Metal Forming Methods . Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. It provides rigorous detail on the three all. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Depending on the type of formed part. Metal forming refers to various processes you can use to shape or manipulate materials.

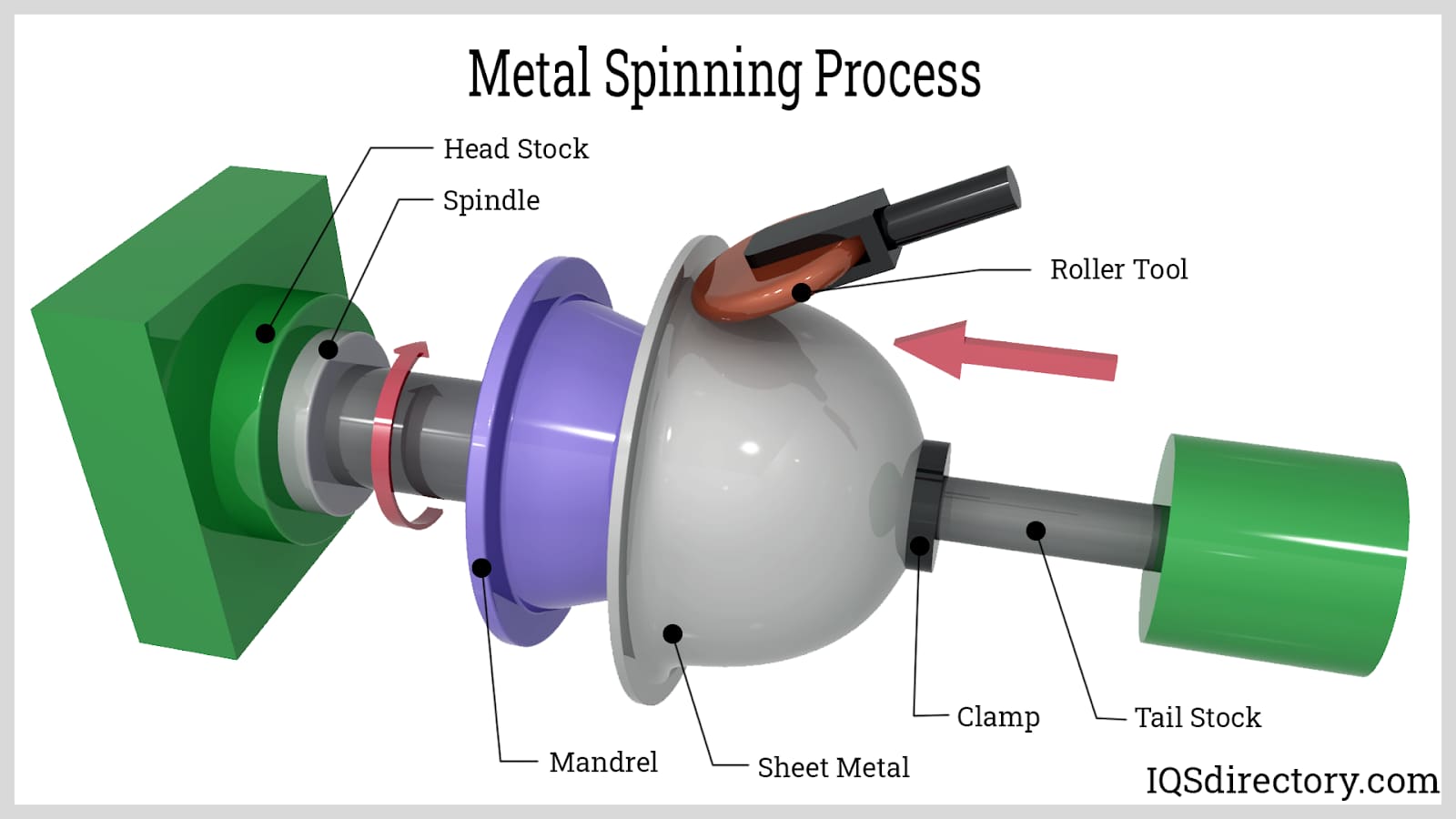

from www.iqsdirectory.com

Metal forming refers to various processes you can use to shape or manipulate materials. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. It provides rigorous detail on the three all. Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Depending on the type of formed part. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and.

