Thread Lapping . Thread turning is one of the commonly used machining methods for single piece or small batch production. We share with you the common problems and solutions when turning threads on cnc lathe. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Learn how lapping is used to achieve high levels of surface quality and precision in industrial manufacturing. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Lapping has the following characteristics: As a cnc lathe, thread turning processing is one of its basic functions. Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate, when threading up to a shoulder is required, when threading a tapered thread, or when the material is brittle. Find out the key parameters,.

from cncpartsxtj.com

We share with you the common problems and solutions when turning threads on cnc lathe. Lapping has the following characteristics: Find out the key parameters,. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate, when threading up to a shoulder is required, when threading a tapered thread, or when the material is brittle. Thread turning is one of the commonly used machining methods for single piece or small batch production. As a cnc lathe, thread turning processing is one of its basic functions. Learn how lapping is used to achieve high levels of surface quality and precision in industrial manufacturing. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and.

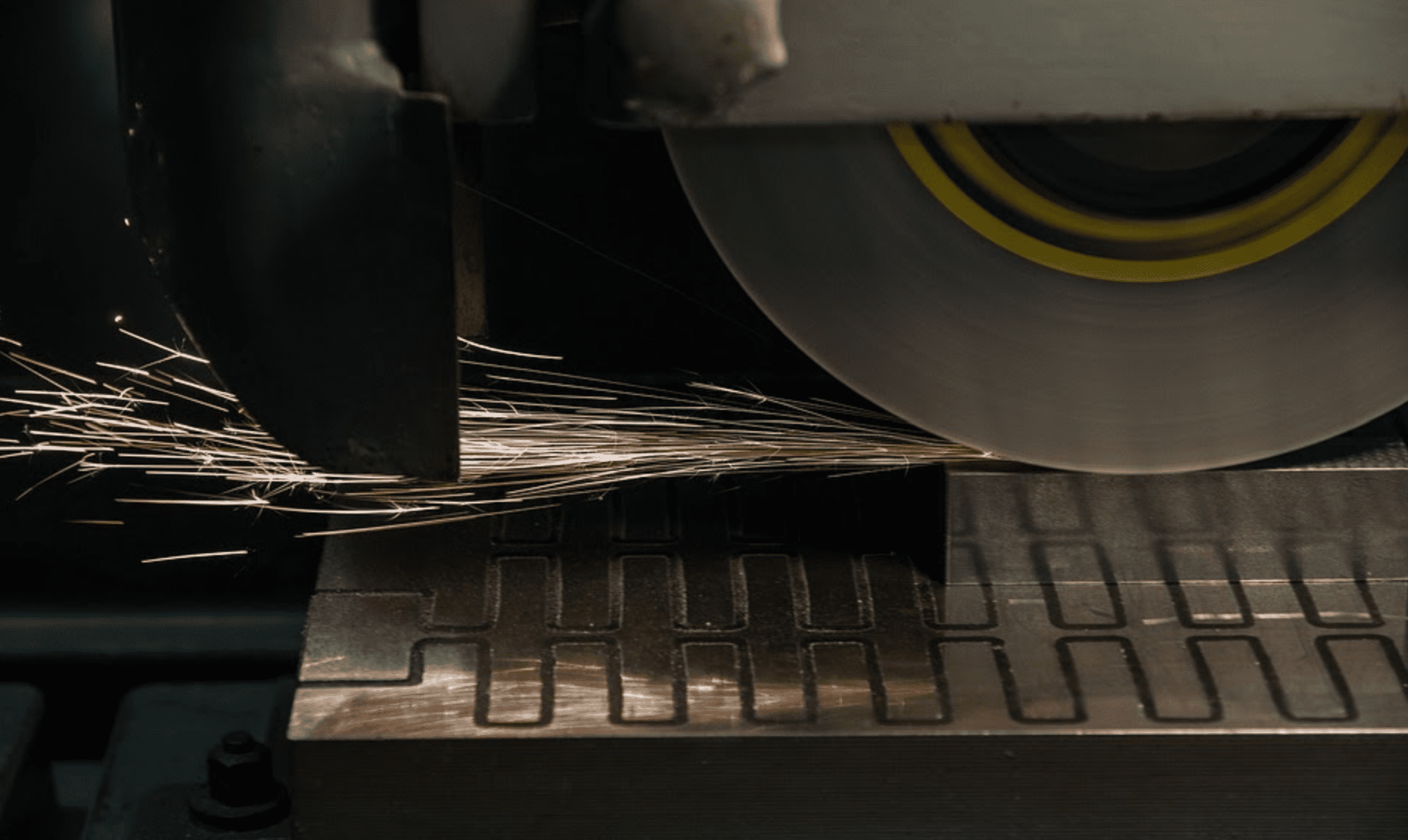

Brief Guide To Lapping Machining And Grinding Online Manufacturing

Thread Lapping Thread turning is one of the commonly used machining methods for single piece or small batch production. Thread turning is one of the commonly used machining methods for single piece or small batch production. Find out the key parameters,. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. We share with you the common problems and solutions when turning threads on cnc lathe. Learn how lapping is used to achieve high levels of surface quality and precision in industrial manufacturing. Lapping has the following characteristics: Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate, when threading up to a shoulder is required, when threading a tapered thread, or when the material is brittle. As a cnc lathe, thread turning processing is one of its basic functions.

