How To Fold Edges Of Sheet Metal . Understand its nature and the forces that. The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. The simplest way to achieve this is to fold the metal over on. Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. The first commandment of sheet metal folding is to wholeheartedly embrace the fold. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform. A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. Bending is one of the most common sheet metal fabrication operations. It shouldn't matter too much if your cut wanders a bit (i.e. Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. Both open hems, which provide additional.

from www.youtube.com

The first commandment of sheet metal folding is to wholeheartedly embrace the fold. Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform. Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. Both open hems, which provide additional. It shouldn't matter too much if your cut wanders a bit (i.e. The simplest way to achieve this is to fold the metal over on. Understand its nature and the forces that. Bending is one of the most common sheet metal fabrication operations.

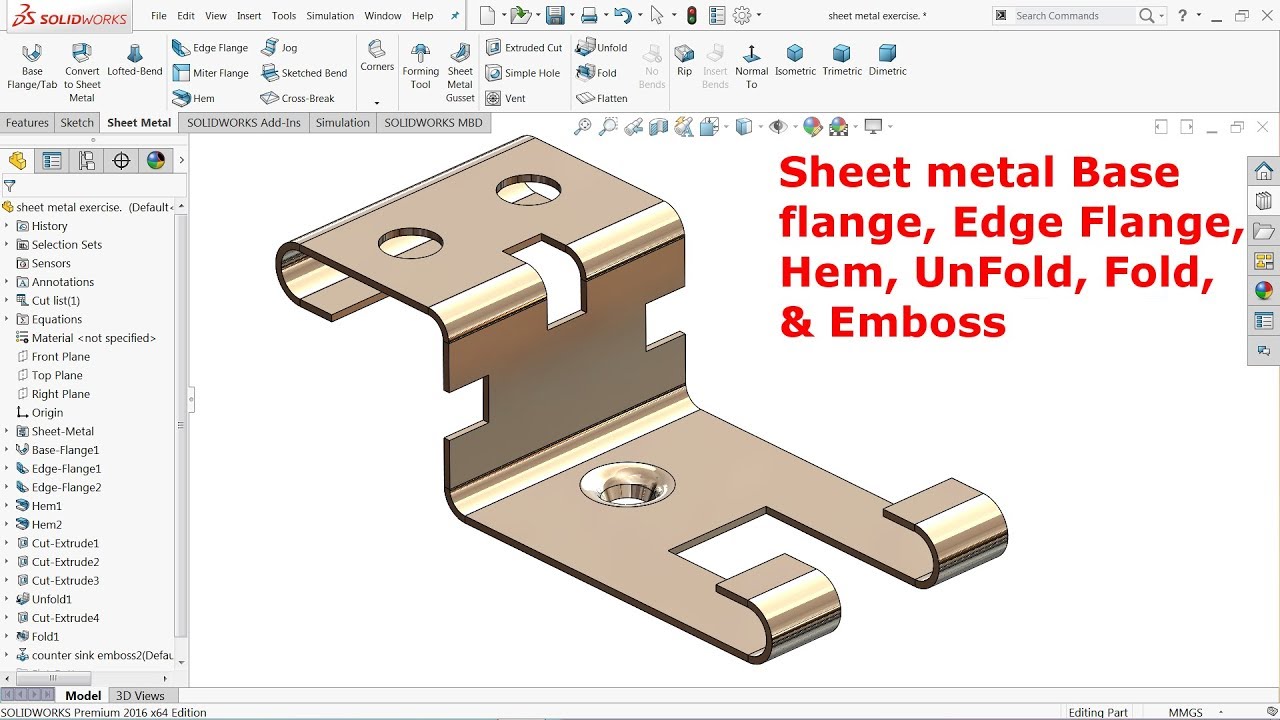

Solidworks sheet metal tutorial base flange, hem, Unfold, Fold and

How To Fold Edges Of Sheet Metal A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. The simplest way to achieve this is to fold the metal over on. The first commandment of sheet metal folding is to wholeheartedly embrace the fold. Bending is one of the most common sheet metal fabrication operations. A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. Both open hems, which provide additional. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform. Understand its nature and the forces that. It shouldn't matter too much if your cut wanders a bit (i.e. Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness.

From www.youtube.com

Solid Edge Sheet Metal Tutorials 5 Convert Solid Part to Sheet Metal How To Fold Edges Of Sheet Metal The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. Understand its nature and the forces that. It shouldn't matter too much if your cut wanders a bit. How To Fold Edges Of Sheet Metal.

From www.alfer.com

Working with sheet metal How To Fold Edges Of Sheet Metal A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform. The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'.. How To Fold Edges Of Sheet Metal.

From www.youtube.com

Solid Edge Tutorial for Beginners Sheet Metal Basic 1 YouTube How To Fold Edges Of Sheet Metal Bending is one of the most common sheet metal fabrication operations. A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. Understand its nature and the forces that. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform. The simplest way to. How To Fold Edges Of Sheet Metal.

