Surface Roughness Polishing Process . The surface of a part can either be rough with visible tool marks or. Polishing is a surface finishing process that uses physical machinery or chemicals to reduce the surface roughness of objects. It is a measure of the. Surface finish is an integral part of manufacturing. It involves the removal of imperfections, such as. This technology achieves a surface roughness of approximately 0.008μm, making it ideal for. It defines the texture and roughness level of a manufactured component. Polishing is the process of reducing the surface roughness of a workpiece using mechanical, chemical, or electrochemical effects to achieve a bright and smooth surface. Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process.

from exocatfoo.blob.core.windows.net

It involves the removal of imperfections, such as. It is a measure of the. Surface finish is an integral part of manufacturing. Polishing is the process of reducing the surface roughness of a workpiece using mechanical, chemical, or electrochemical effects to achieve a bright and smooth surface. This technology achieves a surface roughness of approximately 0.008μm, making it ideal for. It defines the texture and roughness level of a manufactured component. In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process. Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. The surface of a part can either be rough with visible tool marks or. Polishing is a surface finishing process that uses physical machinery or chemicals to reduce the surface roughness of objects.

Surface Roughness Manufacturing Process at Tara Armstead blog

Surface Roughness Polishing Process Surface finish is an integral part of manufacturing. Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. It involves the removal of imperfections, such as. Surface finish is an integral part of manufacturing. Polishing is the process of reducing the surface roughness of a workpiece using mechanical, chemical, or electrochemical effects to achieve a bright and smooth surface. This technology achieves a surface roughness of approximately 0.008μm, making it ideal for. It is a measure of the. Polishing is a surface finishing process that uses physical machinery or chemicals to reduce the surface roughness of objects. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. The surface of a part can either be rough with visible tool marks or. It defines the texture and roughness level of a manufactured component. In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process.

From facfox.com

Selecting right surface roughness for CNC machining FacFox Docs Surface Roughness Polishing Process Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. It is a measure of the. The surface of a part can either be rough with visible tool marks or. Surface finish is an integral part of manufacturing. Polishing is a surface finishing process that uses physical machinery or chemicals to reduce the. Surface Roughness Polishing Process.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Roughness Polishing Process Surface finish is an integral part of manufacturing. The surface of a part can either be rough with visible tool marks or. This technology achieves a surface roughness of approximately 0.008μm, making it ideal for. It is a measure of the. In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process. Polishing. Surface Roughness Polishing Process.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Roughness Polishing Process Surface finish is an integral part of manufacturing. The surface of a part can either be rough with visible tool marks or. Polishing is a surface finishing process that uses physical machinery or chemicals to reduce the surface roughness of objects. It defines the texture and roughness level of a manufactured component. It involves the removal of imperfections, such as.. Surface Roughness Polishing Process.

From www.thefabricator.com

The basics of metal surface finishes Surface Roughness Polishing Process Surface finish is an integral part of manufacturing. The surface of a part can either be rough with visible tool marks or. It is a measure of the. It involves the removal of imperfections, such as. This technology achieves a surface roughness of approximately 0.008μm, making it ideal for. It defines the texture and roughness level of a manufactured component.. Surface Roughness Polishing Process.

From www.youtube.com

Surface Finishing processes Lapping, Honing, Buffing, Superfinishing Surface Roughness Polishing Process It defines the texture and roughness level of a manufactured component. The surface of a part can either be rough with visible tool marks or. Surface finish is an integral part of manufacturing. Polishing is the process of reducing the surface roughness of a workpiece using mechanical, chemical, or electrochemical effects to achieve a bright and smooth surface. This technology. Surface Roughness Polishing Process.

From exocatfoo.blob.core.windows.net

Surface Roughness Manufacturing Process at Tara Armstead blog Surface Roughness Polishing Process This technology achieves a surface roughness of approximately 0.008μm, making it ideal for. Surface finish is an integral part of manufacturing. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. The surface of a part can either be rough with visible tool marks or. Surface finish refers to the process of. Surface Roughness Polishing Process.

From www.researchgate.net

The material removal rate and surface roughness at different polishing Surface Roughness Polishing Process Surface finish is an integral part of manufacturing. It defines the texture and roughness level of a manufactured component. Polishing is the process of reducing the surface roughness of a workpiece using mechanical, chemical, or electrochemical effects to achieve a bright and smooth surface. Polishing can be defined as the process of refining a surface to achieve a smooth and. Surface Roughness Polishing Process.

