Thickness Gauge Disadvantages . Here, we review seven key questions to. In several cases, only one surface requires to be accessed. Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. Ultrasonic testing does have thickness limitations, but these are difficult to reach. The advantages and disadvantages of ultrasonic thickness gauges are as follows: Ultrasonic thickness gauging is a widely used nondestructive test technique for measuring the thickness of a material from one side. In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. When selecting a thickness gauge for your application, there are a number of criteria to consider. Higher sensitivity allows the detection of even extremely small flaws. For this reason, one of the primary uses of ultrasonic testing is actually to gauge the thickness of. If you need to measure the thickness of.

from www.newmantools.com

Here, we review seven key questions to. If you need to measure the thickness of. In several cases, only one surface requires to be accessed. Higher sensitivity allows the detection of even extremely small flaws. Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. Ultrasonic thickness gauging is a widely used nondestructive test technique for measuring the thickness of a material from one side. Ultrasonic testing does have thickness limitations, but these are difficult to reach. The advantages and disadvantages of ultrasonic thickness gauges are as follows: For this reason, one of the primary uses of ultrasonic testing is actually to gauge the thickness of. In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages.

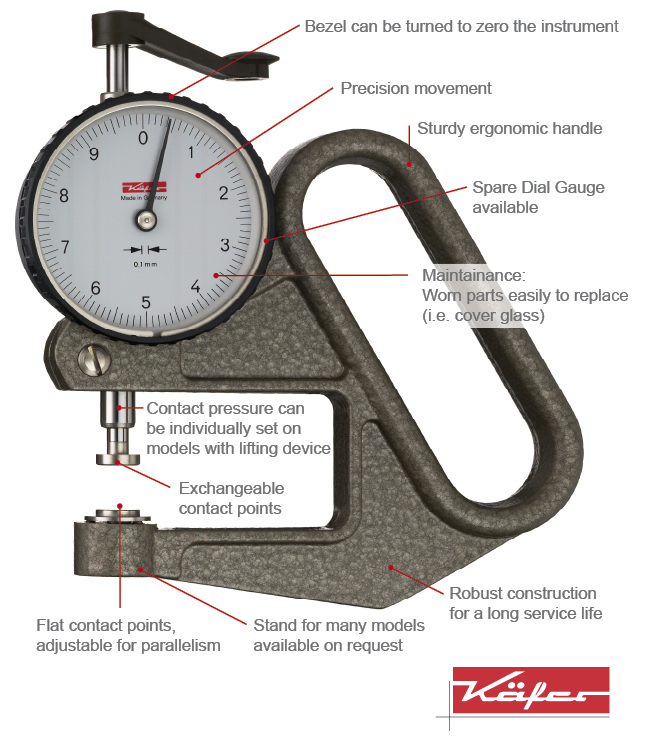

Kafer dial thickness gauges, indicators, gages, manufactured by Kaefer

Thickness Gauge Disadvantages When selecting a thickness gauge for your application, there are a number of criteria to consider. Here, we review seven key questions to. In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. The advantages and disadvantages of ultrasonic thickness gauges are as follows: In several cases, only one surface requires to be accessed. Ultrasonic testing does have thickness limitations, but these are difficult to reach. For this reason, one of the primary uses of ultrasonic testing is actually to gauge the thickness of. Higher sensitivity allows the detection of even extremely small flaws. If you need to measure the thickness of. Ultrasonic thickness gauging is a widely used nondestructive test technique for measuring the thickness of a material from one side. When selecting a thickness gauge for your application, there are a number of criteria to consider.

From www.kency.in

Kency Measuring Instruments Thickness Gauge Disadvantages Ultrasonic thickness gauging is a widely used nondestructive test technique for measuring the thickness of a material from one side. For this reason, one of the primary uses of ultrasonic testing is actually to gauge the thickness of. Higher sensitivity allows the detection of even extremely small flaws. When selecting a thickness gauge for your application, there are a number. Thickness Gauge Disadvantages.

From www.mrclab.com

Series Thickness Gauges Thickness Gauge Disadvantages When selecting a thickness gauge for your application, there are a number of criteria to consider. Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. Ultrasonic testing does have thickness limitations, but these are difficult to reach. Here, we review seven key questions to. Higher. Thickness Gauge Disadvantages.

