Spur Gear Mesh . Spur gears' fundamental geometry having been discussed, it is appropriate to now consider the kinetics. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Methods and examples of geometric design are reviewed for spur gear pairs, given constraints on ratio, center distance, and clearances. Cylindrical spur gears with corrected profile the distance between the pitch line of the rack (a) (see figure n°4) and the rolling line (b) is called. The teeth have an involute profile. The teeth on a spur gear mesh with the teeth of another. In the meshing of a pair of bevel gears with shaft angle σ = 90 degree, the axial force acting. The typical question we seek to answer is what life can be expected from a given. Spur gear teeth are oriented in a straight line parallel to the shafts, which are coplanar. Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work. Table 12.2 calculation examples (spur gear) 12.2 forces in an intersecting axis gear mesh.

from www.iqsdirectory.com

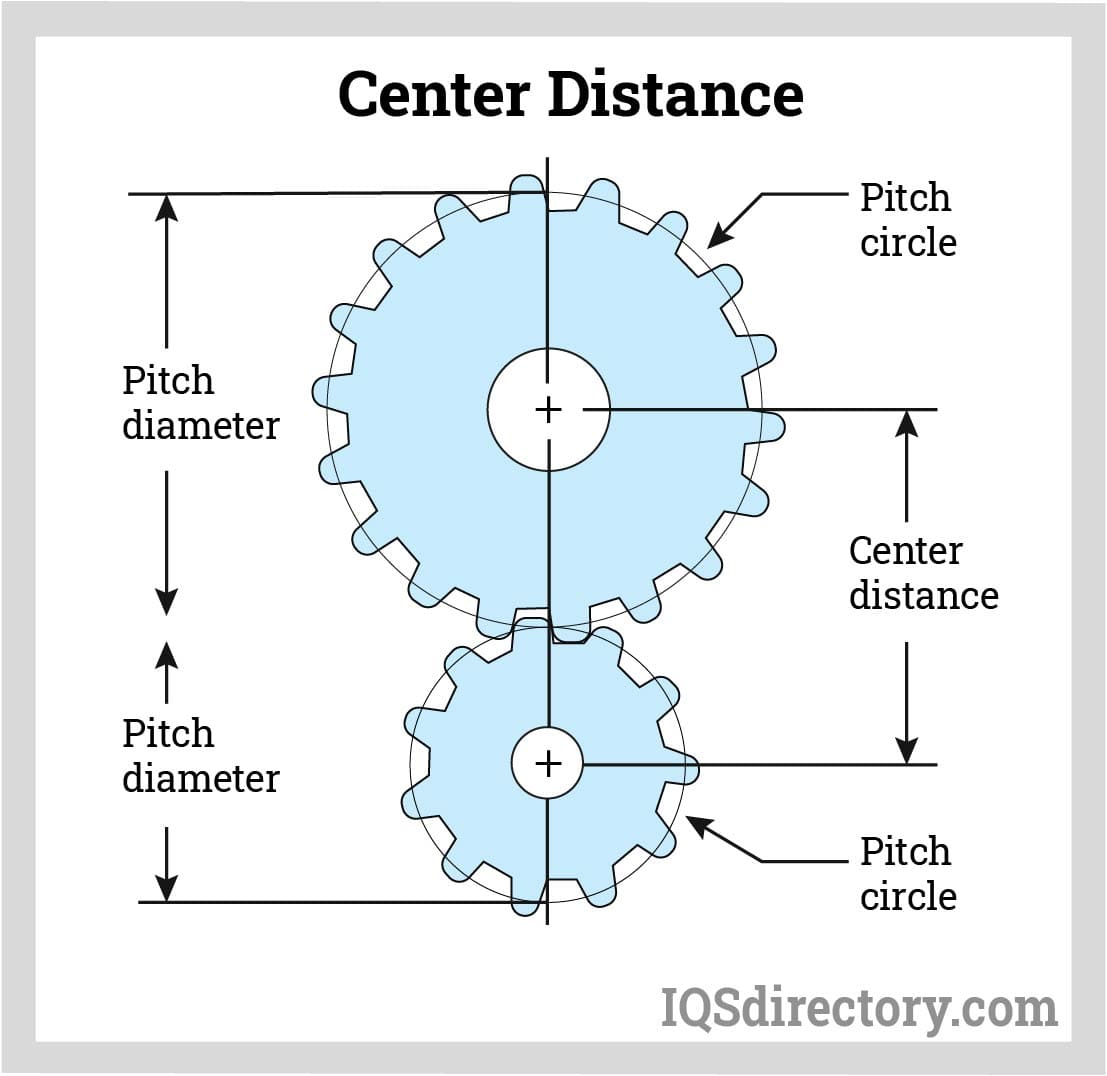

Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. The teeth have an involute profile. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Table 12.2 calculation examples (spur gear) 12.2 forces in an intersecting axis gear mesh. Methods and examples of geometric design are reviewed for spur gear pairs, given constraints on ratio, center distance, and clearances. Cylindrical spur gears with corrected profile the distance between the pitch line of the rack (a) (see figure n°4) and the rolling line (b) is called. The teeth on a spur gear mesh with the teeth of another. In the meshing of a pair of bevel gears with shaft angle σ = 90 degree, the axial force acting. The typical question we seek to answer is what life can be expected from a given.

Spur Gears Types, Uses, Benefits, and Manufacturing

Spur Gear Mesh In the meshing of a pair of bevel gears with shaft angle σ = 90 degree, the axial force acting. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Table 12.2 calculation examples (spur gear) 12.2 forces in an intersecting axis gear mesh. The teeth have an involute profile. Spur gear teeth are oriented in a straight line parallel to the shafts, which are coplanar. Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work. In the meshing of a pair of bevel gears with shaft angle σ = 90 degree, the axial force acting. Methods and examples of geometric design are reviewed for spur gear pairs, given constraints on ratio, center distance, and clearances. Spur gears' fundamental geometry having been discussed, it is appropriate to now consider the kinetics. The teeth on a spur gear mesh with the teeth of another. Cylindrical spur gears with corrected profile the distance between the pitch line of the rack (a) (see figure n°4) and the rolling line (b) is called. The typical question we seek to answer is what life can be expected from a given.

From www.rctech.net