From www.researchgate.net

Effect of abrasive grains' size and their transport medium on the Surface Roughness Polishing Process Polishing is a surface finishing process that uses physical machinery or chemicals to reduce the surface roughness of objects. This technology achieves a surface roughness of approximately 0.008μm, making it ideal for. It defines the texture and roughness level of a manufactured component. It is a measure of the. Polishing can be defined as the process of refining a surface. Surface Roughness Polishing Process.

From www.youtube.com

Lapping Process Surface Finishing Process Abrasive Machining PPT Surface Roughness Polishing Process Surface finish is an integral part of manufacturing. It involves the removal of imperfections, such as. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. It defines the texture and roughness level of a manufactured component. This technology achieves a surface roughness of approximately 0.008μm, making it ideal for. Surface finish. Surface Roughness Polishing Process.

From makenica.com

Surface Finish & Mold Polishing tips for Injection Molding Surface Roughness Polishing Process It is a measure of the. It involves the removal of imperfections, such as. In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process. Surface finish is an integral part of manufacturing. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. Polishing is. Surface Roughness Polishing Process.

From axiumprocess.com

Stainless Steel Polishing Photo Gallery Axium Process Ltd Surface Roughness Polishing Process Polishing is the process of reducing the surface roughness of a workpiece using mechanical, chemical, or electrochemical effects to achieve a bright and smooth surface. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. It involves the removal of imperfections, such as. Polishing is a surface finishing process that uses physical. Surface Roughness Polishing Process.

From www.practicalmachinist.com

How to Use and Choose Surface Roughness Comparators Practical Surface Roughness Polishing Process It is a measure of the. It defines the texture and roughness level of a manufactured component. It involves the removal of imperfections, such as. Surface finish is an integral part of manufacturing. Polishing is the process of reducing the surface roughness of a workpiece using mechanical, chemical, or electrochemical effects to achieve a bright and smooth surface. Polishing can. Surface Roughness Polishing Process.

From www.kemalmfg.com

A Comprehensive Guide to Surface Roughness, its Measurement, Standards Surface Roughness Polishing Process Surface finish is an integral part of manufacturing. It is a measure of the. The surface of a part can either be rough with visible tool marks or. Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. Surface Roughness Polishing Process.