From siosoptical.com

Thickness Gauge Sios Optical Thickness Gauge Disadvantages If you need to measure the thickness of. In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. In several cases, only one surface requires to be accessed. Ultrasonic testing does have thickness limitations, but these are difficult to reach. Ultrasonic thickness gauging is a widely used nondestructive test technique for measuring the thickness of. Thickness Gauge Disadvantages.

From thebombaytools.com

Digital Dial Thickness Gauge547 Series 547360, General Measurement Thickness Gauge Disadvantages For this reason, one of the primary uses of ultrasonic testing is actually to gauge the thickness of. If you need to measure the thickness of. The advantages and disadvantages of ultrasonic thickness gauges are as follows: In several cases, only one surface requires to be accessed. Ultrasonic testing does have thickness limitations, but these are difficult to reach. In. Thickness Gauge Disadvantages.

From issuu.com

COATING THICKNESS GAUGE by bizmax Issuu Thickness Gauge Disadvantages In several cases, only one surface requires to be accessed. Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. The advantages and disadvantages of ultrasonic thickness gauges are as follows: Higher sensitivity allows the detection of even extremely small flaws. Ultrasonic testing does have thickness. Thickness Gauge Disadvantages.

From periodictableoftools.com

Thickness Gauges Thickness Gauge Disadvantages When selecting a thickness gauge for your application, there are a number of criteria to consider. Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. If you need to measure the thickness of. For this reason, one of the primary uses of ultrasonic testing is. Thickness Gauge Disadvantages.

From hvactools.com.au

Thickness Gauges HVACTOOLS Australia Thickness Gauge Disadvantages In several cases, only one surface requires to be accessed. The advantages and disadvantages of ultrasonic thickness gauges are as follows: For this reason, one of the primary uses of ultrasonic testing is actually to gauge the thickness of. Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one. Thickness Gauge Disadvantages.

From erich-hartmann.com

How to choose a thickness gauge An online magazine about style Thickness Gauge Disadvantages Ultrasonic thickness gauging is a widely used nondestructive test technique for measuring the thickness of a material from one side. In several cases, only one surface requires to be accessed. Ultrasonic testing does have thickness limitations, but these are difficult to reach. Higher sensitivity allows the detection of even extremely small flaws. Here, we review seven key questions to. When. Thickness Gauge Disadvantages.

From www.raviscientific.in

Digital Thickness Gauge 12.7 mm Ravi Scientific Industries Thickness Gauge Disadvantages Ultrasonic testing does have thickness limitations, but these are difficult to reach. In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. In several cases, only one surface requires to be accessed. Here, we review seven key questions to. If you need to measure the thickness of. For this reason, one of the primary uses. Thickness Gauge Disadvantages.

From gordyssensors.com

IFELL Thickness Gauge Laser Thickness Gauge System Gordy Sensor Thickness Gauge Disadvantages Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. If you need to measure the thickness of. Ultrasonic thickness gauging is a widely used nondestructive test technique for measuring the thickness of a material from one side. In conclusion, both coating thickness gauges and ultrasonic. Thickness Gauge Disadvantages.

From www.metropolitanleather.com

Thickness Gauge Metropolitan Leather Thickness Gauge Disadvantages Ultrasonic testing does have thickness limitations, but these are difficult to reach. Higher sensitivity allows the detection of even extremely small flaws. If you need to measure the thickness of. In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. Ultrasonic thickness gauging is a widely used nondestructive test technique for measuring the thickness of. Thickness Gauge Disadvantages.

From www.tool.com

High Precision Digital Thickness Gauge, 30mm Depth, 0.001mm Resolution Thickness Gauge Disadvantages Higher sensitivity allows the detection of even extremely small flaws. For this reason, one of the primary uses of ultrasonic testing is actually to gauge the thickness of. In several cases, only one surface requires to be accessed. Ultrasonic thickness gauging is a widely used nondestructive test technique for measuring the thickness of a material from one side. The advantages. Thickness Gauge Disadvantages.

From mextechin.com

What are the Applications and Uses of Coating Thickness Gauge? MEXTECH Thickness Gauge Disadvantages Here, we review seven key questions to. If you need to measure the thickness of. Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. In several cases, only one surface requires to be accessed. For this reason, one of the primary uses of ultrasonic testing. Thickness Gauge Disadvantages.

From erich-hartmann.com

How to choose a thickness gauge An online magazine about style Thickness Gauge Disadvantages In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. The advantages and disadvantages of ultrasonic thickness gauges are as follows: For this reason, one of the primary uses of ultrasonic testing is actually to gauge the thickness of. Here, we review seven key questions to. In several cases, only one surface requires to be. Thickness Gauge Disadvantages.

