Acid Dip Titanium . A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle.

from www.mdpi.com

With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. Surface treatments are applied to titanium for a variety of reasons such as prevention of galling.

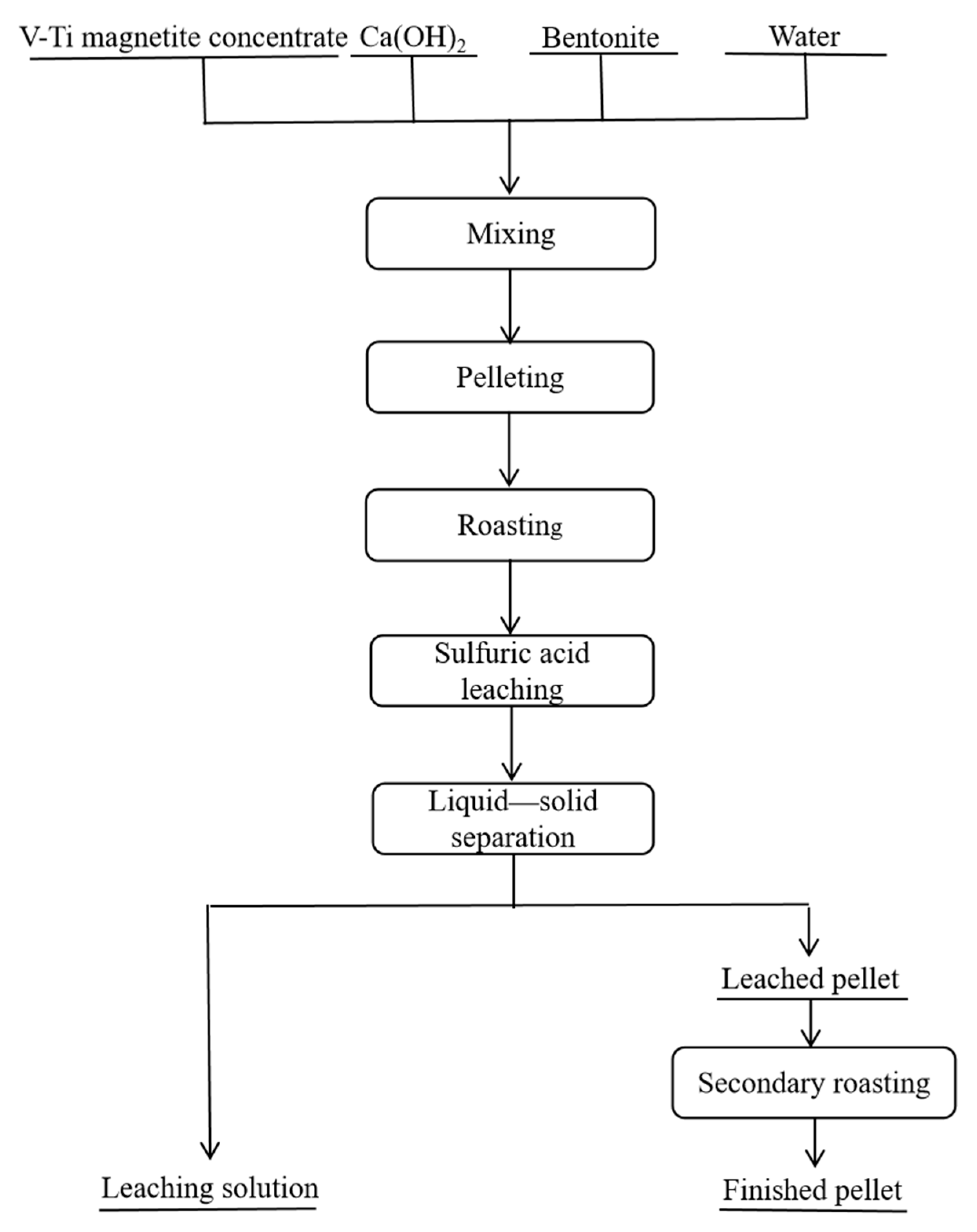

Minerals Free FullText Study on the Properties of Vanadium Pellets

Acid Dip Titanium Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. Surface treatments are applied to titanium for a variety of reasons such as prevention of galling.

From www.dipcanada.com

RawTitaniumDipPearlDYCDipYourCarSatinPlastiDipAerosolSpray Acid Dip Titanium With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. Acid pickling process of. Acid Dip Titanium.

From www.mdpi.com

Gels Free FullText Efficient Tuning of the OptoElectronic Acid Dip Titanium Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. Rectifying smut formation when processing aluminum calls for. Acid Dip Titanium.

From www.carpgear.be

Dream Baits Acid Dip Carp Gear Acid Dip Titanium With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. Surface treatments are applied to titanium for a variety of. Acid Dip Titanium.

From pubs.acs.org

Dip Coating Passivation of Crystalline Silicon by Lewis Acids ACS Nano Acid Dip Titanium Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. Acid pickling process of titanium alloys and its investigation. Acid Dip Titanium.

From www.riogrande.com

Midas Acid Dip Solution Mix AcidBased RioGrande Acid Dip Titanium With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. A combination. Acid Dip Titanium.

From www.neonail.pl

Titanium Dip Powder NN EXPERT 20 g Pure Black • NEONAIL Store Acid Dip Titanium Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. Acid pickling process of. Acid Dip Titanium.

From www.ngl-group.com

Passivation of austenitic and martensitic stainless steels NGL Acid Dip Titanium Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. A combination of acids is frequently used to. Acid Dip Titanium.

