Oil Well Choke Sizes . Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from reservoirs due to high. Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. Let us work closely with you and employ our. Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. And internal choke size diameter, ‘d’.

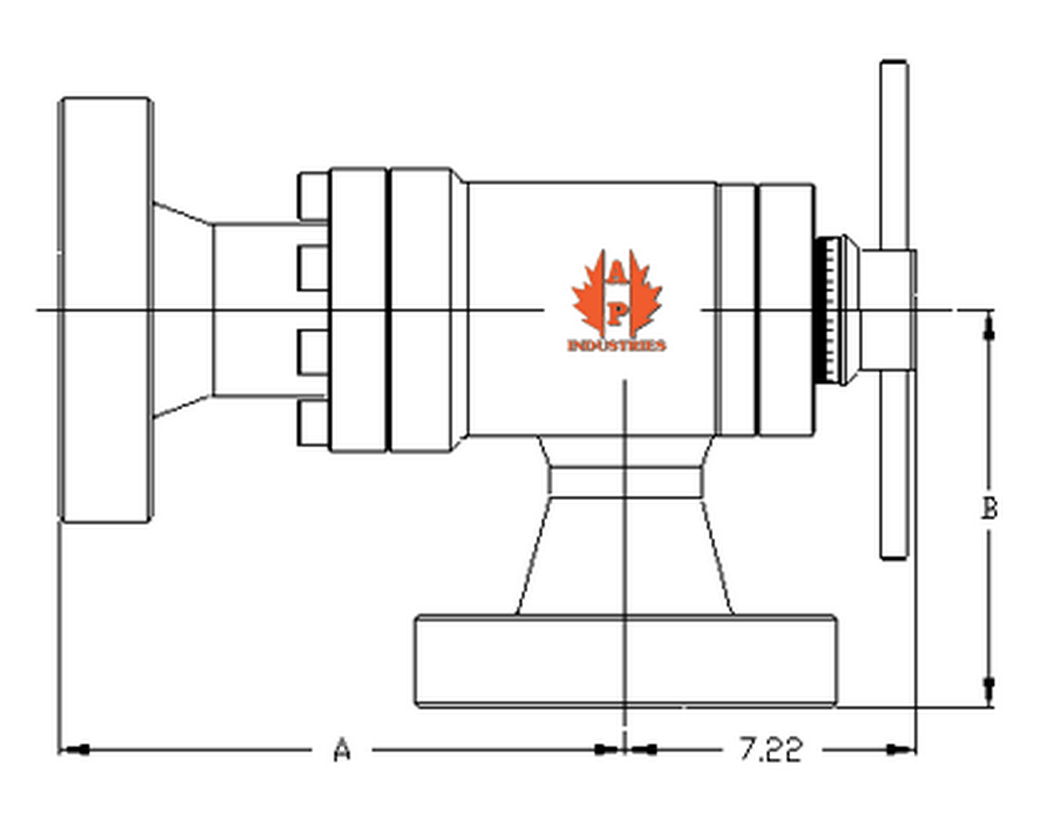

from apibop.com

And internal choke size diameter, ‘d’. Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. Let us work closely with you and employ our. Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from reservoirs due to high.

AP Industries

Oil Well Choke Sizes And internal choke size diameter, ‘d’. Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from reservoirs due to high. Let us work closely with you and employ our. Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. And internal choke size diameter, ‘d’. Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’;

From www.jcwellhead.com

Red Choke Manifold Oil And Gas 2 1/16" X 10000psi For High Pressure Well Testing Oil Well Choke Sizes Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. And internal choke size diameter, ‘d’. In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and. Oil Well Choke Sizes.

From lakepetro.en.made-in-china.com

API 16A Wellhead Chokes for Oil Well Control Equipment China API Choke Manifold and API Kill Oil Well Choke Sizes Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. And internal choke size diameter, ‘d’. Let us work closely with you and employ our. Jffree, that more standard approach. Oil Well Choke Sizes.

From waterfowlchoke.com

Complete Guide to Identifying Choke Tube Sizes WaterfowlChoke Oil Well Choke Sizes Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells.. Oil Well Choke Sizes.

