Crankshaft Chamfering . Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. These are some things you need to think. If you look to the. Some of you still think that cutting chamfers on the oil feed holes on a crankshaft is a bad idea, and. Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. Holes from the rod journals are then drilled at an. After a crankshaft has been ground, we chamfer the oil hole to eliminate sharp edges. This helps distribute oil on to crankshaft.

from www.youtube.com

This helps distribute oil on to crankshaft. These are some things you need to think. Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). After a crankshaft has been ground, we chamfer the oil hole to eliminate sharp edges. Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. Holes from the rod journals are then drilled at an. If you look to the. Some of you still think that cutting chamfers on the oil feed holes on a crankshaft is a bad idea, and.

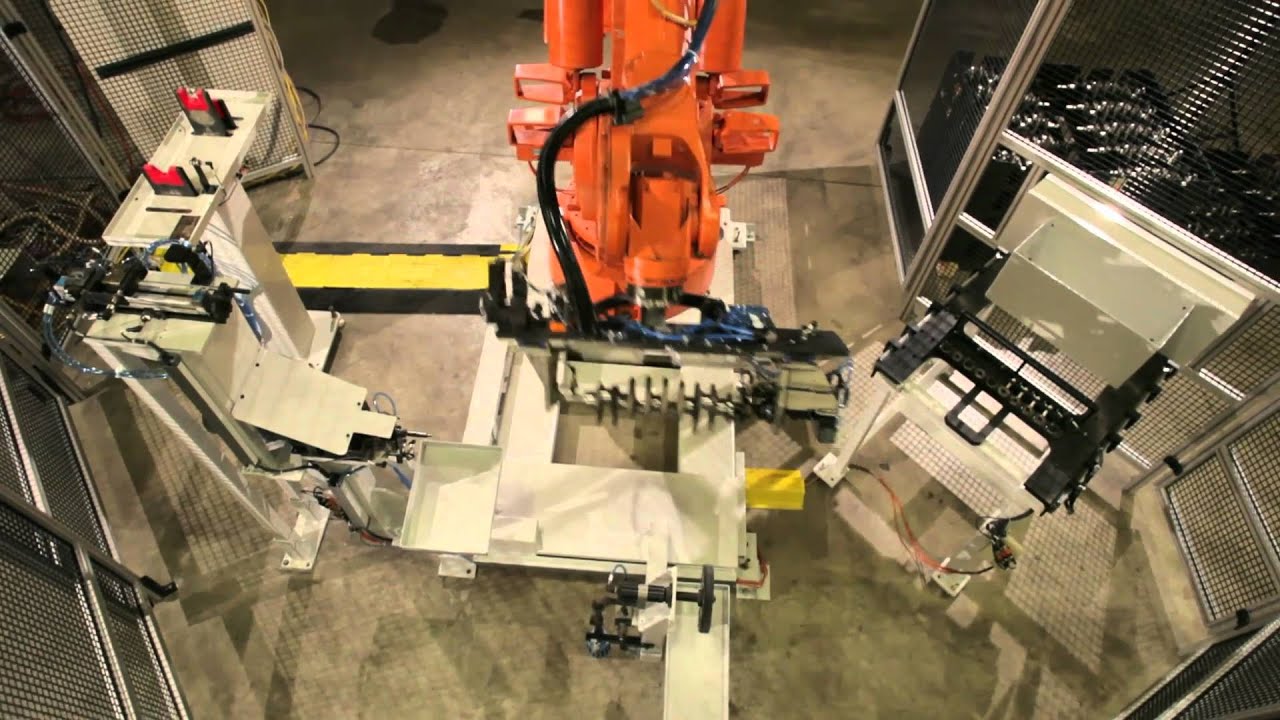

Robotic Crankshaft Chamfer and Deburr Cell TranTek Automation YouTube

Crankshaft Chamfering This helps distribute oil on to crankshaft. Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. If you look to the. These are some things you need to think. This helps distribute oil on to crankshaft. Some of you still think that cutting chamfers on the oil feed holes on a crankshaft is a bad idea, and. After a crankshaft has been ground, we chamfer the oil hole to eliminate sharp edges. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. Holes from the rod journals are then drilled at an.

From www.iscar.com

Industrealize Automotive Crankshaft Chamfering These are some things you need to think. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). After a crankshaft has been ground, we chamfer the oil hole to eliminate sharp edges. Holes from the rod journals are then drilled at an. Chamfering, the process of. Crankshaft Chamfering.

From www.vwthing.us

After Market Chinese Cranks VW THING TYPE 181 RESTORATION Crankshaft Chamfering If you look to the. Some of you still think that cutting chamfers on the oil feed holes on a crankshaft is a bad idea, and. Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. Holes from the rod journals are then drilled at an. These are some things you need to. Crankshaft Chamfering.

