Making A Mold In The Foundry . This series follows a cast iron or steel product through the metal casting process in a. A trip through a foundry from pattern to product. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. By using them, manufacturers can create precise and consistent parts with minimal defects. There are various types of foundry casting, each with. They serve as the bottom half of a mold while the cope serves as the top half. All patterns need a gating. Foundry casting involves using sand molds to create the final product, also known as green sand casting or permanent mold casting. Drag molds help create intricate and complex shapes during the casting processes. The drag mold houses all the necessary details and features of the desired. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities.the mould is therefore essentially a die.in typical foundry terminology, the term “mould” is used when the latter is made with refractory materials (silica sand or other ceramic materials) and is “disposable.

from www.alamy.com

This series follows a cast iron or steel product through the metal casting process in a. They serve as the bottom half of a mold while the cope serves as the top half. By using them, manufacturers can create precise and consistent parts with minimal defects. A trip through a foundry from pattern to product. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities.the mould is therefore essentially a die.in typical foundry terminology, the term “mould” is used when the latter is made with refractory materials (silica sand or other ceramic materials) and is “disposable. Foundry casting involves using sand molds to create the final product, also known as green sand casting or permanent mold casting. Drag molds help create intricate and complex shapes during the casting processes. All patterns need a gating. The drag mold houses all the necessary details and features of the desired. There are various types of foundry casting, each with.

