Heat Exchanger Process Design . Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. Process streams commonly interact through heat exchangers in order to save. To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Heat exchangers are necessary process units that are part of any detailed process flow diagram. Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac.

from mavink.com

Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Process streams commonly interact through heat exchangers in order to save. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Heat exchangers are necessary process units that are part of any detailed process flow diagram. Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial.

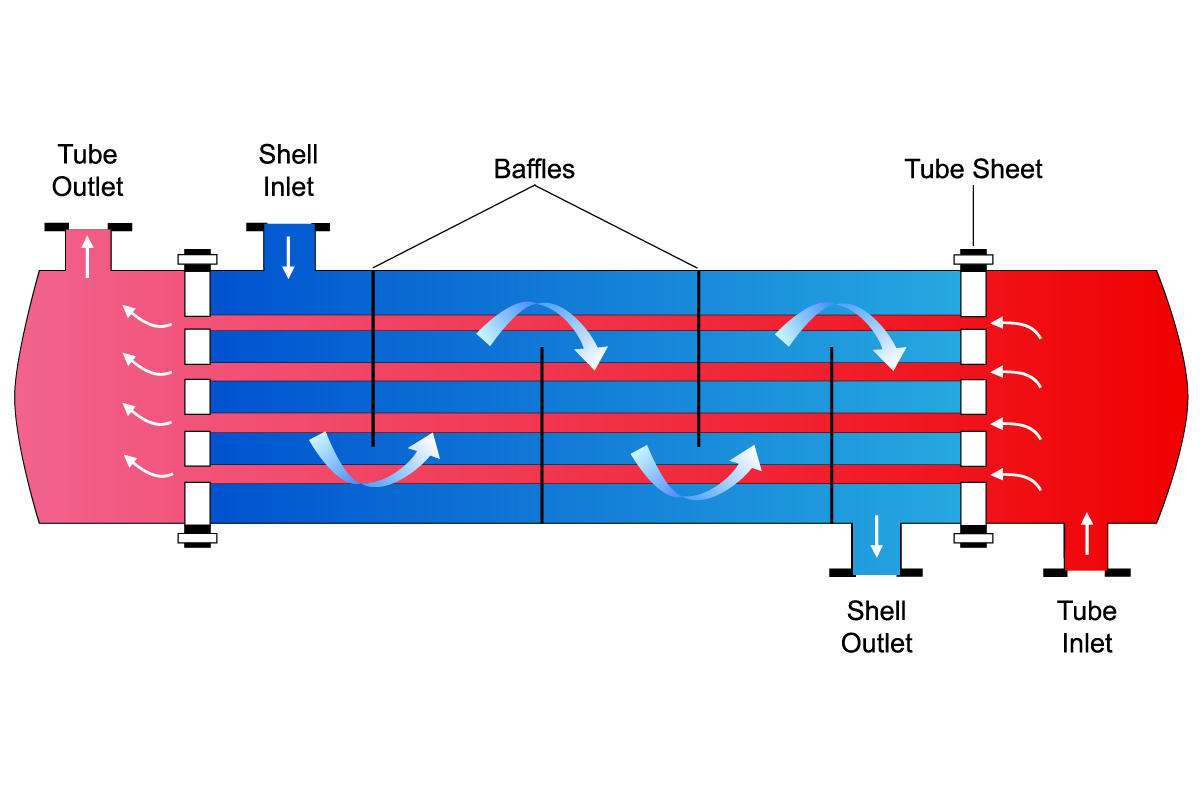

Heat Exchanger Block Diagram

Heat Exchanger Process Design To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Process streams commonly interact through heat exchangers in order to save. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Heat exchangers are necessary process units that are part of any detailed process flow diagram.

From www.linquip.com

Counter Flow Heat Exchangers and its Working Principles Linquip Heat Exchanger Process Design Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Heat exchangers are necessary process units that are part of any detailed process flow diagram. Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Heat exchangers are critical components in. Heat Exchanger Process Design.

