Kyocera Insert Drill Feeds And Speeds . Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. Ipm = (inch / flute) x 5 x rpm. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Sfm x 3.82 / d1. Economical inserts with 4 cutting edges. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. Molded chipbreaker produces three separate chips for smooth chip. The new insert clamp design is. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge.

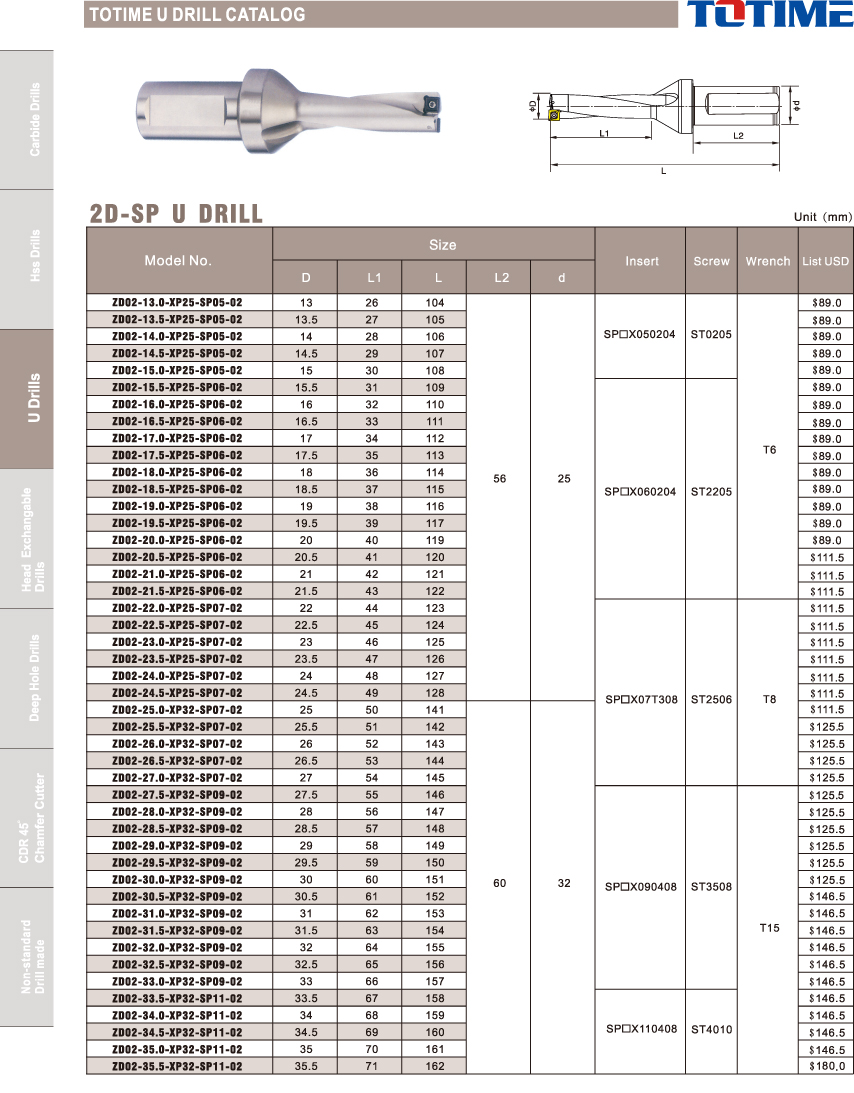

from www.totimetools.com

Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. Ipm = (inch / flute) x 5 x rpm. Sfm x 3.82 / d1. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Molded chipbreaker produces three separate chips for smooth chip. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. The new insert clamp design is. Economical inserts with 4 cutting edges. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge.

U DRILL

Kyocera Insert Drill Feeds And Speeds Molded chipbreaker produces three separate chips for smooth chip. Sfm x 3.82 / d1. Molded chipbreaker produces three separate chips for smooth chip. Economical inserts with 4 cutting edges. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge. Ipm = (inch / flute) x 5 x rpm. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. The new insert clamp design is. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry.

