What Type Of Bearing Should Not Be Lubricated . A few factors will need to be considered to. knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. lubrication is essential to prevent premature ball bearing failure. You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. Reduces friction between these moving parts. make sure you are using the proper type and amount of lubricant for your specific bearing and application. constrains relative motion between two parts to that specified in an overall design. when it comes to finding the best bearing lubrication material, there are two main options: Probably the most critical factor in maintaining operating.

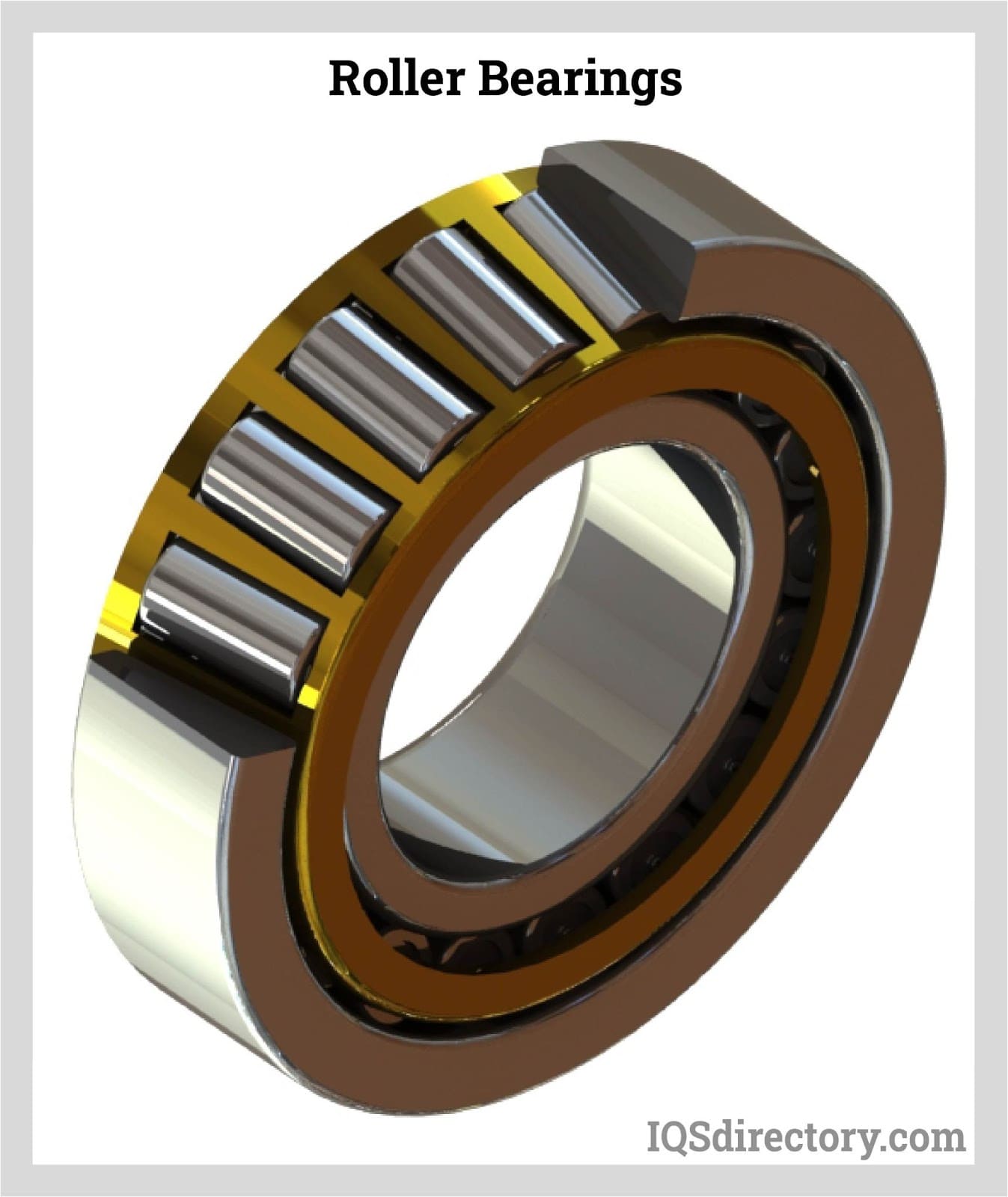

from www.iqsdirectory.com

constrains relative motion between two parts to that specified in an overall design. make sure you are using the proper type and amount of lubricant for your specific bearing and application. Probably the most critical factor in maintaining operating. Reduces friction between these moving parts. A few factors will need to be considered to. knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. when it comes to finding the best bearing lubrication material, there are two main options: lubrication is essential to prevent premature ball bearing failure.