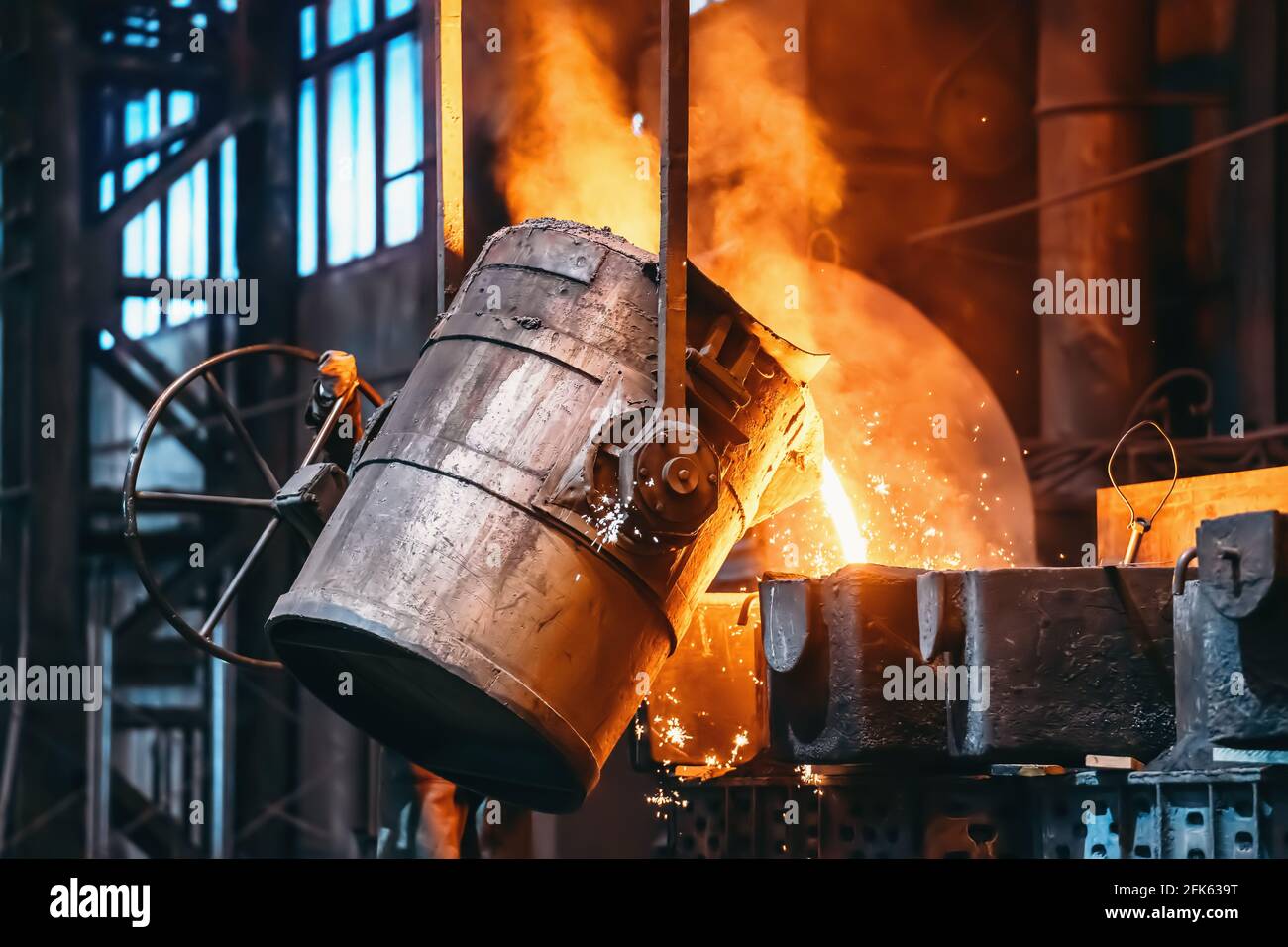

Metal casting process in foundry, liquid metal pouring from container

Making A Mold In The Foundry A trip through a foundry from pattern to product. There are various types of foundry casting, each with. By using them, manufacturers can create precise and consistent parts with minimal defects. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities.the mould is therefore essentially a die.in typical foundry terminology, the term “mould” is used when the latter is made with refractory materials (silica sand or other ceramic materials) and is “disposable. Foundry casting involves using sand molds to create the final product, also known as green sand casting or permanent mold casting. They serve as the bottom half of a mold while the cope serves as the top half. The drag mold houses all the necessary details and features of the desired. This series follows a cast iron or steel product through the metal casting process in a. A trip through a foundry from pattern to product. Drag molds help create intricate and complex shapes during the casting processes. All patterns need a gating. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand.

From www.leclairemfg.com

Ultimate Guide to the Permanent Mold Casting Process Making A Mold In The Foundry Drag molds help create intricate and complex shapes during the casting processes. Foundry casting involves using sand molds to create the final product, also known as green sand casting or permanent mold casting. There are various types of foundry casting, each with. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting. Making A Mold In The Foundry.

From www.pinterest.com

Wooden Foundry Mold Template for foundry work Etsy Wooden, Molding Making A Mold In The Foundry A trip through a foundry from pattern to product. This series follows a cast iron or steel product through the metal casting process in a. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities.the mould is therefore essentially a die.in. Making A Mold In The Foundry.

From www.patriotfoundry.com

Foundry Sand Casting Process Simple Step by Step Patriot Foundry Making A Mold In The Foundry Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities.the mould is therefore essentially a die.in typical foundry terminology, the term “mould” is used when the latter is made with refractory materials (silica sand or other ceramic materials) and is “disposable.. Making A Mold In The Foundry.

From veenaengicast.com

Metal Casting Guide for Beginners Veena Enterprise Making A Mold In The Foundry Foundry casting involves using sand molds to create the final product, also known as green sand casting or permanent mold casting. A trip through a foundry from pattern to product. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. All patterns need a gating. There are various types. Making A Mold In The Foundry.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Making A Mold In The Foundry The drag mold houses all the necessary details and features of the desired. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. A trip through a foundry from pattern to product. Cast iron foundries essentially use silica sands to make the mould in which the casting will be. Making A Mold In The Foundry.

From www.clinchrivercasting.com

Molding Clinch River Casting NoBake Casting Foundry Making A Mold In The Foundry Drag molds help create intricate and complex shapes during the casting processes. Foundry casting involves using sand molds to create the final product, also known as green sand casting or permanent mold casting. By using them, manufacturers can create precise and consistent parts with minimal defects. Foundry pattern making is the process of designing and creating a mold pattern, casting. Making A Mold In The Foundry.

From www.archantiques.com

Wood Foundry Molds — ARCHITECTURAL ANTIQUES Making A Mold In The Foundry Drag molds help create intricate and complex shapes during the casting processes. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with. Making A Mold In The Foundry.

From www.dreamstime.com

Products Foundry Industry. Making Molds and Cores Stock Image Image Making A Mold In The Foundry The drag mold houses all the necessary details and features of the desired. Drag molds help create intricate and complex shapes during the casting processes. This series follows a cast iron or steel product through the metal casting process in a. A trip through a foundry from pattern to product. All patterns need a gating. Foundry casting involves using sand. Making A Mold In The Foundry.