From www.grainger.com

KYOCERA, Indexable Drill Insert 61MP01TCMT12122HPKW10 Grainger Kyocera Insert Drill Feeds And Speeds Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. Economical inserts with 4 cutting edges. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Sfm x 3.82 / d1. Ipm = (inch / flute) x 5 x rpm. The new insert clamp design is. Excellent chip evacuation with large. Kyocera Insert Drill Feeds And Speeds.

From www.mscdirect.com

Kyocera Indexable Drill Insert ZCMT12SP KW10, Solid Carbide MSC Kyocera Insert Drill Feeds And Speeds Economical inserts with 4 cutting edges. Sfm x 3.82 / d1. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Ipm = (inch / flute) x 5 x rpm. Molded chipbreaker produces three separate chips for smooth chip. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix. Kyocera Insert Drill Feeds And Speeds.

From www.mscdirect.com

Kyocera Indexable Drill Insert WCMXM1 CA6535, Solid Carbide MSC Direct Kyocera Insert Drill Feeds And Speeds Sfm x 3.82 / d1. Economical inserts with 4 cutting edges. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry.. Kyocera Insert Drill Feeds And Speeds.

From www.grainger.com

KYOCERA Indexable Insert Drill 61MM64S150DRZ1812725015G Grainger Kyocera Insert Drill Feeds And Speeds “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge. Economical inserts with 4 cutting edges. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. Molded chipbreaker produces three separate. Kyocera Insert Drill Feeds And Speeds.

From www.lowrysupply.com

Kyocera Drilling Inserts Page 1 Kyocera Insert Drill Feeds And Speeds “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Economical inserts with 4 cutting edges. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. Sfm x 3.82 / d1.. Kyocera Insert Drill Feeds And Speeds.

From www.carbidedepot.com

Carbide Depot Technical Resources Kyocera Insert Drill Feeds And Speeds “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. Sfm x 3.82 / d1. Ipm = (inch / flute) x 5 x rpm. Consult kyocera sgs precision tools's entire speeds and feeds. Kyocera Insert Drill Feeds And Speeds.

From mungfali.com

Drill Feed Speed Chart Kyocera Insert Drill Feeds And Speeds Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Molded chipbreaker produces three separate chips for smooth chip. The new insert clamp design is. Ipm = (inch / flute) x 5 x rpm. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during. Kyocera Insert Drill Feeds And Speeds.

From www.mscdirect.com

Kyocera Indexable Drill Insert ZCMT15SP PR1225, Solid Carbide MSC Kyocera Insert Drill Feeds And Speeds Economical inserts with 4 cutting edges. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Sfm x 3.82 / d1. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Molded chipbreaker produces three separate chips for smooth chip. “e” class turning insert · accuracy of. Kyocera Insert Drill Feeds And Speeds.

From giotsrboi.blob.core.windows.net

Kyocera Carbide Drill Speeds And Feeds at Kevin Rueb blog Kyocera Insert Drill Feeds And Speeds Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Molded chipbreaker produces three separate chips for. Kyocera Insert Drill Feeds And Speeds.

From www.mscdirect.com

Kyocera Indexable Drill Insert WCMX06M1 PR905, Solid Carbide MSC Kyocera Insert Drill Feeds And Speeds Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge. Economical inserts with 4 cutting edges. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Single. Kyocera Insert Drill Feeds And Speeds.

From www.amazon.com

KYOCERA ZCMT150408KW10 Indexable Drill Insert, ZCMT, KW10 Grade Kyocera Insert Drill Feeds And Speeds Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Economical inserts with 4 cutting edges. The new insert clamp design is. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm ·. Kyocera Insert Drill Feeds And Speeds.

From www.mscdirect.com

Kyocera ZXMT040203SM GW15 Carbide Indexable Drill Insert 50356211 Kyocera Insert Drill Feeds And Speeds Ipm = (inch / flute) x 5 x rpm. Economical inserts with 4 cutting edges. Molded chipbreaker produces three separate chips for smooth chip. Sfm x 3.82 / d1. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. The new insert clamp design is. Excellent chip evacuation with large thinning cutting edge. Kyocera Insert Drill Feeds And Speeds.

From www.mscdirect.com

Kyocera Indexable Drill Insert ZCMT10 PR1230, Solid Carbide MSC Direct Kyocera Insert Drill Feeds And Speeds Ipm = (inch / flute) x 5 x rpm. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Economical inserts with 4 cutting edges. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed.. Kyocera Insert Drill Feeds And Speeds.

