Mig Welder Wire Slipping . all mig welders have a liner inside the torch, this liner wears out. Contact tips wear down, and you can’t use the same one your machine came with. you can slip the tip back on over the wire once it’s through the torch. first, make sure there is no dust or debris on your drive feeder. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. Then, make sure that your drive roll tension is adequate. It is considered a consumable.

from www.weldingtipsandtricks.com

common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. Contact tips wear down, and you can’t use the same one your machine came with. It is considered a consumable. all mig welders have a liner inside the torch, this liner wears out. first, make sure there is no dust or debris on your drive feeder. Then, make sure that your drive roll tension is adequate. you can slip the tip back on over the wire once it’s through the torch.

Mig Welding Basics part 2

Mig Welder Wire Slipping Contact tips wear down, and you can’t use the same one your machine came with. first, make sure there is no dust or debris on your drive feeder. you can slip the tip back on over the wire once it’s through the torch. Contact tips wear down, and you can’t use the same one your machine came with. all mig welders have a liner inside the torch, this liner wears out. Then, make sure that your drive roll tension is adequate. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. It is considered a consumable.

From www.youtube.com

🔥 MIG Welding Aluminum on a Positioner YouTube Mig Welder Wire Slipping all mig welders have a liner inside the torch, this liner wears out. It is considered a consumable. Contact tips wear down, and you can’t use the same one your machine came with. Then, make sure that your drive roll tension is adequate. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine.. Mig Welder Wire Slipping.

From www.mig-welding.co.uk

torque converter slipping? Page 3 MIG Welding Forum Mig Welder Wire Slipping It is considered a consumable. Contact tips wear down, and you can’t use the same one your machine came with. you can slip the tip back on over the wire once it’s through the torch. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. Then, make sure that your drive roll tension. Mig Welder Wire Slipping.

From www.mig-welding.co.uk

Cebora Stag 186 wire feed slipping MIG Welding Forum Mig Welder Wire Slipping Contact tips wear down, and you can’t use the same one your machine came with. first, make sure there is no dust or debris on your drive feeder. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. all mig welders have a liner inside the torch, this liner wears out. . Mig Welder Wire Slipping.

From www.aliexpress.com

11pcs Mayitr Mig Welding Nozzle Durable Welder Torch Nozzles Tip Holder Mig Welder Wire Slipping Then, make sure that your drive roll tension is adequate. all mig welders have a liner inside the torch, this liner wears out. first, make sure there is no dust or debris on your drive feeder. Contact tips wear down, and you can’t use the same one your machine came with. It is considered a consumable. you. Mig Welder Wire Slipping.

From bakersgas.com

Miller Millermatic 252 MIG Welder w/ Spoolmatic 30A Package 951066 Mig Welder Wire Slipping you can slip the tip back on over the wire once it’s through the torch. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. Then, make sure that your drive roll tension is adequate. It is considered a consumable. Contact tips wear down, and you can’t use the same one your machine. Mig Welder Wire Slipping.

From welderslab.com

Can You Mig Weld Aluminum Without a Spool Gun Welders Lab Mig Welder Wire Slipping common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. It is considered a consumable. first, make sure there is no dust or debris on your drive feeder. all mig welders have a liner inside the torch, this liner wears out. you can slip the tip back on over the wire. Mig Welder Wire Slipping.

From www.mig-welding.co.uk

Installing MIG Wire and Setting Wire Feed Tension Mig Welder Wire Slipping you can slip the tip back on over the wire once it’s through the torch. Contact tips wear down, and you can’t use the same one your machine came with. all mig welders have a liner inside the torch, this liner wears out. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance. Mig Welder Wire Slipping.

From www.mig-welding.co.uk

Installing MIG Wire and Setting Wire Feed Tension Mig Welder Wire Slipping first, make sure there is no dust or debris on your drive feeder. Then, make sure that your drive roll tension is adequate. It is considered a consumable. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. Contact tips wear down, and you can’t use the same one your machine came with.. Mig Welder Wire Slipping.