From isofinishing.com

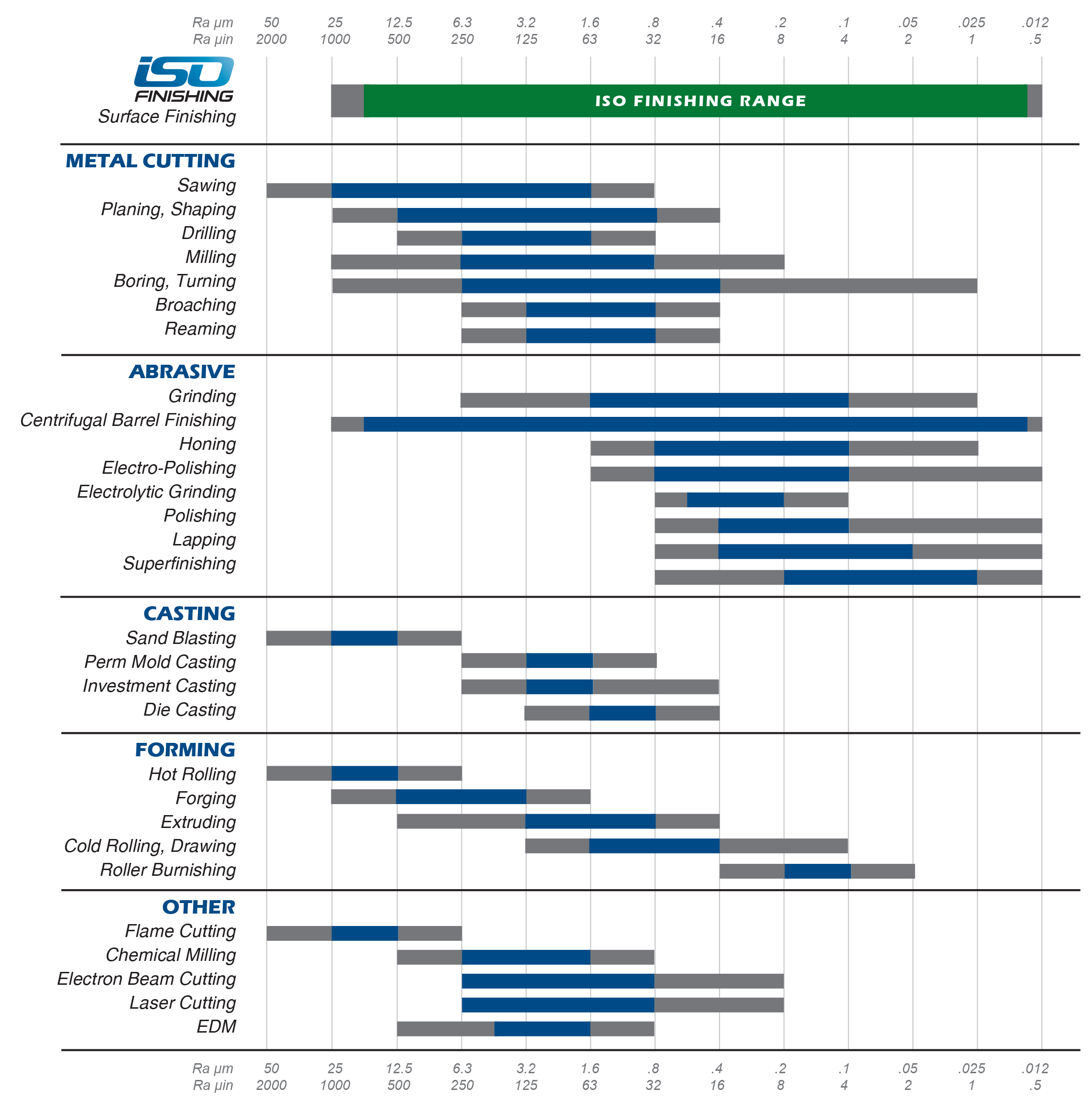

Surface Roughness Chart ISO Finishing Surface Roughness Polishing Process Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. Polishing is a surface finishing process that uses physical machinery or chemicals to reduce the surface roughness of objects. Surface finish is an integral part of manufacturing. The surface of a part can either be rough with visible tool marks or. In. Surface Roughness Polishing Process.

From www.researchgate.net

Surface roughness (Rpv) over polishing time Download Scientific Diagram Surface Roughness Polishing Process Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. It defines the texture and roughness level of a manufactured component. Surface finish is an integral part of manufacturing. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. In this paper, the formation mechanism. Surface Roughness Polishing Process.

From www.researchgate.net

The schematic of the polishing principle Download Scientific Diagram Surface Roughness Polishing Process The surface of a part can either be rough with visible tool marks or. This technology achieves a surface roughness of approximately 0.008μm, making it ideal for. Surface finish is an integral part of manufacturing. Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. Polishing is the process of reducing the surface. Surface Roughness Polishing Process.

From www.rapiddirect.com

Everything You Need to Know About Polishing Surface Finish RapidDirect Surface Roughness Polishing Process It involves the removal of imperfections, such as. In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process. Polishing is a surface finishing process that uses physical machinery or chemicals to reduce the surface roughness of objects. Polishing can be defined as the process of refining a surface to achieve a smooth. Surface Roughness Polishing Process.

From exocatfoo.blob.core.windows.net

Surface Roughness Manufacturing Process at Tara Armstead blog Surface Roughness Polishing Process Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. This technology achieves a surface roughness of approximately 0.008μm, making it ideal for. It is a measure of the. The surface of a part can either be rough with visible tool marks or. Surface finish is an integral part of manufacturing. It defines. Surface Roughness Polishing Process.

From www.engineeringtoolbox.com

Mechanical Processing and Surface Roughness Surface Roughness Polishing Process In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. The surface of a part can either be rough with visible tool marks or. It is a measure of the. Surface finish refers to. Surface Roughness Polishing Process.

From www.edmundoptics.com

Understanding Surface Roughness Edmund Optics Surface Roughness Polishing Process Surface finish is an integral part of manufacturing. The surface of a part can either be rough with visible tool marks or. It defines the texture and roughness level of a manufactured component. It involves the removal of imperfections, such as. It is a measure of the. Polishing is the process of reducing the surface roughness of a workpiece using. Surface Roughness Polishing Process.

From www.mdpi.com

Energies Free FullText Effect of Surface Treatment by Chemical Surface Roughness Polishing Process Polishing is a surface finishing process that uses physical machinery or chemicals to reduce the surface roughness of objects. Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. It defines the texture and roughness level of a manufactured component. In this paper, the formation mechanism and evolution of surface roughness in the. Surface Roughness Polishing Process.

From dxoeequoi.blob.core.windows.net

Surface Roughness Measurement Of Metals at Troy Schneider blog Surface Roughness Polishing Process Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. It defines the texture and roughness level of a manufactured component. Polishing is a surface finishing process that uses physical machinery or chemicals to reduce the surface roughness of objects. It involves the removal of imperfections, such as. Surface finish refers to. Surface Roughness Polishing Process.