From www.ino.com.vn

Plate Heat Exchanger, How it works working principle hvac industrial Heat Exchanger Process Design Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. Process streams commonly interact through heat exchangers in order to save. Heat exchangers are an essential. Heat Exchanger Process Design.

From mepacademy.com

How Plate Heat Exchangers Work MEP Academy Heat Exchanger Process Design To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Heat exchangers are necessary process units that are part of any detailed process flow diagram. Heat exchangers are an essential unit operation in the. Heat Exchanger Process Design.

From www.slideshare.net

Process design of heat exchanger Heat Exchanger Process Design Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. Heat exchangers are necessary process units that are part of any detailed process flow diagram. Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Wildly. Heat Exchanger Process Design.

From mepacademy.com

How Plate Heat Exchangers Work MEP Academy Heat Exchanger Process Design Process streams commonly interact through heat exchangers in order to save. Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Heat exchangers are critical components in the field of thermodynamics and engineering, playing. Heat Exchanger Process Design.

From www.researchgate.net

Design method flow chart for Plate Heat Exchanger (PHX) sizing for the Heat Exchanger Process Design Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. Developing an engineering design and fabricating a shell and tube. Heat Exchanger Process Design.

From www.iqsdirectory.com

Shell and Tube Heat Exchanger What Is It? Types, Process Heat Exchanger Process Design Heat exchangers are necessary process units that are part of any detailed process flow diagram. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Process streams commonly interact through heat exchangers in order to save. To introduce and apply concepts learned in first courses in heat. Heat Exchanger Process Design.

From northslopechillers.com

Heat Exchangers in Process Cooling North Slope Chillers Heat Exchanger Process Design Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. Heat exchangers are necessary process units that are part of any detailed process flow diagram. To introduce and apply. Heat Exchanger Process Design.

From www.slideshare.net

Process design of heat exchanger Heat Exchanger Process Design Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and. Heat Exchanger Process Design.

From www.iqsdirectory.com

Shell and Tube Heat Exchanger What Is It? Types, Process Heat Exchanger Process Design Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Heat exchangers are critical components in the field of thermodynamics and engineering,. Heat Exchanger Process Design.

From www.iqsdirectory.com

Plate Heat Exchangers Components, Types, Applications and Advantages Heat Exchanger Process Design Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several. Heat Exchanger Process Design.

From www.researchgate.net

Flowchart of heat exchanger system Download Scientific Diagram Heat Exchanger Process Design To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. Wildly used. Heat Exchanger Process Design.

From thepipingtalk.com

Types of Heat Exchanger according to construction The piping talk Heat Exchanger Process Design To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. Wildly used in a plethora of industrial applications such as oil and. Heat Exchanger Process Design.

From www.youtube.com

How to design a heat exchanger? YouTube Heat Exchanger Process Design Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe. Heat Exchanger Process Design.

From www.iqsdirectory.com

Shell and Tube Heat Exchanger What Is It? Types, Process Heat Exchanger Process Design Process streams commonly interact through heat exchangers in order to save. To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Heat exchangers are necessary process units that are part of any detailed process flow diagram. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5. Heat Exchanger Process Design.

From www.thomasnet.com

Understanding Heat Exchangers Heat Exchanger Process Design Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. To introduce and. Heat Exchanger Process Design.

From encyclopedia.pub

Heat Exchanger Design Methods Encyclopedia MDPI Heat Exchanger Process Design To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger. Heat Exchanger Process Design.

From kinam.in

Evolution of Heat Exchangers Kinam Engineering Industries Heat Exchanger Process Design Process streams commonly interact through heat exchangers in order to save. Heat exchangers are necessary process units that are part of any detailed process flow diagram. Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. To introduce and apply concepts learned in first courses in heat transfer,. Heat Exchanger Process Design.

From brandfuge.com

What is a Tube Heat Exchanger and How Does it Work? BrandFuge Heat Exchanger Process Design Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. Wildly used in a plethora of industrial applications such. Heat Exchanger Process Design.

From www.semanticscholar.org

[PDF] Controller Design for Temperature Control of Heat Exchanger Heat Exchanger Process Design Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers are necessary process units that are part of any detailed process flow diagram. Water flowing at. Heat Exchanger Process Design.