From www.mscdirect.com

Kyocera Indexable Insert Drill S25DRV170M205, 17.00 mm Max Dia, 34. Kyocera Insert Drill Feeds And Speeds Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Economical inserts with 4 cutting edges. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Sfm x 3.82 / d1. The new insert clamp design is. Consult kyocera sgs precision tools's entire speeds and feeds catalogue. Kyocera Insert Drill Feeds And Speeds.

From mungfali.com

Titanium Feeds And Speeds Chart Kyocera Insert Drill Feeds And Speeds Economical inserts with 4 cutting edges. The new insert clamp design is. Molded chipbreaker produces three separate chips for smooth chip. Sfm x 3.82 / d1. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge. Ipm =. Kyocera Insert Drill Feeds And Speeds.

From www.mscdirect.com

Kyocera ZCMT150408 PR1230 Carbide Indexable Drill Insert 41932013 Kyocera Insert Drill Feeds And Speeds Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. The new insert clamp design is. Excellent chip evacuation with large. Kyocera Insert Drill Feeds And Speeds.

From www.lowrysupply.com

Kyocera Drilling Inserts Page 1 Kyocera Insert Drill Feeds And Speeds Ipm = (inch / flute) x 5 x rpm. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. “e” class turning insert · accuracy. Kyocera Insert Drill Feeds And Speeds.

From www.mscdirect.com

Kyocera 3.28" Max Drill Depth, 5xD, 0.656" Diam, Indexable Insert Kyocera Insert Drill Feeds And Speeds Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. Consult kyocera sgs precision tools's entire speeds and feeds catalogue. Kyocera Insert Drill Feeds And Speeds.

From www.indiamart.com

Kyocera Carbide DRILLING INSERT, Material Grade Ss Grade, Rs 120 /no Kyocera Insert Drill Feeds And Speeds The new insert clamp design is. Sfm x 3.82 / d1. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. Economical inserts with 4 cutting edges. Molded chipbreaker produces three separate chips for smooth chip. Ipm = (inch / flute) x 5 x rpm. “e” class turning insert · accuracy of index. Kyocera Insert Drill Feeds And Speeds.

From www.mscdirect.com

Kyocera Indexable Drill Insert ZXMT17GH PR1230, Solid Carbide MSC Kyocera Insert Drill Feeds And Speeds Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. Economical inserts with 4 cutting edges. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. Molded chipbreaker produces three separate chips for smooth chip. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and.. Kyocera Insert Drill Feeds And Speeds.

From www.lowrysupply.com

Kyocera Drilling Inserts Page 1 Kyocera Insert Drill Feeds And Speeds “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Sfm x 3.82 / d1. The new. Kyocera Insert Drill Feeds And Speeds.

From www.mscdirect.com

Kyocera Indexable Drill Insert ZCMT15 PR1230, Solid Carbide MSC Direct Kyocera Insert Drill Feeds And Speeds Ipm = (inch / flute) x 5 x rpm. Molded chipbreaker produces three separate chips for smooth chip. Sfm x 3.82 / d1. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. Economical inserts with 4 cutting edges. The new. Kyocera Insert Drill Feeds And Speeds.

From www.amazon.com

Kyocera DS 105 PR1210 Grade PVD Carbide, Indexable Drilling Insert (10 Kyocera Insert Drill Feeds And Speeds The new insert clamp design is. Sfm x 3.82 / d1. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge. Molded chipbreaker produces three separate chips for smooth chip. Economical inserts with 4. Kyocera Insert Drill Feeds And Speeds.

From giotsrboi.blob.core.windows.net

Kyocera Carbide Drill Speeds And Feeds at Kevin Rueb blog Kyocera Insert Drill Feeds And Speeds Ipm = (inch / flute) x 5 x rpm. The new insert clamp design is. Economical inserts with 4 cutting edges. Molded chipbreaker produces three separate chips for smooth chip. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. Single insert. Kyocera Insert Drill Feeds And Speeds.

From www.youtube.com

High Efficiency Indexable Insert Drilling with the KYOCERA DRV Magic Kyocera Insert Drill Feeds And Speeds Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. Sfm x 3.82 / d1. Excellent chip evacuation with large thinning. Kyocera Insert Drill Feeds And Speeds.