From www.youtube.com

SolidWorks Tutorial Folding and Unfolding Sheet Metal bends by How To Fold Edges Of Sheet Metal The first commandment of sheet metal folding is to wholeheartedly embrace the fold. Understand its nature and the forces that. It shouldn't matter too much if your cut wanders a bit (i.e. A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. The simplest way to achieve this is to fold. How To Fold Edges Of Sheet Metal.

From www.youtube.com

SolidWorks Tutorial Corner Treatment Sheet Metal Tutorial YouTube How To Fold Edges Of Sheet Metal The first commandment of sheet metal folding is to wholeheartedly embrace the fold. A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform. The edges of thin sheet metals can be extremely. How To Fold Edges Of Sheet Metal.

From grabcad.com

How to fold sheet metal one by one twice. GrabCAD Tutorials How To Fold Edges Of Sheet Metal The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. Also known as press braking , flanging, die bending, folding and edging , this method is used to. How To Fold Edges Of Sheet Metal.

From ar.inspiredpencil.com

Sheet Metal Bending Techniques How To Fold Edges Of Sheet Metal A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform. Both open hems, which provide additional. It shouldn't matter too much if your cut wanders a bit (i.e. Sheet metal hemming is. How To Fold Edges Of Sheet Metal.

From www.customisedsheetmetal.com

Sheet metal folding 5 mustknow basics CSM How To Fold Edges Of Sheet Metal Also known as press braking , flanging, die bending, folding and edging , this method is used to deform. A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. Bending is. How To Fold Edges Of Sheet Metal.

From www.thelibraryofmanufacturing.com

Sheet Metal Bending How To Fold Edges Of Sheet Metal Both open hems, which provide additional. The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. The simplest way to achieve this is to fold. How To Fold Edges Of Sheet Metal.

From dsmetalworks.co.uk

Sheet Metal Folding London Lingfield Surrey DS Metalworks How To Fold Edges Of Sheet Metal It shouldn't matter too much if your cut wanders a bit (i.e. Understand its nature and the forces that. Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. A sharp utility knife will easily cut the tubing to length, then will also allow you to slit. How To Fold Edges Of Sheet Metal.

From grabcad.com

How to fold sheet metal one by one twice. GrabCAD Tutorials How To Fold Edges Of Sheet Metal It shouldn't matter too much if your cut wanders a bit (i.e. The simplest way to achieve this is to fold the metal over on. Both open hems, which provide additional. Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. Bending is one of the most. How To Fold Edges Of Sheet Metal.

From www.slideserve.com

PPT Chapter 4 Sheet Metal Forming PowerPoint Presentation, free How To Fold Edges Of Sheet Metal The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. Bending is one of the most common sheet metal fabrication operations. A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. The simplest way to achieve this is to. How To Fold Edges Of Sheet Metal.

From grabcad.com

How to fold sheet metal one by one twice. GrabCAD Questions How To Fold Edges Of Sheet Metal Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. The first commandment of sheet metal folding is to wholeheartedly embrace the fold. Understand its nature and the forces that. Bending is one of the most common sheet metal fabrication operations. The edges of thin sheet metals. How To Fold Edges Of Sheet Metal.

From www.youtube.com

How to fold and unfold pipes by using Sheet Metal in SolidWorks How To Fold Edges Of Sheet Metal Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. Both open hems, which provide additional. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform. It shouldn't matter too much if your cut wanders a bit (i.e.. How To Fold Edges Of Sheet Metal.

From dsmetalworks.co.uk

Sheet Metal Folding London Lingfield Surrey DS Metalworks How To Fold Edges Of Sheet Metal Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform. Understand its nature and the forces that. It shouldn't matter too much if your cut wanders a bit (i.e. The simplest. How To Fold Edges Of Sheet Metal.

From www.youtube.com

How to Fold Sheet Metal YouTube How To Fold Edges Of Sheet Metal The first commandment of sheet metal folding is to wholeheartedly embrace the fold. Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. The edges of thin. How To Fold Edges Of Sheet Metal.

From dsmetalworks.co.uk

Sheet Metal Folding London Lingfield Surrey DS Metalworks How To Fold Edges Of Sheet Metal Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. It shouldn't matter too much if your cut wanders a bit (i.e. The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. Bending is one. How To Fold Edges Of Sheet Metal.

From www.youtube.com

Simple Sheet Metal Box Part 2 Cutting and Folding YouTube How To Fold Edges Of Sheet Metal Also known as press braking , flanging, die bending, folding and edging , this method is used to deform. It shouldn't matter too much if your cut wanders a bit (i.e. The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. The simplest way to achieve this is. How To Fold Edges Of Sheet Metal.

From www.youtube.com

Solid Edge Sheet Metal Tutorials 3 How to use Contour Flange command How To Fold Edges Of Sheet Metal Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. Understand its nature and the forces that. A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. Sheet metal hemming is a unique technique that involves folding the edge of sheet. How To Fold Edges Of Sheet Metal.

From www.instructables.com

Folding Sheet Metal Instructables How To Fold Edges Of Sheet Metal It shouldn't matter too much if your cut wanders a bit (i.e. The first commandment of sheet metal folding is to wholeheartedly embrace the fold. The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. Bending is one of the most common sheet metal fabrication operations. A sharp. How To Fold Edges Of Sheet Metal.