From enggcyclopedia.com

Shell and tube heat exchanger design procedure EnggCyclopedia Heat Exchanger Process Design Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. Wildly used in a plethora of industrial applications such. Heat Exchanger Process Design.

From helecu.com

All About Shell And Tube Heat Exchangers What You Need To Know (2022) Heat Exchanger Process Design Heat exchangers are necessary process units that are part of any detailed process flow diagram. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. Process streams commonly interact through heat exchangers in order to save. Heat exchangers are an essential unit. Heat Exchanger Process Design.

From savree.com

Plate Heat Exchanger (PHE) Explained saVRee saVRee Heat Exchanger Process Design Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop. Heat Exchanger Process Design.

From fr.slideshare.net

Heat Exchanger Design, Construction and Working Heat Exchanger Process Design Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. Developing an engineering design and fabricating a shell and tube. Heat Exchanger Process Design.

From www.indiamart.com

Process Design For Any Type Of Heat Exchanger in Karamsad ID 21814331933 Heat Exchanger Process Design Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. Process streams commonly interact through heat exchangers in order to save. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas. Heat Exchanger Process Design.

From www.goochthermal.com

Spiral Heat Exchanger Advantages — Gooch Thermal Heat Exchanger Process Design Process streams commonly interact through heat exchangers in order to save. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. Water flowing at a rate of 13.85 kg/s. Heat Exchanger Process Design.

From www.iqsdirectory.com

Plate Heat Exchangers Components, Types, Applications and Advantages Heat Exchanger Process Design Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. Process streams commonly interact through heat exchangers in order to save. Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Heat exchangers are an essential. Heat Exchanger Process Design.

From www.csidesigns.com

How Do Heat Exchangers Work A 101 Guide Heat Exchanger Process Design To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Heat exchangers are necessary process units that are part of any detailed process flow diagram. Developing an. Heat Exchanger Process Design.

From www.iqsdirectory.com

Shell and Tube Heat Exchanger What Is It? Types, Process Heat Exchanger Process Design Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to. Heat Exchanger Process Design.

From mavink.com

Heat Exchanger Block Diagram Heat Exchanger Process Design To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. Water flowing. Heat Exchanger Process Design.

From www.pipingengineer.org

Introduction to Heat Exchangers The Piping Engineering World Heat Exchanger Process Design To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical, food and drink, and hvac. Heat exchangers are an essential. Heat Exchanger Process Design.

From www.researchgate.net

Heat exchanger design procedure. Download Scientific Diagram Heat Exchanger Process Design Developing an engineering design and fabricating a shell and tube heat exchanger typically involves several steps. Process streams commonly interact through heat exchangers in order to save. To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Heat exchangers are an essential unit operation in the design of chemical processes,. Heat Exchanger Process Design.

From savree.com

Plate Heat Exchanger (PHE) Explained saVRee saVRee Heat Exchanger Process Design Heat exchangers are an essential unit operation in the design of chemical processes, usually linked directly with energy efficiency aspects of a facility. Heat exchangers are necessary process units that are part of any detailed process flow diagram. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by. Heat Exchanger Process Design.

From flashsplash.org

Heat Exchangers Unveiled The Masters of Thermal Transformation Heat Exchanger Process Design Process streams commonly interact through heat exchangers in order to save. Heat exchangers are necessary process units that are part of any detailed process flow diagram. To introduce and apply concepts learned in first courses in heat transfer, fluid mechanics, thermodynamics, and calculus, to develop heat. Wildly used in a plethora of industrial applications such as oil and gas, pharmaceutical,. Heat Exchanger Process Design.

From www.iqsdirectory.com

Heat Exchanger What Is It? How Does It Work? Types Of Heat Exchanger Process Design Heat exchangers are critical components in the field of thermodynamics and engineering, playing a pivotal role in a wide array of industrial. Water flowing at a rate of 13.85 kg/s is to be heated from 54.5 to 87.8oc in a double‐pipe heat exchanger by 54,430 kg/h of hot gas flowing. To introduce and apply concepts learned in first courses in. Heat Exchanger Process Design.