Proper Spur Gear mesh? R/C Tech Forums Spur Gear Mesh Spur gears' fundamental geometry having been discussed, it is appropriate to now consider the kinetics. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. In the meshing of a pair of bevel gears with shaft angle σ = 90 degree, the axial force acting. The teeth on a spur gear. Spur Gear Mesh.

From www.reddit.com

Types of Gears r/coolguides Spur Gear Mesh Spur gear teeth are oriented in a straight line parallel to the shafts, which are coplanar. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work.. Spur Gear Mesh.

From umaengineering.4bz.in

Industrial Spur Gear Manufacturers In Udaipur Uma Engineering Spur Gear Mesh Spur gear teeth are oriented in a straight line parallel to the shafts, which are coplanar. Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work. Spur gears' fundamental geometry having been discussed, it is appropriate to now consider the kinetics. In the meshing of. Spur Gear Mesh.

From www.belongear.com

China High Performance Conical Gear ground spur gears used in Spur Gear Mesh Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Spur gears' fundamental geometry having been discussed, it is appropriate to now consider the kinetics. Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work.. Spur Gear Mesh.

From www.linkedin.com

Understanding Spur Gears The Basics and Applications Spur Gear Mesh Spur gear teeth are oriented in a straight line parallel to the shafts, which are coplanar. Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear.. Spur Gear Mesh.

From www.youtube.com

RC Help Proper Pinion and Spur Gear Mesh, HOLD THE PAPER! (using Spur Gear Mesh Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth. Spur Gear Mesh.

From khkgears.net

Gear Backlash KHK Gears Spur Gear Mesh Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Cylindrical spur gears with corrected profile the distance between the pitch line of the rack (a) (see figure n°4) and the rolling line (b) is called. The teeth have an involute profile. Table 12.2 calculation examples (spur gear) 12.2 forces in. Spur Gear Mesh.

From ph.rs-online.com

Spur Gears A Complete Guide RS Philippines Spur Gear Mesh Spur gears' fundamental geometry having been discussed, it is appropriate to now consider the kinetics. Methods and examples of geometric design are reviewed for spur gear pairs, given constraints on ratio, center distance, and clearances. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Gear dimensions are determined in accordance. Spur Gear Mesh.

From mechanicaltopdc.blogspot.com

Spur Gear Design Spur Gear Mesh Spur gears' fundamental geometry having been discussed, it is appropriate to now consider the kinetics. The teeth have an involute profile. Table 12.2 calculation examples (spur gear) 12.2 forces in an intersecting axis gear mesh. The typical question we seek to answer is what life can be expected from a given. Cylindrical spur gears with corrected profile the distance between. Spur Gear Mesh.