From www.youtube.com

Folding sheetmetal accurately by hand YouTube How To Fold Edges Of Sheet Metal Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. The first commandment of sheet metal folding is to wholeheartedly embrace the fold. Both open hems, which provide additional. The simplest way to achieve this is to fold the metal over on. Bending is one of the most common sheet. How To Fold Edges Of Sheet Metal.

From www.hidraulika.net

Sheet metal folding How To Fold Edges Of Sheet Metal The first commandment of sheet metal folding is to wholeheartedly embrace the fold. The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. Understand its nature and the forces that. It shouldn't matter too much if your cut wanders a bit (i.e. The simplest way to achieve this. How To Fold Edges Of Sheet Metal.

From www.sculpteo.com

Mastering Metal Laser Cutting Easy Sheet Folding Techniques How To Fold Edges Of Sheet Metal A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. It shouldn't matter too much if your cut wanders a bit (i.e. Both open hems, which provide additional.. How To Fold Edges Of Sheet Metal.

From www.youtube.com

Solidworks sheet metal tutorial base flange, hem, Unfold, Fold and How To Fold Edges Of Sheet Metal Also known as press braking , flanging, die bending, folding and edging , this method is used to deform. Both open hems, which provide additional. Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. Understand its nature and the forces that. Sheet metal hemming is a unique technique that. How To Fold Edges Of Sheet Metal.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success How To Fold Edges Of Sheet Metal Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. The simplest way to achieve this is to fold the metal over on. Both open hems, which provide additional. Bending is one of the most common sheet metal fabrication operations. A sharp utility knife will easily cut. How To Fold Edges Of Sheet Metal.

From www.sculpteo.com

Mastering Metal Laser Cutting Easy Sheet Folding Techniques How To Fold Edges Of Sheet Metal It shouldn't matter too much if your cut wanders a bit (i.e. The simplest way to achieve this is to fold the metal over on. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform. The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so. How To Fold Edges Of Sheet Metal.

From grabcad.com

How to fold sheet metal one by one twice. GrabCAD Questions How To Fold Edges Of Sheet Metal Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. It shouldn't matter too much if your cut wanders a bit (i.e. Understand its nature and the forces that. Both open hems, which provide additional. The edges of thin sheet metals can be extremely sharp and dangerous,. How To Fold Edges Of Sheet Metal.

From www.youtube.com

Solid Edge Sheet Metal Basic to Advance Practice Exercise for How To Fold Edges Of Sheet Metal The first commandment of sheet metal folding is to wholeheartedly embrace the fold. Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. Bending is one of the most common sheet metal fabrication operations. The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so. How To Fold Edges Of Sheet Metal.

From www.illinoiscontractmfg.com

Sheet Metal Edge Rounding Illinois Contract Manufacturing Experts How To Fold Edges Of Sheet Metal A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. The simplest way to achieve this is to fold the metal over on. Bending is one of the most common sheet. How To Fold Edges Of Sheet Metal.

From www.kitplanes.com

Basic Edge Treatments and Deburring How To Fold Edges Of Sheet Metal Both open hems, which provide additional. A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. Understand its nature and the forces that. It shouldn't matter too much if. How To Fold Edges Of Sheet Metal.

From www.youtube.com

Solid Edge Sheet Metal Tutorials 1 Tab, MultiEdge Flange, Unbend How To Fold Edges Of Sheet Metal Both open hems, which provide additional. Understand its nature and the forces that. A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. The simplest way to achieve this is to fold the metal over on. Bending is one of the most common sheet metal fabrication operations. The edges of thin. How To Fold Edges Of Sheet Metal.

From westberg.com.au

Sheet Metal Folding Bending Sheet Metal Westberg Sheetmetal How To Fold Edges Of Sheet Metal Bending is one of the most common sheet metal fabrication operations. Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. The first commandment of sheet metal folding is to wholeheartedly embrace the fold. It shouldn't matter too much if your cut wanders a bit (i.e. Also. How To Fold Edges Of Sheet Metal.

From www.youtube.com

Fold Forming Sheet steel basic introduction for blacksmiths YouTube How To Fold Edges Of Sheet Metal It shouldn't matter too much if your cut wanders a bit (i.e. Understand its nature and the forces that. Bending is one of the most common sheet metal fabrication operations. A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. Sheet metal hemming is a unique technique that involves folding the. How To Fold Edges Of Sheet Metal.

From www.youtube.com

Solidworks Sheet Metal Corner Treatment YouTube How To Fold Edges Of Sheet Metal Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. The simplest way to achieve this is to fold the metal over on. Bending is one of the most common sheet metal fabrication operations. Both open hems, which provide additional. It shouldn't matter too much if your. How To Fold Edges Of Sheet Metal.

From wiki.dtonline.org

Wired Edge DT Online How To Fold Edges Of Sheet Metal A sharp utility knife will easily cut the tubing to length, then will also allow you to slit it. The simplest way to achieve this is to fold the metal over on. The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. Both open hems, which provide additional.. How To Fold Edges Of Sheet Metal.