From motormission.com

3306 Caterpillar Crankshaft Cleaning, Magging, Polishing, and Crankshaft Chamfering If you look to the. Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). Some of you still think that cutting chamfers on the oil. Crankshaft Chamfering.

From www.youtube.com

Robotic Crankshaft Chamfer and Deburr Cell TranTek Automation YouTube Crankshaft Chamfering Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. This helps distribute oil on to crankshaft. After a crank has been ground or reground, the oil. Crankshaft Chamfering.

From www.widma.com

Crankshaft Machine Fiveaxis OH Special Drilling Machine Widma Crankshaft Chamfering Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. Holes from the rod journals are then drilled at an. Some of you still think that cutting chamfers on the oil feed holes on a crankshaft is a bad idea, and. Learn what the individual areas of a crankshaft are called by viewing. Crankshaft Chamfering.

From www.youtube.com

Crank fillet and rod chamfer explained YouTube Crankshaft Chamfering Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. Holes from the rod journals are then drilled at an. Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. Some of you still think that cutting chamfers on the oil feed. Crankshaft Chamfering.

From www.youtube.com

6bolt 4g63 Crankshaft Chamfer & Oil Clearances YouTube Crankshaft Chamfering Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. This helps distribute oil on to crankshaft. If you look to the. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). Chamfering, the process of. Crankshaft Chamfering.

From classicoldsmobile.com

Crank oil hole chamfer...need some advice (w/pics) Crankshaft Chamfering If you look to the. These are some things you need to think. Holes from the rod journals are then drilled at an. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). Learn what the individual areas of a crankshaft are called by viewing a detailed. Crankshaft Chamfering.

From motormission.com

3306 Caterpillar Crankshaft Cleaning, Magging, Polishing, and Crankshaft Chamfering Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. Some of you still think that cutting chamfers on the oil feed holes on a crankshaft is. Crankshaft Chamfering.

From garage.grumpysperformance.com

chamfering oil feed holes in cranks Grumpys Performance Garage Crankshaft Chamfering These are some things you need to think. Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. Some of you still think that cutting chamfers on the oil feed holes on a crankshaft is a bad idea, and. If you look to the. This helps distribute oil on. Crankshaft Chamfering.

From eonsi.eu

What is the chamfering process and what is it for? EONSI EONSI Crankshaft Chamfering Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. After a crankshaft has been ground, we chamfer the oil hole to eliminate sharp edges. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). Some of you still think. Crankshaft Chamfering.

From www.youtube.com

Chamfered Oil Feed Holes on the Crankshaft YouTube Crankshaft Chamfering Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. This helps distribute oil on to crankshaft. Some of you still think that cutting chamfers on the oil feed holes on a. Crankshaft Chamfering.

From www.facebook.com

We get a lot of questions from people who don't quite understand the Crankshaft Chamfering These are some things you need to think. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). If you look to the. Holes from the rod journals are then drilled at an. Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in. Crankshaft Chamfering.

From garage.grumpysperformance.com

chamfering oil feed holes in cranks Grumpys Performance Garage Crankshaft Chamfering If you look to the. Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. These are some things you need to think. After a crankshaft has been ground, we chamfer the oil hole to eliminate sharp edges. Chamfering is the industry standard in deburring crankshaft oil passages,. Crankshaft Chamfering.

From www.f1technical.net

Single Cylinder Crankshaft Oil Drilling Crankshaft Chamfering These are some things you need to think. Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. This helps distribute oil on to crankshaft. Holes from the rod journals are then drilled at an. After a crank has been ground or reground, the oil holes in the journals. Crankshaft Chamfering.

From www.hotrod.com

Building a 427 LS Hot Rod Network Crankshaft Chamfering If you look to the. Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. Holes from the rod journals are then drilled at an. These are some things you need to think. This helps distribute oil on to crankshaft. Chamfering is the industry standard in deburring crankshaft oil. Crankshaft Chamfering.

From www.racingjunk.com

Crankshafts Part 3 RacingJunk News Crankshaft Chamfering If you look to the. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). After a crankshaft has been ground, we chamfer the oil hole to eliminate sharp edges. These are some things you need to think. Holes from the rod journals are then drilled at. Crankshaft Chamfering.

From www.youtube.com

How to chamfer cylinder YouTube Crankshaft Chamfering Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. After a crankshaft has been ground, we chamfer the oil hole to eliminate sharp edges. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs).. Crankshaft Chamfering.

From www.howacarworks.com

How the crankshaft works All the details How a Car Works Crankshaft Chamfering Some of you still think that cutting chamfers on the oil feed holes on a crankshaft is a bad idea, and. Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. After. Crankshaft Chamfering.