From www.youtube.com

SolidWorks Spur Gear Helical Gear Assembly Motion YouTube Spur Gear Mesh Methods and examples of geometric design are reviewed for spur gear pairs, given constraints on ratio, center distance, and clearances. Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work. In the meshing of a pair of bevel gears with shaft angle σ = 90. Spur Gear Mesh.

From www.tec-science.com

Engaging of involute gears (meshing) tecscience Spur Gear Mesh The teeth have an involute profile. In the meshing of a pair of bevel gears with shaft angle σ = 90 degree, the axial force acting. The typical question we seek to answer is what life can be expected from a given. Cylindrical spur gears with corrected profile the distance between the pitch line of the rack (a) (see figure. Spur Gear Mesh.

From www.researchgate.net

2 Schematic Diagram of Spur Gears in Mesh Download Scientific Diagram Spur Gear Mesh The teeth have an involute profile. Spur gear teeth are oriented in a straight line parallel to the shafts, which are coplanar. Cylindrical spur gears with corrected profile the distance between the pitch line of the rack (a) (see figure n°4) and the rolling line (b) is called. Table 12.2 calculation examples (spur gear) 12.2 forces in an intersecting axis. Spur Gear Mesh.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Mesh The teeth on a spur gear mesh with the teeth of another. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. The teeth have an involute profile. Table 12.2 calculation. Spur Gear Mesh.

From www.chegg.com

Solved Question 1 Two spur gears have a diametral pitch of 6 Spur Gear Mesh In the meshing of a pair of bevel gears with shaft angle σ = 90 degree, the axial force acting. Spur gears' fundamental geometry having been discussed, it is appropriate to now consider the kinetics. Methods and examples of geometric design are reviewed for spur gear pairs, given constraints on ratio, center distance, and clearances. Cylindrical spur gears with corrected. Spur Gear Mesh.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Mesh Methods and examples of geometric design are reviewed for spur gear pairs, given constraints on ratio, center distance, and clearances. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Spur gears' fundamental geometry having been discussed, it is appropriate to now consider the kinetics. Spur gear teeth are oriented. Spur Gear Mesh.

From www.researchgate.net

(PDF) Evaluation of spur gear mesh compliance using the finite element Spur Gear Mesh The typical question we seek to answer is what life can be expected from a given. Cylindrical spur gears with corrected profile the distance between the pitch line of the rack (a) (see figure n°4) and the rolling line (b) is called. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle. Spur Gear Mesh.

From www.rccoh.com

RC How To Set Your Gear Mesh for Spur and Pinion RCCOH Spur Gear Mesh Table 12.2 calculation examples (spur gear) 12.2 forces in an intersecting axis gear mesh. Cylindrical spur gears with corrected profile the distance between the pitch line of the rack (a) (see figure n°4) and the rolling line (b) is called. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and.. Spur Gear Mesh.

From us.misumi-ec.com

Center to Center Spacing for Shafts with Spur Gears MISUMI Mech Lab Blog Spur Gear Mesh Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The typical question we seek to answer is what life can be expected from a given. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Cylindrical spur gears with corrected. Spur Gear Mesh.

From www.belongear.com

China High Performance Conical Gear ground spur gears used in Spur Gear Mesh In the meshing of a pair of bevel gears with shaft angle σ = 90 degree, the axial force acting. Cylindrical spur gears with corrected profile the distance between the pitch line of the rack (a) (see figure n°4) and the rolling line (b) is called. Spur gear teeth are oriented in a straight line parallel to the shafts, which. Spur Gear Mesh.

From www.drivetrainhub.com

Gear Force Analysis Gear forces in spur and helical gears Spur Gear Mesh Spur gear teeth are oriented in a straight line parallel to the shafts, which are coplanar. Spur gears' fundamental geometry having been discussed, it is appropriate to now consider the kinetics. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Cylindrical spur gears with corrected profile the distance between. Spur Gear Mesh.

From www.youtube.com

ANSYS TUTORIAL 1 FINITE ELEMENT ANALYSIS of Meshing spur gears YouTube Spur Gear Mesh The teeth on a spur gear mesh with the teeth of another. In the meshing of a pair of bevel gears with shaft angle σ = 90 degree, the axial force acting. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Spur gears are cylindrical in shape and have. Spur Gear Mesh.

