What Does A Lapping Tool Do . A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. The lapping process is a fine finishing process, which leads to a surface with low roughness and high precision. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. It is used in a variety of industries, including aerospace,. A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low.

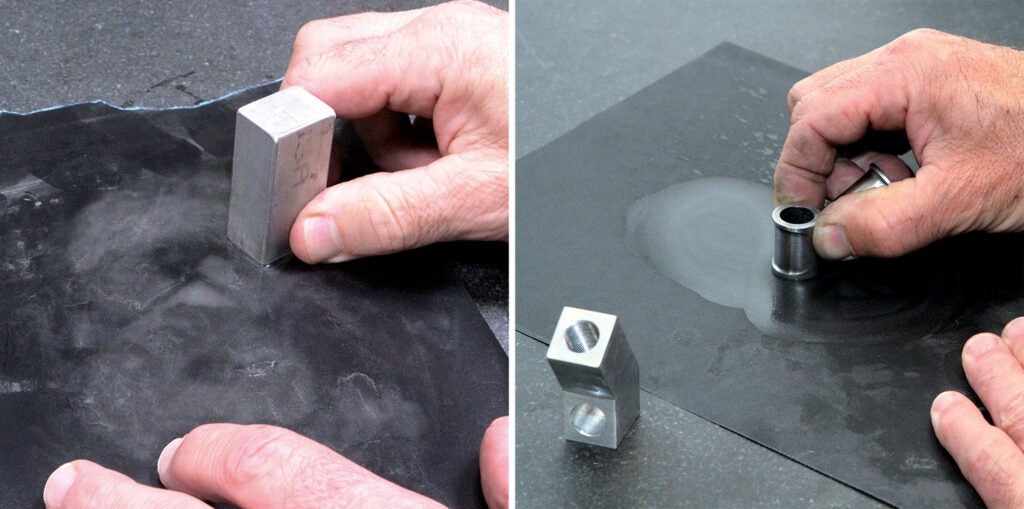

from www.kitplanes.com

The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. The lapping process is a fine finishing process, which leads to a surface with low roughness and high precision. It is used in a variety of industries, including aerospace,. The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece.

Laps and Lapping KITPLANES

What Does A Lapping Tool Do The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. The lapping process is a fine finishing process, which leads to a surface with low roughness and high precision. A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. It is used in a variety of industries, including aerospace,. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree.

From slidingmotion.com

What is Lapping? How Lapping Works? slidingmotion What Does A Lapping Tool Do The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. The lapping process is a fine finishing process, which leads to a surface with low roughness and high precision. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping. What Does A Lapping Tool Do.

From www.youtube.com

Lapping Internal Bore l Lapping l How to Use of Lapping l Lapping What Does A Lapping Tool Do A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. It is used in a variety of industries, including aerospace,. The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. The machining process of lapping involves two surfaces that are rubbing together. What Does A Lapping Tool Do.

From www.youtube.com

LAPPING TOOL (USING A DRILL GUN) YouTube What Does A Lapping Tool Do The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. A lapping plate on which a lapping slurry has been applied moves under the workpiece. What Does A Lapping Tool Do.

From www.aviationpros.com

Lapping Tools Aviation Pros What Does A Lapping Tool Do The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. It is used in a variety of industries, including aerospace,. A lapping. What Does A Lapping Tool Do.

From www.youtube.com

Lapping Process Surface Finishing Process Abrasive Machining PPT What Does A Lapping Tool Do The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. It is used in a variety of industries, including. What Does A Lapping Tool Do.

From watchmaking.weebly.com

Lapping Tool What Does A Lapping Tool Do The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. A lapping plate on which a lapping slurry has been applied moves under the workpiece surface. What Does A Lapping Tool Do.

From www.youtube.com

Lapping Tool YouTube What Does A Lapping Tool Do A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. A lapping machine is a specialised machine used for generating very fine surface finishes on. What Does A Lapping Tool Do.

From watchmaking.weebly.com

Lapping Tool What Does A Lapping Tool Do The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. The machining process of lapping involves two surfaces that are rubbing together. What Does A Lapping Tool Do.

From dxozezeqh.blob.core.windows.net

Lapping Tool Use at Hunter Lerma blog What Does A Lapping Tool Do The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. The lapping process is a fine finishing process, which leads to a surface with low roughness and high precision. A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates. What Does A Lapping Tool Do.

From gadgetbuilder.com

Laps and Lapping in the Home Shop What Does A Lapping Tool Do The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. A lapping machine is a specialised machine used for generating very fine. What Does A Lapping Tool Do.

From roadsumo.com

Valve Lapping [What Is It and How to Lap Valves?] • Road Sumo What Does A Lapping Tool Do The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. A lapping plate on which a lapping slurry has been applied moves under the workpiece surface. What Does A Lapping Tool Do.

From discover.hubpages.com

Difference Between Lapping and Honing Process HubPages What Does A Lapping Tool Do The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. The lapping process is a fine finishing process, which. What Does A Lapping Tool Do.