From www.dla.mil

Casting Mold Making A Mold In The Foundry Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Drag molds help create intricate and complex shapes during the casting processes. They serve as the bottom half of a mold while the cope serves as the top half. This series follows a cast iron or steel product through. Making A Mold In The Foundry.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Making A Mold In The Foundry There are various types of foundry casting, each with. This series follows a cast iron or steel product through the metal casting process in a. By using them, manufacturers can create precise and consistent parts with minimal defects. A trip through a foundry from pattern to product. Foundry casting involves using sand molds to create the final product, also known. Making A Mold In The Foundry.

From firebirdbronze.com

Firebird Bronze Foundry Services Making A Mold In The Foundry By using them, manufacturers can create precise and consistent parts with minimal defects. This series follows a cast iron or steel product through the metal casting process in a. A trip through a foundry from pattern to product. They serve as the bottom half of a mold while the cope serves as the top half. Drag molds help create intricate. Making A Mold In The Foundry.

From www.pinterest.com.au

handverker readymake sand molds Molding, Mold making, Sand Making A Mold In The Foundry There are various types of foundry casting, each with. Drag molds help create intricate and complex shapes during the casting processes. This series follows a cast iron or steel product through the metal casting process in a. They serve as the bottom half of a mold while the cope serves as the top half. A trip through a foundry from. Making A Mold In The Foundry.

From spfoundry.com

castingmold SP Foundry Making A Mold In The Foundry They serve as the bottom half of a mold while the cope serves as the top half. By using them, manufacturers can create precise and consistent parts with minimal defects. All patterns need a gating. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex. Making A Mold In The Foundry.

From www.thompsonfoundry.com

6 cavity zinc ingot mold Thompson Foundry Making A Mold In The Foundry Drag molds help create intricate and complex shapes during the casting processes. This series follows a cast iron or steel product through the metal casting process in a. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. They serve as the bottom half of a mold while the. Making A Mold In The Foundry.

From monroeengineering.com

The 6Step Process of Sand Casting Molding OneMonroe Making A Mold In The Foundry Drag molds help create intricate and complex shapes during the casting processes. Foundry casting involves using sand molds to create the final product, also known as green sand casting or permanent mold casting. This series follows a cast iron or steel product through the metal casting process in a. Cast iron foundries essentially use silica sands to make the mould. Making A Mold In The Foundry.

From vietnamcastiron.com

Instructions for Making Sand Casting Molds in detail Step by Step Making A Mold In The Foundry Drag molds help create intricate and complex shapes during the casting processes. They serve as the bottom half of a mold while the cope serves as the top half. The drag mold houses all the necessary details and features of the desired. This series follows a cast iron or steel product through the metal casting process in a. Foundry pattern. Making A Mold In The Foundry.

From timberridgedesigns.com

Aluminum Casting At Home DIY Aluminum Foundry & Molds Timber Ridge Making A Mold In The Foundry Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. There are various types of foundry casting, each with. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities.the mould. Making A Mold In The Foundry.

From www.dreamstime.com

Molds In Foundry After Casting Stock Image Image of mold, metal Making A Mold In The Foundry By using them, manufacturers can create precise and consistent parts with minimal defects. A trip through a foundry from pattern to product. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities.the mould is therefore essentially a die.in typical foundry terminology,. Making A Mold In The Foundry.

From www.foundrymag.com

A Practical Guide to Placing Chills in Large Molds Foundry Management Making A Mold In The Foundry They serve as the bottom half of a mold while the cope serves as the top half. This series follows a cast iron or steel product through the metal casting process in a. By using them, manufacturers can create precise and consistent parts with minimal defects. There are various types of foundry casting, each with. The drag mold houses all. Making A Mold In The Foundry.

From www.alamy.com

Metal casting process in foundry, liquid metal pouring from container Making A Mold In The Foundry A trip through a foundry from pattern to product. There are various types of foundry casting, each with. Drag molds help create intricate and complex shapes during the casting processes. They serve as the bottom half of a mold while the cope serves as the top half. By using them, manufacturers can create precise and consistent parts with minimal defects.. Making A Mold In The Foundry.

From www.youtube.com

Pouring Molten Aluminum into a 3D Printed Sand Casting Mold YouTube Making A Mold In The Foundry This series follows a cast iron or steel product through the metal casting process in a. By using them, manufacturers can create precise and consistent parts with minimal defects. The drag mold houses all the necessary details and features of the desired. Drag molds help create intricate and complex shapes during the casting processes. Foundry pattern making is the process. Making A Mold In The Foundry.

From batesvilleproducts.com

Tooling Design & Permant Mold Making Batesville Products Making A Mold In The Foundry All patterns need a gating. By using them, manufacturers can create precise and consistent parts with minimal defects. They serve as the bottom half of a mold while the cope serves as the top half. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex. Making A Mold In The Foundry.