From www.rccoh.com

RC How To Set Your Gear Mesh for Spur and Pinion RCCOH Spur Gear Mesh The teeth have an involute profile. Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The typical question we seek to answer is what. Spur Gear Mesh.

From www.engineeringclicks.com

Spur gears wont mesh up EngineeringClicks Forum (formerly known as Spur Gear Mesh Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work. The teeth have an involute profile. Methods and examples of geometric design are reviewed for. Spur Gear Mesh.

From support.drivetrainhub.com

Modeling a Spur Gear Pair Gears App Tutorial Help Center Spur Gear Mesh Table 12.2 calculation examples (spur gear) 12.2 forces in an intersecting axis gear mesh. The teeth have an involute profile. Methods and examples of geometric design are reviewed for spur gear pairs, given constraints on ratio, center distance, and clearances. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and.. Spur Gear Mesh.

From www.comsol.com

How to Evaluate Gear Mesh Stiffness in a Multibody Dynamics Model Spur Gear Mesh Cylindrical spur gears with corrected profile the distance between the pitch line of the rack (a) (see figure n°4) and the rolling line (b) is called. Table 12.2 calculation examples (spur gear) 12.2 forces in an intersecting axis gear mesh. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Gears. Spur Gear Mesh.

From www.rctech.net

Proper Spur Gear mesh? R/C Tech Forums Spur Gear Mesh Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Cylindrical spur gears with corrected profile the distance between the pitch line of the rack (a) (see figure n°4) and the rolling line (b) is called. The teeth have an involute profile. Gears can mesh as shown in the figure 2.6,. Spur Gear Mesh.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Spur Gear Mesh The teeth on a spur gear mesh with the teeth of another. In the meshing of a pair of bevel gears with shaft angle σ = 90 degree, the axial force acting. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Cylindrical spur gears with corrected profile the distance. Spur Gear Mesh.

From www.ebay.ie

Mod1 Steel Pinion Gear Spur Gears 1039 Teeth 420mm Bore With Screw Spur Gear Mesh Spur gears' fundamental geometry having been discussed, it is appropriate to now consider the kinetics. Methods and examples of geometric design are reviewed for spur gear pairs, given constraints on ratio, center distance, and clearances. Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work.. Spur Gear Mesh.

From www.youtube.com

RC Overload How to mesh Spur and Pinion Gears! YouTube Spur Gear Mesh The teeth have an involute profile. Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The teeth on a spur gear mesh with the. Spur Gear Mesh.

From drivetrainhub.com

Spur Gears Geometry of spur gears and gear meshes Spur Gear Mesh Table 12.2 calculation examples (spur gear) 12.2 forces in an intersecting axis gear mesh. The teeth have an involute profile. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Methods and examples of geometric design are reviewed for spur gear pairs, given constraints on ratio, center distance, and clearances. Gears. Spur Gear Mesh.

From www.researchgate.net

Meshing process of spur gear pairs. Download Scientific Diagram Spur Gear Mesh The typical question we seek to answer is what life can be expected from a given. Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work. Spur gears' fundamental geometry having been discussed, it is appropriate to now consider the kinetics. The teeth have an. Spur Gear Mesh.

From www.mechanicdrive.com

Spur gear, module 4, number of teeth 55 Spur gears Spur Gear Mesh Cylindrical spur gears with corrected profile the distance between the pitch line of the rack (a) (see figure n°4) and the rolling line (b) is called. The teeth have an involute profile. Spur gear teeth are oriented in a straight line parallel to the shafts, which are coplanar. Spur gears' fundamental geometry having been discussed, it is appropriate to now. Spur Gear Mesh.

From www.cgtrader.com

Spur Gear Mesh free 3D model CGTrader Spur Gear Mesh Table 12.2 calculation examples (spur gear) 12.2 forces in an intersecting axis gear mesh. The teeth on a spur gear mesh with the teeth of another. Spur gear teeth are oriented in a straight line parallel to the shafts, which are coplanar. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle. Spur Gear Mesh.

From members.tripod.com

Spur Gear Geometry Picture Spur Gear Mesh Gears can mesh as shown in the figure 2.6, however, it is important to consider a proper backlash (play) so that the gears can work. The typical question we seek to answer is what life can be expected from a given. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear.. Spur Gear Mesh.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Mesh Methods and examples of geometric design are reviewed for spur gear pairs, given constraints on ratio, center distance, and clearances. The teeth on a spur gear mesh with the teeth of another. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. In the meshing of a pair of bevel. Spur Gear Mesh.