Ball Bearings Types, Design, Function, and Benefits

What Type Of Bearing Should Not Be Lubricated A few factors will need to be considered to. Reduces friction between these moving parts. You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. Probably the most critical factor in maintaining operating. knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. make sure you are using the proper type and amount of lubricant for your specific bearing and application. A few factors will need to be considered to. lubrication is essential to prevent premature ball bearing failure. when it comes to finding the best bearing lubrication material, there are two main options: constrains relative motion between two parts to that specified in an overall design.

From www.skf.com

Typical shaftbearing combinations SKF What Type Of Bearing Should Not Be Lubricated when it comes to finding the best bearing lubrication material, there are two main options: Reduces friction between these moving parts. constrains relative motion between two parts to that specified in an overall design. make sure you are using the proper type and amount of lubricant for your specific bearing and application. Probably the most critical factor. What Type Of Bearing Should Not Be Lubricated.

From www.linquip.com

Different Types of Bearings (PDF & Charts) Linquip What Type Of Bearing Should Not Be Lubricated lubrication is essential to prevent premature ball bearing failure. when it comes to finding the best bearing lubrication material, there are two main options: make sure you are using the proper type and amount of lubricant for your specific bearing and application. A few factors will need to be considered to. constrains relative motion between two. What Type Of Bearing Should Not Be Lubricated.

From www.iqsdirectory.com

Ball Bearings Types, Design, Function, and Benefits What Type Of Bearing Should Not Be Lubricated You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. when it comes to finding the best bearing lubrication material, there are two main options: lubrication is essential to prevent premature ball bearing failure. constrains relative motion between two parts to that specified in an overall design. Probably the most critical. What Type Of Bearing Should Not Be Lubricated.

From www.carsflow.com

5 Common Types of Bearings You Should Know Of What Type Of Bearing Should Not Be Lubricated lubrication is essential to prevent premature ball bearing failure. Reduces friction between these moving parts. make sure you are using the proper type and amount of lubricant for your specific bearing and application. when it comes to finding the best bearing lubrication material, there are two main options: Probably the most critical factor in maintaining operating. You. What Type Of Bearing Should Not Be Lubricated.

From mavink.com

Bearing Identification Chart What Type Of Bearing Should Not Be Lubricated Probably the most critical factor in maintaining operating. when it comes to finding the best bearing lubrication material, there are two main options: constrains relative motion between two parts to that specified in an overall design. You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. make sure you are using. What Type Of Bearing Should Not Be Lubricated.

From wiki.opensourceecology.org

Bearings 101 Open Source Ecology What Type Of Bearing Should Not Be Lubricated knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. constrains relative motion between two parts to that specified in an overall design. A few factors will need to be considered to. Reduces friction between these moving parts. You can run bearings dry for slow moving applications such as tonearm. What Type Of Bearing Should Not Be Lubricated.

From jvnbearings.com

Bearing Defects & Preventive Measures JVN Bearings FZE What Type Of Bearing Should Not Be Lubricated lubrication is essential to prevent premature ball bearing failure. Probably the most critical factor in maintaining operating. make sure you are using the proper type and amount of lubricant for your specific bearing and application. constrains relative motion between two parts to that specified in an overall design. knowing which bearing lubricant to use for the. What Type Of Bearing Should Not Be Lubricated.

From www.brighthubengineering.com

What is Ball Bearing? Types of Ball Bearings. What Type Of Bearing Should Not Be Lubricated make sure you are using the proper type and amount of lubricant for your specific bearing and application. lubrication is essential to prevent premature ball bearing failure. Reduces friction between these moving parts. You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. A few factors will need to be considered to.. What Type Of Bearing Should Not Be Lubricated.

From www.thomsonlinear.com

Four Linear Bearing and Guide Lubrication Mistakes that Can Bring Your What Type Of Bearing Should Not Be Lubricated A few factors will need to be considered to. lubrication is essential to prevent premature ball bearing failure. Probably the most critical factor in maintaining operating. You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. Reduces friction between these moving parts. knowing which bearing lubricant to use for the right application. What Type Of Bearing Should Not Be Lubricated.

From www.youtube.com

Introduction to Bearing Basic Video what is Bearing? Bearing What Type Of Bearing Should Not Be Lubricated when it comes to finding the best bearing lubrication material, there are two main options: make sure you are using the proper type and amount of lubricant for your specific bearing and application. You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. Probably the most critical factor in maintaining operating. A. What Type Of Bearing Should Not Be Lubricated.

From www.iqsdirectory.com

Ball Bearings Types, Design, Function, and Benefits What Type Of Bearing Should Not Be Lubricated lubrication is essential to prevent premature ball bearing failure. when it comes to finding the best bearing lubrication material, there are two main options: Probably the most critical factor in maintaining operating. make sure you are using the proper type and amount of lubricant for your specific bearing and application. Reduces friction between these moving parts. A. What Type Of Bearing Should Not Be Lubricated.