From www.researchgate.net

Range of surface roughness obtained in various machining processes [22 Surface Roughness Polishing Process Polishing is the process of reducing the surface roughness of a workpiece using mechanical, chemical, or electrochemical effects to achieve a bright and smooth surface. It involves the removal of imperfections, such as. Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. This technology achieves a surface roughness of approximately 0.008μm, making. Surface Roughness Polishing Process.

From www.researchgate.net

SEM image and surface roughness when polishing with different APs Surface Roughness Polishing Process In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process. Polishing is the process of reducing the surface roughness of a workpiece using mechanical, chemical, or electrochemical effects to achieve a bright and smooth surface. It defines the texture and roughness level of a manufactured component. Polishing can be defined as the. Surface Roughness Polishing Process.

From qbhmetal.com

Guide on Polishing Surface Finish for Custom Metal Parts Surface Roughness Polishing Process The surface of a part can either be rough with visible tool marks or. In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process. It is a measure of the. Surface finish is an integral part of manufacturing. Polishing can be defined as the process of refining a surface to achieve a. Surface Roughness Polishing Process.

From www.youtube.com

Surface Texture Roughness and Waviness Flaws & Lay Profile What Surface Roughness Polishing Process In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. It is a measure of the. Polishing is a surface finishing process that uses physical machinery or chemicals to reduce the surface roughness of. Surface Roughness Polishing Process.

From www.suginocorp.com

Surface Roughness for Lathe Turning Surface Roughness Polishing Process This technology achieves a surface roughness of approximately 0.008μm, making it ideal for. In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process. The surface of a part can either be rough with visible tool marks or. Surface finish is an integral part of manufacturing. Surface finish refers to the process of. Surface Roughness Polishing Process.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Roughness Polishing Process Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. Surface finish is an integral part of manufacturing. Polishing is a surface finishing process that uses physical machinery or chemicals to reduce the surface roughness of objects. The surface of a part can either be rough with visible tool marks or. In this. Surface Roughness Polishing Process.

From www.kemet.co.uk

Surface Finishing Technologies, Process Types and Methods Kemet Surface Roughness Polishing Process Surface finish is an integral part of manufacturing. The surface of a part can either be rough with visible tool marks or. It is a measure of the. It involves the removal of imperfections, such as. Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. In this paper, the formation mechanism and. Surface Roughness Polishing Process.

From mavink.com

Surface Roughness Symbols And Meanings Surface Roughness Polishing Process It is a measure of the. The surface of a part can either be rough with visible tool marks or. Polishing is the process of reducing the surface roughness of a workpiece using mechanical, chemical, or electrochemical effects to achieve a bright and smooth surface. Surface finish refers to the process of altering a metal’s surface that involves removing, adding,. Surface Roughness Polishing Process.

From acton-finishing.co.uk

Dry Electropolishing for Surface Finishing Medical Implants Surface Roughness Polishing Process This technology achieves a surface roughness of approximately 0.008μm, making it ideal for. The surface of a part can either be rough with visible tool marks or. In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process. Polishing can be defined as the process of refining a surface to achieve a smooth. Surface Roughness Polishing Process.

From www.researchgate.net

Mechanism of texturing and chemical polishing of silicate glass to tune Surface Roughness Polishing Process In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process. It is a measure of the. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. It. Surface Roughness Polishing Process.

From deburringtechnologies.com

Modern Surface Finishing and Polishing Operations in Manufacturing Surface Roughness Polishing Process Polishing is the process of reducing the surface roughness of a workpiece using mechanical, chemical, or electrochemical effects to achieve a bright and smooth surface. Polishing is a surface finishing process that uses physical machinery or chemicals to reduce the surface roughness of objects. It is a measure of the. It involves the removal of imperfections, such as. In this. Surface Roughness Polishing Process.

From blog.thepipingmart.com

What is Metal Polishing? Process and Types Surface Roughness Polishing Process This technology achieves a surface roughness of approximately 0.008μm, making it ideal for. It defines the texture and roughness level of a manufactured component. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. It is a measure of the. Surface finish is an integral part of manufacturing. The surface of a. Surface Roughness Polishing Process.

From get-it-made.co.uk

Surface Roughness Explained Ra Roughness Chart Surface Roughness Polishing Process In this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear thickening polishing process. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. It is a measure of the. The surface of a part can either be rough with visible tool marks or. It involves the removal. Surface Roughness Polishing Process.