From masonsummers.z13.web.core.windows.net

Choke Bean Size Chart Oil Well Choke Sizes Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. Let us work closely with you and employ our. And internal choke size diameter, ‘d’. Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. Common. Oil Well Choke Sizes.

From www.eng-tips.com

choke valve Petroleum engineering general discussion EngTips Oil Well Choke Sizes In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. Let us work closely with you and employ our. Jffree, that more standard approach for the haynesville. Oil Well Choke Sizes.

From peakoilbarrel.com

More on Bakken Production, Choke Theory Peak Oil Barrel Oil Well Choke Sizes Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. And internal choke size diameter, ‘d’. Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from reservoirs due to high. Common flow sizes are about. Oil Well Choke Sizes.

From bceweb.org

Choke Size Oil And Gas Chart A Visual Reference of Charts Chart Master Oil Well Choke Sizes Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while. Oil Well Choke Sizes.

From www.kentintrol.com

Surface Choke Valves Oil and Gas Kent Introl Oil Well Choke Sizes Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke. Oil Well Choke Sizes.

From laurenrhodes.z21.web.core.windows.net

Choke Bean Size Chart Oil Well Choke Sizes Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. Let us work closely with you and employ our. And internal choke size diameter, ‘d’. Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. In this. Oil Well Choke Sizes.

From journals.sagepub.com

Choke Valve Technology in Subsea Environments Simon Tattersall, 2016 Oil Well Choke Sizes Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from reservoirs due to high. In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; Let us work closely with you and employ our. Evaluate data from wellhead chokes to better. Oil Well Choke Sizes.

From peakoilbarrel.com

More on Bakken Production, Choke Theory Peak Oil Barrel Oil Well Choke Sizes Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells.. Oil Well Choke Sizes.

From apibop.com

AP Industries Oil Well Choke Sizes Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; Choke. Oil Well Choke Sizes.

From pet-oil.blogspot.com

Chapter 5 Well Heads, Chokes and SSSVs lec ( 14 ) petroleum Oil Well Choke Sizes And internal choke size diameter, ‘d’. Let us work closely with you and employ our. Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; Evaluate data from wellhead chokes to. Oil Well Choke Sizes.

From pet-oil.blogspot.com

Chapter 5 Well Heads, Chokes and SSSVs lec ( 14 ) petroleum Oil Well Choke Sizes In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; And internal choke size diameter, ‘d’. Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. Choke sizing is the most critical part of the choke application and incorrect sizing is. Oil Well Choke Sizes.

From www.youtube.com

Oil and Gas Engineering Choke Valve (Part 4B) YouTube Oil Well Choke Sizes And internal choke size diameter, ‘d’. Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from reservoirs due to high. Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. In this type of formulas, fluid flow rate. Oil Well Choke Sizes.

From hxvalves.com

API 6A Choke valve Choke valve ButterflyGateGlobeBall valveChina valve manufacturer and Oil Well Choke Sizes Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. And internal choke size diameter, ‘d’. Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. Choke sizing is the most critical part of the choke application and incorrect sizing is. Oil Well Choke Sizes.

From whatispiping.com

Types, Applications, and Selection of Choke Valves for Oil and Gas Operations What Is Piping Oil Well Choke Sizes Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. Let us work closely with you and employ our. Accurate modeling of choke performance and selection of. Oil Well Choke Sizes.

From www.researchgate.net

Change in the CGR of the well mixture depending on the size of the... Download Scientific Diagram Oil Well Choke Sizes Let us work closely with you and employ our. Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. And internal choke size diameter, ‘d’. Common. Oil Well Choke Sizes.

From chokefortrap.com

Choke Tube Chart with Size and Constriction TabChoke For Trap Oil Well Choke Sizes Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. Let us work closely with you and employ our. And internal choke size diameter, ‘d’. In this type of formulas,. Oil Well Choke Sizes.

From www.researchgate.net

Image of fixed or positive wellhead chokes with 32/64 in or ½ in apertures Download Scientific Oil Well Choke Sizes Let us work closely with you and employ our. Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; And internal choke size diameter, ‘d’. Evaluate data. Oil Well Choke Sizes.

