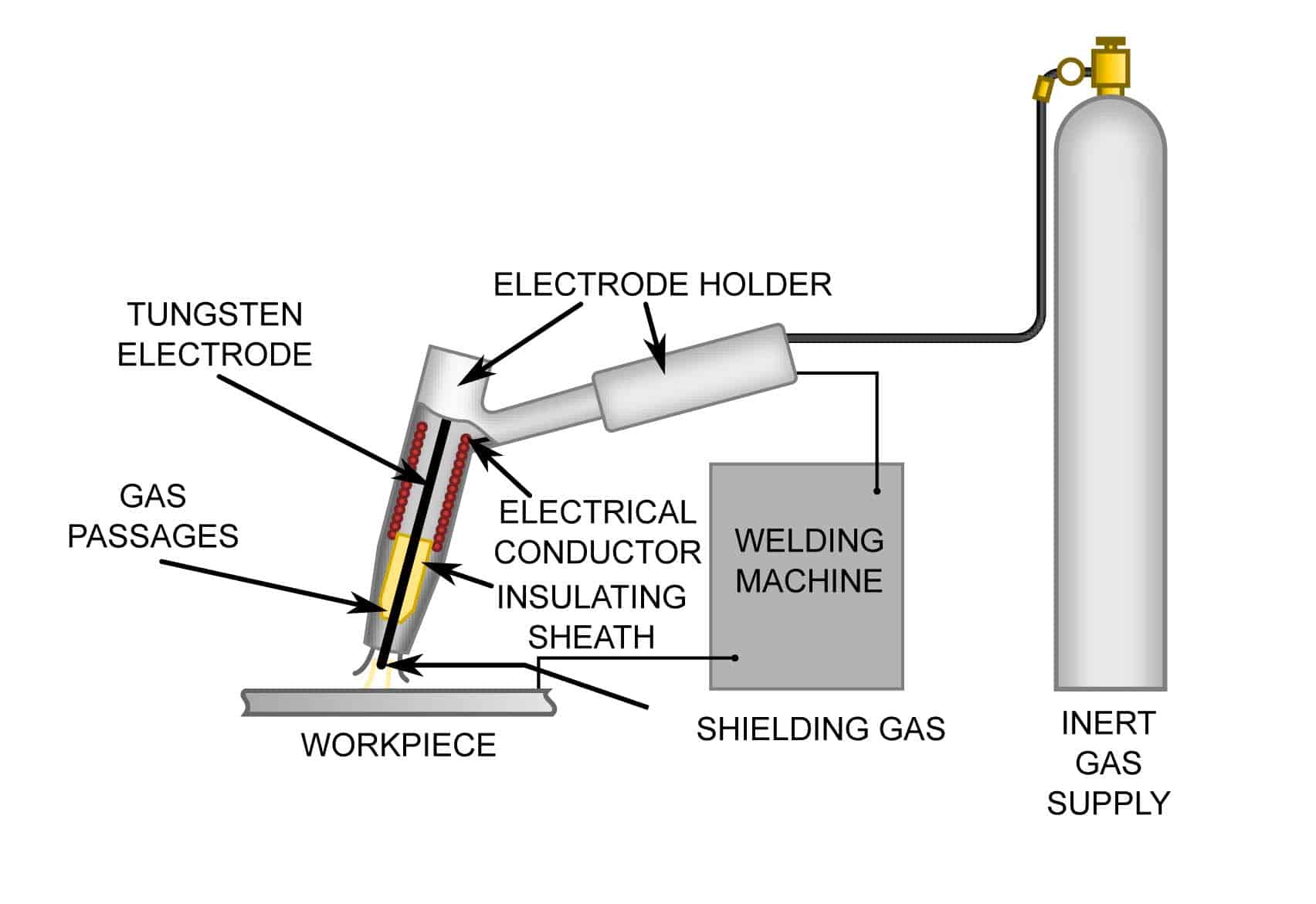

Does Tig Welding Need A Ground . as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or to the metal. The first important part of a tig welder is the work lead, which is also known as a ground. since there is no hf, the scratching or tapping method helps establish a better path to ground as it offers the opportunity to. what is tig welding? the end needs to be ground to a point (see images below). Brand new electrodes will always need to be prepared in this way. the work lead.

from weldingpros.net

as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. the end needs to be ground to a point (see images below). since there is no hf, the scratching or tapping method helps establish a better path to ground as it offers the opportunity to. The first important part of a tig welder is the work lead, which is also known as a ground. what is tig welding? the work lead. the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or to the metal. Brand new electrodes will always need to be prepared in this way.

How to TIG Weld Steel and Aluminum Basics, Setup and Tips

Does Tig Welding Need A Ground Brand new electrodes will always need to be prepared in this way. what is tig welding? the work lead. the end needs to be ground to a point (see images below). since there is no hf, the scratching or tapping method helps establish a better path to ground as it offers the opportunity to. The first important part of a tig welder is the work lead, which is also known as a ground. as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. Brand new electrodes will always need to be prepared in this way. the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or to the metal. According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to.

