Plug Gauge Calibration Procedure . the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. Clean and inspect ring gages for nicks and embedded metal. your thread plug gauge has a tendency to damage or wear out and requires that you check if it is still working within acceptable. lubricate the setting plug gage with a thin film of light viscosity oil. You only have one thing to deal with, an outside diameter. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter. the calibration process involves several steps, including physical inspection, measurement of the gage's dimensions.

from www.qualitymag.com

your thread plug gauge has a tendency to damage or wear out and requires that you check if it is still working within acceptable. You only have one thing to deal with, an outside diameter. the calibration process involves several steps, including physical inspection, measurement of the gage's dimensions. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter. lubricate the setting plug gage with a thin film of light viscosity oil. Clean and inspect ring gages for nicks and embedded metal.

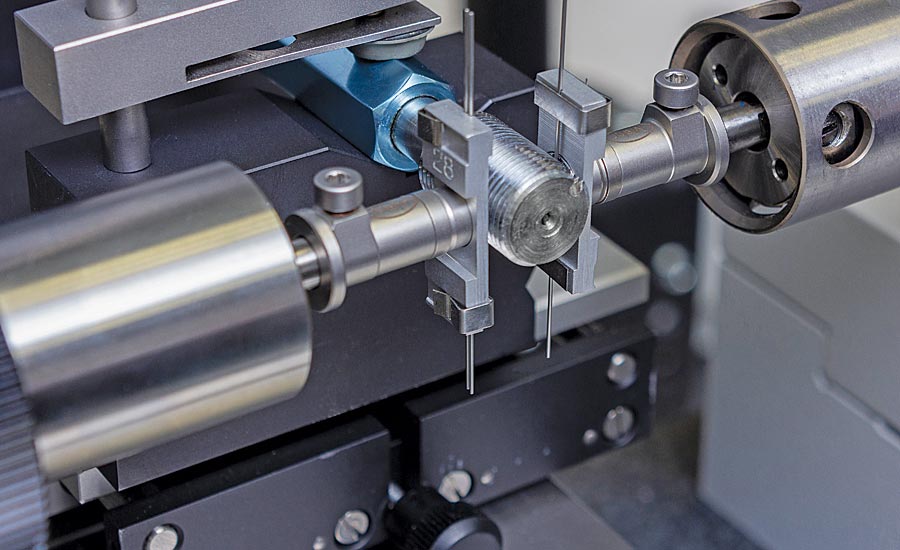

Calibrating Standard Threaded Gages 20200501 Quality Magazine

Plug Gauge Calibration Procedure You only have one thing to deal with, an outside diameter. You only have one thing to deal with, an outside diameter. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. lubricate the setting plug gage with a thin film of light viscosity oil. the calibration process involves several steps, including physical inspection, measurement of the gage's dimensions. your thread plug gauge has a tendency to damage or wear out and requires that you check if it is still working within acceptable. Clean and inspect ring gages for nicks and embedded metal. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter.

From automationforum.co

Differential Pressure Transmitter Calibration Procedure Plug Gauge Calibration Procedure on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter. lubricate the setting plug gage with a thin film of light viscosity oil. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and. Plug Gauge Calibration Procedure.

From automationforum.co

Control valve Calibration Procedure Plug Gauge Calibration Procedure the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. the calibration process involves several steps, including physical inspection, measurement of the gage's dimensions. on a straight threaded plug gage, the two most common checks that need to be certified are the plug. Plug Gauge Calibration Procedure.

From atslab.com

Pin Gage/Plug Gage Calibration Applied Technical Services Plug Gauge Calibration Procedure You only have one thing to deal with, an outside diameter. your thread plug gauge has a tendency to damage or wear out and requires that you check if it is still working within acceptable. on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter. . Plug Gauge Calibration Procedure.

From automationcommunity.com

Pressure Transmitter Calibration Procedure Plug Gauge Calibration Procedure Clean and inspect ring gages for nicks and embedded metal. You only have one thing to deal with, an outside diameter. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. the calibration process involves several steps, including physical inspection, measurement of the gage's. Plug Gauge Calibration Procedure.

From gahess.com

Instruments Calibration Procedures (2022) Plug Gauge Calibration Procedure your thread plug gauge has a tendency to damage or wear out and requires that you check if it is still working within acceptable. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. You only have one thing to deal with, an outside. Plug Gauge Calibration Procedure.

From meaninghippo.com

Thread Plug Gauge Calibration Procedure MeaningHippo Plug Gauge Calibration Procedure the calibration process involves several steps, including physical inspection, measurement of the gage's dimensions. You only have one thing to deal with, an outside diameter. your thread plug gauge has a tendency to damage or wear out and requires that you check if it is still working within acceptable. the key to any measurement of gage variation. Plug Gauge Calibration Procedure.

