Hydraulic Pipe Standard Sizes . The dimensions and sizing of the most common hydraulic fittings follow standards set forth by sae (society of automotive engineers) international. Din 2353 l (light) and din 2353 s (heavy) classes. Fittings are available in two categories: Proper tube material, type and size for a given application and type of fitting is critical for efficient and trouble free operation of the fluid. Each has its own tube sizes and thread dimensions as shown in the following table: These standards help to maintain size. Data given in based on. 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. Lip welded steel pipe has a strength of 50.000. Burst strength has been figured on a tensile strength of 40,000 psi* for butt welded steel pipe. In order for fluid systems to be efficient and trouble free, it is critical to have proper tube material, type, and size for a given application.

from www.hoseandfittings.com

The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. These standards help to maintain size. Proper tube material, type and size for a given application and type of fitting is critical for efficient and trouble free operation of the fluid. Din 2353 l (light) and din 2353 s (heavy) classes. The dimensions and sizing of the most common hydraulic fittings follow standards set forth by sae (society of automotive engineers) international. Each has its own tube sizes and thread dimensions as shown in the following table: In order for fluid systems to be efficient and trouble free, it is critical to have proper tube material, type, and size for a given application. Fittings are available in two categories: Burst strength has been figured on a tensile strength of 40,000 psi* for butt welded steel pipe. Data given in based on.

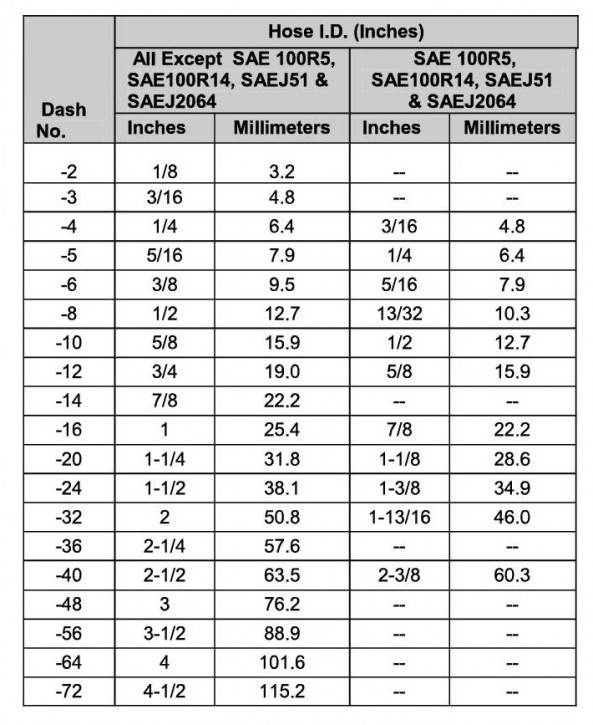

STAMPED Hydraulic Fitting Size Chart

Hydraulic Pipe Standard Sizes Fittings are available in two categories: Proper tube material, type and size for a given application and type of fitting is critical for efficient and trouble free operation of the fluid. The dimensions and sizing of the most common hydraulic fittings follow standards set forth by sae (society of automotive engineers) international. The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. In order for fluid systems to be efficient and trouble free, it is critical to have proper tube material, type, and size for a given application. Each has its own tube sizes and thread dimensions as shown in the following table: Lip welded steel pipe has a strength of 50.000. Data given in based on. 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Fittings are available in two categories: These standards help to maintain size. Burst strength has been figured on a tensile strength of 40,000 psi* for butt welded steel pipe. Din 2353 l (light) and din 2353 s (heavy) classes.

From www.pinterest.it

Pin on JIC JIS BSP DIN ISO SAE hydraulic fittings Drawing size Chart Hydraulic Pipe Standard Sizes These standards help to maintain size. Fittings are available in two categories: Lip welded steel pipe has a strength of 50.000. Each has its own tube sizes and thread dimensions as shown in the following table: The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. Proper tube material, type and size. Hydraulic Pipe Standard Sizes.

From www.pinterest.ca

Pin on JIC JIS BSP DIN ISO SAE hydraulic fittings Drawing size Chart Hydraulic Pipe Standard Sizes 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Data given in based on. The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. The dimensions and sizing of the most common hydraulic fittings follow standards set forth by. Hydraulic Pipe Standard Sizes.