From www.dycasia.com.sg

DYC Asia Licensed Distributor for DipYourCar® & Plasti Dip® Products Acid Dip Titanium A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. With the growing demands for bone implant therapy, titanium. Acid Dip Titanium.

From www.youtube.com

Boric Acid Dip as a Jewelry Soldering Protective Covering YouTube Acid Dip Titanium With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. Surface treatments are. Acid Dip Titanium.

From www.mdpi.com

Metals Free FullText Martensite Formation and during Acid Dip Titanium Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. With the. Acid Dip Titanium.

From www.researchgate.net

AsB images of the Ti6Al4V alloy with starting martensitic Acid Dip Titanium A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. With the growing demands for bone implant therapy, titanium (ti). Acid Dip Titanium.

From www.iqsdirectory.com

Acid Etching Acid Types, Metal Types, Applications, and Benefits Acid Dip Titanium Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. A combination of acids is frequently used to. Acid Dip Titanium.

From www.scribd.com

Bright Dipping Aluminum PDF Nitric Acid Aluminium Acid Dip Titanium With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. Acid pickling process of titanium alloys and its investigation. Acid Dip Titanium.

From www.mdpi.com

Coatings Free FullText Surface Modified Techniques and Emerging Acid Dip Titanium A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. Acid pickling process of. Acid Dip Titanium.

From www.riogrande.com

Midas Bright Acid Copper Plating Solution, AcidBased Acid Dip Titanium A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. Acid pickling process of. Acid Dip Titanium.

From www.researchgate.net

Formation of acicular martensite at Ti FZ Download Scientific Diagram Acid Dip Titanium With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. Surface treatments are. Acid Dip Titanium.

From www.mdpi.com

Minerals Free FullText Study on the Properties of Vanadium Pellets Acid Dip Titanium A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. With the growing demands for bone implant therapy, titanium. Acid Dip Titanium.

From metaldipping.com

Acid Dipping Metal Dipping Acid Dip Titanium Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices. Acid Dip Titanium.

From www.diamondalloys.co.uk

Acid Dip Alloy Wheels Removes Corrosion Diamond Alloys Acid Dip Titanium Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. A synergy of 6.0. Acid Dip Titanium.

From www.purplewave.com

(2) acid dip tanks in Mount Hope, KS Item J7855 sold Purple Wave Acid Dip Titanium A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. Rectifying smut formation. Acid Dip Titanium.

From www.dipyourcarcanada.com

Raw Titanium Aerosol dipyourcarcanada Acid Dip Titanium With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping. Acid Dip Titanium.

From informacionpublica.svet.gob.gt

Mini Body Before And After Acid Dipping Acid Dip Titanium Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. A combination. Acid Dip Titanium.

From www.researchgate.net

TEM images of the twinning structure in martensite plates (a Acid Dip Titanium Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. Rectifying smut formation when processing aluminum calls for the. Acid Dip Titanium.

From metaldipping.com

Acid Tank Metal Dipping Acid Dip Titanium With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. Surface treatments are applied. Acid Dip Titanium.

From www.researchgate.net

Martensitic microstructure of Spanish cast highchromium white irons Acid Dip Titanium A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. Surface treatments are applied to titanium for a variety of. Acid Dip Titanium.

From www.purplewave.com

(2) acid dip tanks in Mount Hope, KS Item J7855 sold Purple Wave Acid Dip Titanium Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. A combination of acids is frequently used to. Acid Dip Titanium.

From www.mdpi.com

Applied Sciences Free FullText Development of a Surface Acid Dip Titanium Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility. Acid Dip Titanium.

From www.scribd.com

Preparation and Characterization of Peroxo Titanic Acid Solution Using Acid Dip Titanium Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. A synergy of. Acid Dip Titanium.

From metaldipping.com

Metal Dipping Classic Car Acid Dipping to remove paint & rust Acid Dip Titanium Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. Surface treatments are applied to titanium for a variety of. Acid Dip Titanium.

From www.mdpi.com

Applied Sciences Free FullText Titanium Dioxide in Chromogenic Acid Dip Titanium Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility. Acid Dip Titanium.

From www.lelworld.com

Kojic Acid Dipalmitate L'eternel World, LLC Acid Dip Titanium With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. Rectifying smut formation when. Acid Dip Titanium.

From phys.org

Polymer membranes could benefit from taking a dip Acid Dip Titanium Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. Surface treatments are applied to titanium for a variety of reasons such as prevention of galling. A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. A synergy of 6.0 wt% aluminum and 0.3 wt%. Acid Dip Titanium.

From www.alexmakina.com

Asit Dip 1 kg Kaplama Kimyasalları Çeşitleri ve Fiyatları Alex Makina Acid Dip Titanium A combination of acids is frequently used to pretreat the ti surfaces [25, 26]. Acid pickling process of titanium alloys and its investigation of intergranular corrosion and pitting corrosion. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. With the growing demands for bone implant therapy, titanium (ti). Acid Dip Titanium.

From www.diamondalloys.co.uk

Acid Dip Alloy Wheels Removes Corrosion Diamond Alloys Acid Dip Titanium With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices for the load. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping. Acid Dip Titanium.

From www.cointalk.com

Rolled thin planchet vs Aciddipped coin Coin Talk Acid Dip Titanium Rectifying smut formation when processing aluminum calls for the use of titanium or stainless [steel] racks and stripping at every cycle. A synergy of 6.0 wt% aluminum and 0.3 wt% oxygen provides the best combination of strength and ductility at cryogenic temperature. With the growing demands for bone implant therapy, titanium (ti) and its alloys are considered as appropriate choices. Acid Dip Titanium.