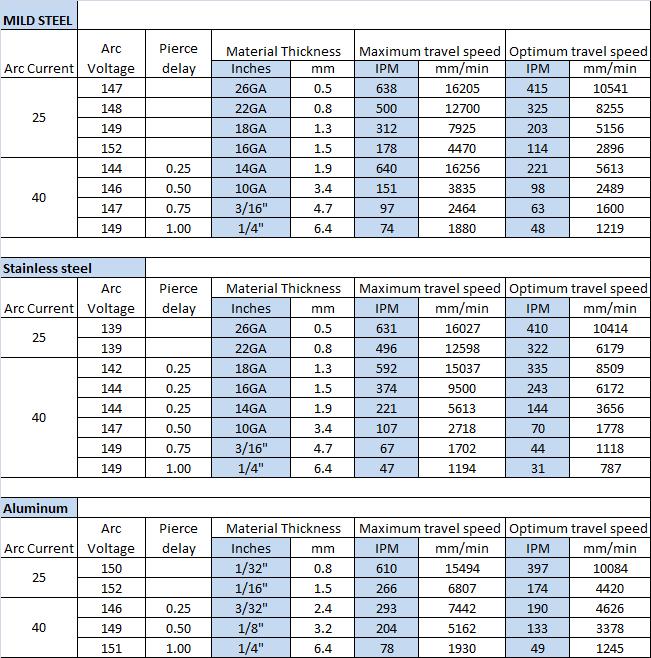

Plasma Cutting Travel Speed . The cut speed is the speed you. So you can almost eliminate distortion from excessive heat and skyrocket productivity. Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second would be 100 ms, 0.2 seconds would be 200 ms, etc. That’s why cobots or cnc can drastically boost your productivity. The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. Our cobot cutter can easily cut faster than 100 ipm (depending on thickness). They are intended as a guide. A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). Your owner's manual should contain a chart that compares material thickness to travel speed in inches per minute (ipm). When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key.

from wiki.opensourceecology.org

The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second would be 100 ms, 0.2 seconds would be 200 ms, etc. The cut speed is the speed you. Our cobot cutter can easily cut faster than 100 ipm (depending on thickness). A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). So you can almost eliminate distortion from excessive heat and skyrocket productivity. Your owner's manual should contain a chart that compares material thickness to travel speed in inches per minute (ipm). They are intended as a guide. When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. That’s why cobots or cnc can drastically boost your productivity.

CNC Torch Table 2/Control Overview Open Source Ecology

Plasma Cutting Travel Speed Our cobot cutter can easily cut faster than 100 ipm (depending on thickness). The cut speed is the speed you. Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second would be 100 ms, 0.2 seconds would be 200 ms, etc. When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. Your owner's manual should contain a chart that compares material thickness to travel speed in inches per minute (ipm). That’s why cobots or cnc can drastically boost your productivity. Our cobot cutter can easily cut faster than 100 ipm (depending on thickness). So you can almost eliminate distortion from excessive heat and skyrocket productivity. They are intended as a guide. A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30.

From www.kjellberg.de

Kjellberg Plasma Cutting Travel Speed The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. They are intended as a guide. That’s why cobots or cnc can drastically boost your productivity. Shown in seconds. Plasma Cutting Travel Speed.

From veracitytechs.com

Veracity Plasma Cutting Machine Specialists Plasma Cutting Travel Speed The cut speed is the speed you. The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. Your owner's manual should contain a chart that compares material thickness to travel speed in inches per minute (ipm). Shown in seconds in this chart, many systems will be in milliseconds so 0.1. Plasma Cutting Travel Speed.

From www.pierceengineering.com.au

Plasma Cutting Pierce Engineering Plasma Cutting Travel Speed The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. A rated cut is the thickness of mild metal that an operator can manually cut at a rate of. Plasma Cutting Travel Speed.

From www.majer-holz.com

CNC Plasma Cutting system controlled by MACH 3 MAJER HOLZ Plasma Cutting Travel Speed They are intended as a guide. When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. The cut speed is the speed you. So you can almost eliminate distortion from excessive heat and skyrocket productivity. Your owner's manual should contain a chart that compares material thickness to travel speed. Plasma Cutting Travel Speed.

From rhinocnc.en.made-in-china.com

Hypertherm 65A 105A 200A CNC Plasma Cutting Machine China CNC Plasma Plasma Cutting Travel Speed So you can almost eliminate distortion from excessive heat and skyrocket productivity. The cut speed is the speed you. They are intended as a guide. The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. A rated cut is the thickness of mild metal that an operator can manually cut. Plasma Cutting Travel Speed.

From mellowpine.com

Laser Cutting vs Plasma Cutting Which do you Need? MellowPine Plasma Cutting Travel Speed So you can almost eliminate distortion from excessive heat and skyrocket productivity. A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). Our cobot cutter can easily cut faster than 100 ipm (depending on thickness). Your owner's manual should contain a chart that compares material thickness. Plasma Cutting Travel Speed.