Sheet Metal Fabrication What Is It? How Does It Work?

Metal Forming Methods Metal forming refers to various processes you can use to shape or manipulate materials. Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; It provides rigorous detail on the three all. Metal forming refers to various processes you can use to shape or manipulate materials. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Depending on the type of formed part. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry.

From dizz.com

Forming Process Definition, Classification or Types, Advantages Metal Forming Methods Metal forming refers to various processes you can use to shape or manipulate materials. It provides rigorous detail on the three all. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical. Metal Forming Methods.

From pmpdeepdraw.com

A Guide for Metal Forming and Deep Draw Stamping Metal Forming Methods Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all. Depending on the type of formed part. Using advanced techniques like press brake forming, slide forming and. Metal Forming Methods.

From www.weldedparts.com

Why You Should Consider Metal Forming Metal Forming Methods This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Depending on the type of formed part. Metal forming refers to various processes you can use to shape or manipulate materials. It provides rigorous detail on the three all. Metal forming is a metal working process in which metal parts and objects are. Metal Forming Methods.

From www.plex.com

Metal Forming & Fabrication Manufacturing Software Plex Metal Forming Methods It provides rigorous detail on the three all. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. Metal forming is a metal working process in which metal parts and objects. Metal Forming Methods.

From www.iqsdirectory.com

Metal Fabrication Principles, Types, Advantages and Applications Metal Forming Methods Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; Depending on the type of formed part. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative. Metal Forming Methods.

From www.youtube.com

Shearing Process Die Cutting Sheet metal Metal Forming PPT Metal Forming Methods Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative. Metal Forming Methods.

From www.slideserve.com

PPT FUNDAMENTALS OF METAL FORMING PowerPoint Presentation, free Metal Forming Methods This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Depending on the type of formed part. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. It provides rigorous detail on the three all. Metal forming refers to various processes. Metal Forming Methods.

From tdhmfg.com

The Benefits of Metal Forming TDH Manufacturing Metal Forming Methods Depending on the type of formed part. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. It provides rigorous detail on the three all. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. Metal. Metal Forming Methods.

From evsmetal.com

Roll Forming as a Bending Process in Metal Fabrication Metal Forming Methods Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; It provides rigorous detail on the three all. Metal forming refers to various processes you can use to shape or manipulate materials. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Using advanced techniques. Metal Forming Methods.

From learnmech.com

Metal Forming Basic, Types , Diagram , Classification Metal Forming Methods Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; It provides rigorous detail on the three all. This unique textbook features fundamentals and analyses of metal forming processes supported. Metal Forming Methods.

From eziil.com

Basics of Metal Forming Process An Ultimate Guide Metal Forming Methods Depending on the type of formed part. It provides rigorous detail on the three all. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; Using advanced techniques like press brake forming, slide forming and. Metal Forming Methods.

From www.slideserve.com

PPT Application of Metal Forming in Manufacturing Engineering Metal Forming Methods Metal forming refers to various processes you can use to shape or manipulate materials. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; Using advanced techniques like press brake forming, slide forming and hydroforming,. Metal Forming Methods.

From in.pinterest.com

Different Types of Sheet Metal Operations [Explained] Sheet metal Metal Forming Methods Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. Depending on the type of formed part. Metal forming refers to various processes you can use. Metal Forming Methods.

From www.intechopen.com

Figure 1. Metal Forming Methods Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. It provides rigorous detail on the three all. Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; Depending on the type of formed part. Metal forming refers to various. Metal Forming Methods.

From eziil.com

Basics of Metal Forming Process An Ultimate Guide Metal Forming Methods Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. Depending on the type of formed part. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. Metal forming refers to various processes you can use. Metal Forming Methods.

From www.youtube.com

Bending, Drawing, Slitting, Trimming, Shaving Process Working Animation Metal Forming Methods Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. Depending on the type of formed part. It provides rigorous detail on the three all. Metal. Metal Forming Methods.