From www.amazon.com

TIG Welding Brass Ground Clamp, 260A MMA ARC Welder Earth Clamp 3Meter Does Tig Welding Need A Ground the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or to the metal. the end needs to be ground to a point (see images below). the work lead. what is tig welding? Brand new electrodes will always need to be prepared in this way. The first. Does Tig Welding Need A Ground.

From sensibledigs.com

How To TIG Weld (StepbyStep Process) Sensible Digs Does Tig Welding Need A Ground Brand new electrodes will always need to be prepared in this way. the work lead. According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. what is tig welding? since there is no hf, the scratching or tapping method helps establish a better path to ground as. Does Tig Welding Need A Ground.

From openart.ai

Tig welding OpenArt Does Tig Welding Need A Ground the end needs to be ground to a point (see images below). since there is no hf, the scratching or tapping method helps establish a better path to ground as it offers the opportunity to. According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. what is. Does Tig Welding Need A Ground.

From lessonlibalveolitis.z19.web.core.windows.net

Welding Symbols Worksheets Does Tig Welding Need A Ground The first important part of a tig welder is the work lead, which is also known as a ground. According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or. Does Tig Welding Need A Ground.

From www.arccaptain.com

Getting Started with TIG Welding Does Tig Welding Need A Ground the end needs to be ground to a point (see images below). as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. the work lead, often. Does Tig Welding Need A Ground.

From exoxpojqw.blob.core.windows.net

What Is Welding Machine Definition at Heather Doss blog Does Tig Welding Need A Ground According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. the end needs to be ground to a point (see images below). what is tig welding?. Does Tig Welding Need A Ground.

From www.hollyfab.com

Common Welding Methods Does Tig Welding Need A Ground the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or to the metal. what is tig welding? According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. as a subtype of gas metal arc welding (gmaw), tig. Does Tig Welding Need A Ground.

From www.youtube.com

6G Max T TIG Welding For Beginners! From Root To Cap! YouTube Does Tig Welding Need A Ground Brand new electrodes will always need to be prepared in this way. According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. the end needs to be ground to a point (see images below). as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc. Does Tig Welding Need A Ground.

From www.familyhandyman.com

What You Need to Know About TIG Welding Family Handyman Does Tig Welding Need A Ground According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. Brand new electrodes will always need to be prepared in this way. what is tig welding? the work lead. since there is no hf, the scratching or tapping method helps establish a better path to ground as. Does Tig Welding Need A Ground.

From weldguru.com

What is GMAW (MIG Welding) & How Does it Work? Weld Guru Does Tig Welding Need A Ground the end needs to be ground to a point (see images below). since there is no hf, the scratching or tapping method helps establish a better path to ground as it offers the opportunity to. The first important part of a tig welder is the work lead, which is also known as a ground. the work lead,. Does Tig Welding Need A Ground.

From dxowaejmi.blob.core.windows.net

Best Welding Tips Mig at Kathleen Coghill blog Does Tig Welding Need A Ground The first important part of a tig welder is the work lead, which is also known as a ground. as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. Brand new electrodes will always need to be prepared in this way. since there is no hf, the. Does Tig Welding Need A Ground.

From alroys.com

What is TIG welding and how does it work? Alroys Does Tig Welding Need A Ground since there is no hf, the scratching or tapping method helps establish a better path to ground as it offers the opportunity to. According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. The first important part of a tig welder is the work lead, which is also known. Does Tig Welding Need A Ground.

From weldguru.com

Yeswelder MIG205DS Review Is It Worth It? Weld Guru Does Tig Welding Need A Ground Brand new electrodes will always need to be prepared in this way. The first important part of a tig welder is the work lead, which is also known as a ground. as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. the end needs to be ground. Does Tig Welding Need A Ground.

From wiredatairitisga.z22.web.core.windows.net

Types Of Arc Welding Pdf Does Tig Welding Need A Ground the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or to the metal. since there is no hf, the scratching or tapping method helps establish a better path to ground as it offers the opportunity to. the work lead. According to the welding institute (twi), tig welding. Does Tig Welding Need A Ground.

From makemoneywelding.com

MIG vs. TIG Welding Differences Which Is Better? Does Tig Welding Need A Ground Brand new electrodes will always need to be prepared in this way. the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or to the metal. The first important part of a tig welder is the work lead, which is also known as a ground. since there is no. Does Tig Welding Need A Ground.

From weldingpros.net

How to TIG Weld Steel and Aluminum Basics, Setup and Tips Does Tig Welding Need A Ground since there is no hf, the scratching or tapping method helps establish a better path to ground as it offers the opportunity to. the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or to the metal. The first important part of a tig welder is the work lead,. Does Tig Welding Need A Ground.

From makemoneywelding.com

MIG vs. TIG Welding Differences Which Is Better? Does Tig Welding Need A Ground the end needs to be ground to a point (see images below). The first important part of a tig welder is the work lead, which is also known as a ground. the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or to the metal. Brand new electrodes will. Does Tig Welding Need A Ground.

