Method Of Pipe Threading . Involves physically rotating the threading tool by hand, usually for smaller jobs. To facilitate the assembly and disassembly of pipes or fittings and. Pipe threading is vital for successful plumbing. Different from tapered threads which seal on the flanks of the threads,. G, npt, and pt, and discussing their. To create a seal that prevents leaks. Understand the process, explore different threading machines and learn how to thread a pipe in this thorough guide. Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. Threaded steel fittings are made by forging. Even though threaded fittings are mostly used for small bore piping connections, threaded fittings are available in up to 4” (nps 4) sizes and are sometimes used. The operator needs to apply. They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. Pipe threads are helical ridges carved onto the outer surface of a pipe or fitting, designed to create a secure connection between two components. Pipe threading involves creating ridges and valleys (known as threads) around the end of pipes for use in connections of one pipe to another. In this article, we will delve into the world of pipe threads, exploring the three main types:

from www.youtube.com

In this article, we will delve into the world of pipe threads, exploring the three main types: Understand the process, explore different threading machines and learn how to thread a pipe in this thorough guide. G, npt, and pt, and discussing their. They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. Pipe threading is vital for successful plumbing. These threads serve two primary purposes: Pipe threads are helical ridges carved onto the outer surface of a pipe or fitting, designed to create a secure connection between two components. Different from tapered threads which seal on the flanks of the threads,. Threaded steel fittings are made by forging. To create a seal that prevents leaks.

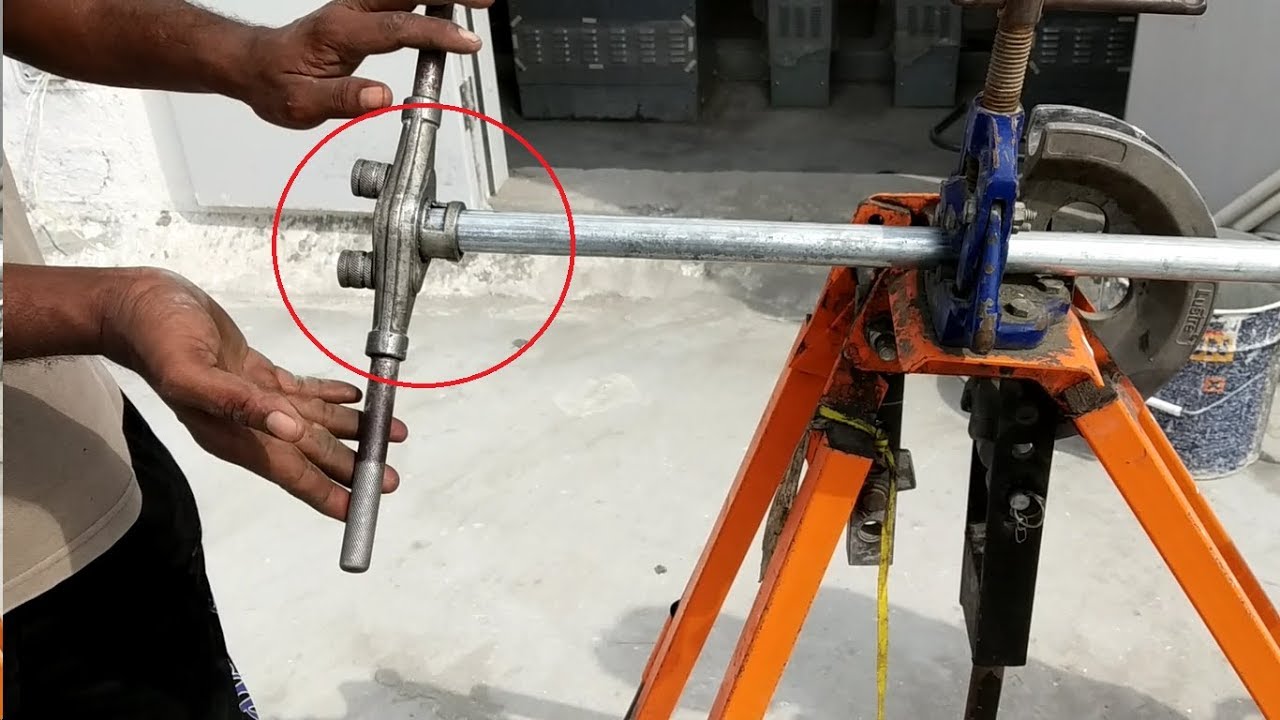

Making Threads on a GI Pipe practical work YouTube

Method Of Pipe Threading Threaded steel fittings are made by forging. These threads serve two primary purposes: G, npt, and pt, and discussing their. To facilitate the assembly and disassembly of pipes or fittings and. Understand the process, explore different threading machines and learn how to thread a pipe in this thorough guide. Even though threaded fittings are mostly used for small bore piping connections, threaded fittings are available in up to 4” (nps 4) sizes and are sometimes used. In this article, we will delve into the world of pipe threads, exploring the three main types: The operator needs to apply. To create a seal that prevents leaks. Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. Pipe threads are helical ridges carved onto the outer surface of a pipe or fitting, designed to create a secure connection between two components. They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. Pipe threading is vital for successful plumbing. Threaded steel fittings are made by forging. Different from tapered threads which seal on the flanks of the threads,. Pipe threading involves creating ridges and valleys (known as threads) around the end of pipes for use in connections of one pipe to another.