From www.nskbearingcatalogue.com

the working principle and precautions of thrust load bearing What Type Of Bearing Should Not Be Lubricated A few factors will need to be considered to. lubrication is essential to prevent premature ball bearing failure. make sure you are using the proper type and amount of lubricant for your specific bearing and application. when it comes to finding the best bearing lubrication material, there are two main options: knowing which bearing lubricant to. What Type Of Bearing Should Not Be Lubricated.

From fractory.com

Types of Bearings Uses & Working Mechanisms Explained What Type Of Bearing Should Not Be Lubricated when it comes to finding the best bearing lubrication material, there are two main options: lubrication is essential to prevent premature ball bearing failure. You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned. What Type Of Bearing Should Not Be Lubricated.

From www.skf.com

Arrangements and their bearing types SKF What Type Of Bearing Should Not Be Lubricated lubrication is essential to prevent premature ball bearing failure. when it comes to finding the best bearing lubrication material, there are two main options: constrains relative motion between two parts to that specified in an overall design. A few factors will need to be considered to. Reduces friction between these moving parts. make sure you are. What Type Of Bearing Should Not Be Lubricated.

From bearingsdubai.blogspot.com

Macina Bearings and Belt What are the types and functions of bearings? What Type Of Bearing Should Not Be Lubricated lubrication is essential to prevent premature ball bearing failure. when it comes to finding the best bearing lubrication material, there are two main options: Reduces friction between these moving parts. Probably the most critical factor in maintaining operating. make sure you are using the proper type and amount of lubricant for your specific bearing and application. You. What Type Of Bearing Should Not Be Lubricated.

From www.bearingtips.com

When should I use solid film lubricants? Bearing Tips What Type Of Bearing Should Not Be Lubricated when it comes to finding the best bearing lubrication material, there are two main options: A few factors will need to be considered to. Probably the most critical factor in maintaining operating. make sure you are using the proper type and amount of lubricant for your specific bearing and application. Reduces friction between these moving parts. knowing. What Type Of Bearing Should Not Be Lubricated.

From dxolkhzmb.blob.core.windows.net

How To Fix Broken Ball Bearings at Morris Charles blog What Type Of Bearing Should Not Be Lubricated You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. when it comes to finding the best bearing lubrication material, there are two main options: lubrication is essential to prevent premature ball bearing failure. constrains relative motion between two parts to that specified in an overall design. Probably the most critical. What Type Of Bearing Should Not Be Lubricated.

From dxoolvhnd.blob.core.windows.net

Types Of Bearings In A Car at Ann Ware blog What Type Of Bearing Should Not Be Lubricated when it comes to finding the best bearing lubrication material, there are two main options: Probably the most critical factor in maintaining operating. constrains relative motion between two parts to that specified in an overall design. make sure you are using the proper type and amount of lubricant for your specific bearing and application. lubrication is. What Type Of Bearing Should Not Be Lubricated.

From www.bearingtips.com

When should I use grease for my bearing? Bearing Tips What Type Of Bearing Should Not Be Lubricated when it comes to finding the best bearing lubrication material, there are two main options: knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. constrains relative motion between two parts to that specified in an overall design. make sure you are using the proper type and amount. What Type Of Bearing Should Not Be Lubricated.

From www.thomsonlinear.com

Four Linear Bearing and Guide Lubrication Mistakes that Can Bring Your What Type Of Bearing Should Not Be Lubricated lubrication is essential to prevent premature ball bearing failure. constrains relative motion between two parts to that specified in an overall design. Probably the most critical factor in maintaining operating. make sure you are using the proper type and amount of lubricant for your specific bearing and application. knowing which bearing lubricant to use for the. What Type Of Bearing Should Not Be Lubricated.

From www.pumpengineering.net

The Basics of Bearing Remanufacturing Pump Engineering Co.Pump What Type Of Bearing Should Not Be Lubricated Probably the most critical factor in maintaining operating. lubrication is essential to prevent premature ball bearing failure. knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. make sure you are using the proper type and amount of lubricant for your specific bearing and application. A few factors will. What Type Of Bearing Should Not Be Lubricated.

From www.aubearing.com

Bearing Types You Should Know AUBEARING What Type Of Bearing Should Not Be Lubricated A few factors will need to be considered to. knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. Reduces friction between these moving parts. lubrication is essential to prevent premature ball bearing failure. constrains relative motion between two parts to that specified in an overall design. when. What Type Of Bearing Should Not Be Lubricated.

From gesrepair.com

7 Bearing Maintenance Tips Maintain Your Bearing Equipment What Type Of Bearing Should Not Be Lubricated knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. lubrication is essential to prevent premature ball bearing failure. constrains relative motion between two parts to that specified in an overall design. A few factors will need to be considered to. You can run bearings dry for slow moving. What Type Of Bearing Should Not Be Lubricated.