From www.mig-welding.co.uk

Cebora Stag 186 wire feed slipping MIG Welding Forum Mig Welder Wire Slipping common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. all mig welders have a liner inside the torch, this liner wears out. Then, make sure that your drive roll tension is adequate. first, make sure there is no dust or debris on your drive feeder. you can slip the tip. Mig Welder Wire Slipping.

From www.youtube.com

MIG Welding Stainless Steel YouTube Mig Welder Wire Slipping Then, make sure that your drive roll tension is adequate. Contact tips wear down, and you can’t use the same one your machine came with. It is considered a consumable. first, make sure there is no dust or debris on your drive feeder. you can slip the tip back on over the wire once it’s through the torch.. Mig Welder Wire Slipping.

From www.instructables.com

How to Fix a Lincoln MIG Welder That 'stutters' 5 Steps Instructables Mig Welder Wire Slipping you can slip the tip back on over the wire once it’s through the torch. It is considered a consumable. all mig welders have a liner inside the torch, this liner wears out. Then, make sure that your drive roll tension is adequate. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance. Mig Welder Wire Slipping.

From www.mig-welding.co.uk

Installing MIG Wire and Setting Wire Feed Tension Mig Welder Wire Slipping you can slip the tip back on over the wire once it’s through the torch. Contact tips wear down, and you can’t use the same one your machine came with. all mig welders have a liner inside the torch, this liner wears out. first, make sure there is no dust or debris on your drive feeder. Then,. Mig Welder Wire Slipping.

From www.purplewave.com

Lincoln 216 wire feed mig welder in Colorado Springs, CO Item EP9552 Mig Welder Wire Slipping common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. Contact tips wear down, and you can’t use the same one your machine came with. It is considered a consumable. you can slip the tip back on over the wire once it’s through the torch. all mig welders have a liner inside. Mig Welder Wire Slipping.

From www.youtube.com

Learn How to put Wire Spool into the MIG gun in Welding Philadelphia Mig Welder Wire Slipping It is considered a consumable. first, make sure there is no dust or debris on your drive feeder. Then, make sure that your drive roll tension is adequate. you can slip the tip back on over the wire once it’s through the torch. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance. Mig Welder Wire Slipping.

From workshopfixcarbonises.z13.web.core.windows.net

Millermatic 252 Welding Machine Mig Welder Wire Slipping Contact tips wear down, and you can’t use the same one your machine came with. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. all mig welders have a liner inside the torch, this liner wears out. Then, make sure that your drive roll tension is adequate. first, make sure there. Mig Welder Wire Slipping.

From www.youtube.com

How to MIG Weld Aluminum The Complete Guide YouTube Mig Welder Wire Slipping Then, make sure that your drive roll tension is adequate. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. you can slip the tip back on over the wire once it’s through the torch. first, make sure there is no dust or debris on your drive feeder. all mig welders. Mig Welder Wire Slipping.

From weldingweb.com

LTec 225 MIG wire feed motor slipping Mig Welder Wire Slipping first, make sure there is no dust or debris on your drive feeder. Then, make sure that your drive roll tension is adequate. you can slip the tip back on over the wire once it’s through the torch. all mig welders have a liner inside the torch, this liner wears out. Contact tips wear down, and you. Mig Welder Wire Slipping.

From www.weldingtipsandtricks.com

Mig Welding Basics part 2 Mig Welder Wire Slipping Then, make sure that your drive roll tension is adequate. you can slip the tip back on over the wire once it’s through the torch. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. first, make sure there is no dust or debris on your drive feeder. It is considered a. Mig Welder Wire Slipping.

From www.pinterest.com.au

MIG welding torch with tip and shroud removed Metal welding, Welding Mig Welder Wire Slipping you can slip the tip back on over the wire once it’s through the torch. It is considered a consumable. all mig welders have a liner inside the torch, this liner wears out. Then, make sure that your drive roll tension is adequate. Contact tips wear down, and you can’t use the same one your machine came with.. Mig Welder Wire Slipping.