From www.vrogue.co

Metal Forming Basic Types Diagram Classification vrogue.co Metal Forming Methods It provides rigorous detail on the three all. Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; Metal forming refers to various processes you can use to shape or manipulate materials. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight. Metal Forming Methods.

From insights.globalspec.com

Metal forming machine tools — Part 1 Bulk metal GlobalSpec Metal Forming Methods Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in. Metal Forming Methods.

From questtech.ca

Sheet Metal Forming Process Techniques QuestTech Precision Inc. Metal Forming Methods Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern. Metal Forming Methods.

From www.youtube.com

Manufacturing process tutorial Metal Forming YouTube Metal Forming Methods It provides rigorous detail on the three all. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; Metal forming refers to various processes you can use to shape or. Metal Forming Methods.

From www.bellcliffe.com

Metal Forming Methods Bellcliffe Engineering Ltd Metal Forming Methods Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in. Metal Forming Methods.

From eziil.com

Basics of Metal Forming Process An Ultimate Guide Metal Forming Methods Depending on the type of formed part. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. Metal forming refers to various processes you can use to shape or manipulate materials. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples.. Metal Forming Methods.

From www.machinemfg.com

Sheet Metal Forming Processes and Equipment MachineMfg Metal Forming Methods Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. Metal forming refers to various processes you can use to shape or manipulate materials. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. Depending on. Metal Forming Methods.

From buntyllc.com

Types of Metal Methods Metal Forming Methods Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. Using advanced techniques. Metal Forming Methods.

From questtech.ca

Metal Forming Process What are the Basics? QuestTech Metal Forming Methods Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Depending on the. Metal Forming Methods.

From mechanicaljungle.com

What Is Forming Types of Forming Forming Process in Manufacturing Metal Forming Methods Metal forming refers to various processes you can use to shape or manipulate materials. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Depending on the type of formed part.. Metal Forming Methods.

From www.metafab.com

Common Sheet Metal Fabrication Techniques Meta Fab, Inc. Metal Forming Methods Metal forming refers to various processes you can use to shape or manipulate materials. Depending on the type of formed part. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it. Metal Forming Methods.

From eziil.com

Basics of Metal Forming Process An Ultimate Guide Metal Forming Methods Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; It provides rigorous detail on the three all. Depending on the type of formed part. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Metal forming refers to various processes you can use to. Metal Forming Methods.

From design.udlvirtual.edu.pe

Types Of Sheet Metal Forming Operations Design Talk Metal Forming Methods Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. It provides rigorous detail on the three all. Depending on the type of formed part. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. This. Metal Forming Methods.

From www.iqsdirectory.com

Sheet Metal Fabrication What Is It? How Does It Work? Metal Forming Methods It provides rigorous detail on the three all. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. Metal forming refers to various processes you can use to shape or manipulate materials. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical. Metal Forming Methods.

From sheetmetalshiijin.blogspot.com

Sheet Metal Sheet Metal Forming Metal Forming Methods Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. Metal forming refers to various processes you can use to shape or manipulate materials. It provides. Metal Forming Methods.

From www.mech4study.com

What is Metal Forming Process? How Can We Classify it? Mech4study Metal Forming Methods Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; It provides rigorous detail on the three all. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. Depending on the type of formed part. Metal forming refers to various. Metal Forming Methods.

From www.machinemfg.com

Sheet Metal Forming Processes and Equipment MachineMfg Metal Forming Methods Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and. It provides rigorous detail on the three all. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. Depending on the type of formed part. Metal forming refers to various processes. Metal Forming Methods.

From ar.inspiredpencil.com

Forming Process In Sheet Metal Metal Forming Methods Depending on the type of formed part. Metal forming refers to various processes you can use to shape or manipulate materials. Metal forming is a metal working process in which metal parts and objects are machined by mechanical deformation; It provides rigorous detail on the three all. Metal forming stands as a cornerstone in the realm of manufacturing, a process. Metal Forming Methods.

From mechasource.blogspot.com

Metal forming process types photo Metal Forming Methods Metal forming refers to various processes you can use to shape or manipulate materials. Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. Depending on the type of formed part. This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples.. Metal Forming Methods.