From www.uipintl.com

Hydraulic Hose UIP International Hydraulic Hose and Fittings Hydraulic Pipe Standard Sizes Din 2353 l (light) and din 2353 s (heavy) classes. Fittings are available in two categories: Data given in based on. Lip welded steel pipe has a strength of 50.000. In order for fluid systems to be efficient and trouble free, it is critical to have proper tube material, type, and size for a given application. Proper tube material, type. Hydraulic Pipe Standard Sizes.

From www.qchydraulics.com

An Fitting Size Chart A guide To the right Size QC Hydraulics Hydraulic Pipe Standard Sizes 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. These standards help to maintain size. The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. The dimensions and sizing of the most common hydraulic fittings follow standards set forth. Hydraulic Pipe Standard Sizes.

From www.qchydraulics.com

Hydraulic Fitting Identification QC Hydraulics Hydraulic Pipe Standard Sizes The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. Lip welded steel pipe has a strength of 50.000. Din 2353 l (light) and din 2353 s (heavy) classes. These standards help to maintain size. Proper tube material, type and size for a given application and type of fitting is critical for. Hydraulic Pipe Standard Sizes.

From www.av8rdas.com

Hydraulic Diameter Hydraulic Pipe Standard Sizes Fittings are available in two categories: 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Lip welded steel pipe has a strength of 50.000. Data given in based on. The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2.. Hydraulic Pipe Standard Sizes.

From www.jiayuanfitting.com

BSP hydraulic fittings dimensions Knowledge Yuyao Jiayuan Hydraulic Hydraulic Pipe Standard Sizes 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. These standards help to maintain size. Lip welded steel pipe has a strength of 50.000. Din 2353 l (light) and din 2353 s (heavy) classes. The standard materials used in the manufacture of industrial pipe and adapter fittings. Hydraulic Pipe Standard Sizes.

From www.hydraulicsdirect.com

Hydraulic Fitting Thread Chart Hydraulics Direct Hydraulic Pipe Standard Sizes Lip welded steel pipe has a strength of 50.000. Din 2353 l (light) and din 2353 s (heavy) classes. 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Data given in based on. Burst strength has been figured on a tensile strength of 40,000 psi* for butt. Hydraulic Pipe Standard Sizes.

From blog.brennaninc.com

Metric Hydraulic Fittings DIN, JIS and Komatsu Hydraulic Pipe Standard Sizes Din 2353 l (light) and din 2353 s (heavy) classes. Data given in based on. The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. Lip welded steel pipe has a strength of 50.000. These standards help to maintain size. Each has its own tube sizes and thread dimensions as shown in. Hydraulic Pipe Standard Sizes.

From successimg.com

hydraulic fittings thread sizes chart Success Hydraulic Pipe Standard Sizes The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. Lip welded steel pipe has a strength of 50.000. Burst strength has been figured on a tensile strength of 40,000 psi* for butt welded steel pipe. The dimensions and sizing of the most common hydraulic fittings follow standards set forth by sae. Hydraulic Pipe Standard Sizes.

From leonwheeler.z13.web.core.windows.net

Hydraulic Hose Size Chart Hydraulic Pipe Standard Sizes Fittings are available in two categories: The dimensions and sizing of the most common hydraulic fittings follow standards set forth by sae (society of automotive engineers) international. These standards help to maintain size. In order for fluid systems to be efficient and trouble free, it is critical to have proper tube material, type, and size for a given application. Proper. Hydraulic Pipe Standard Sizes.

From www.pugetsoundhydraulics.com

Puget Sound Hydraulics Tube & Pipe Chart Hydraulic Pipe Standard Sizes Fittings are available in two categories: In order for fluid systems to be efficient and trouble free, it is critical to have proper tube material, type, and size for a given application. 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Each has its own tube sizes. Hydraulic Pipe Standard Sizes.

From www.citizenpipes.net

Schedule 40 Pipe Mild Steel MS Sch 40 Pipe Mild Steel Schedule 40 Hydraulic Pipe Standard Sizes Data given in based on. Fittings are available in two categories: Each has its own tube sizes and thread dimensions as shown in the following table: The dimensions and sizing of the most common hydraulic fittings follow standards set forth by sae (society of automotive engineers) international. These standards help to maintain size. In order for fluid systems to be. Hydraulic Pipe Standard Sizes.