From www.newmantools.com

Kafer dial thickness gauges, indicators, gages, manufactured by Kaefer Thickness Gauge Disadvantages The advantages and disadvantages of ultrasonic thickness gauges are as follows: When selecting a thickness gauge for your application, there are a number of criteria to consider. In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has. Thickness Gauge Disadvantages.

From ndt-kits.com

Coating Thickness Gauge Definition and Working Principle NDTKITS Thickness Gauge Disadvantages Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. For this reason, one of the primary uses of ultrasonic testing is actually to gauge the thickness of. The advantages and disadvantages of ultrasonic thickness gauges are as follows: In several cases, only one surface requires. Thickness Gauge Disadvantages.

From www.walmart.com

Stainless Steel Thickness Gauges Wire Gauge Measurement Tool Metal Thickness Gauge Disadvantages For this reason, one of the primary uses of ultrasonic testing is actually to gauge the thickness of. When selecting a thickness gauge for your application, there are a number of criteria to consider. The advantages and disadvantages of ultrasonic thickness gauges are as follows: If you need to measure the thickness of. Here, we review seven key questions to.. Thickness Gauge Disadvantages.

From thebombaytools.com

Shop Dial Thickness Gauge 7327 Online, Dial Thickness Gauge 7327 Thickness Gauge Disadvantages Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. In several cases, only one surface requires to be accessed. In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. Ultrasonic thickness gauging is a widely used nondestructive test technique for. Thickness Gauge Disadvantages.

From us.misumi-ec.com

Thickness Gauge (Leaf Width 12.7 mm) NIIGATA SEIKI MISUMI Thickness Gauge Disadvantages In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. If you need to measure the thickness of. For this reason, one of the primary uses of ultrasonic testing is actually to gauge the thickness of. Higher sensitivity allows the detection of even extremely small flaws. The advantages and disadvantages of ultrasonic thickness gauges are. Thickness Gauge Disadvantages.

From www.amazon.com

DoubleSided Wire Gauge Measurement Tool 036 American Standard and Thickness Gauge Disadvantages Ultrasonic testing does have thickness limitations, but these are difficult to reach. When selecting a thickness gauge for your application, there are a number of criteria to consider. Here, we review seven key questions to. Higher sensitivity allows the detection of even extremely small flaws. The advantages and disadvantages of ultrasonic thickness gauges are as follows: If you need to. Thickness Gauge Disadvantages.

From stonesandfindings.com

Gauge Thickness Chart Thickness Gauge Disadvantages If you need to measure the thickness of. Ultrasonic thickness gauging is a widely used nondestructive test technique for measuring the thickness of a material from one side. Ultrasonic testing does have thickness limitations, but these are difficult to reach. In several cases, only one surface requires to be accessed. For this reason, one of the primary uses of ultrasonic. Thickness Gauge Disadvantages.

From sendcutsend.com

Guide to Understanding Gauge Thickness SendCutSend Thickness Gauge Disadvantages When selecting a thickness gauge for your application, there are a number of criteria to consider. In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. Higher sensitivity allows the detection. Thickness Gauge Disadvantages.

From tjibc.com

Gauge Steel Thickness Sheet Metal Gauge Chart IBC Group Thickness Gauge Disadvantages Here, we review seven key questions to. In several cases, only one surface requires to be accessed. When selecting a thickness gauge for your application, there are a number of criteria to consider. In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. If you need to measure the thickness of. Ultrasonic thickness gauges are. Thickness Gauge Disadvantages.

From slideplayer.info

Alat ukur dan teknik pengukuran ppt download Thickness Gauge Disadvantages Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. Ultrasonic testing does have thickness limitations, but these are difficult to reach. Here, we review seven key questions to. In several cases, only one surface requires to be accessed. When selecting a thickness gauge for your. Thickness Gauge Disadvantages.

From www.guoou-testers.com

Advantages And Disadvantages Of Induction Coating Thickness Thickness Gauge Disadvantages The advantages and disadvantages of ultrasonic thickness gauges are as follows: Higher sensitivity allows the detection of even extremely small flaws. Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. Here, we review seven key questions to. When selecting a thickness gauge for your application,. Thickness Gauge Disadvantages.