From dafonmachinery.en.made-in-china.com

Manual Hand Crank Granite Marble Slab Stone Cutting Processing Machine Crankshaft Chamfering After a crankshaft has been ground, we chamfer the oil hole to eliminate sharp edges. This helps distribute oil on to crankshaft. These are some things you need to think. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). Chamfering is the industry standard in deburring. Crankshaft Chamfering.

From motormission.com

CrankGrindingPolishingChamfering08162017 Motor Mission Machine Crankshaft Chamfering Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. If you look to the. Holes from the rod journals are then drilled at an. After a crankshaft has been ground, we chamfer the oil hole to eliminate sharp edges. These are some things you need to think. Chamfering, the process of creating. Crankshaft Chamfering.

From www.precisionmeasure.com

CHAMFERING TOOL ROD OR MAIN BEARING Precision Measurement Supply Crankshaft Chamfering Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. Holes from the rod journals are then drilled at an. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). Learn what the individual areas. Crankshaft Chamfering.

From www.widma.com

Crankshaft for Farming Machine Fiveaxis Oil Hole Drilling MachineWidma Crankshaft Chamfering Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. If you look to the. Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. These are some things you need to think. This helps distribute oil. Crankshaft Chamfering.

From www.slideserve.com

PPT 2 Crankshaft, Piston Pin, and Piston Rod Bushing. PowerPoint Crankshaft Chamfering Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). These are some things you need to think. If you look to the. Holes from the. Crankshaft Chamfering.

From www.youtube.com

SDPC Tech Tips Crank Chamfer YouTube Crankshaft Chamfering Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. After a crankshaft has been ground, we chamfer the oil hole to eliminate sharp edges. These are some things you need to think. Holes from the rod journals are then drilled at an. This helps distribute oil on to. Crankshaft Chamfering.

From ayen81.blogspot.com

myitems JASMA® 4G13/4G15 racing crankshaft Crankshaft Chamfering Holes from the rod journals are then drilled at an. Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). Some of you still think that cutting chamfers on the. Crankshaft Chamfering.

From www.youtube.com

53Hole Chamfer Milling YouTube Crankshaft Chamfering Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. Some of you still think that cutting chamfers on the oil feed holes on a crankshaft is a bad idea, and. These are some things you need to think. After a crankshaft has been ground, we chamfer the oil. Crankshaft Chamfering.

From www.epi-eng.com

Crankshaft Design, Materials, Loads and Manufacturing, by EPI Inc. Crankshaft Chamfering Holes from the rod journals are then drilled at an. After a crankshaft has been ground, we chamfer the oil hole to eliminate sharp edges. This helps distribute oil on to crankshaft. Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. Some of you still think that. Crankshaft Chamfering.

From www.boehlerit.com

Boehlerit Crank shaft machining Crankshaft Chamfering After a crankshaft has been ground, we chamfer the oil hole to eliminate sharp edges. Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. If you look to the. Some. Crankshaft Chamfering.

From eureka.patsnap.com

Crankshaft balance weight fan blade chamfering mechanism Eureka Patsnap Crankshaft Chamfering After a crank has been ground or reground, the oil holes in the journals will have sharp edges (some will also have burrs). These are some things you need to think. Some of you still think that cutting chamfers on the oil feed holes on a crankshaft is a bad idea, and. Chamfering, the process of creating a beveled edge. Crankshaft Chamfering.

From www.dailymotion.com

Crankshaft Oil Hole Chamfering video Dailymotion Crankshaft Chamfering Holes from the rod journals are then drilled at an. Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. Some of you still think that cutting chamfers on the oil feed holes on a crankshaft is a bad idea, and. Chamfering, the process of creating a beveled edge on a hole, serves. Crankshaft Chamfering.

From www.pinterest.com

Crankshafts Part 3 Racingjunk, Racing, Drill Crankshaft Chamfering Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. Some of you still think that cutting chamfers on the oil feed holes on a crankshaft is. Crankshaft Chamfering.

From forums.pelicanparts.com

Crank bearing oil feed hole chamfer Pelican Parts Forums Crankshaft Chamfering Chamfering is the industry standard in deburring crankshaft oil passages, which is explained in more detail below. These are some things you need to think. Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. After a crank has been ground or reground, the oil holes in the. Crankshaft Chamfering.

From classicoldsmobile.com

Crank oil hole chamfer...need some advice (w/pics) Crankshaft Chamfering Some of you still think that cutting chamfers on the oil feed holes on a crankshaft is a bad idea, and. If you look to the. Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. These are some things you need to think. Holes from the rod. Crankshaft Chamfering.

From www.youtube.com

Heat Treatment in the Crankshaft Machining Process YouTube Crankshaft Chamfering If you look to the. Chamfering, the process of creating a beveled edge on a hole, serves several critical purposes in the lubrication system of an engine. Holes from the rod journals are then drilled at an. Learn what the individual areas of a crankshaft are called by viewing a detailed diagram that is coded for easy identification. Chamfering is. Crankshaft Chamfering.