From www.thomasnet.com

Plasma Cutting Definition, Process, Types, Machines Plasma Cutting Travel Speed When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. They are intended as a guide. A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). The cut speed is the speed you. Shown in. Plasma Cutting Travel Speed.

From www.youtube.com

Plasma Cutter How It Works ??? YouTube Plasma Cutting Travel Speed A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). So you can almost eliminate distortion from excessive heat and skyrocket productivity. The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. They are intended as. Plasma Cutting Travel Speed.

From www.manufacturesolutions.com

Used 2013 Voortman VCS Multi 2500 High Definition Plasma Cutting Ma... Plasma Cutting Travel Speed The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. The cut speed is the speed you. Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second would be 100 ms, 0.2 seconds would be 200 ms, etc. They are intended as a guide. That’s. Plasma Cutting Travel Speed.

From www.canadianmetalworking.com

Plasma cutting service shop buys time by doubling cut speed Plasma Cutting Travel Speed A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). So you can almost eliminate distortion from excessive heat and skyrocket productivity. They are intended as a guide. That’s why cobots or cnc can drastically boost your productivity. When it comes to plasma cutter setup and. Plasma Cutting Travel Speed.

From www.wenzelmetalspinning.com

Plasma Cutting Wenzel Metal Spinning Plasma Cutting Travel Speed When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. Our cobot cutter can easily cut faster than 100 ipm (depending on thickness). They are intended as a guide. The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30.. Plasma Cutting Travel Speed.

From www.youtube.com

Plasma Cutting for Beginners Amperage and Travel Speed YouTube Plasma Cutting Travel Speed The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. Your owner's manual should contain a chart that compares material thickness to travel speed in inches per minute (ipm). When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key.. Plasma Cutting Travel Speed.

From www.maverickcnc.com

Understanding CNC Plasma Cutting Cut Speed MaverickCNC Plasma Cutting Plasma Cutting Travel Speed So you can almost eliminate distortion from excessive heat and skyrocket productivity. They are intended as a guide. The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. The cut speed is the speed you. A rated cut is the thickness of mild metal that an operator can manually cut. Plasma Cutting Travel Speed.

From tfwarren.com

Plasma Cutting Plasma Cutting Travel Speed Our cobot cutter can easily cut faster than 100 ipm (depending on thickness). The cut speed is the speed you. So you can almost eliminate distortion from excessive heat and skyrocket productivity. A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). They are intended as. Plasma Cutting Travel Speed.

From artizono.com

Plasma Cutting And Laser Cutting Explained Artizono Plasma Cutting Travel Speed They are intended as a guide. Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second would be 100 ms, 0.2 seconds would be 200 ms, etc. So you can almost eliminate distortion from excessive heat and skyrocket productivity. That’s why cobots or cnc can drastically boost your productivity. The cut speed is the speed. Plasma Cutting Travel Speed.

From www.youtube.com

Advantages of a Plasma Cutter and OxyFuel Cutting System YouTube Plasma Cutting Travel Speed So you can almost eliminate distortion from excessive heat and skyrocket productivity. When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). That’s why cobots. Plasma Cutting Travel Speed.

From travelexperta.com

Plasma Cutting Tips and Tricks for Beginners Travel Experta Plasma Cutting Travel Speed The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second would be 100 ms, 0.2 seconds would be 200 ms, etc. Your owner's manual should contain a chart that compares material thickness to travel speed. Plasma Cutting Travel Speed.

From svseeker.com

CNC Plasma Plasma Cutting Travel Speed When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. A rated cut is the thickness of mild metal that an operator can manually cut at a rate of. Plasma Cutting Travel Speed.

From www.formingpres.com

High Speed Sheet Plasma Cutting Machine Plasma Cutting Travel Speed Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second would be 100 ms, 0.2 seconds would be 200 ms, etc. When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. The cut speed is the speed you. So you can almost eliminate distortion. Plasma Cutting Travel Speed.

From www.jasic.co.uk

Jasic Guide to Plasma Cutting Jasic Blog Plasma Cutting Travel Speed Our cobot cutter can easily cut faster than 100 ipm (depending on thickness). The cut speed is the speed you. That’s why cobots or cnc can drastically boost your productivity. The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. A rated cut is the thickness of mild metal that. Plasma Cutting Travel Speed.

From arccutting.com

The Pro 20 Plasma Cutting Machine Plasma Cutting Travel Speed That’s why cobots or cnc can drastically boost your productivity. So you can almost eliminate distortion from excessive heat and skyrocket productivity. Our cobot cutter can easily cut faster than 100 ipm (depending on thickness). The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. Your owner's manual should contain. Plasma Cutting Travel Speed.