From roadsumo.com

Valve Lapping [What Is It and How to Lap Valves?] • Road Sumo What Does A Lapping Tool Do The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. The lapping process is a fine finishing process, which leads to a surface with low roughness and high precision. It is used. What Does A Lapping Tool Do.

From www.kitplanes.com

Laps and Lapping KITPLANES What Does A Lapping Tool Do The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. The lapping process is a fine finishing process, which leads to a surface with low roughness and high precision. A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece.. What Does A Lapping Tool Do.

From watchmaking.weebly.com

Lapping Tool What Does A Lapping Tool Do The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. It is used in a variety of industries, including aerospace,. The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally. What Does A Lapping Tool Do.

From www.researchgate.net

Installation method of the lapping tool. Download Scientific Diagram What Does A Lapping Tool Do A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. It is used in a variety of industries, including aerospace,. The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. The machining process of lapping involves. What Does A Lapping Tool Do.

From www.cermac.com

Lapping Machining Lapping Manufacturing CerMac Inc. What Does A Lapping Tool Do The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. The lapping process is a fine finishing process, which leads to a surface with low roughness and high precision. The lapping tool serves as the mold for lapping, imparting its own geometric accuracy. What Does A Lapping Tool Do.

From www.aviationpros.com

Lapping Tools Aviation Pros What Does A Lapping Tool Do The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. The term lapping is used to describe a number of various surface finishing operations where. What Does A Lapping Tool Do.

From www.mech4study.com

Lapping Process Principle, Types and Advantages mech4study What Does A Lapping Tool Do The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. A lapping machine is a specialised machine used for. What Does A Lapping Tool Do.

From www.youtube.com

making an ID lapping tool YouTube What Does A Lapping Tool Do The lapping process is a fine finishing process, which leads to a surface with low roughness and high precision. The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. It is used in a variety of industries, including aerospace,. A lapping plate on. What Does A Lapping Tool Do.

From cncpartsxtj.com

Brief Guide To Lapping Machining And Grinding Online Manufacturing What Does A Lapping Tool Do The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. It is used in a variety of industries, including aerospace,. A lapping machine is a. What Does A Lapping Tool Do.

From triaticinc.com

Diamond Barrel Lapping Tools DiamondCoated Lapping Tool What Does A Lapping Tool Do A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. It is used in a variety of industries, including aerospace,. A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. The machining process of lapping involves two surfaces that. What Does A Lapping Tool Do.

From www.youtube.com

ID and OD lapping simplified. YouTube What Does A Lapping Tool Do A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. It is used in a variety of industries, including aerospace,. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. The lapping tool serves as the mold for lapping,. What Does A Lapping Tool Do.

From roadsumo.com

Valve Lapping [What Is It and How to Lap Valves?] • Road Sumo What Does A Lapping Tool Do The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. It is used in a variety of industries, including aerospace,. The lapping process is a fine finishing process, which leads to a. What Does A Lapping Tool Do.

From watchmaking.weebly.com

Lapping Tool What Does A Lapping Tool Do The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. It is used in a variety of industries, including aerospace,. The lapping process is a fine finishing process, which leads to a surface with low roughness and high precision. The lapping tool serves as the mold. What Does A Lapping Tool Do.

From mungfali.com

Lapping Machine Process What Does A Lapping Tool Do The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped. What Does A Lapping Tool Do.

From www.bhphotovideo.com

Weaver 30mm Lapping Tool Kit 849726 B&H Photo Video What Does A Lapping Tool Do A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are. What Does A Lapping Tool Do.

From www.stahliusa.com

What is a Lapping Process and what does it consist of doing? What Does A Lapping Tool Do A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. The term lapping is used to describe a number of various surface. What Does A Lapping Tool Do.

From www.youtube.com

Precision Lapping 101 YouTube What Does A Lapping Tool Do The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. The lapping tool serves as the mold for lapping,. What Does A Lapping Tool Do.

From www.slideserve.com

PPT Technology II. PowerPoint Presentation, free download ID3296556 What Does A Lapping Tool Do It is used in a variety of industries, including aerospace,. The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low. A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping. What Does A Lapping Tool Do.

From watchmaking.weebly.com

Lapping Tool What Does A Lapping Tool Do A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. The lapping process is a fine finishing process, which leads to a surface with low. What Does A Lapping Tool Do.

From watchmaking.weebly.com

Lapping Tool What Does A Lapping Tool Do A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. What Does A Lapping Tool Do.

From watchmaking.weebly.com

Lapping Tool What Does A Lapping Tool Do A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. It is used in a variety of industries, including aerospace,. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. The lapping process is a fine finishing process, which. What Does A Lapping Tool Do.

From www.enginelabs.com

EngineLabs’ Tool Of The Month Koul Tools P51B Surseat Lapping Tool What Does A Lapping Tool Do The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. A lapping machine is a specialised machine used for generating very fine surface finishes on. What Does A Lapping Tool Do.

From germanspecialisttools.com

Valve Lapping Tool Kit German Specialist Tools What Does A Lapping Tool Do A lapping machine is a specialised machine used for generating very fine surface finishes on a workpiece. The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. It is used in a variety of industries, including aerospace,. The lapping process is a fine finishing process, which leads to a. What Does A Lapping Tool Do.