From www.youtube.com

TIG Welding Tips and Arc Length YouTube Does Tig Welding Need A Ground the end needs to be ground to a point (see images below). The first important part of a tig welder is the work lead, which is also known as a ground. the work lead. what is tig welding? According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode. Does Tig Welding Need A Ground.

From diktjiececo.blob.core.windows.net

Tig Welding Machine Symbols at Elizabeth Acevedo blog Does Tig Welding Need A Ground as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. the end needs to be ground to a point (see images below). The first important part of a tig welder is the work lead, which is also known as a ground. since there is no hf,. Does Tig Welding Need A Ground.

From makemoneywelding.com

MIG vs. TIG Welding Differences Which Is Better? Does Tig Welding Need A Ground the end needs to be ground to a point (see images below). According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. Brand new electrodes will always need to be prepared in this way. The first important part of a tig welder is the work lead, which is also. Does Tig Welding Need A Ground.

From www.technoxmachine.com

MIG vs TIG Welding Types, Materials, and Applications A Guide Does Tig Welding Need A Ground The first important part of a tig welder is the work lead, which is also known as a ground. the end needs to be ground to a point (see images below). what is tig welding? as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. According. Does Tig Welding Need A Ground.

From weldersmanual.com

TIG Welding Polarity A Beginners Guide Welders Manual Does Tig Welding Need A Ground According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. Brand new electrodes will always need to be prepared in this way. as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. The first important part of a. Does Tig Welding Need A Ground.

From weldguru.com

What is TIG Welding (GTAW) & How it Works Weld Guru Does Tig Welding Need A Ground as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. the end needs to be ground to a point (see images below). According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. the work lead. . Does Tig Welding Need A Ground.

From aspiringyouths.com

Advantages and Disadvantages of Tig Welding Does Tig Welding Need A Ground According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or to the metal. Brand new electrodes will always need to be prepared in this way. what is tig. Does Tig Welding Need A Ground.

From schematiclibfriars99.z22.web.core.windows.net

Miller Welding Machine 220v Does Tig Welding Need A Ground what is tig welding? the work lead. as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. the end needs to be ground to a point (see images below). According to the welding institute (twi), tig welding is a fusion welding process that uses a. Does Tig Welding Need A Ground.

From www.weldingtipsandtricks.com

Tig Welding Carbon Steel lap joints Does Tig Welding Need A Ground Brand new electrodes will always need to be prepared in this way. since there is no hf, the scratching or tapping method helps establish a better path to ground as it offers the opportunity to. The first important part of a tig welder is the work lead, which is also known as a ground. the work lead, often. Does Tig Welding Need A Ground.

From www.perfectwelders.com

TIG PERFECT POWER Welders, Welding Wire, Welding Equipment Does Tig Welding Need A Ground the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or to the metal. as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. the end needs to be ground to a point (see images below). . Does Tig Welding Need A Ground.

From weldingmastermind.com

How to Clean and Prepare Metal for TIG Welding Welding Mastermind Does Tig Welding Need A Ground what is tig welding? According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. The first important part of a tig welder is the work lead, which is also known as a ground. the work lead, often referred to as a ground cable with a clamp, must be. Does Tig Welding Need A Ground.

From www.youtube.com

Manual to TIG Welding YouTube Does Tig Welding Need A Ground According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. The first important part of a tig welder is the work lead, which is also known as a ground. the end needs to be ground to a point (see images below). the work lead. as a subtype. Does Tig Welding Need A Ground.

From yeswelder.com

Getting Started with TIG Welding YesWelder Does Tig Welding Need A Ground as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. the end needs to be ground to a point (see images below). the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or to the metal. . Does Tig Welding Need A Ground.

From schematicjayciferxp.z4.web.core.windows.net

Types Of Welding Process With Diagram Does Tig Welding Need A Ground According to the welding institute (twi), tig welding is a fusion welding process that uses a nonconsumable (tungsten) electrode to. Brand new electrodes will always need to be prepared in this way. the work lead. the work lead, often referred to as a ground cable with a clamp, must be attached to the workpiece or to the metal.. Does Tig Welding Need A Ground.

From www.codinter.com

TIG vs. MIG Welding Which one to use in every case Codinter Americas Does Tig Welding Need A Ground the work lead. what is tig welding? since there is no hf, the scratching or tapping method helps establish a better path to ground as it offers the opportunity to. Brand new electrodes will always need to be prepared in this way. the end needs to be ground to a point (see images below). as. Does Tig Welding Need A Ground.

From www.youtube.com

TIG WELDING STAINLESS STEEL HOW TO TIG WELD STAINLESS STEEL FOR Does Tig Welding Need A Ground the work lead. what is tig welding? as a subtype of gas metal arc welding (gmaw), tig welding—or gas tungsten arc welding (gtaw) as it’s formally known—stands out. the end needs to be ground to a point (see images below). The first important part of a tig welder is the work lead, which is also known. Does Tig Welding Need A Ground.