From studentlesson.com

Things you need to know about lapping process studentlesson Thread Lapping We share with you the common problems and solutions when turning threads on cnc lathe. As a cnc lathe, thread turning processing is one of its basic functions. Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate, when threading. Thread Lapping.

From www.thedriller.com

Drill Pipe Threads 101 The Basics of Good Connections The Driller Thread Lapping We share with you the common problems and solutions when turning threads on cnc lathe. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. As a cnc lathe, thread turning processing is one of its basic functions. Lapping has the following characteristics: Thread machining is. Thread Lapping.

From www.qualiturn.co.uk

Threading Thread Lapping Find out the key parameters,. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Learn how lapping is used to achieve high levels of surface quality and precision in industrial manufacturing. Lapping has the following characteristics: We share with you the common problems and solutions when turning threads on cnc lathe. Thread turning is one. Thread Lapping.

From madchem.com

Lapping Madison Chemical Thread Lapping Learn how lapping is used to achieve high levels of surface quality and precision in industrial manufacturing. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. Thread turning is one of the commonly used machining methods for single piece or small batch production. (1) the. Thread Lapping.

From www.practicalmachinist.com

thread lapping Thread Lapping Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate, when threading up to a shoulder is required, when threading a tapered thread, or when the material is brittle. We share with you the common problems and solutions when turning. Thread Lapping.

From slidingmotion.com

What is Lapping? How Lapping Works? slidingmotion Thread Lapping Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate, when threading up to a shoulder is required, when threading a tapered thread, or when the material is brittle. As a cnc lathe, thread turning processing is one of its. Thread Lapping.

From cncpartsxtj.com

Brief Guide To Lapping Machining And Grinding Online Manufacturing Thread Lapping (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. As a cnc lathe, thread turning processing is one of its basic functions. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. We share with you the common problems and solutions when turning threads on cnc lathe. The. Thread Lapping.

From hubpages.com

Difference between Lapping and Honing process HubPages Thread Lapping Find out the key parameters,. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is. Thread Lapping.

From www.youtube.com

Lapping Tool YouTube Thread Lapping Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate, when threading up to a shoulder is required, when threading a tapered thread, or when the material is brittle. Thread turning is one of the commonly used machining methods for. Thread Lapping.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Lapping (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Thread turning is one of the commonly used machining methods for single piece or small batch production. Lapping has the following characteristics: As a cnc lathe, thread turning processing is one of its basic functions. We share with you the common problems and solutions when turning. Thread Lapping.

From www.stahliusa.com

Inspection of Lapping Plate Thread Lapping The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. We share with you the common problems and solutions when turning threads on cnc lathe. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. (1) the workpiece’s surface. Thread Lapping.

From www.kitplanes.com

Laps and Lapping KITPLANES Thread Lapping Find out the key parameters,. We share with you the common problems and solutions when turning threads on cnc lathe. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. The machining process of lapping involves two surfaces that. Thread Lapping.

From www.lapping.com

Professional Lapping Services Abrading Methods Inc. Thread Lapping Learn how lapping is used to achieve high levels of surface quality and precision in industrial manufacturing. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Find out the key parameters,. We share with you the common problems and solutions when turning threads on cnc lathe. As a cnc lathe, thread turning processing is one. Thread Lapping.

From www.youtube.com

Thread joint lapping demonstration YouTube Thread Lapping Find out the key parameters,. We share with you the common problems and solutions when turning threads on cnc lathe. Thread turning is one of the commonly used machining methods for single piece or small batch production. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. As a cnc lathe, thread turning processing is one. Thread Lapping.

From www.dhgate.com

Innovative 4 Layer Thread Lapping Machine By New Mini Zinc Alloy Thread Lapping We share with you the common problems and solutions when turning threads on cnc lathe. Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate, when threading up to a shoulder is required, when threading a tapered thread, or when. Thread Lapping.

From www.youtube.com

making an ID lapping tool YouTube Thread Lapping The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate, when threading up to a shoulder. Thread Lapping.

From www.youtube.com

Hand Lapping by Don Bailey YouTube Thread Lapping Find out the key parameters,. As a cnc lathe, thread turning processing is one of its basic functions. Thread turning is one of the commonly used machining methods for single piece or small batch production. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. (1). Thread Lapping.

From www.practicalmachinist.com

Crowning/Lapping Best Practice Thread Lapping Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. We share with you the common problems and solutions when turning threads on cnc lathe. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. Thread cutting, as compared. Thread Lapping.