From www.creativefabrica.com

Thickness Gauge Icon Graphic by aimagenarium · Creative Fabrica Thickness Gauge Disadvantages For this reason, one of the primary uses of ultrasonic testing is actually to gauge the thickness of. Here, we review seven key questions to. Ultrasonic testing does have thickness limitations, but these are difficult to reach. The advantages and disadvantages of ultrasonic thickness gauges are as follows: If you need to measure the thickness of. Ultrasonic thickness gauges are. Thickness Gauge Disadvantages.

From primetek.in

Integrated Floor Thickness Gauge Primetek Instruments & Technology Thickness Gauge Disadvantages In several cases, only one surface requires to be accessed. If you need to measure the thickness of. Ultrasonic thickness gauging is a widely used nondestructive test technique for measuring the thickness of a material from one side. Higher sensitivity allows the detection of even extremely small flaws. Ultrasonic testing does have thickness limitations, but these are difficult to reach.. Thickness Gauge Disadvantages.

From www.checkline.eu

TMG universal thickness gauge for ASTM, DIN, EN & ISO norms Thickness Gauge Disadvantages Here, we review seven key questions to. Ultrasonic testing does have thickness limitations, but these are difficult to reach. In several cases, only one surface requires to be accessed. When selecting a thickness gauge for your application, there are a number of criteria to consider. For this reason, one of the primary uses of ultrasonic testing is actually to gauge. Thickness Gauge Disadvantages.

From ja.wikipedia.org

ファイルThickness gauge.jpg Wikipedia Thickness Gauge Disadvantages The advantages and disadvantages of ultrasonic thickness gauges are as follows: Higher sensitivity allows the detection of even extremely small flaws. In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. When selecting a thickness gauge for your application, there are a number of criteria to consider. Ultrasonic thickness gauging is a widely used nondestructive. Thickness Gauge Disadvantages.

From www.accud.com

THICKNESS GAUGE ACCUD Thickness Gauge Disadvantages For this reason, one of the primary uses of ultrasonic testing is actually to gauge the thickness of. In several cases, only one surface requires to be accessed. Ultrasonic testing does have thickness limitations, but these are difficult to reach. The advantages and disadvantages of ultrasonic thickness gauges are as follows: When selecting a thickness gauge for your application, there. Thickness Gauge Disadvantages.

From www.saga.com.sg

Thickness Gauge Series HTGA Saga Instruments Pte Ltd Thickness Gauge Disadvantages The advantages and disadvantages of ultrasonic thickness gauges are as follows: If you need to measure the thickness of. When selecting a thickness gauge for your application, there are a number of criteria to consider. Ultrasonic thickness gauging is a widely used nondestructive test technique for measuring the thickness of a material from one side. For this reason, one of. Thickness Gauge Disadvantages.

From www.modsonic.com

How Do Ultrasonic Thickness Gauges Work? Thickness Gauge Disadvantages Ultrasonic testing does have thickness limitations, but these are difficult to reach. Higher sensitivity allows the detection of even extremely small flaws. When selecting a thickness gauge for your application, there are a number of criteria to consider. Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side. Thickness Gauge Disadvantages.

From gambrick.com

12 vs 14 gauge wire thickness infographic chart 1.0 Modern Design Thickness Gauge Disadvantages In several cases, only one surface requires to be accessed. In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. Here, we review seven key questions to. When selecting a thickness gauge for your application, there are a number of criteria to consider. Ultrasonic testing does have thickness limitations, but these are difficult to reach.. Thickness Gauge Disadvantages.

From jaibros.com

Dial Thickness Gauge Jaibros Thickness Gauge Disadvantages Ultrasonic testing does have thickness limitations, but these are difficult to reach. Here, we review seven key questions to. When selecting a thickness gauge for your application, there are a number of criteria to consider. Ultrasonic thickness gauges are often used to determine the thickness of a material where an inspector only has access to one side of the. The. Thickness Gauge Disadvantages.

From www.sisco.com

What are the Types of Thickness Gauges? Thickness Gauge Disadvantages In several cases, only one surface requires to be accessed. If you need to measure the thickness of. Here, we review seven key questions to. Ultrasonic testing does have thickness limitations, but these are difficult to reach. In conclusion, both coating thickness gauges and ultrasonic thickness gauges offer unique advantages and disadvantages. Ultrasonic thickness gauging is a widely used nondestructive. Thickness Gauge Disadvantages.