From sapphirehydraulics.com

Hydraulic Hose Fittings & Connector Sizes Charts Sapphire Hydraulics Hydraulic Pipe Standard Sizes Data given in based on. The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. Din 2353 l (light) and din 2353 s (heavy) classes. Burst strength has been figured on a tensile strength of 40,000 psi* for butt welded steel pipe. Lip welded steel pipe has a strength of 50.000. 37. Hydraulic Pipe Standard Sizes.

From www.sino-alloy.com

Specifications of Standard series hydraulic pipe clamps Hydraulic Pipe Standard Sizes The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. These standards help to maintain size. Fittings are available in two categories: Lip welded steel pipe has a strength of 50.000. The dimensions and sizing of the most common hydraulic fittings follow standards set forth by sae (society of automotive engineers) international.. Hydraulic Pipe Standard Sizes.

From blog.enerpac.com

How to Select the Right Hydraulic Fittings and Couplers Enerpac Blog Hydraulic Pipe Standard Sizes Proper tube material, type and size for a given application and type of fitting is critical for efficient and trouble free operation of the fluid. Din 2353 l (light) and din 2353 s (heavy) classes. In order for fluid systems to be efficient and trouble free, it is critical to have proper tube material, type, and size for a given. Hydraulic Pipe Standard Sizes.

From www.youtube.com

PIPE SIZING LINE SIZING EXAMPLE HYDRAULICS PIPING MANTRA Hydraulic Pipe Standard Sizes Proper tube material, type and size for a given application and type of fitting is critical for efficient and trouble free operation of the fluid. These standards help to maintain size. Fittings are available in two categories: 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. The. Hydraulic Pipe Standard Sizes.

From imagefreehd.com

Hydraulic Tube Sizes images Hydraulic Pipe Standard Sizes Din 2353 l (light) and din 2353 s (heavy) classes. Burst strength has been figured on a tensile strength of 40,000 psi* for butt welded steel pipe. 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Proper tube material, type and size for a given application and. Hydraulic Pipe Standard Sizes.

From www.vrogue.co

Hydraulic Fitting Size Chart Qc Hydraulics vrogue.co Hydraulic Pipe Standard Sizes Each has its own tube sizes and thread dimensions as shown in the following table: Data given in based on. The dimensions and sizing of the most common hydraulic fittings follow standards set forth by sae (society of automotive engineers) international. Din 2353 l (light) and din 2353 s (heavy) classes. 37 rows the following chart gives standard pipe schedule. Hydraulic Pipe Standard Sizes.

From wiredatadapporto7c.z22.web.core.windows.net

Standard Stainless Steel Pipe Sizes In Mm Hydraulic Pipe Standard Sizes Burst strength has been figured on a tensile strength of 40,000 psi* for butt welded steel pipe. Proper tube material, type and size for a given application and type of fitting is critical for efficient and trouble free operation of the fluid. Fittings are available in two categories: Din 2353 l (light) and din 2353 s (heavy) classes. In order. Hydraulic Pipe Standard Sizes.

From se.jiayuanmfg.com

DIN Fitting Size Chart Kunskap Yuyao Jiayuan Hydraulisk Fitting Factory Hydraulic Pipe Standard Sizes In order for fluid systems to be efficient and trouble free, it is critical to have proper tube material, type, and size for a given application. Proper tube material, type and size for a given application and type of fitting is critical for efficient and trouble free operation of the fluid. Din 2353 l (light) and din 2353 s (heavy). Hydraulic Pipe Standard Sizes.

From mungfali.com

Hydraulic Fitting Sizes Hydraulic Pipe Standard Sizes Din 2353 l (light) and din 2353 s (heavy) classes. Each has its own tube sizes and thread dimensions as shown in the following table: In order for fluid systems to be efficient and trouble free, it is critical to have proper tube material, type, and size for a given application. Burst strength has been figured on a tensile strength. Hydraulic Pipe Standard Sizes.

From www.hoseandfittings.com

STAMPED Hydraulic Fitting Size Chart Hydraulic Pipe Standard Sizes The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. Lip welded steel pipe has a strength of 50.000. Burst strength has been figured on a tensile strength of 40,000 psi* for butt welded steel pipe. In order for fluid systems to be efficient and trouble free, it is critical to have. Hydraulic Pipe Standard Sizes.

From www.precision-steeltube.com

Custom Seamless Cold Drawn Honed Hydraulic Cylinder Tubing 30mm Wall Hydraulic Pipe Standard Sizes The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. Each has its own tube sizes and thread dimensions as shown in the following table: 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Din 2353 l (light) and. Hydraulic Pipe Standard Sizes.