From at-machining.com

Plasma Cutting 101 The Ultimate Guide to Choosing Your Machining AT Plasma Cutting Travel Speed The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). The cut speed is the speed you. Shown in seconds in this chart, many systems will. Plasma Cutting Travel Speed.

From www.hypertherm.com

Improve cut quality with these CNC steel and metal cutting tips Plasma Cutting Travel Speed A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. Our cobot cutter can easily cut faster than 100 ipm (depending on thickness). The cut. Plasma Cutting Travel Speed.

From shapecut.com.au

What is plasma cutting and how does it work? ShapeCUT Plasma Cutting Travel Speed So you can almost eliminate distortion from excessive heat and skyrocket productivity. Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second would be 100 ms, 0.2 seconds would be 200 ms, etc. The cut speed is the speed you. When it comes to plasma cutter setup and technique, setting the correct amperage and using. Plasma Cutting Travel Speed.

From www.youtube.com

Plasma cutting with fast speed YouTube Plasma Cutting Travel Speed Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second would be 100 ms, 0.2 seconds would be 200 ms, etc. The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. So you can almost eliminate distortion from excessive heat and skyrocket productivity. A rated. Plasma Cutting Travel Speed.

From www.thefabricator.com

A check list for a plasma cutting table retrofit The Fabricator Plasma Cutting Travel Speed That’s why cobots or cnc can drastically boost your productivity. Your owner's manual should contain a chart that compares material thickness to travel speed in inches per minute (ipm). The cut speed is the speed you. Our cobot cutter can easily cut faster than 100 ipm (depending on thickness). They are intended as a guide. A rated cut is the. Plasma Cutting Travel Speed.

From blog.thepipingmart.com

5 Advantages and Disadvantages of Plasma Cutting Plasma Cutting Travel Speed They are intended as a guide. When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). The cut speed is the speed you. The following. Plasma Cutting Travel Speed.

From plasmacut.ie

PlasmaCut.ie CNC Plasma Cutter vs. Laser Cutter A Comprehensive Plasma Cutting Travel Speed So you can almost eliminate distortion from excessive heat and skyrocket productivity. They are intended as a guide. The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. The cut speed is the speed you. Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second. Plasma Cutting Travel Speed.

From www.cyriousmetalworks.com

What You Need To Know About Plasma Cutting Speed Cyrious Metal Works Plasma Cutting Travel Speed Your owner's manual should contain a chart that compares material thickness to travel speed in inches per minute (ipm). A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). They are intended as a guide. The cut speed is the speed you. Our cobot cutter can. Plasma Cutting Travel Speed.

From www.sunteccnc.com

Mini portable plasma cutting machine for metal sheet cutting _JINAN Plasma Cutting Travel Speed So you can almost eliminate distortion from excessive heat and skyrocket productivity. Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second would be 100 ms, 0.2 seconds would be 200 ms, etc. The cut speed is the speed you. The following parameters can be used as a guide to cutting diferent materials and thicknesses. Plasma Cutting Travel Speed.

From wiki.opensourceecology.org

CNC Torch Table 2/Control Overview Open Source Ecology Plasma Cutting Travel Speed A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. Your owner's manual should contain a chart that compares material thickness to travel speed in. Plasma Cutting Travel Speed.

From www.thefabricator.com

Improved plasma cutting of stainless steel The Fabricator Plasma Cutting Travel Speed Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second would be 100 ms, 0.2 seconds would be 200 ms, etc. Your owner's manual should contain a chart that compares material thickness to travel speed in inches per minute (ipm). Our cobot cutter can easily cut faster than 100 ipm (depending on thickness). The following. Plasma Cutting Travel Speed.

From blog.prv-engineering.co.uk

Plasma Cutting Processes Explained PRV Engineering Blog Plasma Cutting Travel Speed The cut speed is the speed you. They are intended as a guide. Your owner's manual should contain a chart that compares material thickness to travel speed in inches per minute (ipm). So you can almost eliminate distortion from excessive heat and skyrocket productivity. Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second would. Plasma Cutting Travel Speed.

From www.formingpres.com

High Speed Sheet Plasma Cutting Machine Plasma Cutting Travel Speed Your owner's manual should contain a chart that compares material thickness to travel speed in inches per minute (ipm). They are intended as a guide. The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. Shown in seconds in this chart, many systems will be in milliseconds so 0.1 second. Plasma Cutting Travel Speed.

From www.cuttingweldingmachine.com

High Speed Cnc Plasma Cutting System , 1.5 X 3m High Precision Plasma Plasma Cutting Travel Speed That’s why cobots or cnc can drastically boost your productivity. A rated cut is the thickness of mild metal that an operator can manually cut at a rate of 15 inches per minute (ipm). When it comes to plasma cutter setup and technique, setting the correct amperage and using the right travel speed are key. Your owner's manual should contain. Plasma Cutting Travel Speed.