distressed before it has completely solidified. The most 7 common soldering mistakes. Despite being a relatively straightforward process, there are nine distinct soldering problems that can. Soldering Issues.

From www.electronicdesign.com

Common PCB Soldering Problems to Avoid Electronic Design Soldering Issues Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. Read some practical pointers on how to ensure quality solder joints that will endure. Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc tests or, worse, fail in the field.. Soldering Issues.

From people.bath.ac.uk

ThroughHole Soldering EE12001 Soldering Issues This movement can be an unstable work surface or human error which will cause the solder to become distressed before it has completely solidified. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Read some practical pointers on how to ensure quality solder joints that will endure. Disturbed joints arise when there. Soldering Issues.

From us.misumi-ec.com

Soldering Issues MISUMI Blog Soldering Issues Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Disturbed joints arise when there is movement of. Soldering Issues.

From www.ourpcb.com

Insufficient Solder What It Is and What to Do About It Soldering Issues This movement can be an unstable work surface or human error which will cause the solder to become distressed before it has completely solidified. Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. The most 7 common soldering. Soldering Issues.

From www.youtube.com

Soldering Iron Overheating Problem Soldering Iron Repair YouTube Soldering Issues Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. The most 7 common soldering mistakes. Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc tests or, worse,. Soldering Issues.

From electronics.stackexchange.com

soldering Solder paste issues Electrical Engineering Stack Exchange Soldering Issues This movement can be an unstable work surface or human error which will cause the solder to become distressed before it has completely solidified. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Despite being a relatively. Soldering Issues.

From www.raypcb.com

What is a Cold Joint Solder and How Can You Prevent it? RAYPCB Soldering Issues This movement can be an unstable work surface or human error which will cause the solder to become distressed before it has completely solidified. Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc tests or, worse, fail in the field. We’ll explore the reasons behind. Get tips on causes, inspection. Soldering Issues.

From www.venatormfg.com

Basics of ThroughHole Soldering Venator Technologies Soldering Issues Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Despite being a relatively straightforward process, there are. Soldering Issues.

From www.conro.com

How do I remove flux after soldering the PCB board? ConRo Electronics Soldering Issues Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. The most 7 common soldering mistakes. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Despite being. Soldering Issues.

From www.reddit.com

Check my soldering? MechanicalKeyboards Soldering Issues This movement can be an unstable work surface or human error which will cause the solder to become distressed before it has completely solidified. We’ll explore the reasons behind. Despite being a relatively straightforward process, there are nine distinct soldering problems that can cause boards to fail qc tests or, worse, fail in the field. Get tips on causes, inspection. Soldering Issues.

From www.finepowertools.com

9 Types of Soldering Defects and Their Solutions Soldering Issues The most 7 common soldering mistakes. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Read some practical pointers on how to ensure quality solder joints that will endure. We’ll explore the reasons behind. This movement. Soldering Issues.

From www.bmrsolutions.co.uk

What is a Soldering Technician? BMR Solutions Soldering Issues We’ll explore the reasons behind. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. This movement can be an unstable work surface or human error which will cause the solder to become distressed before it has completely solidified. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and. Soldering Issues.

From www.muggyweld.com

Troubleshooting Brazing and Soldering Common Issues and Solutions Soldering Issues Read some practical pointers on how to ensure quality solder joints that will endure. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. We’ll explore the reasons behind. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Cold joints, characterized by a dull and grainy appearance,. Soldering Issues.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Soldering Issues Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. We’ll explore the reasons behind. Cold joints, characterized by a dull and grainy appearance, occur when solder doesn’t adequately flow and adhere to the components. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Get tips. Soldering Issues.

From www.anzer-usa.com

Q PCB Soldering Problems What Are They Anzer USA Blog Soldering Issues Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. We’ll explore the reasons behind. Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Cold joints, characterized by a dull and. Soldering Issues.

From www.ourpcb.com

Cold Solder Joint A Dry or Cracked Solder Joint Caused by Improper Soldering Issues Disturbed joints arise when there is movement of any kind during the cooling/solidifying of the solder. We’ll explore the reasons behind. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Cold joints, characterized by a dull and. Soldering Issues.