From blog.eaglegroupmanufacturers.com

Getting Started with Permanent Mold Casting Making A Mold In The Foundry They serve as the bottom half of a mold while the cope serves as the top half. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities.the mould is therefore essentially a die.in typical foundry terminology, the term “mould” is used. Making A Mold In The Foundry.

From klaiwfluu.blob.core.windows.net

Casting The Molding at Oswaldo Perkins blog Making A Mold In The Foundry Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Drag molds help create intricate and complex shapes during the casting processes. They serve as the bottom half of a mold while the cope serves as the top half. This series follows a cast iron or steel product through. Making A Mold In The Foundry.

From precision-casting.co.id

Precision Casting Manufacturing Process Metal Foundry Making A Mold In The Foundry They serve as the bottom half of a mold while the cope serves as the top half. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. All patterns need a gating. Cast iron foundries essentially use silica sands to make the mould in which the casting will be. Making A Mold In The Foundry.

From www.youtube.com

Foundry Green Sand Mixing for making casting molds. YouTube Making A Mold In The Foundry A trip through a foundry from pattern to product. Foundry casting involves using sand molds to create the final product, also known as green sand casting or permanent mold casting. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. They serve as the bottom half of a mold. Making A Mold In The Foundry.

From www.clinchrivercasting.com

Molding NoBake Iron Foundry Clinch River Casting Making A Mold In The Foundry Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities.the mould is therefore essentially a die.in typical foundry terminology, the term “mould” is used when the latter is made with refractory materials (silica sand or other ceramic materials) and is “disposable.. Making A Mold In The Foundry.

From www.youtube.com

Shell Molding Expandable Mold Casting Processes YouTube Making A Mold In The Foundry Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. All patterns need a gating. Drag molds help create intricate and complex shapes during the casting processes. A trip through a foundry from pattern to product. This series follows a cast iron or steel product through the metal casting. Making A Mold In The Foundry.

From www.jamaicaplainnews.com

Mold Making and Metal CastingJamaica Plain News Making A Mold In The Foundry There are various types of foundry casting, each with. By using them, manufacturers can create precise and consistent parts with minimal defects. The drag mold houses all the necessary details and features of the desired. Foundry casting involves using sand molds to create the final product, also known as green sand casting or permanent mold casting. Drag molds help create. Making A Mold In The Foundry.

From www.tyrolice.com

FoundryMold Making A Mold In The Foundry Foundry casting involves using sand molds to create the final product, also known as green sand casting or permanent mold casting. They serve as the bottom half of a mold while the cope serves as the top half. This series follows a cast iron or steel product through the metal casting process in a. All patterns need a gating. By. Making A Mold In The Foundry.

From www.reliance-foundry.com

Sand Casting Metal Casting Resources Making A Mold In The Foundry They serve as the bottom half of a mold while the cope serves as the top half. The drag mold houses all the necessary details and features of the desired. This series follows a cast iron or steel product through the metal casting process in a. There are various types of foundry casting, each with. A trip through a foundry. Making A Mold In The Foundry.

From studentlesson.com

Everything you need to know about foundry process studentlesson Making A Mold In The Foundry The drag mold houses all the necessary details and features of the desired. By using them, manufacturers can create precise and consistent parts with minimal defects. This series follows a cast iron or steel product through the metal casting process in a. Drag molds help create intricate and complex shapes during the casting processes. They serve as the bottom half. Making A Mold In The Foundry.

From www.polichtallix.com

mold making polich tallix fine art foundrypolich tallix fine art Making A Mold In The Foundry A trip through a foundry from pattern to product. There are various types of foundry casting, each with. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. All patterns need a gating. The drag mold houses all the necessary details and features of the desired. They serve as. Making A Mold In The Foundry.

From frankieflood.blogspot.com

handverker readymake sand molds Making A Mold In The Foundry The drag mold houses all the necessary details and features of the desired. By using them, manufacturers can create precise and consistent parts with minimal defects. All patterns need a gating. A trip through a foundry from pattern to product. There are various types of foundry casting, each with. Foundry pattern making is the process of designing and creating a. Making A Mold In The Foundry.

From www.youtube.com

Making a green sand mold Casting 2 YouTube Making A Mold In The Foundry There are various types of foundry casting, each with. By using them, manufacturers can create precise and consistent parts with minimal defects. They serve as the bottom half of a mold while the cope serves as the top half. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to. Making A Mold In The Foundry.