From mechtics.com

Classification of bearings Mechtics Mechtics What Type Of Bearing Should Not Be Lubricated lubrication is essential to prevent premature ball bearing failure. when it comes to finding the best bearing lubrication material, there are two main options: knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. You can run bearings dry for slow moving applications such as tonearm bearings or clock. What Type Of Bearing Should Not Be Lubricated.

From www.pinterest.ph

Types of Bearings Bearing Types Different Types of Bearings What Type Of Bearing Should Not Be Lubricated You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. Probably the most critical factor in maintaining operating. knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. constrains relative motion between two parts to that specified in an overall design. lubrication is. What Type Of Bearing Should Not Be Lubricated.

From www.youtube.com

Avoid These 3 Common Mistakes When Lubricating Bearings YouTube What Type Of Bearing Should Not Be Lubricated constrains relative motion between two parts to that specified in an overall design. Probably the most critical factor in maintaining operating. A few factors will need to be considered to. lubrication is essential to prevent premature ball bearing failure. Reduces friction between these moving parts. You can run bearings dry for slow moving applications such as tonearm bearings. What Type Of Bearing Should Not Be Lubricated.

From www.dragzine.com

Tech Choosing The Proper Bearings For Your Engine What Type Of Bearing Should Not Be Lubricated A few factors will need to be considered to. Reduces friction between these moving parts. when it comes to finding the best bearing lubrication material, there are two main options: make sure you are using the proper type and amount of lubricant for your specific bearing and application. knowing which bearing lubricant to use for the right. What Type Of Bearing Should Not Be Lubricated.

From classicautoadvisors.com

How to Know If Your Wheel Bearings Need Replacement What Type Of Bearing Should Not Be Lubricated Probably the most critical factor in maintaining operating. A few factors will need to be considered to. make sure you are using the proper type and amount of lubricant for your specific bearing and application. constrains relative motion between two parts to that specified in an overall design. lubrication is essential to prevent premature ball bearing failure.. What Type Of Bearing Should Not Be Lubricated.

From www.popularvirals.com

The Common Types Of Bearings That You Should Know Of What Type Of Bearing Should Not Be Lubricated Probably the most critical factor in maintaining operating. knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. lubrication is essential to prevent premature ball bearing failure. A few factors will need to be considered to. constrains relative motion between two parts to that specified in an overall design.. What Type Of Bearing Should Not Be Lubricated.

From www.electricalapparatus.net

Guide to the Different Ball Bearing Types Electrical Apparatus What Type Of Bearing Should Not Be Lubricated Probably the most critical factor in maintaining operating. when it comes to finding the best bearing lubrication material, there are two main options: You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. lubrication is essential to prevent premature ball bearing failure. A few factors will need to be considered to. . What Type Of Bearing Should Not Be Lubricated.

From www.vrogue.co

7 Popular Types Of Bearings You Should Know vrogue.co What Type Of Bearing Should Not Be Lubricated Reduces friction between these moving parts. lubrication is essential to prevent premature ball bearing failure. A few factors will need to be considered to. constrains relative motion between two parts to that specified in an overall design. knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. when. What Type Of Bearing Should Not Be Lubricated.

From www.bdsbearing.com

What Causes Bearing Failures and Preventative Measures You Need to Know What Type Of Bearing Should Not Be Lubricated make sure you are using the proper type and amount of lubricant for your specific bearing and application. constrains relative motion between two parts to that specified in an overall design. knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. Probably the most critical factor in maintaining operating.. What Type Of Bearing Should Not Be Lubricated.

From engineeringlearn.com

Types of Bearings Definition, Function, Uses, Advantages What Type Of Bearing Should Not Be Lubricated when it comes to finding the best bearing lubrication material, there are two main options: Probably the most critical factor in maintaining operating. Reduces friction between these moving parts. constrains relative motion between two parts to that specified in an overall design. lubrication is essential to prevent premature ball bearing failure. You can run bearings dry for. What Type Of Bearing Should Not Be Lubricated.

From ar.inspiredpencil.com

Types Of Bearings And Applications What Type Of Bearing Should Not Be Lubricated You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. lubrication is essential to prevent premature ball bearing failure. knowing which bearing lubricant to use for the right application extends the equipment’s life and avoids unplanned maintenance. make sure you are using the proper type and amount of lubricant for your. What Type Of Bearing Should Not Be Lubricated.

From mechasource.blogspot.com

Introduction To Wheel Bearings Types and Installation What Type Of Bearing Should Not Be Lubricated constrains relative motion between two parts to that specified in an overall design. when it comes to finding the best bearing lubrication material, there are two main options: A few factors will need to be considered to. You can run bearings dry for slow moving applications such as tonearm bearings or clock bearings. lubrication is essential to. What Type Of Bearing Should Not Be Lubricated.