From www.willowelectric.com

Pipe Threading Services Willow Electrical Supply Method Of Pipe Threading In this article, we will delve into the world of pipe threads, exploring the three main types: The operator needs to apply. Different from tapered threads which seal on the flanks of the threads,. Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. These threads serve two primary purposes: They are available. Method Of Pipe Threading.

From www.scribd.com

Pipe Threading MachineRidgid1234 PDF PDF Switch Pipe (Fluid Method Of Pipe Threading These threads serve two primary purposes: Involves physically rotating the threading tool by hand, usually for smaller jobs. Pipe threads are helical ridges carved onto the outer surface of a pipe or fitting, designed to create a secure connection between two components. Different from tapered threads which seal on the flanks of the threads,. G, npt, and pt, and discussing. Method Of Pipe Threading.

From www.plumbingsuperstore.co.uk

The essential pipe size terminology guide Plumbing Superstore Help Method Of Pipe Threading The operator needs to apply. Pipe threads are helical ridges carved onto the outer surface of a pipe or fitting, designed to create a secure connection between two components. These threads serve two primary purposes: Pipe threading is vital for successful plumbing. Understand the process, explore different threading machines and learn how to thread a pipe in this thorough guide.. Method Of Pipe Threading.

From www.youtube.com

How to Make Threaded Pipe Connections YouTube Method Of Pipe Threading In this article, we will delve into the world of pipe threads, exploring the three main types: Understand the process, explore different threading machines and learn how to thread a pipe in this thorough guide. They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. The operator needs to apply. Even though threaded fittings are. Method Of Pipe Threading.

From www.youtube.com

How to Thread Pipe EXTREMELY FAST YouTube Method Of Pipe Threading G, npt, and pt, and discussing their. Pipe threading is vital for successful plumbing. To create a seal that prevents leaks. These threads serve two primary purposes: Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. In this article, we will delve into the world of pipe threads, exploring the three main. Method Of Pipe Threading.

From www.balkanplumbing.com

Ultimate 7 Step Pipe Threading Guide for Plumbing or Gas Work Method Of Pipe Threading Pipe threading involves creating ridges and valleys (known as threads) around the end of pipes for use in connections of one pipe to another. In this article, we will delve into the world of pipe threads, exploring the three main types: Pipe threads are helical ridges carved onto the outer surface of a pipe or fitting, designed to create a. Method Of Pipe Threading.

From www.middletoncoop.com

Pipe Cutting and Threading Middleton Farmers Cooperative Co Method Of Pipe Threading Pipe threads are helical ridges carved onto the outer surface of a pipe or fitting, designed to create a secure connection between two components. G, npt, and pt, and discussing their. The operator needs to apply. Different from tapered threads which seal on the flanks of the threads,. Understand the process, explore different threading machines and learn how to thread. Method Of Pipe Threading.

From www.pcfspn.com

The Science Behind Pipe Threads and How They Work and Why They Matter Method Of Pipe Threading Threaded steel fittings are made by forging. To facilitate the assembly and disassembly of pipes or fittings and. These threads serve two primary purposes: The operator needs to apply. G, npt, and pt, and discussing their. Involves physically rotating the threading tool by hand, usually for smaller jobs. In this article, we will delve into the world of pipe threads,. Method Of Pipe Threading.

From pipewiki.blogspot.com

National pipe thread Method Of Pipe Threading Understand the process, explore different threading machines and learn how to thread a pipe in this thorough guide. G, npt, and pt, and discussing their. They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. Involves physically rotating the threading tool by hand, usually for smaller jobs. Pipe threading involves creating ridges and valleys (known. Method Of Pipe Threading.

From www.slideserve.com

PPT Threads, Fasteners, and Springs PowerPoint Presentation, free Method Of Pipe Threading Even though threaded fittings are mostly used for small bore piping connections, threaded fittings are available in up to 4” (nps 4) sizes and are sometimes used. Involves physically rotating the threading tool by hand, usually for smaller jobs. They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. G, npt, and pt, and discussing. Method Of Pipe Threading.