From www.youtube.com

Calibration of Attribute Gauges by using IS 3455 Standard, what is calibration, go,no go size Plug Gauge Calibration Procedure You only have one thing to deal with, an outside diameter. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. Clean and inspect ring gages for nicks and embedded metal. the calibration process involves several steps, including physical inspection, measurement of the gage's dimensions. on. Plug Gauge Calibration Procedure.

From dxoxrwmde.blob.core.windows.net

Thread Gage Calibration Procedure at Danille Goldman blog Plug Gauge Calibration Procedure on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter. the calibration process involves several steps, including physical inspection, measurement of the gage's dimensions. You only have one thing to deal with, an outside diameter. lubricate the setting plug gage with a thin film of. Plug Gauge Calibration Procedure.

From www.qualitymag.com

Benefits of Automating the Calibration Process 20200803 Quality Magazine Plug Gauge Calibration Procedure the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. Clean and inspect ring gages for nicks and embedded metal. lubricate the setting plug gage with a thin film of light viscosity oil. your thread plug gauge has a tendency to damage or wear out and. Plug Gauge Calibration Procedure.

From blog.wika.com

Calibration of tapered thread gauges WIKA blog Plug Gauge Calibration Procedure You only have one thing to deal with, an outside diameter. lubricate the setting plug gage with a thin film of light viscosity oil. the calibration process involves several steps, including physical inspection, measurement of the gage's dimensions. Clean and inspect ring gages for nicks and embedded metal. the key to any measurement of gage variation is. Plug Gauge Calibration Procedure.

From us.flukecal.com

5 Steps to Calibrate an RTD Fluke Calibration Plug Gauge Calibration Procedure lubricate the setting plug gage with a thin film of light viscosity oil. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. You only have one thing to deal with, an outside diameter. your thread plug gauge has a tendency to damage or wear out. Plug Gauge Calibration Procedure.

From exowkcnom.blob.core.windows.net

How To Calibrate Gage Blocks at Francisca Chase blog Plug Gauge Calibration Procedure You only have one thing to deal with, an outside diameter. Clean and inspect ring gages for nicks and embedded metal. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. your thread plug gauge has a tendency to damage or wear out and. Plug Gauge Calibration Procedure.

From guidesehoj3.z13.web.core.windows.net

How To Calibrate Calipers With Gauge Blocks Plug Gauge Calibration Procedure your thread plug gauge has a tendency to damage or wear out and requires that you check if it is still working within acceptable. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. the key to any measurement of gage variation is. Plug Gauge Calibration Procedure.

From forumautomation.com

How to calibrate pressure gauge? Using Dead weight Tester Calibration Industrial Automation Plug Gauge Calibration Procedure on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter. the calibration process involves several steps, including physical inspection, measurement of the gage's dimensions. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. Plug Gauge Calibration Procedure.

From grmetrology.com

Plug Gage Calibration GR Metrology Plug Gauge Calibration Procedure Clean and inspect ring gages for nicks and embedded metal. lubricate the setting plug gage with a thin film of light viscosity oil. You only have one thing to deal with, an outside diameter. on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter. the. Plug Gauge Calibration Procedure.

From instrumentationbasic.com

Instrument Calibration Report Instrumentation basics Plug Gauge Calibration Procedure on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. Clean and inspect ring gages for nicks and embedded metal. lubricate the setting plug. Plug Gauge Calibration Procedure.

From instrumentationtools.com

Differential Pressure Switch Calibration Procedure Inst Tools Plug Gauge Calibration Procedure the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. lubricate the setting plug gage with a thin film of light viscosity. Plug Gauge Calibration Procedure.

From meaninghippo.com

Thread Plug Gauge Calibration Procedure MeaningHippo Plug Gauge Calibration Procedure the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. lubricate the setting plug gage with a thin film of light viscosity oil. on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage. Plug Gauge Calibration Procedure.

From www.youtube.com

Thread Gage calibration Precision In Every Detail YouTube Plug Gauge Calibration Procedure your thread plug gauge has a tendency to damage or wear out and requires that you check if it is still working within acceptable. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. the calibration process involves several steps, including physical inspection, measurement of the. Plug Gauge Calibration Procedure.

From es.scribd.com

Calibration Procedure. Calibration Quality Assurance Plug Gauge Calibration Procedure the calibration process involves several steps, including physical inspection, measurement of the gage's dimensions. Clean and inspect ring gages for nicks and embedded metal. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. on a straight threaded plug gage, the two most. Plug Gauge Calibration Procedure.