From www.lowrysupply.com

Kyocera Drilling Inserts Page 1 Kyocera Insert Drill Feeds And Speeds Molded chipbreaker produces three separate chips for smooth chip. Sfm x 3.82 / d1. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. Ipm = (inch / flute) x 5 x rpm. The new insert clamp design is. Ramp at 5 degrees or less, using slotting speed and feed rates (do not. Kyocera Insert Drill Feeds And Speeds.

From www.lowrysupply.com

Kyocera Drilling Inserts Page 1 Kyocera Insert Drill Feeds And Speeds Molded chipbreaker produces three separate chips for smooth chip. Sfm x 3.82 / d1. The new insert clamp design is. Economical inserts with 4 cutting edges. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Single. Kyocera Insert Drill Feeds And Speeds.

From www.cnccookbook.com

Unlocking the Potential of Insert Drills [+Speeds and Feeds Kyocera Insert Drill Feeds And Speeds Ipm = (inch / flute) x 5 x rpm. Molded chipbreaker produces three separate chips for smooth chip. Economical inserts with 4 cutting edges. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during. Kyocera Insert Drill Feeds And Speeds.

From www.totimetools.com

U DRILL Kyocera Insert Drill Feeds And Speeds Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Economical inserts with 4 cutting edges. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. Consult kyocera sgs precision. Kyocera Insert Drill Feeds And Speeds.

From www.atsontools.com

KYOCERA CARBIDE INSERTS Kyocera Carbide Inserts Wholesale Trader from Kyocera Insert Drill Feeds And Speeds Ipm = (inch / flute) x 5 x rpm. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. Molded chipbreaker produces three separate chips for smooth chip. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. Economical inserts with 4 cutting edges. “e” class turning insert · accuracy of. Kyocera Insert Drill Feeds And Speeds.

From www.mscdirect.com

Kyocera Indexable Drill Insert WCMX06M1 PR1230, Solid Carbide MSC Kyocera Insert Drill Feeds And Speeds Economical inserts with 4 cutting edges. Ipm = (inch / flute) x 5 x rpm. Molded chipbreaker produces three separate chips for smooth chip. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro chipping during edge. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and.. Kyocera Insert Drill Feeds And Speeds.

From www.mscdirect.com

Kyocera Indexable Insert Drill CD2060C, 2.1598" Max Dia, 3.1252" Max Kyocera Insert Drill Feeds And Speeds Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. Molded chipbreaker produces three separate chips for smooth chip. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. “e” class turning insert · accuracy of index position after insert replacement ±0.1mm ±0.02mm · reduced micro. Kyocera Insert Drill Feeds And Speeds.

From www.grainger.com

KYOCERA, Indexable Drill Insert 61MN79SCMT040209GHIPR1535 Grainger Kyocera Insert Drill Feeds And Speeds Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. Single insert in both pockets and four cutting edges per insert promotes cost savings and increased efficiency. Ipm = (inch / flute) x 5 x rpm. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Ramp at 5 degrees or less,. Kyocera Insert Drill Feeds And Speeds.

From www.youtube.com

Selecting Correct Speeds and Feeds for Drilling YouTube Kyocera Insert Drill Feeds And Speeds Economical inserts with 4 cutting edges. The new insert clamp design is. Molded chipbreaker produces three separate chips for smooth chip. Ipm = (inch / flute) x 5 x rpm. Excellent chip evacuation with large thinning cutting edge angle reduce burr by large helix angle and. Sfm x 3.82 / d1. “e” class turning insert · accuracy of index position. Kyocera Insert Drill Feeds And Speeds.

From www.grainger.com

KYOCERA, Indexable Insert Drill 61MN60S150DRV1875214 Grainger Kyocera Insert Drill Feeds And Speeds The new insert clamp design is. Sfm x 3.82 / d1. Molded chipbreaker produces three separate chips for smooth chip. Ipm = (inch / flute) x 5 x rpm. Consult kyocera sgs precision tools's entire speeds and feeds catalogue on directindustry. Ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) reduce speed. Excellent chip. Kyocera Insert Drill Feeds And Speeds.