From www.wwaccuracy.com

Jig lapping Thread Lapping As a cnc lathe, thread turning processing is one of its basic functions. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. Thread machining is a precise manufacturing operation used to. Thread Lapping.

From www.youtube.com

ID and OD lapping simplified. YouTube Thread Lapping Find out the key parameters,. Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate, when threading up to a shoulder is required, when threading a tapered thread, or when the material is brittle. The machining process of lapping involves. Thread Lapping.

From studentlesson.com

Things You Need To Know About Lapping Process Studentlesson Thread Lapping Find out the key parameters,. Thread turning is one of the commonly used machining methods for single piece or small batch production. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when. Thread Lapping.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Lapping Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Lapping has the following characteristics: We share with you the common problems and solutions when turning threads on cnc lathe. As a cnc lathe, thread turning processing is one of its basic functions. Find out the key parameters,. Learn how lapping is used. Thread Lapping.

From minnesotagrinding.com

Precision Grinding Techniques Minnesota Grinding Thread Lapping Find out the key parameters,. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. As a cnc lathe, thread turning processing is one of its basic functions. Thread turning is one of the commonly used machining methods for single piece or small batch production. We share with you the common problems and solutions when turning. Thread Lapping.

From www.youtube.com

whitworth 3 plate method for making lapping plates YouTube Thread Lapping Learn how lapping is used to achieve high levels of surface quality and precision in industrial manufacturing. Thread turning is one of the commonly used machining methods for single piece or small batch production. Find out the key parameters,. As a cnc lathe, thread turning processing is one of its basic functions. (1) the workpiece’s surface roughness can reach ra. Thread Lapping.

From heritage-arms.com

Barrel Threading Heritage Arms, Inc. Thread Lapping Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate, when threading up to a shoulder is required, when threading a tapered thread, or when the material is brittle. (1) the workpiece’s surface roughness can reach ra = 0.006 to. Thread Lapping.

From watchmaking.weebly.com

Lapping Tool Thread Lapping Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate, when threading up to a shoulder is required, when threading a tapered thread,. Thread Lapping.

From www.unitedcenterlessgrinding.net

Precision Lapping Services United Centerless Grinding Thread Lapping As a cnc lathe, thread turning processing is one of its basic functions. Thread turning is one of the commonly used machining methods for single piece or small batch production. Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate,. Thread Lapping.

From cpdingli.en.made-in-china.com

Steel Mechanical One Touch Lapping Rebar Coupler Thread Used Pipe Thread Lapping Learn how lapping is used to achieve high levels of surface quality and precision in industrial manufacturing. Thread turning is one of the commonly used machining methods for single piece or small batch production. Lapping has the following characteristics: We share with you the common problems and solutions when turning threads on cnc lathe. Find out the key parameters,. As. Thread Lapping.

From www.rolledthreads.com

How Does the Thread Rolling Process Work? Thread Lapping Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity is small, when the blank is not very accurate, when threading up to a shoulder is required, when threading a tapered thread, or when the material is brittle. We share with you the common problems and solutions when turning. Thread Lapping.

From www.industrialpress.com.my

ENGIS Hyprez Flat Lapping Machine Abrasives Industrial Press Malaysia Thread Lapping Find out the key parameters,. We share with you the common problems and solutions when turning threads on cnc lathe. Learn how lapping is used to achieve high levels of surface quality and precision in industrial manufacturing. Lapping has the following characteristics: The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid. Thread Lapping.

From www.cermac.com

Lapping Machining Lapping Manufacturing CerMac Inc. Thread Lapping Lapping has the following characteristics: As a cnc lathe, thread turning processing is one of its basic functions. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Find out the key parameters,. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Learn how lapping is used to. Thread Lapping.

From ms.copernicus.org

MS A modified ball screw lapping method and optimized lapping factors Thread Lapping (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Learn how lapping is used to achieve high levels of surface quality and precision in industrial manufacturing. Thread turning is one of the commonly used machining methods for single piece or small batch production. Thread machining is a precise manufacturing operation used to create helical or. Thread Lapping.

From www.machinemfg.com

Lapping Basics Characteristics and Applications MachineMFG Thread Lapping (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Learn how lapping is used to achieve high levels of surface quality and precision in industrial manufacturing. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and lapping grit) trapped between them. Thread machining is a precise. Thread Lapping.

From www.gemsons.com

Difference between Honing and Lapping Process PrecisionTurned Thread Lapping Thread turning is one of the commonly used machining methods for single piece or small batch production. Learn how lapping is used to achieve high levels of surface quality and precision in industrial manufacturing. Lapping has the following characteristics: Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity. Thread Lapping.

From www.youtube.com

What is Lapping Process ?? YouTube Thread Lapping Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Lapping has the following characteristics: Thread turning is one of the commonly used machining methods for single piece or small batch production. Thread cutting, as compared to thread forming and rolling, can be used when full thread depth is required, when the quantity. Thread Lapping.