From lgimonline.blogspot.com

How To Measure Thread Size Metric / Thread Id Made Easy Learn All About Method Of Pipe Threading The operator needs to apply. Pipe threads are helical ridges carved onto the outer surface of a pipe or fitting, designed to create a secure connection between two components. Pipe threading is vital for successful plumbing. To facilitate the assembly and disassembly of pipes or fittings and. To create a seal that prevents leaks. These threads serve two primary purposes:. Method Of Pipe Threading.

From www.youtube.com

Cutting and Threading Steel Conduit YouTube Method Of Pipe Threading Pipe threading involves creating ridges and valleys (known as threads) around the end of pipes for use in connections of one pipe to another. Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. Understand the process, explore. Method Of Pipe Threading.

From www.youtube.com

Pipe Threading 5" Rigid YouTube Method Of Pipe Threading G, npt, and pt, and discussing their. Understand the process, explore different threading machines and learn how to thread a pipe in this thorough guide. To create a seal that prevents leaks. Involves physically rotating the threading tool by hand, usually for smaller jobs. The operator needs to apply. These threads serve two primary purposes: Even though threaded fittings are. Method Of Pipe Threading.

From narae-aitken.blogspot.com

How To Measure Pipe Thread / How To Measure Pipe And Fitting Sizes Zoro Method Of Pipe Threading Even though threaded fittings are mostly used for small bore piping connections, threaded fittings are available in up to 4” (nps 4) sizes and are sometimes used. G, npt, and pt, and discussing their. Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. These threads serve two primary purposes: Pipe threads are. Method Of Pipe Threading.

From www.youtube.com

Making Threads on a GI Pipe practical work YouTube Method Of Pipe Threading Threaded steel fittings are made by forging. Pipe threading is vital for successful plumbing. They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. The operator needs to apply. To create a seal that prevents leaks. Understand the process, explore different threading machines and learn how to thread a pipe in this thorough guide. In. Method Of Pipe Threading.

From www.ostermfg.com

Pipe Threading Machine Oster Power Threading Handbook Method Of Pipe Threading Even though threaded fittings are mostly used for small bore piping connections, threaded fittings are available in up to 4” (nps 4) sizes and are sometimes used. Threaded steel fittings are made by forging. They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. Parallel pipe threads (also referenced as straight threads) are applied parallel. Method Of Pipe Threading.

From www.dreamstime.com

The Worker Use Pipe Threading Machinesteel in Factory Shop Stock Image Method Of Pipe Threading Pipe threads are helical ridges carved onto the outer surface of a pipe or fitting, designed to create a secure connection between two components. To create a seal that prevents leaks. Involves physically rotating the threading tool by hand, usually for smaller jobs. Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting.. Method Of Pipe Threading.

From wikihow.com

How to Thread Pipe (with Pictures) wikiHow Method Of Pipe Threading In this article, we will delve into the world of pipe threads, exploring the three main types: G, npt, and pt, and discussing their. Even though threaded fittings are mostly used for small bore piping connections, threaded fittings are available in up to 4” (nps 4) sizes and are sometimes used. They are available in various thread types like npt,. Method Of Pipe Threading.

From wikihow.com

How to Thread Pipe (with Pictures) wikiHow Method Of Pipe Threading Even though threaded fittings are mostly used for small bore piping connections, threaded fittings are available in up to 4” (nps 4) sizes and are sometimes used. G, npt, and pt, and discussing their. Different from tapered threads which seal on the flanks of the threads,. Pipe threading is vital for successful plumbing. Understand the process, explore different threading machines. Method Of Pipe Threading.

From www.youtube.com

Internal Threading A Beginners Guide YouTube Method Of Pipe Threading Even though threaded fittings are mostly used for small bore piping connections, threaded fittings are available in up to 4” (nps 4) sizes and are sometimes used. They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. Threaded. Method Of Pipe Threading.

From offtgrid.com

Master Pipe Threading Tools Stay Ahead of the Competition! Method Of Pipe Threading In this article, we will delve into the world of pipe threads, exploring the three main types: Pipe threads are helical ridges carved onto the outer surface of a pipe or fitting, designed to create a secure connection between two components. Pipe threading is vital for successful plumbing. They are available in various thread types like npt, bspp, bspt, pf,. Method Of Pipe Threading.

From www.youtube.com

How to Cut Pipe Threads HandCutting Pipe Thread Iron Wolf Method Of Pipe Threading To create a seal that prevents leaks. Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. Pipe threads are helical ridges carved onto the outer surface of a pipe or fitting, designed to create a secure connection between two components. To facilitate the assembly and disassembly of pipes or fittings and. Different. Method Of Pipe Threading.

From dengarden.com

A Complete Guide to Pipe Fittings and How to Use Them to Connect PEX Method Of Pipe Threading Pipe threading is vital for successful plumbing. To create a seal that prevents leaks. These threads serve two primary purposes: They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. Even though threaded fittings are mostly used for small bore piping connections, threaded fittings are available in up to 4” (nps 4) sizes and are. Method Of Pipe Threading.