From www.ecvv.com

API oil well choke manifoldchoke bean 4/64" 192/64" adjustable from China Manufacturer Oil Well Choke Sizes Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from reservoirs due to high. Choke sizing is the most critical part of the choke application and incorrect sizing is. Oil Well Choke Sizes.

From github.com

MLforChokeSizeestimationofoilgaswell/choke.ipynb at main · binaryvexjuiit/MLforChoke Oil Well Choke Sizes Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from reservoirs due to high. Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and. Oil Well Choke Sizes.

From www.researchgate.net

Choke Size Calculations. Download Table Oil Well Choke Sizes Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from reservoirs due to high. In this type of formulas, fluid flow rate of well is related to upstream. Oil Well Choke Sizes.

From www.drillingformulas.com

What is a choke in well control? Oil Well Choke Sizes In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from reservoirs due to high. Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64. Oil Well Choke Sizes.

From www.researchgate.net

PERFORMANCE CURVE OF AN ADJUSTABLE CHOKE FOR SEVERAL CHOKE OPENINGS... Download Scientific Diagram Oil Well Choke Sizes Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. Let us work closely with you and employ our. Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. Common flow sizes are about 8 through. Oil Well Choke Sizes.

From kentintrol.com

Surface Choke Valves Oil and Gas Kent Introl Oil Well Choke Sizes Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues. Oil Well Choke Sizes.

From github.com

GitHub 1oo1/Chokesizeprediction A Gas flow rate via choke size prediction of bangladeshi Oil Well Choke Sizes Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum. Oil Well Choke Sizes.

From www.researchgate.net

Pressure drop across the choke vs flow rate per choke size. Download Scientific Diagram Oil Well Choke Sizes Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from reservoirs due to high. Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64. Oil Well Choke Sizes.

From www.zztopoiltools.com

Oil Well Testing Hydraulic Choke Manifold 5000 Psi For Wellhead Flow Control API 16C Oil Well Choke Sizes Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from reservoirs due to high. Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64. Oil Well Choke Sizes.

From oilfieldvalve.net

Oil Field Valve Service & Supply Oil Well Choke Sizes Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke. Oil Well Choke Sizes.

From pet-oil.blogspot.com

Chapter 5 Well Heads, Chokes and SSSVs lec ( 14 ) petroleum Oil Well Choke Sizes Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. Accurate modeling of choke performance and selection of optimum choke size is vitally important for. Oil Well Choke Sizes.

From www.alibaba.com

Oil And Gas Well Positive Choke Valve / Positive Chokes And Choke Beans Buy Positive Chokes Oil Well Choke Sizes Let us work closely with you and employ our. Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. Accurate modeling of choke performance and selection of. Oil Well Choke Sizes.

From www.goodsupplierglobal.com

Wellhead Production Choke Oil Well Choke Sizes Common flow sizes are about 8 through more than 20 (in 64ths) for small to moderate rate gas wells. Jffree, that more standard approach for the haynesville shale are choke sizes of 20/64 to 26/64 while the restricted choke. Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from. Oil Well Choke Sizes.

From lightfir.en.made-in-china.com

API 6A Oilfield Oil and Gas Drilling Well Control Choke Manifold Kill Manifold Manual Choke Oil Well Choke Sizes In this type of formulas, fluid flow rate of well is related to upstream choke pressure, ‘p 1 ’; Choke sizing is the most critical part of the choke application and incorrect sizing is the source of most choke issues in the field. Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or. Oil Well Choke Sizes.

From www.youtube.com

BOP Choke and Kill Line Specifications Oil and Gas Land Drilling Rig YouTube Oil Well Choke Sizes Evaluate data from wellhead chokes to better understand and ascertain the effects of choke sizes and or types on wellhead during. Accurate modeling of choke performance and selection of optimum choke size is vitally important for a petroleum engineer in production from reservoirs due to high. Choke sizing is the most critical part of the choke application and incorrect sizing. Oil Well Choke Sizes.