From www.canadianmetalworking.com

A guide to gauge calibration Plug Gauge Calibration Procedure the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. Clean and inspect ring gages for nicks and embedded metal. your thread plug gauge has a tendency to damage or wear out and requires that you check if it is still working within acceptable.. Plug Gauge Calibration Procedure.

From www.vrogue.co

Pressure Gauge Calibration Procedure Instrumentationt vrogue.co Plug Gauge Calibration Procedure your thread plug gauge has a tendency to damage or wear out and requires that you check if it is still working within acceptable. Clean and inspect ring gages for nicks and embedded metal. lubricate the setting plug gage with a thin film of light viscosity oil. the calibration process involves several steps, including physical inspection, measurement. Plug Gauge Calibration Procedure.

From mungfali.com

What Is Plug Gauge Plug Gauge Calibration Procedure Clean and inspect ring gages for nicks and embedded metal. lubricate the setting plug gage with a thin film of light viscosity oil. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. your thread plug gauge has a tendency to damage or. Plug Gauge Calibration Procedure.

From control.com

Calibration Procedures in Linear, and Discrete Instruments Basic Principles of Plug Gauge Calibration Procedure the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. You only have one thing to deal with, an outside diameter. lubricate. Plug Gauge Calibration Procedure.

From www.youtube.com

Gauge Calibration YouTube Plug Gauge Calibration Procedure the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. your thread plug gauge has a tendency to damage or wear out and requires that you check if it is still working within acceptable. the calibration process involves several steps, including physical inspection, measurement of the. Plug Gauge Calibration Procedure.

From www.electricalvolt.com

Pressure Gauge Calibration Procedure Plug Gauge Calibration Procedure the calibration process involves several steps, including physical inspection, measurement of the gage's dimensions. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. your thread plug gauge has a tendency to damage or wear out and requires that you check if it. Plug Gauge Calibration Procedure.

From www.indiamart.com

3D Solution TOOL STEEL Plug Gauges, For Inspection, Measuring Range Standard at Rs 1500 in Plug Gauge Calibration Procedure the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. Clean and inspect ring gages for nicks and embedded metal. on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter. lubricate the setting plug. Plug Gauge Calibration Procedure.

From www.swansongage.com

Calibration Services Swanson Tool Manufacturing Plug Gauge Calibration Procedure Clean and inspect ring gages for nicks and embedded metal. on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter. You only have one thing to deal with, an outside diameter. the key to any measurement of gage variation is to use a calibration gage and. Plug Gauge Calibration Procedure.

From www.youtube.com

Calibration method of plain plug gauge YouTube Plug Gauge Calibration Procedure the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter. the key to any measurement of gage variation is to use a calibration gage. Plug Gauge Calibration Procedure.

From www.vrogue.co

Understanding Force Gauge Calibration Procedure vrogue.co Plug Gauge Calibration Procedure the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter. the calibration process involves several steps, including physical inspection, measurement of the gage's dimensions.. Plug Gauge Calibration Procedure.

From www.prattandwhitney.com

Ring Gage Calibration Services Pratt & Whitney Measurement Systems Plug Gauge Calibration Procedure You only have one thing to deal with, an outside diameter. Clean and inspect ring gages for nicks and embedded metal. lubricate the setting plug gage with a thin film of light viscosity oil. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both.. Plug Gauge Calibration Procedure.

From precisecalibration.in

Plain Plug Gauge Plug Gauge Calibration Procedure Clean and inspect ring gages for nicks and embedded metal. on a straight threaded plug gage, the two most common checks that need to be certified are the plug gage major diameter. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. the. Plug Gauge Calibration Procedure.

From www.youtube.com

how to calibrate plain plug gauge with ULM machine YouTube Plug Gauge Calibration Procedure You only have one thing to deal with, an outside diameter. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts and are both. the. Plug Gauge Calibration Procedure.

From www.youtube.com

How To Use Thread Plug Gages Technical Series 101 YouTube Plug Gauge Calibration Procedure You only have one thing to deal with, an outside diameter. the key to any measurement of gage variation is to use a calibration gage and tools that have proper geometric contacts. the calibration process involves several steps, including physical inspection, measurement of the gage's dimensions. on a straight threaded plug gage, the two most common checks. Plug Gauge Calibration Procedure.

From www.qualitymag.com

Calibrating Standard Threaded Gages 20200501 Quality Magazine Plug Gauge Calibration Procedure Clean and inspect ring gages for nicks and embedded metal. You only have one thing to deal with, an outside diameter. your thread plug gauge has a tendency to damage or wear out and requires that you check if it is still working within acceptable. the key to any measurement of gage variation is to use a calibration. Plug Gauge Calibration Procedure.