From www.pinterest.com

JIC hydraulic fittings catalogue Hydraulic, Fittings, Catalog Hydraulic Pipe Standard Sizes Burst strength has been figured on a tensile strength of 40,000 psi* for butt welded steel pipe. Din 2353 l (light) and din 2353 s (heavy) classes. In order for fluid systems to be efficient and trouble free, it is critical to have proper tube material, type, and size for a given application. The standard materials used in the manufacture. Hydraulic Pipe Standard Sizes.

From www.jiayuanfitting.com

All DIN standards of hydraulic fittings overview Knowledge Yuyao Hydraulic Pipe Standard Sizes These standards help to maintain size. Din 2353 l (light) and din 2353 s (heavy) classes. Lip welded steel pipe has a strength of 50.000. 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. In order for fluid systems to be efficient and trouble free, it is. Hydraulic Pipe Standard Sizes.

From www.qchydraulics.com

What's Metric Size QC Hydraulics Hydraulic Pipe Standard Sizes 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Din 2353 l (light) and din 2353 s (heavy) classes. The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. Lip welded steel pipe has a strength of 50.000. The. Hydraulic Pipe Standard Sizes.

From energy-models.com

Pipe Sizing Charts Tables Hydraulic Pipe Standard Sizes These standards help to maintain size. 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Fittings are available in two categories: Lip welded steel pipe has a strength of 50.000. Din 2353 l (light) and din 2353 s (heavy) classes. The dimensions and sizing of the most. Hydraulic Pipe Standard Sizes.

From www.thehopegroup.com

Hydraulic Hose Fittings Guide How to Find the Right One Hydraulic Pipe Standard Sizes In order for fluid systems to be efficient and trouble free, it is critical to have proper tube material, type, and size for a given application. These standards help to maintain size. Fittings are available in two categories: Data given in based on. The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table. Hydraulic Pipe Standard Sizes.

From www.gerrardhydraulics.com.au

Understanding Heavy & Light Metrics Gerrard Hydraulics Gerrard Hydraulic Pipe Standard Sizes The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. In order for fluid systems to be efficient and trouble free, it is critical to have proper tube material, type, and size for a given application. The dimensions and sizing of the most common hydraulic fittings follow standards set forth by sae. Hydraulic Pipe Standard Sizes.

From www.egmec.com

BSP Threads Introduction 2 Hydraulic Hose Fittings Hydraulic Pipe Standard Sizes In order for fluid systems to be efficient and trouble free, it is critical to have proper tube material, type, and size for a given application. Din 2353 l (light) and din 2353 s (heavy) classes. The dimensions and sizing of the most common hydraulic fittings follow standards set forth by sae (society of automotive engineers) international. Data given in. Hydraulic Pipe Standard Sizes.

From guidealaphs.z13.web.core.windows.net

Pipe Standard Size Chart Hydraulic Pipe Standard Sizes The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. Fittings are available in two categories: The dimensions and sizing of the most common hydraulic fittings follow standards set forth by sae (society of automotive engineers) international. Burst strength has been figured on a tensile strength of 40,000 psi* for butt welded. Hydraulic Pipe Standard Sizes.

From www.valvers.com

AN and JIC Fittings Hydraulic Pipe Standard Sizes 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Fittings are available in two categories: Proper tube material, type and size for a given application and type of fitting is critical for efficient and trouble free operation of the fluid. The standard materials used in the manufacture. Hydraulic Pipe Standard Sizes.

From www.gridgit.com

6 Best Images of Hydraulic Fitting Size Chart Parker Hydraulic Hydraulic Pipe Standard Sizes Each has its own tube sizes and thread dimensions as shown in the following table: Proper tube material, type and size for a given application and type of fitting is critical for efficient and trouble free operation of the fluid. The standard materials used in the manufacture of industrial pipe and adapter fittings are shown in table g2. Din 2353. Hydraulic Pipe Standard Sizes.

From lessonabend.z19.web.core.windows.net

Hydraulic Fitting Size Chart Pdf Hydraulic Pipe Standard Sizes 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Din 2353 l (light) and din 2353 s (heavy) classes. Fittings are available in two categories: Data given in based on. In order for fluid systems to be efficient and trouble free, it is critical to have proper. Hydraulic Pipe Standard Sizes.