From www.pinterest.com

Pulse MIG 0.45 with a Lincoln s500 Power wave. Vertical weld joining Mig Welder Wire Slipping you can slip the tip back on over the wire once it’s through the torch. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. Then, make sure that your drive roll tension is adequate. first, make sure there is no dust or debris on your drive feeder. It is considered a. Mig Welder Wire Slipping.

From weldingzilla.com

MIG vs. TIG Welding How to choose between MIG and TIG Welding Mig Welder Wire Slipping first, make sure there is no dust or debris on your drive feeder. you can slip the tip back on over the wire once it’s through the torch. Contact tips wear down, and you can’t use the same one your machine came with. all mig welders have a liner inside the torch, this liner wears out. Then,. Mig Welder Wire Slipping.

From www.youtube.com

HARBOUR FREIGHT 90 amp flux welder wire feed slipping fix YouTube Mig Welder Wire Slipping It is considered a consumable. Contact tips wear down, and you can’t use the same one your machine came with. you can slip the tip back on over the wire once it’s through the torch. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. all mig welders have a liner inside. Mig Welder Wire Slipping.

From www.mig-welding.co.uk

Replacing a Wire Liner SIP Migmate, Topmig and Cosmo Mig Welder Wire Slipping all mig welders have a liner inside the torch, this liner wears out. Then, make sure that your drive roll tension is adequate. first, make sure there is no dust or debris on your drive feeder. you can slip the tip back on over the wire once it’s through the torch. common wire feed welding issues. Mig Welder Wire Slipping.

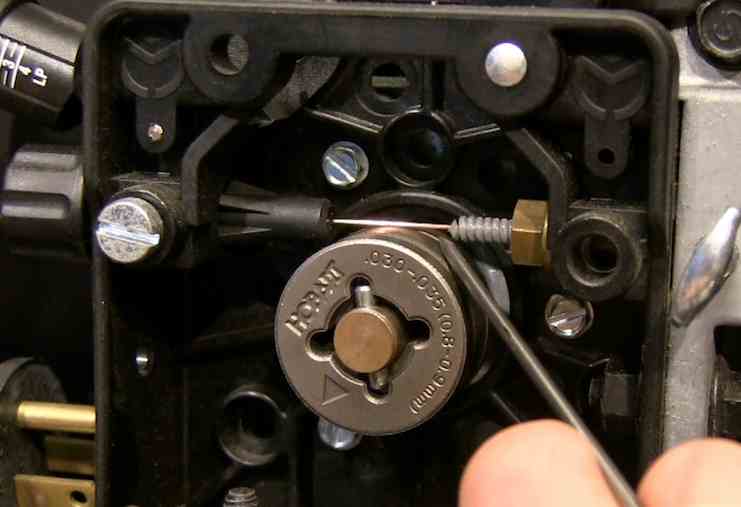

From www.hobartwelders.com

Slip Type MIG Nozzle, 1/2" HobartWelders Mig Welder Wire Slipping first, make sure there is no dust or debris on your drive feeder. It is considered a consumable. Then, make sure that your drive roll tension is adequate. Contact tips wear down, and you can’t use the same one your machine came with. you can slip the tip back on over the wire once it’s through the torch.. Mig Welder Wire Slipping.

From www.mig-welding.co.uk

Installing MIG Wire and Setting Wire Feed Tension Mig Welder Wire Slipping Contact tips wear down, and you can’t use the same one your machine came with. you can slip the tip back on over the wire once it’s through the torch. all mig welders have a liner inside the torch, this liner wears out. Then, make sure that your drive roll tension is adequate. first, make sure there. Mig Welder Wire Slipping.

From baileylineroad.com

How to Use a Wire Feed Welder Why These Tools Are So Great Mig Welder Wire Slipping Then, make sure that your drive roll tension is adequate. first, make sure there is no dust or debris on your drive feeder. common wire feed welding issues are surmountable with proper knowledge and a proactive maintenance routine. It is considered a consumable. Contact tips wear down, and you can’t use the same one your machine came with.. Mig Welder Wire Slipping.