From dengarden.com

A Complete Guide to Pipe Fittings and How to Use Them to Connect PEX Method Of Pipe Threading Pipe threads are helical ridges carved onto the outer surface of a pipe or fitting, designed to create a secure connection between two components. Pipe threading is vital for successful plumbing. Understand the process, explore different threading machines and learn how to thread a pipe in this thorough guide. These threads serve two primary purposes: Involves physically rotating the threading. Method Of Pipe Threading.

From www.slideserve.com

PPT Topics PowerPoint Presentation, free download ID345512 Method Of Pipe Threading The operator needs to apply. Pipe threading involves creating ridges and valleys (known as threads) around the end of pipes for use in connections of one pipe to another. To facilitate the assembly and disassembly of pipes or fittings and. Different from tapered threads which seal on the flanks of the threads,. G, npt, and pt, and discussing their. To. Method Of Pipe Threading.

From www.carichardson.com

How To Measure a Pipe Thread Method Of Pipe Threading Pipe threading involves creating ridges and valleys (known as threads) around the end of pipes for use in connections of one pipe to another. The operator needs to apply. Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. Pipe threading is vital for successful plumbing. Understand the process, explore different threading machines. Method Of Pipe Threading.

From www.youtube.com

Fire Fighting Pipe Threading, Grooving & machine Setting & Step by Step Method Of Pipe Threading Understand the process, explore different threading machines and learn how to thread a pipe in this thorough guide. Pipe threading is vital for successful plumbing. These threads serve two primary purposes: They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. Involves physically rotating the threading tool by hand, usually for smaller jobs. Pipe threading. Method Of Pipe Threading.

From www.sterling-group.in

Understanding Pipe Threads A Guide to Different Types of Fittings Method Of Pipe Threading Pipe threading is vital for successful plumbing. To create a seal that prevents leaks. Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. Involves physically rotating the threading tool by hand, usually for smaller jobs. Understand the process, explore different threading machines and learn how to thread a pipe in this thorough. Method Of Pipe Threading.

From blog.thepipingmart.com

5 Types of Pipe Thread and Their Uses Method Of Pipe Threading To create a seal that prevents leaks. These threads serve two primary purposes: Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. Involves physically rotating the threading tool by hand, usually for smaller jobs. Pipe threading is vital for successful plumbing. G, npt, and pt, and discussing their. Threaded steel fittings are. Method Of Pipe Threading.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Method Of Pipe Threading Different from tapered threads which seal on the flanks of the threads,. Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. Threaded steel fittings are made by forging. These threads serve two primary purposes: To facilitate the assembly and disassembly of pipes or fittings and. Pipe threading is vital for successful plumbing.. Method Of Pipe Threading.

From www.pipsisland.com

9 Simple Steps to Thread Pipe Method Of Pipe Threading To create a seal that prevents leaks. Even though threaded fittings are mostly used for small bore piping connections, threaded fittings are available in up to 4” (nps 4) sizes and are sometimes used. They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. Understand the process, explore different threading machines and learn how to. Method Of Pipe Threading.

From sunshoweronline.com.au

How to Measure BSP Threads and PVC Pipe 💧 Method Of Pipe Threading Involves physically rotating the threading tool by hand, usually for smaller jobs. In this article, we will delve into the world of pipe threads, exploring the three main types: They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. Pipe threading involves creating ridges and valleys (known as threads) around the end of pipes for. Method Of Pipe Threading.

From baileylineroad.com

THREADING STEEL PIPE Watch How We Do It In Our Shop Baileylineroad Method Of Pipe Threading Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. These threads serve two primary purposes: Pipe threading involves creating ridges and valleys (known as threads) around the end of pipes for use in connections of one pipe to another. The operator needs to apply. Pipe threads are helical ridges carved onto the. Method Of Pipe Threading.

From offtgrid.com

Master Pipe Threading Tools Stay Ahead of the Competition! Method Of Pipe Threading Parallel pipe threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. Pipe threading involves creating ridges and valleys (known as threads) around the end of pipes for use in connections of one pipe to another. Threaded steel fittings are made by forging. Different from tapered threads which seal on the flanks of the threads,.. Method Of Pipe Threading.

From www.youtube.com

How to Thread Pipe; A Beginner's Tutorial YouTube Method Of Pipe Threading They are available in various thread types like npt, bspp, bspt, pf, pt, and mpt. Pipe threading is vital for successful plumbing. Understand the process, explore different threading machines and learn how to thread a pipe in this thorough guide. Involves physically rotating the threading tool by hand, usually for smaller jobs. Threaded steel fittings are made by forging. These. Method Of Pipe Threading.